- Sanitation systems

- Treatment of wastewater, sludges, organic waste, excreta

- Anaerobic treatment systems (biogas sanitation)

- Biogas sanitation (systems focusing on biogas production)

- Biogas generator powered by self-sustaining mixing mechanism (Frontier Environmental Technology, USA)

Biogas generator powered by self-sustaining mixing mechanism (Frontier Environmental Technology, USA)

52.1k views

- Elisabeth

-

- User is blocked

- Freelance consultant since 2012

Less- Posts: 3372

- Karma: 54

- Likes received: 932

Re: Biogas generator powered by self-sustaining mixing mechanism (Frontier Environmental Technology, USA)

For those of you wanting to learn a bit more about Jianmin's research, I can recommend watching this online discussion that we recorded with Jianmin on 1 July.

His explanation about his project (without a powerpoint) starts at 15:29 into the recording; it is followed by questions and answers that start at around 22:55 until 28:44.

I have added the Youtube link below to start at exactly the right time:

In the question session, the following was discussed:

Arno asked if farm-based reactors in China could be retrofitted with this mixing device. Jianmin explained that this is not really possible because his mixing device works best with a taller reactor, not with a flat one. He explained that the main purpose of the mixing is to prevent sludge deposition at the bottom and to break up floating sludge.

Jianmin proposed that his biogas reactors would be smaller and could be built at a centralised location (factory) to minimise the problem of leakage that often occurs with locally-made digesters.

Toni asked Jianmin if his system is not very similar to existing European mixing systems for digesters, in particular these two:

Dranco: www.ows.be/household_waste/dranco/

and:

Valorga: www.valorgainternational.fr/fr/

Jianmin wasn't able to answer this question because he didn't know those particular companies, although he felt that mixing by collecting gas in the middle of the tall reactor is the novel aspect.

Gabrielle asked about the % increase in biogas production: Jianmin said it is about 30% increase in biogas production with his mixing system. He thinks that more increase would be possible with taller reactors, and hopes to be able to research this in the future if he gets more research funds.

Thank you, Jianmin, for your participation in this! (and please correct me if I noted anything done incorrectly)

His explanation about his project (without a powerpoint) starts at 15:29 into the recording; it is followed by questions and answers that start at around 22:55 until 28:44.

I have added the Youtube link below to start at exactly the right time:

In the question session, the following was discussed:

Arno asked if farm-based reactors in China could be retrofitted with this mixing device. Jianmin explained that this is not really possible because his mixing device works best with a taller reactor, not with a flat one. He explained that the main purpose of the mixing is to prevent sludge deposition at the bottom and to break up floating sludge.

Jianmin proposed that his biogas reactors would be smaller and could be built at a centralised location (factory) to minimise the problem of leakage that often occurs with locally-made digesters.

Toni asked Jianmin if his system is not very similar to existing European mixing systems for digesters, in particular these two:

Dranco: www.ows.be/household_waste/dranco/

and:

Valorga: www.valorgainternational.fr/fr/

Jianmin wasn't able to answer this question because he didn't know those particular companies, although he felt that mixing by collecting gas in the middle of the tall reactor is the novel aspect.

Gabrielle asked about the % increase in biogas production: Jianmin said it is about 30% increase in biogas production with his mixing system. He thinks that more increase would be possible with taller reactors, and hopes to be able to research this in the future if he gets more research funds.

Thank you, Jianmin, for your participation in this! (and please correct me if I noted anything done incorrectly)

Dr. Elisabeth von Muench

Freelance consultant on environmental and climate projects

Freelance consultant on environmental and climate projects

Please Log in to join the conversation.

You need to login to replyRe: Biogas generator powered by self-sustaining mixing mechanism (Frontier Environmental Technology, USA)

JKMakowka -

The anaerobic digestion has two phases - acid formation and methane formation. The first phase produce acid and lower pH, while the second phase consume acid and raise pH. Unfortunately the bugs like neutral pH to be happy, and these two phases work together to keep the pH neutral. So if you split them into two different phases, they will not work. This splitted "two-phase" has been tried 30 years ago and some people are still trying .... sorry you are not the first one .

.

sjoerdnienhuys -

Your process is essentially a two-stage process, with the first stage being used to handle raw influent and the second stage to handle that from the first stage. Yes - this will improve gas production. The mixing might work, but they are pretty mild. I wonder if this biogas gain is worth the effort due to the more complexed design.

Jianmin

The anaerobic digestion has two phases - acid formation and methane formation. The first phase produce acid and lower pH, while the second phase consume acid and raise pH. Unfortunately the bugs like neutral pH to be happy, and these two phases work together to keep the pH neutral. So if you split them into two different phases, they will not work. This splitted "two-phase" has been tried 30 years ago and some people are still trying .... sorry you are not the first one

sjoerdnienhuys -

Your process is essentially a two-stage process, with the first stage being used to handle raw influent and the second stage to handle that from the first stage. Yes - this will improve gas production. The mixing might work, but they are pretty mild. I wonder if this biogas gain is worth the effort due to the more complexed design.

Jianmin

Jianmin Wang

Please Log in to join the conversation.

You need to login to replyRe: Reply: Biogas generator powered by self-sustaining mixing mechanism (Frontier Environmental Technology, USA)

Thanks for the clarification in regards to the air intake.

Not sure about using the "play-pump" approach to stirring bio-digesters...

Not sure about using the "play-pump" approach to stirring bio-digesters...

Please Log in to join the conversation.

You need to login to replyRe: Reply: Biogas generator powered by self-sustaining mixing mechanism (Frontier Environmental Technology, USA)

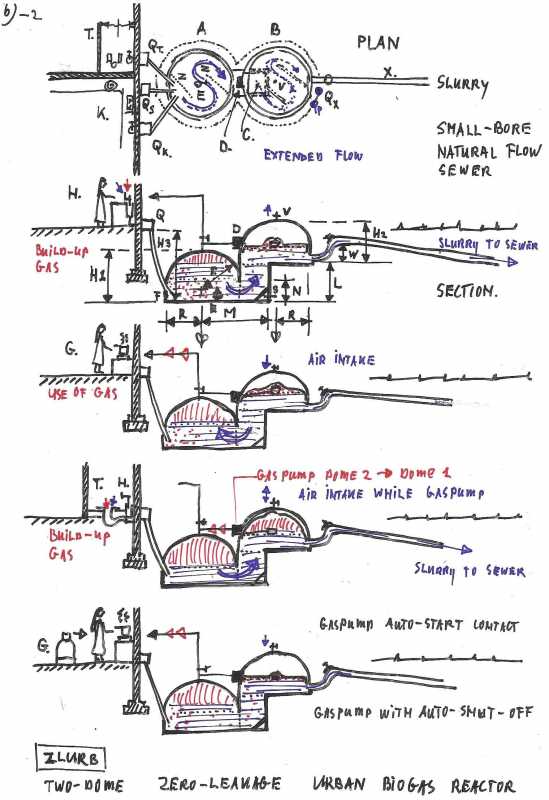

balance tank included.

The second dome, counted from from the feeder, also serves as a balance tank since it is communicating with the elevated overflow. Since the design is for an urban situation, the overflow continues into a small city sewer. Instead of the city sewer you can alo make a large sub-soil surface collection tank from which you can collect the effluent for processing as fertilizer. In the particular design the urine was collected separately and also has to be collected from a sub-soil tank.

The second dome, counted from from the feeder, also serves as a balance tank since it is communicating with the elevated overflow. Since the design is for an urban situation, the overflow continues into a small city sewer. Instead of the city sewer you can alo make a large sub-soil surface collection tank from which you can collect the effluent for processing as fertilizer. In the particular design the urine was collected separately and also has to be collected from a sub-soil tank.

Sjoerd from The Netherlands.

Pronounce: 'Sured'

Some of my work on: www.nienhuys.info

for correspondence: This email address is being protected from spambots. You need JavaScript enabled to view it.

Pronounce: 'Sured'

Some of my work on: www.nienhuys.info

for correspondence: This email address is being protected from spambots. You need JavaScript enabled to view it.

Please Log in to join the conversation.

You need to login to replyRe: Reply: Biogas generator powered by self-sustaining mixing mechanism (Frontier Environmental Technology, USA)

air intake.

The sketch may not be clear enough, but the second dome has a membrane inside. Under the membrane is the biogas and above a dome to allow the membrane to be protected and expand. I got several quotations from the membrane manufacturers who use them in very large size thermophillic biogas reactors.

In this design three ways of mixing occurred; one by the z flow over the bottom sludge blanket; two by the flowing back and forth between the domes when gas is extracted, and three by the pedal operated mixer.

The design of the pedal operated mixer turned to be rather simple using the boat-drive shaft seal design. In urban environments there will be plenty of children willing to operate the bike a few times; maybe the bike can be made fancier. Other playing tools can be used for the stirring, like they use in South Africa for waterpumping.

The sketch may not be clear enough, but the second dome has a membrane inside. Under the membrane is the biogas and above a dome to allow the membrane to be protected and expand. I got several quotations from the membrane manufacturers who use them in very large size thermophillic biogas reactors.

In this design three ways of mixing occurred; one by the z flow over the bottom sludge blanket; two by the flowing back and forth between the domes when gas is extracted, and three by the pedal operated mixer.

The design of the pedal operated mixer turned to be rather simple using the boat-drive shaft seal design. In urban environments there will be plenty of children willing to operate the bike a few times; maybe the bike can be made fancier. Other playing tools can be used for the stirring, like they use in South Africa for waterpumping.

Sjoerd from The Netherlands.

Pronounce: 'Sured'

Some of my work on: www.nienhuys.info

for correspondence: This email address is being protected from spambots. You need JavaScript enabled to view it.

Pronounce: 'Sured'

Some of my work on: www.nienhuys.info

for correspondence: This email address is being protected from spambots. You need JavaScript enabled to view it.

The following user(s) like this post: JKMakowka

Please Log in to join the conversation.

You need to login to replyRe: Reply: Biogas generator powered by self-sustaining mixing mechanism (Frontier Environmental Technology, USA)

jmwang wrote: 3. A balance tank will be needed because, if the biogas is consumed the liquid level in the second tank will drop and air will be sucked to the second dome, then be pumped to the first dome - the tank will explode after air is mixed to the methane.

From a quick glance at sjoerdnienhuys sketch, that would be a concern in general, no? It specifically states that there is an air intake (to avoid sucking a vacuum in the second tank I guess), but that would clearly involve getting a dangerous gas/air mixture.

However overall the design seems similar to the "supergas" I linked above, so a similar mixing mechanism should be easy to include (sjoerdnienhuys design has slow mixing too, but the pressure release fast mixing is probably more efficient, even though higher gas pressures mean more gas leakage most likely too).

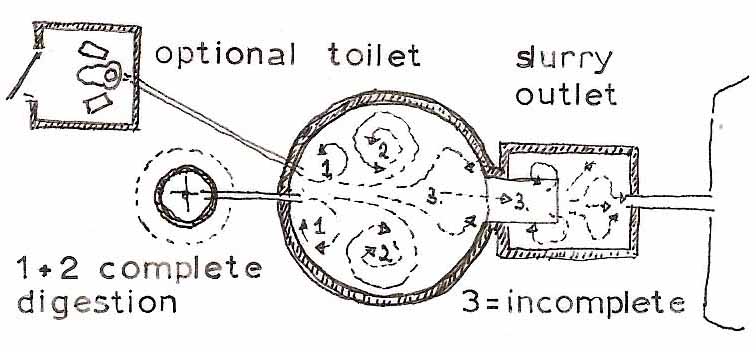

A bit OT: has anyone ever tried to make a single dome, but two step digestion system to work? From the biogas theory it would be beneficial to have the first acidification reaction separated from methanogenesis phase. I think this is done in some larger scale commercial biogas plants, and some rural biogas manuals suggest letting the ready feed material sit in the liquid solution a few hours before feeding it in the digestor, but is there also a design that includes this step automatically?

An overflowing inner ring might do the trick, while at the same time increasing the mean residual time of the material in the digestor... but I doubt that I am the first one to think of this...

Please Log in to join the conversation.

You need to login to replyRe: Reply: Biogas generator powered by self-sustaining mixing mechanism (Frontier Environmental Technology, USA)

You try to use the second dome to collect the biogas that could be otherwise wasted. There could be a number of things to consider:

1. What gas pump can you use to pump gas from one tank to the other one? Fish tank pump may not work because it takes gas from surrounding environment. The pump must have a intake port and discharge port, and has to be sealed all the time.

2. Second dome may not introduce good mixing, which is the key to differentiate high rate and low rate digesters.

3. A balance tank will be needed because, if the biogas is consumed the liquid level in the second tank will drop and air will be sucked to the second dome, then be pumped to the first dome - the tank will explode after air is mixed to the methane.

Jianmin

1. What gas pump can you use to pump gas from one tank to the other one? Fish tank pump may not work because it takes gas from surrounding environment. The pump must have a intake port and discharge port, and has to be sealed all the time.

2. Second dome may not introduce good mixing, which is the key to differentiate high rate and low rate digesters.

3. A balance tank will be needed because, if the biogas is consumed the liquid level in the second tank will drop and air will be sucked to the second dome, then be pumped to the first dome - the tank will explode after air is mixed to the methane.

Jianmin

Jianmin Wang

Please Log in to join the conversation.

You need to login to replyRe: Reply: Biogas generator powered by self-sustaining mixing mechanism (Frontier Environmental Technology, USA)

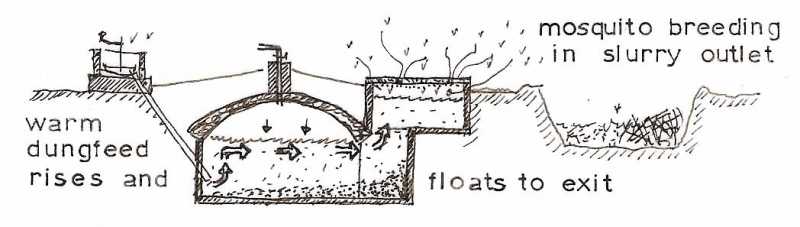

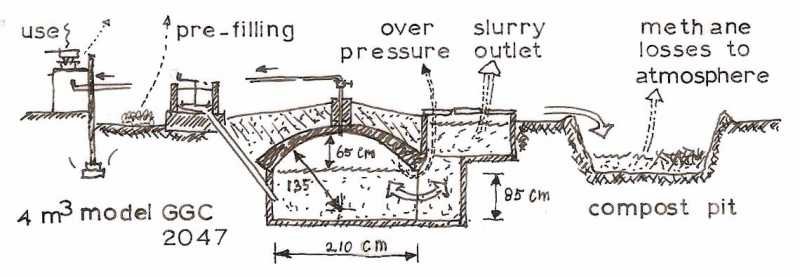

On the issue of gas leakage I was merely referring to the single dome biogas reactors with good quality dome structure and only a pressure balance tank attached directly to the dome outlet. From field mesuring large amounts of gas escaped from the balance tank and when the main dome was not very regularly use for kitchen cooking.

A possible solution was to have a Z shaped wall structure inside and a second dome which also could capture gas. Using a simple fishtank airpump on a solar panel the gas from the second tank is pumped back to the first tank.

The Z profile in the two tanks increased the average retention period because there was no direct flow from the intake to the outlet as occurs of one volume domes. see sketches.

The internal PDM diaphragm turned out to be too costly and complicated.

A possible solution was to have a Z shaped wall structure inside and a second dome which also could capture gas. Using a simple fishtank airpump on a solar panel the gas from the second tank is pumped back to the first tank.

The Z profile in the two tanks increased the average retention period because there was no direct flow from the intake to the outlet as occurs of one volume domes. see sketches.

The internal PDM diaphragm turned out to be too costly and complicated.

Sjoerd from The Netherlands.

Pronounce: 'Sured'

Some of my work on: www.nienhuys.info

for correspondence: This email address is being protected from spambots. You need JavaScript enabled to view it.

Pronounce: 'Sured'

Some of my work on: www.nienhuys.info

for correspondence: This email address is being protected from spambots. You need JavaScript enabled to view it.

Attachments:

-

zlubrdirec...0008.jpg

(Filesize: 24KB)

zlubrdirec...0008.jpg

(Filesize: 24KB)

-

zlubrgasle...0007.jpg

(Filesize: 29KB)

zlubrgasle...0007.jpg

(Filesize: 29KB)

-

zlubrwhirl...kort.jpg

(Filesize: 73KB)

zlubrwhirl...kort.jpg

(Filesize: 73KB)

-

ZLURB6-2march2008.jpg

(Filesize: 55KB)

ZLURB6-2march2008.jpg

(Filesize: 55KB)

Please Log in to join the conversation.

You need to login to replyRe: Reply: Biogas generator powered by self-sustaining mixing mechanism (Frontier Environmental Technology, USA)

sjoerdnienhuys,

Yes - you are right. The traditional biogas generators are so large that they have to be constructed in field using local materials and by local labor, which could easily cause leak. In one region of China (I forgot where it is), over 90% of biogas generator does not work due to leak. They are abandoned and could course safety issue.

The function is dependent on the digester size - That is why I wanted to test it in a field scale. When the unit is larger, all conduit is becoming larger, and less clogging could occur. I think, for a family size unit, I can make it work as long as the particle is less than 1 inch. I would also use a screen or a manual grinder as part of the intake so it can reduce the size of the feed particles. I think for most household waste, the particle size will be less than 1 inch.

We have tested very thick sludge up to 5% of solids. If the feed is very thick, the effluent can be returned to dilute it.

I get an idea what you want to achieve. However, both ideas will cause continuous action. Due to the low gas production, this continuous action may not be sufficient enough. In my design, I have all gas collected and release them at once, causing a strong surge action, which shakes the reactor and cause periodic mixing. Also, in my case, the surge mixer lift all sludge from the bottom of the reactor, to eliminate sludge deposition at the bottom.

I notice that you have done lots of thinking in biogas generator. I would be very interested in further discussing ideas with you.

Jianmin

Yes - you are right. The traditional biogas generators are so large that they have to be constructed in field using local materials and by local labor, which could easily cause leak. In one region of China (I forgot where it is), over 90% of biogas generator does not work due to leak. They are abandoned and could course safety issue.

The function is dependent on the digester size - That is why I wanted to test it in a field scale. When the unit is larger, all conduit is becoming larger, and less clogging could occur. I think, for a family size unit, I can make it work as long as the particle is less than 1 inch. I would also use a screen or a manual grinder as part of the intake so it can reduce the size of the feed particles. I think for most household waste, the particle size will be less than 1 inch.

We have tested very thick sludge up to 5% of solids. If the feed is very thick, the effluent can be returned to dilute it.

I get an idea what you want to achieve. However, both ideas will cause continuous action. Due to the low gas production, this continuous action may not be sufficient enough. In my design, I have all gas collected and release them at once, causing a strong surge action, which shakes the reactor and cause periodic mixing. Also, in my case, the surge mixer lift all sludge from the bottom of the reactor, to eliminate sludge deposition at the bottom.

I notice that you have done lots of thinking in biogas generator. I would be very interested in further discussing ideas with you.

Jianmin

Jianmin Wang

Please Log in to join the conversation.

You need to login to replyRe: Reply: Biogas generator powered by self-sustaining mixing mechanism (Frontier Environmental Technology, USA)

This is very promising because it speeds up the fermentation. Currently the smaller size biogas installations with single fermentation chambers in combination with an overflow have large gas leakage into the atmosphere. The creation of a double fermentation chamber reduces the leakage, but also the stirring.

I suppose the fed-in liquid has to be really liquid and cannot contain long fibres such as may occur with adding kitchen waste.

I have tried to work out the coffee percolator principle but did not succeed.

Also I have thought about the waterwheel principle; the design is upside down and the water substituded by the raising gas. The other buckets on the wheel move down through the slurry ans cause the stirr. You need a rectangular tank to make it work. Also in such a case the slurry should be really thin. The disadvantage is that it will be difficult to maintain when getting stick.

I suppose the fed-in liquid has to be really liquid and cannot contain long fibres such as may occur with adding kitchen waste.

I have tried to work out the coffee percolator principle but did not succeed.

Also I have thought about the waterwheel principle; the design is upside down and the water substituded by the raising gas. The other buckets on the wheel move down through the slurry ans cause the stirr. You need a rectangular tank to make it work. Also in such a case the slurry should be really thin. The disadvantage is that it will be difficult to maintain when getting stick.

Sjoerd from The Netherlands.

Pronounce: 'Sured'

Some of my work on: www.nienhuys.info

for correspondence: This email address is being protected from spambots. You need JavaScript enabled to view it.

Pronounce: 'Sured'

Some of my work on: www.nienhuys.info

for correspondence: This email address is being protected from spambots. You need JavaScript enabled to view it.

Please Log in to join the conversation.

You need to login to replyRe: Reply: Biogas generator powered by self-sustaining mixing mechanism (Frontier Environmental Technology, USA)

Thanks for sharing that information. It is a very interesting design, and the valve design is very smart. However, in terms of mixing intensity, it is similar to those traditional ones that have a large outlet tank.

Our self-mixing device continuously pump the sludge from the tank bottom to the top, and the scum layer could be minimized as a result of the surge action of the mixing device, which could help to improve performance. Also, the self-mixing biogas generator should be easier to set up due to the one-tank design. Unfortunately it has not been field tested to prove these points due to the limitation of the resources.

Jianmin Wang

Our self-mixing device continuously pump the sludge from the tank bottom to the top, and the scum layer could be minimized as a result of the surge action of the mixing device, which could help to improve performance. Also, the self-mixing biogas generator should be easier to set up due to the one-tank design. Unfortunately it has not been field tested to prove these points due to the limitation of the resources.

Jianmin Wang

Jianmin Wang

Please Log in to join the conversation.

You need to login to replyRe: Reply: Biogas generator powered by self-sustaining mixing mechanism (Frontier Environmental Technology, USA)

Seems similar to this one:

www.supergas.dk/technicaldescription/supergasprincipe/

www.supergas.dk/technicaldescription/supergasprincipe/

Please Log in to join the conversation.

You need to login to reply

Share this thread:

- Sanitation systems

- Treatment of wastewater, sludges, organic waste, excreta

- Anaerobic treatment systems (biogas sanitation)

- Biogas sanitation (systems focusing on biogas production)

- Biogas generator powered by self-sustaining mixing mechanism (Frontier Environmental Technology, USA)

Recently active users. Who else has been active?

Time to create page: 0.147 seconds