- Sanitation systems

- Toilets without urine diversion

- Container-based, mobile or bag-based toilets

- Open discussion on MOSAN toilet design

Open discussion on MOSAN toilet design

42.7k views

@Mona: You can reach me via This email address is being protected from spambots. You need JavaScript enabled to view it. (Ich spreche ebenfalls deutsch). UWASNET could link you up with local NGO/CBOs working in urban slum areas and facilitate the process. However, as a local Ugandan NGO network we do not have a lot of financial means available to directly support this interesting project.

Note by moderator (EvM): This thread is now closed for discussion. Further discussions on MoSan are taking place here on the forum:

forum.susana.org/forum/categories/52-mob...n-mosan-now-in-kenya

Note by moderator (EvM): This thread is now closed for discussion. Further discussions on MoSan are taking place here on the forum:

forum.susana.org/forum/categories/52-mob...n-mosan-now-in-kenya

The following user(s) like this post: Mona

You need to login to reply

The topic has been locked.

Hello Mona,

Your toilet appearance and design is very unique! It should be very good in many places. Thanks to this forum for bringing those concerned with seeking simple sanitation together.

Regarding design perfecting as another poster said, the bowl should be deep enough so males sitting on the toilet don't have a problem with skin contact inside the bow. On the toilets I have been devolving this has been an issue, and I simply had to make the bowl deeper than I first thought. It is rare, yet it also happens that the water level in a normal flush stools is too high, and males do not appreciate the resulting physical contact with the water.

In my development it also has been a challenge to put the urine feces divider as the right place. That is to put it back far as possible to intercept as much urine as possible, yet still forward far enough so feces do not end up on the urine pan.

One of the toilets I have been working on is quite a bit like yours (although not as attractive). One difference is that I employ a gate that covers the feces compartment, and which only needs opened for defecating. Admitted this feature has both pro and cons. The cons being a gate needs opened to defecate, and the bowl cannot be quite as nicely rounded. Yet it has the advantage of additional sanitation, as the solid waste area is additionally obstructed and can even remain obstructed when one needs to merely urinate. The gate cuts greatly cuts the odor, while using a minimum of covering material. Another vital advantage of the gate is that more urine is intercepted and less enters the feces area. This also saves mess and covering material and space in the feces container. I believe I can get up to a 98 percent average urine interception with my toilet with the gate. The only time it does not intercept all the urine is when females use it with the gate open for defeceting, then some urine is not interecepted.

You possibly could make one model with a gate and one without. Feel free copy my design in anyway you wish. My aim is to help people and help bring better sanitation to those who need it. You can see one of my toilet designs with a gate at this link. forum.susana.org/forum/categories/34-uri...on-bucketmate-toilet . www.exnapo.com shows many others.

Blessings

Amos Bender

Your toilet appearance and design is very unique! It should be very good in many places. Thanks to this forum for bringing those concerned with seeking simple sanitation together.

Regarding design perfecting as another poster said, the bowl should be deep enough so males sitting on the toilet don't have a problem with skin contact inside the bow. On the toilets I have been devolving this has been an issue, and I simply had to make the bowl deeper than I first thought. It is rare, yet it also happens that the water level in a normal flush stools is too high, and males do not appreciate the resulting physical contact with the water.

In my development it also has been a challenge to put the urine feces divider as the right place. That is to put it back far as possible to intercept as much urine as possible, yet still forward far enough so feces do not end up on the urine pan.

One of the toilets I have been working on is quite a bit like yours (although not as attractive). One difference is that I employ a gate that covers the feces compartment, and which only needs opened for defecating. Admitted this feature has both pro and cons. The cons being a gate needs opened to defecate, and the bowl cannot be quite as nicely rounded. Yet it has the advantage of additional sanitation, as the solid waste area is additionally obstructed and can even remain obstructed when one needs to merely urinate. The gate cuts greatly cuts the odor, while using a minimum of covering material. Another vital advantage of the gate is that more urine is intercepted and less enters the feces area. This also saves mess and covering material and space in the feces container. I believe I can get up to a 98 percent average urine interception with my toilet with the gate. The only time it does not intercept all the urine is when females use it with the gate open for defeceting, then some urine is not interecepted.

You possibly could make one model with a gate and one without. Feel free copy my design in anyway you wish. My aim is to help people and help bring better sanitation to those who need it. You can see one of my toilet designs with a gate at this link. forum.susana.org/forum/categories/34-uri...on-bucketmate-toilet . www.exnapo.com shows many others.

Blessings

Amos Bender

Amish background. Natural born questioner, researcher, and developer.

The following user(s) like this post: Mona

You need to login to reply

The topic has been locked.

Dear Julius,

great, many thanks for your feedback and offering your support for piloting the toilet in Uganda. We should definitely discuss this further by email and skype! Please let me know your email address.

Regarding your remarks,

- Weight: we stressed the toilet (main pot+seat) with 130kg at the workshop. The seat bends slightly and goes directly back to its initial shape. PE has the great property that it is more flexible than brittle. Which means, it is very difficult to break it. I tested this by throwing the toilet on concrete ground, the reaction was, the toilet just "jumped" away without any damage.

- Since the shape of the seat is angled and becomes wider till the edges, the weight distributes evenly and the seat doesn't slip inside the main pot.

- Handles: It is right, the two side handles were removed for several reasons (simpler molds=easier demolding=cheaper production) But instead I designed the outer edge between seat and main pot big enough to work perfectly as a all round handle. This means, even if the toilet is placed at a very narrow space you can lift the toilet from all sides, without being limited to 2 handles. This is meant to add mobility than lowering it!

- Lid: The lid is in production this week. On Friday I can post more pictures! Thanks for this advise. We are currently discussing with GIZ in Zambia to test the MoSan toilet with people with disabilities.

- Colour: The colour is caused by production and not chosen on purpose. White (called "nature") is the most common colour of PE and also the cheapest. All other colours, like black or blue are inked by pigments and are more expensive. If we produce more than 10 prototypes it is of course possible to order colored plastics, but so far it is not feasible. My preferred colour is still a blue-turquoise, since I think it communicates cleanliness, freshness and nature at once

[img size=100x100]blog-imgs-24.fc2.com/d/a/i/dailydisplay/326c.jpg[/img]

all the best,

Mona

great, many thanks for your feedback and offering your support for piloting the toilet in Uganda. We should definitely discuss this further by email and skype! Please let me know your email address.

Regarding your remarks,

- Weight: we stressed the toilet (main pot+seat) with 130kg at the workshop. The seat bends slightly and goes directly back to its initial shape. PE has the great property that it is more flexible than brittle. Which means, it is very difficult to break it. I tested this by throwing the toilet on concrete ground, the reaction was, the toilet just "jumped" away without any damage.

- Since the shape of the seat is angled and becomes wider till the edges, the weight distributes evenly and the seat doesn't slip inside the main pot.

- Handles: It is right, the two side handles were removed for several reasons (simpler molds=easier demolding=cheaper production) But instead I designed the outer edge between seat and main pot big enough to work perfectly as a all round handle. This means, even if the toilet is placed at a very narrow space you can lift the toilet from all sides, without being limited to 2 handles. This is meant to add mobility than lowering it!

- Lid: The lid is in production this week. On Friday I can post more pictures! Thanks for this advise. We are currently discussing with GIZ in Zambia to test the MoSan toilet with people with disabilities.

- Colour: The colour is caused by production and not chosen on purpose. White (called "nature") is the most common colour of PE and also the cheapest. All other colours, like black or blue are inked by pigments and are more expensive. If we produce more than 10 prototypes it is of course possible to order colored plastics, but so far it is not feasible. My preferred colour is still a blue-turquoise, since I think it communicates cleanliness, freshness and nature at once

[img size=100x100]blog-imgs-24.fc2.com/d/a/i/dailydisplay/326c.jpg[/img]

all the best,

Mona

MoSan - Mobile Sanitation

is.gd/mobilesanitation

is.gd/mobilesanitation

The following user(s) like this post: JKMakowka

You need to login to reply

The topic has been locked.

Looks great so far, and I see you lowered the interior a bit for male users

Quick remarks:

-Color should definitely be looked into, a light yellow or brown is probably the best.

-How much weight does the new bottom withstand? It looks quite flexible, so there might be a risk of the top slipping partially into it, when uneven pressure is applied from the top.

- I see the grips at the sides where cut from the design... I guess since it will be mostly the containers inside that are moved, that isn't such a big issue, but the mobility inside the house is definitely lowered by that.

-can you post pictures of the lid? I think since this is partially an innovation for the disabled and elderly, special care needs to be taken designing the grip so that it can be used without help. Edit: the easiest for that would probably be the option to attach an additional wire hook to it somehow, which can then be formed for the best usability individually. So two solid flanges which can be drilled for holes to hold the wire would probably be best.

P.S.: If you are interested in a pilot of the new design in urban Kampala (Uganda) we could probably arrange for it. Here in Kampala there are also PE production capacities, so it could be locally produced (if one comes up for funding to make the molds).

Quick remarks:

-Color should definitely be looked into, a light yellow or brown is probably the best.

-How much weight does the new bottom withstand? It looks quite flexible, so there might be a risk of the top slipping partially into it, when uneven pressure is applied from the top.

- I see the grips at the sides where cut from the design... I guess since it will be mostly the containers inside that are moved, that isn't such a big issue, but the mobility inside the house is definitely lowered by that.

-can you post pictures of the lid? I think since this is partially an innovation for the disabled and elderly, special care needs to be taken designing the grip so that it can be used without help. Edit: the easiest for that would probably be the option to attach an additional wire hook to it somehow, which can then be formed for the best usability individually. So two solid flanges which can be drilled for holes to hold the wire would probably be best.

P.S.: If you are interested in a pilot of the new design in urban Kampala (Uganda) we could probably arrange for it. Here in Kampala there are also PE production capacities, so it could be locally produced (if one comes up for funding to make the molds).

The topic has been locked.

Dear readers,

please check out the MoSan blog for first results from deep-drawing with thermoplastics! The day at the workshop was great and the results are amazing. I am very happy we took the time to change the process from manual laminating to deep-drawing. With the new way of production the design was optimized:

- all parts are stackable

- surfaces are smooth and easy to clean

- measurements are optimized regarding ergonomic feedback

- simplifications for easier production

Cant wait to hear your feedback!

Best,

Mona

mosan-bangladesh.tumblr.com

please check out the MoSan blog for first results from deep-drawing with thermoplastics! The day at the workshop was great and the results are amazing. I am very happy we took the time to change the process from manual laminating to deep-drawing. With the new way of production the design was optimized:

- all parts are stackable

- surfaces are smooth and easy to clean

- measurements are optimized regarding ergonomic feedback

- simplifications for easier production

Cant wait to hear your feedback!

Best,

Mona

mosan-bangladesh.tumblr.com

MoSan - Mobile Sanitation

is.gd/mobilesanitation

is.gd/mobilesanitation

Attachments:

-

IMG_9745.jpg

(Filesize: 24KB)

IMG_9745.jpg

(Filesize: 24KB)

The topic has been locked.

Dear readers,

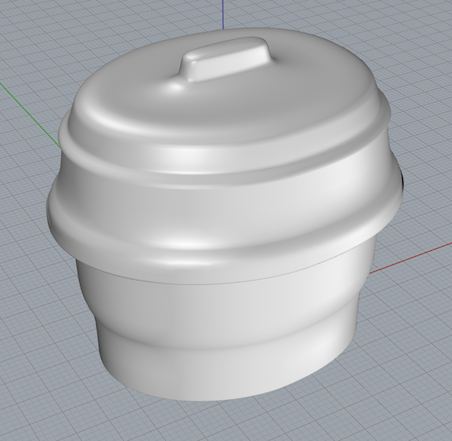

we are finally producing the long-awaited prototypes. Last week the mold for the main pot was milled, the seat is in production right now. On Thursday we will deep-draw the first prototype made from durable ABS plastics. All parts will have different wall-thicknesses to optimize stability, weight and costs. The lid will be produced in the end, after we tested the stability of the seat and the main pot. It could be necessary to chose thicker plastic sheets for deep-drawing and this will affect the size of the lid.

As a "sneak preview" here a picture of the CAD draft.

If you are wondering where the side-handles are: the outer edge between seat and main pot is big enough to grab the toilet and carry it easily.

we are finally producing the long-awaited prototypes. Last week the mold for the main pot was milled, the seat is in production right now. On Thursday we will deep-draw the first prototype made from durable ABS plastics. All parts will have different wall-thicknesses to optimize stability, weight and costs. The lid will be produced in the end, after we tested the stability of the seat and the main pot. It could be necessary to chose thicker plastic sheets for deep-drawing and this will affect the size of the lid.

As a "sneak preview" here a picture of the CAD draft.

If you are wondering where the side-handles are: the outer edge between seat and main pot is big enough to grab the toilet and carry it easily.

Attachment not found

MoSan - Mobile Sanitation

is.gd/mobilesanitation

is.gd/mobilesanitation

Attachments:

-

Bildschirm...8.41.png

(Filesize: 203KB)

Bildschirm...8.41.png

(Filesize: 203KB)

The following user(s) like this post: tmsinnovation

You need to login to reply

The topic has been locked.

- petersluk

-

Less

- Posts: 3

- Likes received: 2

Re: Open discussion on MOSAN toilet design

Hi Mona,

I think it might be helpful to consider the types of disabilities shown when designing a supportive structure for the people with disability. In some cases people that normally use wheelchairs crawl around on all fours since the houses are to cramped or the floors to uneven to use a wheel chairs. This means they will have to get up on the Mosan toilet from the floor.

Hope this helps

Cheers,

Lukas

I think it might be helpful to consider the types of disabilities shown when designing a supportive structure for the people with disability. In some cases people that normally use wheelchairs crawl around on all fours since the houses are to cramped or the floors to uneven to use a wheel chairs. This means they will have to get up on the Mosan toilet from the floor.

Hope this helps

Cheers,

Lukas

The topic has been locked.

- bracken

-

- Working throughout Africa since 1996 in development cooperation. Involved with sustainable sanitation systems since 2002. Currently working for the AHT GROUP AG (a private consultancy office in Germany).

Less- Posts: 47

- Karma: 14

- Likes received: 33

hi Lukas,

I'll be in Zambia soon on a short term mission for the GIZ water programme out in Chipata looking at rural sanitation. I'd be interested in hearing what progress you may have made so far. Please mail me at This email address is being protected from spambots. You need JavaScript enabled to view it..

Thanks.

Patrick

I'll be in Zambia soon on a short term mission for the GIZ water programme out in Chipata looking at rural sanitation. I'd be interested in hearing what progress you may have made so far. Please mail me at This email address is being protected from spambots. You need JavaScript enabled to view it..

Thanks.

Patrick

Water and Sanitation Specialist

AHT GROUP AG

Management & Engineering

D-45128 Essen, Huyssenallee 66-68

Germany

AHT GROUP AG

Management & Engineering

D-45128 Essen, Huyssenallee 66-68

Germany

The topic has been locked.

Great! I would love to get an insight in current habits in Zambia. Please upload the video on an external server, like www.ge.tt or in your public dropbox folder and post the links, so the SuSanA community can also watch the videos ;-)

Many thanks!

Many thanks!

MoSan - Mobile Sanitation

is.gd/mobilesanitation

is.gd/mobilesanitation

The topic has been locked.

- petersluk

-

Less

- Posts: 3

- Likes received: 2

Re: Open discussion on MOSAN toilet design

Dear Mona,

Im currently working in the GIZ water program in Zambia and my current task is to design a latrine for people with disabilities in Sambia. I am a Product Design Engineer and I have a little experience with deep drawing from projects in University but non in Africa or Zambia.

I tried to upload some videos of people with disability in the peri-urban areas here, that might help but it doesnt seem to work. So if you give me an email address i can try to send them to you.

Cheers,

Lukas

Im currently working in the GIZ water program in Zambia and my current task is to design a latrine for people with disabilities in Sambia. I am a Product Design Engineer and I have a little experience with deep drawing from projects in University but non in Africa or Zambia.

I tried to upload some videos of people with disability in the peri-urban areas here, that might help but it doesnt seem to work. So if you give me an email address i can try to send them to you.

Cheers,

Lukas

The following user(s) like this post: Mona

You need to login to reply

The topic has been locked.

Dear Lukas,

thanks so much for your precise advise. As you said, we are working close with manufacturers and learn from their experience. For their machines 1° is enough to release the parts easily from the molds, but my knowledge is that 2-3° work better, especially if we have no compressor unit for releasing. Do you have experience with deep-drawing in Zambia?

For the final production deep-drawing could be a cost-effective method and the results are of very good quality (depending on the plastics). Rotational moulding is a good option too, but the initial costs for molds are much higher than for deep-drawing. So the final method will relate on the scale of the production.

To add additional support for people with disabilities is very important too. Our idea is to design a railing fitted to the place where MoSan will be used. Either fixed to a wall or a mobile version standing on the ground.

It is really nice to hear that you confirm our ideas and concepts from your point of view and your experience in Zambia. For which organization are you working? MoSan could be a great solution for peri-urban areas as well Please stay in touch!

Please stay in touch!

Best, Mona

thanks so much for your precise advise. As you said, we are working close with manufacturers and learn from their experience. For their machines 1° is enough to release the parts easily from the molds, but my knowledge is that 2-3° work better, especially if we have no compressor unit for releasing. Do you have experience with deep-drawing in Zambia?

For the final production deep-drawing could be a cost-effective method and the results are of very good quality (depending on the plastics). Rotational moulding is a good option too, but the initial costs for molds are much higher than for deep-drawing. So the final method will relate on the scale of the production.

To add additional support for people with disabilities is very important too. Our idea is to design a railing fitted to the place where MoSan will be used. Either fixed to a wall or a mobile version standing on the ground.

It is really nice to hear that you confirm our ideas and concepts from your point of view and your experience in Zambia. For which organization are you working? MoSan could be a great solution for peri-urban areas as well

Best, Mona

MoSan - Mobile Sanitation

is.gd/mobilesanitation

is.gd/mobilesanitation

The following user(s) like this post: tmsinnovation

You need to login to reply

The topic has been locked.

- petersluk

-

Less

- Posts: 3

- Likes received: 2

Re: Open discussion on MOSAN toilet design

Dear Mona,

I really like your product and I think its great that you are taking it through so many tests.

Just some general issues with the Prototyping, which you have probably already thought of:

- Since you say you want to make the product stackable you are probably thinking of changing the shape of the pot anyway to make the cross-section area (viewed from top) decrease towards the bottom. When designing this you should consider minimum angles and thicknesses of material for vacuum forming or deep drawing but you can best discuss this with the person operating the vacuum forming or deep drawing machine.

- If you are designing the product for manufacture what manufacturing processes are you considering for a final product? I think you might be able to do some interesting things with rotational moulding. You could make the whole thing out of one mould or two lids, two main pots out of one mould. You then simply cut it into the separate parts.

- Also consider adding ribs into your prototypes. They would make the final product stronger and long lasting but might effect the user interaction when cleaning.

I am currently working on a project that focuses on sanitation facilities for disabled in peri-urban areas in Zambia. I think your Idea of targeting the product at elderly or disabled is good. There are many who have difficulties traveling to pit latrines in wheelchairs or with Crutches on the uneven terrain especially at night and rely on others to take them. So for them a portable solution with a container that can be emptied by someone else would be ideal. However if you really want to target these groups you should consider designing extra supportive structures or something for them to hold onto and help them get onto the toilet from a wheelchair or the floor.

Regards Lukas

I really like your product and I think its great that you are taking it through so many tests.

Just some general issues with the Prototyping, which you have probably already thought of:

- Since you say you want to make the product stackable you are probably thinking of changing the shape of the pot anyway to make the cross-section area (viewed from top) decrease towards the bottom. When designing this you should consider minimum angles and thicknesses of material for vacuum forming or deep drawing but you can best discuss this with the person operating the vacuum forming or deep drawing machine.

- If you are designing the product for manufacture what manufacturing processes are you considering for a final product? I think you might be able to do some interesting things with rotational moulding. You could make the whole thing out of one mould or two lids, two main pots out of one mould. You then simply cut it into the separate parts.

- Also consider adding ribs into your prototypes. They would make the final product stronger and long lasting but might effect the user interaction when cleaning.

I am currently working on a project that focuses on sanitation facilities for disabled in peri-urban areas in Zambia. I think your Idea of targeting the product at elderly or disabled is good. There are many who have difficulties traveling to pit latrines in wheelchairs or with Crutches on the uneven terrain especially at night and rely on others to take them. So for them a portable solution with a container that can be emptied by someone else would be ideal. However if you really want to target these groups you should consider designing extra supportive structures or something for them to hold onto and help them get onto the toilet from a wheelchair or the floor.

Regards Lukas

The following user(s) like this post: Mona

You need to login to reply

The topic has been locked.

Share this thread:

- Sanitation systems

- Toilets without urine diversion

- Container-based, mobile or bag-based toilets

- Open discussion on MOSAN toilet design

Recently active users. Who else has been active?

Time to create page: 0.242 seconds