- Forum

- categories

- Sanitation systems

- Faecal sludge management (FSM)

- Faecal sludge transport (including emptying of pits and septic tanks, transfer stations)

- The excrevator (power auger) to empty pits (North Carolina State University, USA) - now field testing

The excrevator (power auger) to empty pits (North Carolina State University, USA) - now field testing

69.9k views

- Elisabeth

-

- User is blocked

- Freelance consultant since 2012

Less- Posts: 3372

- Karma: 54

- Likes received: 932

Re: The excrevator (power auger) to empty pits (North Carolina State University, USA) - now field testing

Dear all,

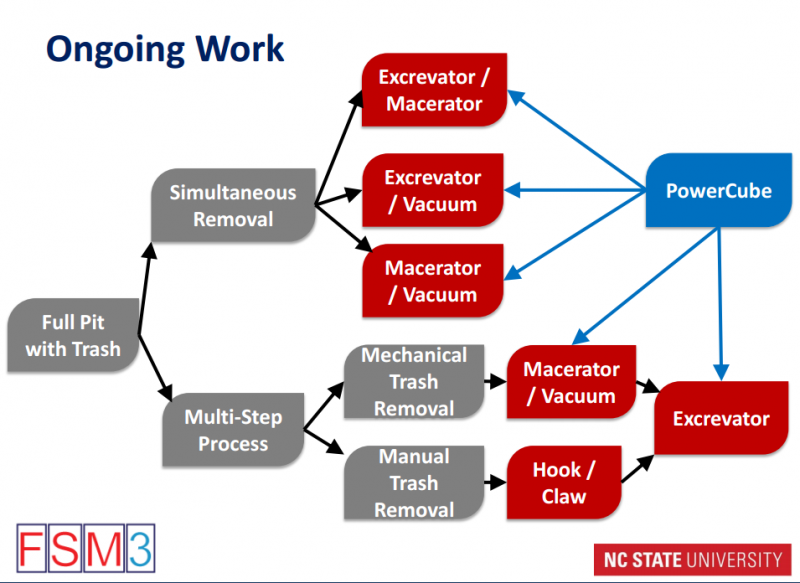

For those of you following progress of the excrevator tool by the group of Francis at North Carolina State University, take a look at this presentation at the FMS3 conference:

The “Excrevator” - Safe and Effective Pit Emptying: Tate Rogers, North Carolina State University, Raleigh, NC, USA

www.susana.org/images/documents/07-cap-d...1/2-1-3-6-Rogers.pdf

It includes results from their field testing in:

As far as I know, their current phase of funding is coming (or has come) to an end, so I think they are looking for more funds for further R&D, so I wish them good luck with that!

Regards,

Elisabeth

+++++++++++

Note by moderator: we have closed this thread. Further discussions are taking place here:

forum.susana.org/99-faecal-sludge-transp...pits-trash-exclusion

Or look for further posts by Francis de los Reyes by clicking on his forum profile when you are logged in.

For those of you following progress of the excrevator tool by the group of Francis at North Carolina State University, take a look at this presentation at the FMS3 conference:

The “Excrevator” - Safe and Effective Pit Emptying: Tate Rogers, North Carolina State University, Raleigh, NC, USA

www.susana.org/images/documents/07-cap-d...1/2-1-3-6-Rogers.pdf

It includes results from their field testing in:

- Hyderabad, India

- Durban, South Africa

- Mzuzu, Malawi

- The Excrevator is an effective pit emptying tool if trash content can be managed

- An assortment of tools are necessary to empty the high variability of existing pits

- Field testing to continue in Malawi in Early 2015

- New field testing locations to be determined

As far as I know, their current phase of funding is coming (or has come) to an end, so I think they are looking for more funds for further R&D, so I wish them good luck with that!

Regards,

Elisabeth

+++++++++++

Note by moderator: we have closed this thread. Further discussions are taking place here:

forum.susana.org/99-faecal-sludge-transp...pits-trash-exclusion

Or look for further posts by Francis de los Reyes by clicking on his forum profile when you are logged in.

Dr. Elisabeth von Muench

Freelance consultant on environmental and climate projects

Freelance consultant on environmental and climate projects

Attachments:

-

ongoingwork.png

(Filesize: 296KB)

ongoingwork.png

(Filesize: 296KB)

The topic has been locked.

Re: The excrevator (power auger) to empty pits (North Carolina State University, USA) - now field testing

Hello Scoop Squad,

Sorry for the delayed response. I am not sure if I responded to you by email. I thought I did, but maybe not...

Please send me an email again so I can respond to your specific questions. Thanks!

Sorry for the delayed response. I am not sure if I responded to you by email. I thought I did, but maybe not...

Please send me an email again so I can respond to your specific questions. Thanks!

Francis de los Reyes III

Professor/TED Fellow

Professor/TED Fellow

The topic has been locked.

- ScoopSquad

-

Less

- Posts: 1

- Likes received: 0

Re: Design Project

Hello Francis,

We are a sophomore design group from Iowa State University. Our task in this course is to build a prototype of a machine that can help a developing country in some way. Our problem that we have chosen was based off of a video we found of you speaking on a TED Talks stage. We want to create something similar to the invention on this forum, but runs only on human power.

Trying to research specifics on current conditions in India has proven difficult, and we would like to discuss with you some of your research and obtain a better understanding of the situation in places like India.

Regards,

Scoop Squad -

Brian, Michael, Andrew, Jacob, Lucas, Everett

We are a sophomore design group from Iowa State University. Our task in this course is to build a prototype of a machine that can help a developing country in some way. Our problem that we have chosen was based off of a video we found of you speaking on a TED Talks stage. We want to create something similar to the invention on this forum, but runs only on human power.

Trying to research specifics on current conditions in India has proven difficult, and we would like to discuss with you some of your research and obtain a better understanding of the situation in places like India.

Regards,

Scoop Squad -

Brian, Michael, Andrew, Jacob, Lucas, Everett

The topic has been locked.

- nashalbu

-

Less

- Posts: 2

- Likes received: 0

Re: Power auger modification to empty pits (North Carolina State University, USA and South Africa)

Dear Francis

I would be interested to see the results of your field testing during 2014.

Harriet (Nash)

I would be interested to see the results of your field testing during 2014.

Harriet (Nash)

The topic has been locked.

- Tsepo

-

Less

- Posts: 6

- Likes received: 1

Re: Power auger modification to empty pits (North Carolina State University, USA and South Africa)

Hi Francis

Can you be able to tell how far your working relationship was with the Ethekwini Municipality in planning to implementing this excavation of pit latrines. I am in communication with a company called Amanz' abantu based here in South Africa Eastern Cape

of which I was referred to them by Dr Sudhir Pillay.

I am looking of this excavation from the business point of view and would just love to join in the implementation of healthy sanitation for the good lives of those who do not have

Can you be able to tell how far your working relationship was with the Ethekwini Municipality in planning to implementing this excavation of pit latrines. I am in communication with a company called Amanz' abantu based here in South Africa Eastern Cape

of which I was referred to them by Dr Sudhir Pillay.

I am looking of this excavation from the business point of view and would just love to join in the implementation of healthy sanitation for the good lives of those who do not have

The topic has been locked.

Re: Reply: The excravator (power auger) to empty pits (North Carolina State University, USA) - now field testing

Hi Tsepo,

Actually, Chris Buckley at UKZN has a prototype of the Excrevator. Unfortunately, we need to solve the trash problem- there is too much trash in many VIPs in Durban, and that will jam the screw auger. We are working on other methods for trash removal before pit emptying.

Francis

Actually, Chris Buckley at UKZN has a prototype of the Excrevator. Unfortunately, we need to solve the trash problem- there is too much trash in many VIPs in Durban, and that will jam the screw auger. We are working on other methods for trash removal before pit emptying.

Francis

Francis de los Reyes III

Professor/TED Fellow

Professor/TED Fellow

The topic has been locked.

- Tsepo

-

Less

- Posts: 6

- Likes received: 1

Re: Reply: The excravator (power auger) to empty pits (North Carolina State University, USA) - now field testing

Hi Francis

I am based in South Africa Durban do you have any one I may talk to in this matter to take it further??

I am based in South Africa Durban do you have any one I may talk to in this matter to take it further??

The topic has been locked.

Hi Tsepo,

Thank you for your interest in the Excavator. While the machine works, we feel that it is not yet optimized, particularly if there is significant trash in the pit. We are working on modifications, and hopefully will be able to test a modified design and pit emptying method early next year. We are testing several components in Malawi in December.

Once finalized, we intend to make the design available to anyone. Where are you located?

-Francis

Thank you for your interest in the Excavator. While the machine works, we feel that it is not yet optimized, particularly if there is significant trash in the pit. We are working on modifications, and hopefully will be able to test a modified design and pit emptying method early next year. We are testing several components in Malawi in December.

Once finalized, we intend to make the design available to anyone. Where are you located?

-Francis

Francis de los Reyes III

Professor/TED Fellow

Professor/TED Fellow

The topic has been locked.

- Tsepo

-

Less

- Posts: 6

- Likes received: 1

Re: Power auger modification to empty pits

Good Day Sir

Kindly advise how does one get hold of this devise so that I commercially implement it.

I am entreprenuer and I notice that emptying PT LATRINES as a big market

which one can get into

Kindly advise how does one get hold of this devise so that I commercially implement it.

I am entreprenuer and I notice that emptying PT LATRINES as a big market

which one can get into

The topic has been locked.

- twrogers

-

Less

Less- Posts: 2

- Karma: 1

- Likes received: 1

Re: Video of interview and demonstration for excravator - power auger to empty pits

In regards to the question about cutting trash:

Pits with trash pose several challenges for emptying. For the "Excrevator", fibrous materials such as bags, rope, hair, etc. can get caught in the auger and cause jamming, which leaves us with two main options:

1) Put a screen around the inlet to prevent objects from entering

2) introduce a cutting device at the inlet to reduce the size of the material coming in to a point at which it can move up the auger.

The difficulty with option 1 is that often the sludge in the pits does not readily flow, so it would not pass through the screen or make it into the auger. If the sludge does pass through the screen, then your faced with the problem of trash clogging the screen and preventing flow into the auger.

The cutting designs we are currently working on here at NC State, would connect directly to the end of the Excrevator. The blades will shear materials that pass through it to sizes that will flow easier through the auger in addition to mixing the surrounding sludge to make it flow easier into the auger. Larger trash items such as shoes, large rocks, etc. would not make it into the auger and can be removed manually after the sludge has been removed.

In regards to having small pieces of trash mixed in with the sludge, this will be more or less of an issue depending on the downstream treatment process. Some technologies (like the LeDePa I believe) have a screening process on the front end that can remove trash before treatment. Also, if the treatment process involves some sort of combustion the trash may not be a big issue. Another option may be to have a screening process at the outlet of the Excrevator to separate the trash and sludge before transport.

We are early in our cutting technology development and will know more about the feasibility of the design after testing in South Africa in July and August.

As mentioned in the webinar, the best comprehensive solution for trash in pits is to design the toilets or to incentivize the users so that trash is never introduced to the pits. Programs like the one in Ethekwini have shown a significant reduction in the amount of trash found in the pits. Hopefully, in the near future trash will not be a huge issue, but currently it is a problem that needs solving for pit emptying technologies.

Tate Rogers

Pits with trash pose several challenges for emptying. For the "Excrevator", fibrous materials such as bags, rope, hair, etc. can get caught in the auger and cause jamming, which leaves us with two main options:

1) Put a screen around the inlet to prevent objects from entering

2) introduce a cutting device at the inlet to reduce the size of the material coming in to a point at which it can move up the auger.

The difficulty with option 1 is that often the sludge in the pits does not readily flow, so it would not pass through the screen or make it into the auger. If the sludge does pass through the screen, then your faced with the problem of trash clogging the screen and preventing flow into the auger.

The cutting designs we are currently working on here at NC State, would connect directly to the end of the Excrevator. The blades will shear materials that pass through it to sizes that will flow easier through the auger in addition to mixing the surrounding sludge to make it flow easier into the auger. Larger trash items such as shoes, large rocks, etc. would not make it into the auger and can be removed manually after the sludge has been removed.

In regards to having small pieces of trash mixed in with the sludge, this will be more or less of an issue depending on the downstream treatment process. Some technologies (like the LeDePa I believe) have a screening process on the front end that can remove trash before treatment. Also, if the treatment process involves some sort of combustion the trash may not be a big issue. Another option may be to have a screening process at the outlet of the Excrevator to separate the trash and sludge before transport.

We are early in our cutting technology development and will know more about the feasibility of the design after testing in South Africa in July and August.

As mentioned in the webinar, the best comprehensive solution for trash in pits is to design the toilets or to incentivize the users so that trash is never introduced to the pits. Programs like the one in Ethekwini have shown a significant reduction in the amount of trash found in the pits. Hopefully, in the near future trash will not be a huge issue, but currently it is a problem that needs solving for pit emptying technologies.

Tate Rogers

The following user(s) like this post: Elisabeth

You need to login to reply

The topic has been locked.

- Elisabeth

-

- User is blocked

- Freelance consultant since 2012

Less- Posts: 3372

- Karma: 54

- Likes received: 932

Re: Video of interview and demonstration for excravator - power auger to empty pits

If you are interested in innovative pit emtpying technologies, then make sure you view the presentation by Francis de los Reyes, which he gave at the recent SuSanA-SEI webinar on 29 April:

The Playlist list for the entire webinar is here:

www.youtube.com/playlist?list=PL0gMdVBup...ymOPomtqL_XYT5YtLTSK

The video includes the presentation as well as a question and answer session which I briefly summarise below (the questions start here in the video: ):

(1)

Arno asked how the Excravator deals with the solid waste (trash) that is in the pits of VIPs (or any pit that doesn't have a water seal on the toilet), since people tend to use the pits also as a general rubbish dump?

Answer by Francis: One aspect is education to teach the households to throw less trash in the pits (example eThekwini Municipality) (my own addition: or to give them alternatives for solid waste collection).

But in terms of the Excrevator: what enters the auger, normally gets pushed up due the rotational force. They are working on new designs to cut the trash by using the rotational power from the hydraulic motor - to "slice" the materials. So it should be able to handle some trash; they are experimenting with how the auger can deal with ropes and fabrics. But some other larger trash items will be left in the pit and it is then perhaps easier to take that out manually (once the rest of the sludge is gone).

--> follow-up question: a disadvantage of cutting of the trash is that you end up with e.g. small pieces of plastic mixed into your faecal sludge which will could reduce the reuse potential of the faecal sludge (in agriculture). From that point of view is it perhaps better to leave the trash as larger pieces would could be removed at a sorting facility of some sorts later?

(2)

I asked how easy or difficult it is for a professor in the USA to do research on pit emptying and what academic twist (research questions) can be put on it.

Francis highlighted that the "currency" of academics everywhere is publications and results. When you dig deeper into this topic (pardon the pun!) you realise how many open questions and knowledge gaps there are about the details, and this gives room for scientific publications. It gets more exciting the deeper you dig.

Research questions: Mechanical properties, operation, design, how people would use the tool, keeping the costs down --> it all becomes quite a challenge.

The students are actually very keen to do work on developing countries issues. It's not glamorous work but the students enjoy the challenge of this type of work

One problem is that it is very hard to simulate the pit content and pit empyting in the lab! The key is to go out in the field and to iterate in the field and that's what they will do this year. For example: How do you standardise trash content in a VIP pit (collaborationg with Uni UKZN in Durban, South Africa) - pit contents will be different in India to South Africa, differences for toilets with water seal (pour flush) to toilets withoug etc.

(3)

Question by Brian: you are working on cutting technology for the input solid waste to augers, is this something you would collaborate on with other grantees (like with us)?

Answer by Francis: "Yes, sure. We have a new design that we are testing in the lab, we feel that we can harness the rotational motion and power of the auger for cutting. The auger will hopefully also change a bit the quality of the sludge and the size of particles as the faecal sludge passes through the auger during the pit emptying. The input of energy will alter the sludge characteristics."

In the general discussion video, Francis was asked again by Mutala about source separation, i.e. how to get less trash in to the pits.

You can listen to Mutala's question and Francis' answer here:

The answer to this question is more or less the same as given under Point 1 above.

The general discussion video for the entire webinar is here:

I hope you found this useful and I am curious to know what other people who are working in the field with similar devices think of the Excravator? Sounds great but too expensive in practice? Or price OK, but too difficult to operate? Or all great? What are your thoughts?

Regards,

Elisabeth

The Playlist list for the entire webinar is here:

www.youtube.com/playlist?list=PL0gMdVBup...ymOPomtqL_XYT5YtLTSK

The video includes the presentation as well as a question and answer session which I briefly summarise below (the questions start here in the video: ):

(1)

Arno asked how the Excravator deals with the solid waste (trash) that is in the pits of VIPs (or any pit that doesn't have a water seal on the toilet), since people tend to use the pits also as a general rubbish dump?

Answer by Francis: One aspect is education to teach the households to throw less trash in the pits (example eThekwini Municipality) (my own addition: or to give them alternatives for solid waste collection).

But in terms of the Excrevator: what enters the auger, normally gets pushed up due the rotational force. They are working on new designs to cut the trash by using the rotational power from the hydraulic motor - to "slice" the materials. So it should be able to handle some trash; they are experimenting with how the auger can deal with ropes and fabrics. But some other larger trash items will be left in the pit and it is then perhaps easier to take that out manually (once the rest of the sludge is gone).

--> follow-up question: a disadvantage of cutting of the trash is that you end up with e.g. small pieces of plastic mixed into your faecal sludge which will could reduce the reuse potential of the faecal sludge (in agriculture). From that point of view is it perhaps better to leave the trash as larger pieces would could be removed at a sorting facility of some sorts later?

(2)

I asked how easy or difficult it is for a professor in the USA to do research on pit emptying and what academic twist (research questions) can be put on it.

Francis highlighted that the "currency" of academics everywhere is publications and results. When you dig deeper into this topic (pardon the pun!) you realise how many open questions and knowledge gaps there are about the details, and this gives room for scientific publications. It gets more exciting the deeper you dig.

Research questions: Mechanical properties, operation, design, how people would use the tool, keeping the costs down --> it all becomes quite a challenge.

The students are actually very keen to do work on developing countries issues. It's not glamorous work but the students enjoy the challenge of this type of work

One problem is that it is very hard to simulate the pit content and pit empyting in the lab! The key is to go out in the field and to iterate in the field and that's what they will do this year. For example: How do you standardise trash content in a VIP pit (collaborationg with Uni UKZN in Durban, South Africa) - pit contents will be different in India to South Africa, differences for toilets with water seal (pour flush) to toilets withoug etc.

(3)

Question by Brian: you are working on cutting technology for the input solid waste to augers, is this something you would collaborate on with other grantees (like with us)?

Answer by Francis: "Yes, sure. We have a new design that we are testing in the lab, we feel that we can harness the rotational motion and power of the auger for cutting. The auger will hopefully also change a bit the quality of the sludge and the size of particles as the faecal sludge passes through the auger during the pit emptying. The input of energy will alter the sludge characteristics."

In the general discussion video, Francis was asked again by Mutala about source separation, i.e. how to get less trash in to the pits.

You can listen to Mutala's question and Francis' answer here:

The answer to this question is more or less the same as given under Point 1 above.

The general discussion video for the entire webinar is here:

I hope you found this useful and I am curious to know what other people who are working in the field with similar devices think of the Excravator? Sounds great but too expensive in practice? Or price OK, but too difficult to operate? Or all great? What are your thoughts?

Regards,

Elisabeth

Dr. Elisabeth von Muench

Freelance consultant on environmental and climate projects

Freelance consultant on environmental and climate projects

The topic has been locked.

- Elisabeth

-

- User is blocked

- Freelance consultant since 2012

Less- Posts: 3372

- Karma: 54

- Likes received: 932

Re: Video of interview and demonstration for excravator - power auger to empty pits

As I mentioned in another thread, we had a great SEI-SuSanA webinar on 29 April with 50 participants and 3 excellent teams giving presentations about their research. Here is the presentation and the chat content for the presentation by Francis. The recorded videos will also be available tomorrow, we hope (we will put it into this Playlist: www.youtube.com/playlist?list=PL0gMdVBup...ymOPomtqL_XYT5YtLTSK).

This is the presentation that Franics used, with the title

"Is a power auger "Excrevator" a suitable tool to empty pit latrines in South Africa and septic tanks in India?":

Or see here:

susana.org/lang-en/library/library?view=...eitem&type=2&id=1745

And here is the log from the chat:

(the questions were answered by Francis and Tate; keep in mind that they were multi-tasking with their presentation, that's why some answers are only given further below in the chat. You see it here pretty much in chronological order how the chats were made, with some minor adjustments for clarity purposes).

+++++++++++

Laura Talsma: How is the auger powered? Could it work manually or does it need a generator?

Brian von Herzen: and what is the power level required electrically?

Tate Rogers: the auger is rotated by a hydraulic motor, which is powered by a gasoline engine.

Brian von Herzen: ok, what power level?

Tate Rogers: currently we are using an 11 HP engine, but that may be more than we actually need.

Brian von Herzen: Would a pour flush toilet address rope and newspaper and textiles?

Moritz Gold: Does it fit in any superstructure? Looks pretty big for slum areas.

Tate Rogers: manual operation would be difficult since you are often working in very dense sludge and need speeds over 300 rpm for it to be viable. It's less than 2 ft wide, also the bottom section is removable so you can attach it at the pit if necessary.

Lesego Toteng: Have you also taken into account heavy stuff/substances that people tend to through into these pits? And of these foreign materials, how likely are they to affect the excrevator performance?

Tate Rogers: Lesego- larger materials (shoes, rocks, etc) are not an issue because they are not allowed to enter the auger. Fibrous materials such as hair, rope, pants, underwear pose more of a problem which is why we are developing cutting mechanisms at the inlet of the auger.

Tate Rogers: Brian, typically, cultures that use water for cleansing have cleaner pits, so less trash. Several African countries, however, have basic pit latrines and often use them like a trash can since there is no MSW systems.

Brian von Herzen: Would NCSU be open to collaboration on the cutting technology? This is a common problem of interest among several groups.

Tate Rogers: Brian - yes, we would definitely be open to collaboration on cutting devices, we are currently working on a few designs now.

Brian von Herzen: very good, thanks!

Laura Talsma: Synapse did interesting research for their pit emptying technology, you probably already know this but otherwise interesting to talk to them.

Tate Rogers: Laura - thanks for the suggestion - we have actually been in contact with Synapse.

Rémi Kaupp: This system looks like a "gulper on steroids" in the sense that it is like a gulper, discharges into a barrel, but goes faster thanks to the auger... however the main challenge with the gulper is the cleanliness of the operation (entrepreneurs using it are adapting it) , and the time to clean it afterwards, sometimes more than the actual pumping! With a faster pump like this one, how can you ensure sufficient cleanliness and reduce time of cleaning?

Tate Rogers: Remi - great question - clean up afterwards is an issue for any pit emptying technology.

Brian von Herzen: good question on the cleaning, inside and outside...

Tate Rogers: we are working to ensure that the waste is never open to contact with the user - so we want to keep the waste in the machine and in the drums at all times. We are looking at mechanisms to cap the machine between pits and we are looking at using a superhydrophobic spray to keep the outside of the pipe clean.

Rémi Kaupp: Thanks Tate... of course the question is then how to procure / manufacture such a spray locally : -)

Tate Rogers: yes - the spray we have here is now available in local hardware stores.

Carol McCreary: Glad to see you're going to work with Banka Bioloos. They seem smart and nice.

Elisabeth von Muench: Tate, what can you tell us about the expected costs of such an Excravator? And what is you plan later, if this works, will the Excravator be built under licence by certain manufacturers in the target countries? At what point would you "hand over" the technology to a company?

Tate Rogers: Elisabeth (1st question) - the current price of the prototype is ~$4,500, but the engine and motor is $4,000 of that cost. We believe we can greatly reduce the cost of the engine/motor if we move into a manufacturing stage

Elisabeth von Muench: So it's 4000 USD for the engine and motor and 500 USD for the auger and housing? How long would you say this auger and housing would last before needing major maintenance and replacement?

Tate Rogers: That difficult to say, since we haven't tested over long periods of time.

Elisabeth von Muench: At what cost would you say it would become commercially viable for "normal" pit emptiers in Africa? I have the suspicion they cannnot afford anything more than 100 USD, or maybe the whole business model for this kind of sanitation business needs to be changed?

Tate Rogers: How it fits into the sanitation market definitely needs to be explored further. However we received a lot of interest at the fair from both Asian and African countries that didn't seem very concerned about the cost of the prototype.

Francis de los Reyes: Elisabeth, one pit emptier in Durban told me that $3000 was doable. Of course, he was assuming that the technology was robust, would work, would increase the number of pits emptied per day, etc.

Francis de los Reyes: Elisabeth, re: your question-we're still trying to figure out how to scale up. We are attending an Xcelerator workshop sponsored by the Gates Foundation, so we'll see what the best approach is. Our goal is to reach as many pit emptiers as possible.

Jamie Radford: Elisabeth - I could see it fitting into a franchise model where a franchise may own numerous cheaper pumps more suited to septage/weak sludge, and then one excrevator for more occasional desludging of the stronger stuff.

Elisabeth von Muench: Is the excravator meant to also work for faecal sludge from septic tanks? Or is that too liquid or too much volume.

Tate Rogers: Elisabeth, our system is designed to work best with denser sludge. For septic tanks, often this sludge is left in the bottom after emptying so your pit volume continues to decrease.

Francis de los Reyes: For fecal sludge in septic tanks, we think that the upper portion is more liquid, but he bottom is a compact sludge layer. We will be testing in Hyderabad next month.

Tate Rogers: So, one possibility is to use the Excrevator in parallel with a vacuum system to empty the entire contents of a pit.

Francis de los Reyes: Or use the liquid layer to "mix" with the dense compact layer.

Aaron Forbis-Stokes: Sounds like the Excrevator would work well for septic because removing solids is the main concern there. Have you looked at trying out in rural areas of North Carolina?

Tate Rogers: Aaron - yes, but you have to jump through several more hoops to test septic tanks in the US.

Elisabeth von Muench: Rémi or others: how would you say it compares to the Gulper/Rammer or it is a comparison that doesn't make sense (comparing apples with pears?). What sets the excravator apart from other devices (Rammer, Gulper, eVac, omni-ingestor) ? What are the main differences?

Francis de los Reyes: Elisabeth, there are of course differences with respect to cost, ease of operation, etc. But if you are asking about the "kinds" of sludges that can be emptied, that requires characterizing the sludge better than we are doing now. So sludge strength data (for example, as measured by a penetrometer), "stickiness", trash contents, etc. So some form of standardized testing of pits in the field, creating "standardized" sludges, and testing the pit emptying technology.

Jamie Radford: Francis - Apologies if I missed this in your talk, but what do you have in mind for 'standardised' field trials? I would suggest that one of the big issues with field trials is knowing what you're actually pumping - where that particular pit sits on the wide spectrum of latrines/tanks out there.

Francis de los Reyes: Jamie, I think you and I agree that if we have penetrometer data from pits all over the world, that would be a huge step forward. So on a spectrum of sludge strengths, we can place the appropriate pit emptying technologies.

Jamie Radford: Francis - OK, that makes sense, I thought you were perhaps thinking of standard performance metrics to use, or testing procedures.

Tate Rogers: Nelson - They have seen a reduction in trash in the pits since this payment system was implemented [at eThekwini, Durban - listen to question in recording / video].

++++++++++

Thanks again to all presenters and participants! Further questions or comments by anyone, please do put them here, thanks.

Regards,

Elisabeth

This is the presentation that Franics used, with the title

"Is a power auger "Excrevator" a suitable tool to empty pit latrines in South Africa and septic tanks in India?":

This attachment is hidden for guests.

Please log in or register to see it.

Please log in or register to see it.

Or see here:

susana.org/lang-en/library/library?view=...eitem&type=2&id=1745

And here is the log from the chat:

(the questions were answered by Francis and Tate; keep in mind that they were multi-tasking with their presentation, that's why some answers are only given further below in the chat. You see it here pretty much in chronological order how the chats were made, with some minor adjustments for clarity purposes).

+++++++++++

Laura Talsma: How is the auger powered? Could it work manually or does it need a generator?

Brian von Herzen: and what is the power level required electrically?

Tate Rogers: the auger is rotated by a hydraulic motor, which is powered by a gasoline engine.

Brian von Herzen: ok, what power level?

Tate Rogers: currently we are using an 11 HP engine, but that may be more than we actually need.

Brian von Herzen: Would a pour flush toilet address rope and newspaper and textiles?

Moritz Gold: Does it fit in any superstructure? Looks pretty big for slum areas.

Tate Rogers: manual operation would be difficult since you are often working in very dense sludge and need speeds over 300 rpm for it to be viable. It's less than 2 ft wide, also the bottom section is removable so you can attach it at the pit if necessary.

Lesego Toteng: Have you also taken into account heavy stuff/substances that people tend to through into these pits? And of these foreign materials, how likely are they to affect the excrevator performance?

Tate Rogers: Lesego- larger materials (shoes, rocks, etc) are not an issue because they are not allowed to enter the auger. Fibrous materials such as hair, rope, pants, underwear pose more of a problem which is why we are developing cutting mechanisms at the inlet of the auger.

Tate Rogers: Brian, typically, cultures that use water for cleansing have cleaner pits, so less trash. Several African countries, however, have basic pit latrines and often use them like a trash can since there is no MSW systems.

Brian von Herzen: Would NCSU be open to collaboration on the cutting technology? This is a common problem of interest among several groups.

Tate Rogers: Brian - yes, we would definitely be open to collaboration on cutting devices, we are currently working on a few designs now.

Brian von Herzen: very good, thanks!

Laura Talsma: Synapse did interesting research for their pit emptying technology, you probably already know this but otherwise interesting to talk to them.

Tate Rogers: Laura - thanks for the suggestion - we have actually been in contact with Synapse.

Rémi Kaupp: This system looks like a "gulper on steroids" in the sense that it is like a gulper, discharges into a barrel, but goes faster thanks to the auger... however the main challenge with the gulper is the cleanliness of the operation (entrepreneurs using it are adapting it) , and the time to clean it afterwards, sometimes more than the actual pumping! With a faster pump like this one, how can you ensure sufficient cleanliness and reduce time of cleaning?

Tate Rogers: Remi - great question - clean up afterwards is an issue for any pit emptying technology.

Brian von Herzen: good question on the cleaning, inside and outside...

Tate Rogers: we are working to ensure that the waste is never open to contact with the user - so we want to keep the waste in the machine and in the drums at all times. We are looking at mechanisms to cap the machine between pits and we are looking at using a superhydrophobic spray to keep the outside of the pipe clean.

Rémi Kaupp: Thanks Tate... of course the question is then how to procure / manufacture such a spray locally : -)

Tate Rogers: yes - the spray we have here is now available in local hardware stores.

Carol McCreary: Glad to see you're going to work with Banka Bioloos. They seem smart and nice.

Elisabeth von Muench: Tate, what can you tell us about the expected costs of such an Excravator? And what is you plan later, if this works, will the Excravator be built under licence by certain manufacturers in the target countries? At what point would you "hand over" the technology to a company?

Tate Rogers: Elisabeth (1st question) - the current price of the prototype is ~$4,500, but the engine and motor is $4,000 of that cost. We believe we can greatly reduce the cost of the engine/motor if we move into a manufacturing stage

Elisabeth von Muench: So it's 4000 USD for the engine and motor and 500 USD for the auger and housing? How long would you say this auger and housing would last before needing major maintenance and replacement?

Tate Rogers: That difficult to say, since we haven't tested over long periods of time.

Elisabeth von Muench: At what cost would you say it would become commercially viable for "normal" pit emptiers in Africa? I have the suspicion they cannnot afford anything more than 100 USD, or maybe the whole business model for this kind of sanitation business needs to be changed?

Tate Rogers: How it fits into the sanitation market definitely needs to be explored further. However we received a lot of interest at the fair from both Asian and African countries that didn't seem very concerned about the cost of the prototype.

Francis de los Reyes: Elisabeth, one pit emptier in Durban told me that $3000 was doable. Of course, he was assuming that the technology was robust, would work, would increase the number of pits emptied per day, etc.

Francis de los Reyes: Elisabeth, re: your question-we're still trying to figure out how to scale up. We are attending an Xcelerator workshop sponsored by the Gates Foundation, so we'll see what the best approach is. Our goal is to reach as many pit emptiers as possible.

Jamie Radford: Elisabeth - I could see it fitting into a franchise model where a franchise may own numerous cheaper pumps more suited to septage/weak sludge, and then one excrevator for more occasional desludging of the stronger stuff.

Elisabeth von Muench: Is the excravator meant to also work for faecal sludge from septic tanks? Or is that too liquid or too much volume.

Tate Rogers: Elisabeth, our system is designed to work best with denser sludge. For septic tanks, often this sludge is left in the bottom after emptying so your pit volume continues to decrease.

Francis de los Reyes: For fecal sludge in septic tanks, we think that the upper portion is more liquid, but he bottom is a compact sludge layer. We will be testing in Hyderabad next month.

Tate Rogers: So, one possibility is to use the Excrevator in parallel with a vacuum system to empty the entire contents of a pit.

Francis de los Reyes: Or use the liquid layer to "mix" with the dense compact layer.

Aaron Forbis-Stokes: Sounds like the Excrevator would work well for septic because removing solids is the main concern there. Have you looked at trying out in rural areas of North Carolina?

Tate Rogers: Aaron - yes, but you have to jump through several more hoops to test septic tanks in the US.

Elisabeth von Muench: Rémi or others: how would you say it compares to the Gulper/Rammer or it is a comparison that doesn't make sense (comparing apples with pears?). What sets the excravator apart from other devices (Rammer, Gulper, eVac, omni-ingestor) ? What are the main differences?

Francis de los Reyes: Elisabeth, there are of course differences with respect to cost, ease of operation, etc. But if you are asking about the "kinds" of sludges that can be emptied, that requires characterizing the sludge better than we are doing now. So sludge strength data (for example, as measured by a penetrometer), "stickiness", trash contents, etc. So some form of standardized testing of pits in the field, creating "standardized" sludges, and testing the pit emptying technology.

Jamie Radford: Francis - Apologies if I missed this in your talk, but what do you have in mind for 'standardised' field trials? I would suggest that one of the big issues with field trials is knowing what you're actually pumping - where that particular pit sits on the wide spectrum of latrines/tanks out there.

Francis de los Reyes: Jamie, I think you and I agree that if we have penetrometer data from pits all over the world, that would be a huge step forward. So on a spectrum of sludge strengths, we can place the appropriate pit emptying technologies.

Jamie Radford: Francis - OK, that makes sense, I thought you were perhaps thinking of standard performance metrics to use, or testing procedures.

Tate Rogers: Nelson - They have seen a reduction in trash in the pits since this payment system was implemented [at eThekwini, Durban - listen to question in recording / video].

++++++++++

Thanks again to all presenters and participants! Further questions or comments by anyone, please do put them here, thanks.

Regards,

Elisabeth

Dr. Elisabeth von Muench

Freelance consultant on environmental and climate projects

Freelance consultant on environmental and climate projects

This message has an attachment file.

Please log in or register to see it.

The following user(s) like this post: sahidul93

You need to login to reply

The topic has been locked.

Share this thread:

- Forum

- categories

- Sanitation systems

- Faecal sludge management (FSM)

- Faecal sludge transport (including emptying of pits and septic tanks, transfer stations)

- The excrevator (power auger) to empty pits (North Carolina State University, USA) - now field testing

Recently active users. Who else has been active?

Time to create page: 0.242 seconds