- Sanitation systems

- Various topics related to sanitation systems

- Vortex bioreactors for the processing of contaminated wastewater (Plymouth Marine Laboratory, UK)

Vortex bioreactors for the processing of contaminated wastewater (Plymouth Marine Laboratory, UK)

23.9k views

- mikeallen

-

Topic Author

Topic Author- I'm a marine biologist by trade and a molecular biologist by training. I specialise in algal virology, in particular the giant viruses that infect E. huxleyi. I'm also interested in technology development and bioprocessing using vortex reactors and PBRs

Less- Posts: 9

- Karma: 2

- Likes received: 3

Vortex bioreactors for the processing of contaminated wastewater (Plymouth Marine Laboratory, UK)

Dear all,

I would like to introduce to you a research grant with funding from the Bill & Melinda Gates Foundation which I am leading. It’s been a very exciting grant to work on and the results have been very promising. Initially, we were developing this technology for the production of biofuels from microalgae (and still are). This is where our expertise lies (I work at Plymouth Marine Laboratory), however we obtained funding from BMGF to develop the technology for water disinfection. We have proved the principle, but really need your help to take it to the next stage. We are currently applying for Phase 2 funding (in the next two weeks) and are looking for partners to field test our technology. Take a look at the information below and if you’re interested, please drop me an email (This email address is being protected from spambots. You need JavaScript enabled to view it.).

Looking forward to working with you

Mike

Title of grant: Manually-driven decentralized Vortex bioreactors for the processing of (faecal sludge and) wastewater

Subtitle (more descriptive title): Manually-driven decentralized Vortex bioreactors for the processing of secondary effluent. Our idea is to engineer low-cost, small foot-print, hand/bicycle/motor-driven vortex bioreactors which can completely sterilize pathogen contaminated water in 2-3 minutes. To our knowledge, there is no scalable device in the world today that can generate microbe-free water so rapidly and so reliably with minimal energy input.

Name of lead organization: Plymouth Marine Laboratory

Primary contact at lead organization: Mike Allen

Grantee location: Plymouth, United Kingdom

Developing country where the research is being tested: We are currently looking for partners/collaborators/stakeholders/any interested party to test the vortex bioreactor in both laboratory and field trials. See below for details of potential field deployment opportunities!

Short description of the project:

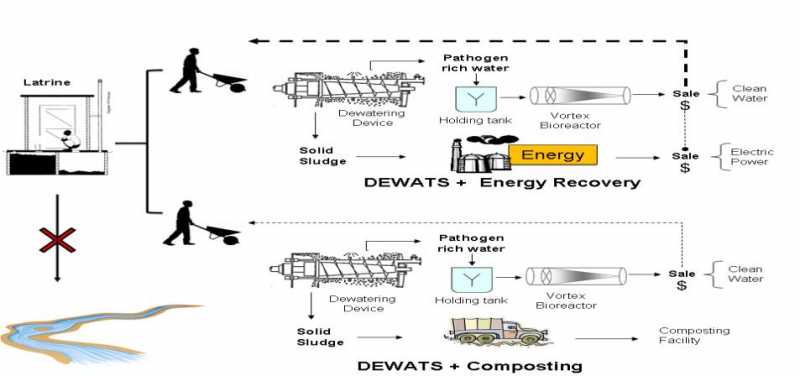

The bioreactor will find application in a wide variety of sanitation systems in a large number of countries: it is an extremely versatile tool for water sterilization. In this project, we will be focusing on testing the bioreactor as a means of treating the effluent separated from high BOD load sludge before further treatment, reuse or discharge

Goal(s):

The original goal of this project was to develop a low-cost, manually-driven vortex bioreactor which reduces the total viable count of faecal contaminated waste water through the intense mixing and subsequent separation of the wastewater into liquid and solids. WE HAVE CHANGED THIS GOAL TO FOCUS ON THE DISINFECTION OF SECONDARY EFFLUENT (LIQUID ONLY), BECAUSE THIS SEEMS TODAY THE SINGLE MOST IMPORTANT APPLICATION. Vortex separation systems are common within the sanitation industry to physically separate wastewater into distinct output streams which have the same biological and chemical properties than before.

The vortex bioreactor is subtly, but crucially different: the focus is not on separation, but on exploiting the intense mixing zone produced within a vortex. By bringing a destructive agent (we’ve been using a fully recyclable copper-alginate bead, which destroys the bacteria through the ‘oligodynamic effect’, most likely redox stress) into intense contact with the microbial fraction, we can disinfect the water. The simple design of the vortex bioreactor is completely scalable and can just as easily deal with a few liters of water a day (single toilet), to tens of thousands of gallons a minute (municipal). Hand/bicycle driven vortex bioreactors are cheap to construct, can efficiently disinfect contaminated water, and are highly versatile. With just one moving part, a simple design and the potential to utilize local materials, the vortex bioreactor is a scalable solution to high throughout water processing. Any sanitation or treatment system that currently produces high BOD water can potentially use the vortex bioreactor as a low capital and operation expenditure alternative to UV sterilization. Crucially, there is unlikely to be a reduction in performance under high turbidity (we will be testing this in phase 2).

Vortex bioreactor prototypes

Methods:

Built scaled-down, desktop, closed loop vortex bioreactor with a working volume of 7 litres and 5% solids, E. coli counts were reduced by utilizing a fully recyclable copper-alginate bead. The reactor was powered by means of a simple electric drill at setting 3 of a possible 15 speeds (1 lowest, 15 maximum) and a standard 5 blade model boat impeller.

Preliminary Results (Phase I):

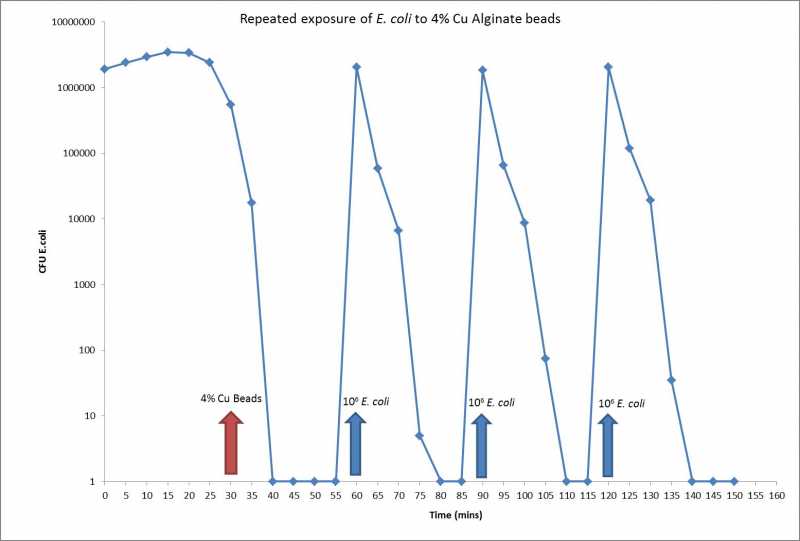

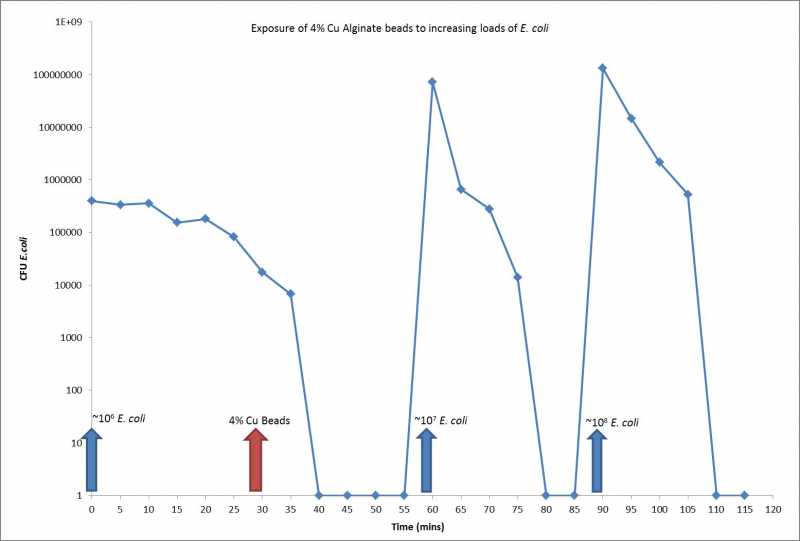

We have various prototype devices. A pilot-scale device has been developed that can reduce viable counts in microbial contaminated water. So far E. coli counts were reduced from 99.85% within 10 minutes (106 per ml, i.e. nearly 1010cells in total, to zero within 15 minutes; 99.85% were destroyed within 10 minutes). The lead lytic agent, copper-alginate, is also fully recyclable and has shown negligible loss of activity and/or degradation through repeated process cycles.

To date, the mixing kinetics to achieve maximum kill rates have not been optimized (only one speed and one impeller design were selected for initial testing and base line data generation). Under optimised conditions, disinfection performance is expected to be higher. However, the relatively slow speed of rotation used suggests that the construction of a manually driven device for small scale processing is perfectly feasible.

Outlook (Phase 2)

We will be looking to improve on our existing 4-log reduction in 5 minutes to, ideally, a 4-log reduction in less than 1 minute. Nothing is yet optimized: we still have the impeller, speed, tube and bead composition to improve upon. We will also be investigating the use of alternative, cheaper materials instead of copper as the active agent (such as local metal ores), as well as alginate extracted from locally sourced seaweed. Once we’ve determined the optimum speed of rotation, we can develop hand and leg powered systems (depending on the volumes involved) with the appropriate gear boxes (such as a modified bicycle or a hand cranked drill) for efficient turning.

Main field of application/target audience: We are looking to help anyone with contaminated water, at any scale, but our greatest impact will mostly likely be working within a DEWATS system setting.

Start and end date: November 2011 to April 31st, 2013

Grant type: Grand Challenges Explorations, Round 7 (GCE R7)

Funding for this research currently ongoing: BMGF Phase 1 and Phase 1 Extension. This technology is also being developed for biofuel production, through funding from the UK’s Technology Strategy Board.

Research or implementation partners: The technology is being developed with partners Protein Technology Ltd, as well as with chemical engineering support from the Bouygues Group and fluidic engineering support from University College London.

Current state of affairs:

TRL5, looking for Phase 2 funding to get it to TRL9.

WE NEED PARTNERS TO FIELD AND LABORATORY TEST THE VORTEX BIOREACTOR IN REAL WORLD SITUATIONS/ENVIRONMENTS. It’s easy to use, low energy, and the reactors we have built are modular in design to allow easy future development following feedback. Ideally we would like to test the prototype in the following environments: small scale waste water treatment plants, individual toilet systems, and contaminated ground water settings such as drinking wells. Once we know how big your pipe/reservoir is and the flow rate, we can adapt our units to your requirements. Any modified components can be sent out in the post and retrofitted easily, and standard operating procedures updated via email.

So far, if we get Phase 2 funding, we’ll be providing vortex bioreactors to:

IF YOU CAN THINK OF AN APPLICATION, OR THIS CAN BE BOLTED ON TO YOUR EXISTING SYSTEM, OR YOU CAN OFFER ANY ASSISTANCE IN ITS DEVELOPMENT, PLEASE JOIN OUR TEAM!

Biggest successes so far:

The vortex bioreactor is great for microbial destruction. We’ve had a lot of interest in the technology, which is viewed by many as a true ENABLING TECHNOLOGY.

We have also received a Phase 1 extension to deal with helminth eggs.

Main challenges / frustration:

Dealing with the helminth issue, as they are quite indestructible chemically and are difficult to destroy at scale in an economical and efficient manner. We have decided not to destroy, but to SEPARATE the eggs out using either floating or sinking bead-binding materials and exploiting the separation properties of the vortex bioreactor. Results are looking promising, however the separation properties of the vortex bioreactor is antagonistic to the mixing properties (currently being applied very successfully to microbial destruction), therefore we need to tweak the system to address this. It is possible we’ll need a dual propeller system. On the plus side, the removal of helminth eggs following microbial destruction can be combined with the removal of any leached copper from the first microbial destruction step, making the discharged water even ‘cleaner’.

Links, further readings, etc:

- Project and result description on Partners in Development (PID) homepage: www.pid.co.za/index.php/abstracts2/77-vo...tment-systems-dewats

- Video clip of presentation at FSM2 in Durban (October 2012):

I would like to introduce to you a research grant with funding from the Bill & Melinda Gates Foundation which I am leading. It’s been a very exciting grant to work on and the results have been very promising. Initially, we were developing this technology for the production of biofuels from microalgae (and still are). This is where our expertise lies (I work at Plymouth Marine Laboratory), however we obtained funding from BMGF to develop the technology for water disinfection. We have proved the principle, but really need your help to take it to the next stage. We are currently applying for Phase 2 funding (in the next two weeks) and are looking for partners to field test our technology. Take a look at the information below and if you’re interested, please drop me an email (This email address is being protected from spambots. You need JavaScript enabled to view it.).

Looking forward to working with you

Mike

Title of grant: Manually-driven decentralized Vortex bioreactors for the processing of (faecal sludge and) wastewater

Subtitle (more descriptive title): Manually-driven decentralized Vortex bioreactors for the processing of secondary effluent. Our idea is to engineer low-cost, small foot-print, hand/bicycle/motor-driven vortex bioreactors which can completely sterilize pathogen contaminated water in 2-3 minutes. To our knowledge, there is no scalable device in the world today that can generate microbe-free water so rapidly and so reliably with minimal energy input.

Name of lead organization: Plymouth Marine Laboratory

Primary contact at lead organization: Mike Allen

Grantee location: Plymouth, United Kingdom

Developing country where the research is being tested: We are currently looking for partners/collaborators/stakeholders/any interested party to test the vortex bioreactor in both laboratory and field trials. See below for details of potential field deployment opportunities!

Short description of the project:

The bioreactor will find application in a wide variety of sanitation systems in a large number of countries: it is an extremely versatile tool for water sterilization. In this project, we will be focusing on testing the bioreactor as a means of treating the effluent separated from high BOD load sludge before further treatment, reuse or discharge

Goal(s):

The original goal of this project was to develop a low-cost, manually-driven vortex bioreactor which reduces the total viable count of faecal contaminated waste water through the intense mixing and subsequent separation of the wastewater into liquid and solids. WE HAVE CHANGED THIS GOAL TO FOCUS ON THE DISINFECTION OF SECONDARY EFFLUENT (LIQUID ONLY), BECAUSE THIS SEEMS TODAY THE SINGLE MOST IMPORTANT APPLICATION. Vortex separation systems are common within the sanitation industry to physically separate wastewater into distinct output streams which have the same biological and chemical properties than before.

The vortex bioreactor is subtly, but crucially different: the focus is not on separation, but on exploiting the intense mixing zone produced within a vortex. By bringing a destructive agent (we’ve been using a fully recyclable copper-alginate bead, which destroys the bacteria through the ‘oligodynamic effect’, most likely redox stress) into intense contact with the microbial fraction, we can disinfect the water. The simple design of the vortex bioreactor is completely scalable and can just as easily deal with a few liters of water a day (single toilet), to tens of thousands of gallons a minute (municipal). Hand/bicycle driven vortex bioreactors are cheap to construct, can efficiently disinfect contaminated water, and are highly versatile. With just one moving part, a simple design and the potential to utilize local materials, the vortex bioreactor is a scalable solution to high throughout water processing. Any sanitation or treatment system that currently produces high BOD water can potentially use the vortex bioreactor as a low capital and operation expenditure alternative to UV sterilization. Crucially, there is unlikely to be a reduction in performance under high turbidity (we will be testing this in phase 2).

Vortex bioreactor prototypes

Methods:

Built scaled-down, desktop, closed loop vortex bioreactor with a working volume of 7 litres and 5% solids, E. coli counts were reduced by utilizing a fully recyclable copper-alginate bead. The reactor was powered by means of a simple electric drill at setting 3 of a possible 15 speeds (1 lowest, 15 maximum) and a standard 5 blade model boat impeller.

Preliminary Results (Phase I):

We have various prototype devices. A pilot-scale device has been developed that can reduce viable counts in microbial contaminated water. So far E. coli counts were reduced from 99.85% within 10 minutes (106 per ml, i.e. nearly 1010cells in total, to zero within 15 minutes; 99.85% were destroyed within 10 minutes). The lead lytic agent, copper-alginate, is also fully recyclable and has shown negligible loss of activity and/or degradation through repeated process cycles.

To date, the mixing kinetics to achieve maximum kill rates have not been optimized (only one speed and one impeller design were selected for initial testing and base line data generation). Under optimised conditions, disinfection performance is expected to be higher. However, the relatively slow speed of rotation used suggests that the construction of a manually driven device for small scale processing is perfectly feasible.

Outlook (Phase 2)

We will be looking to improve on our existing 4-log reduction in 5 minutes to, ideally, a 4-log reduction in less than 1 minute. Nothing is yet optimized: we still have the impeller, speed, tube and bead composition to improve upon. We will also be investigating the use of alternative, cheaper materials instead of copper as the active agent (such as local metal ores), as well as alginate extracted from locally sourced seaweed. Once we’ve determined the optimum speed of rotation, we can develop hand and leg powered systems (depending on the volumes involved) with the appropriate gear boxes (such as a modified bicycle or a hand cranked drill) for efficient turning.

Main field of application/target audience: We are looking to help anyone with contaminated water, at any scale, but our greatest impact will mostly likely be working within a DEWATS system setting.

Start and end date: November 2011 to April 31st, 2013

Grant type: Grand Challenges Explorations, Round 7 (GCE R7)

Funding for this research currently ongoing: BMGF Phase 1 and Phase 1 Extension. This technology is also being developed for biofuel production, through funding from the UK’s Technology Strategy Board.

Research or implementation partners: The technology is being developed with partners Protein Technology Ltd, as well as with chemical engineering support from the Bouygues Group and fluidic engineering support from University College London.

Current state of affairs:

TRL5, looking for Phase 2 funding to get it to TRL9.

WE NEED PARTNERS TO FIELD AND LABORATORY TEST THE VORTEX BIOREACTOR IN REAL WORLD SITUATIONS/ENVIRONMENTS. It’s easy to use, low energy, and the reactors we have built are modular in design to allow easy future development following feedback. Ideally we would like to test the prototype in the following environments: small scale waste water treatment plants, individual toilet systems, and contaminated ground water settings such as drinking wells. Once we know how big your pipe/reservoir is and the flow rate, we can adapt our units to your requirements. Any modified components can be sent out in the post and retrofitted easily, and standard operating procedures updated via email.

So far, if we get Phase 2 funding, we’ll be providing vortex bioreactors to:

- Karl Linden, University of Colorado Boulder for UV comparison.

- Steve Sugden of Water for People will deploy the vortex bioreactor in Malawi and Uganda.

- Bincy Baby of Eram Scientific Solutions will utilize the vortex bioreactor in the field in Kerala, India.

- Chris Buckley and the team at University of KwaZulu-Natal will help develop the helminth binding add-on module to the vortex bioreactor.

IF YOU CAN THINK OF AN APPLICATION, OR THIS CAN BE BOLTED ON TO YOUR EXISTING SYSTEM, OR YOU CAN OFFER ANY ASSISTANCE IN ITS DEVELOPMENT, PLEASE JOIN OUR TEAM!

Biggest successes so far:

The vortex bioreactor is great for microbial destruction. We’ve had a lot of interest in the technology, which is viewed by many as a true ENABLING TECHNOLOGY.

We have also received a Phase 1 extension to deal with helminth eggs.

Main challenges / frustration:

Dealing with the helminth issue, as they are quite indestructible chemically and are difficult to destroy at scale in an economical and efficient manner. We have decided not to destroy, but to SEPARATE the eggs out using either floating or sinking bead-binding materials and exploiting the separation properties of the vortex bioreactor. Results are looking promising, however the separation properties of the vortex bioreactor is antagonistic to the mixing properties (currently being applied very successfully to microbial destruction), therefore we need to tweak the system to address this. It is possible we’ll need a dual propeller system. On the plus side, the removal of helminth eggs following microbial destruction can be combined with the removal of any leached copper from the first microbial destruction step, making the discharged water even ‘cleaner’.

Links, further readings, etc:

- Project and result description on Partners in Development (PID) homepage: www.pid.co.za/index.php/abstracts2/77-vo...tment-systems-dewats

- Video clip of presentation at FSM2 in Durban (October 2012):

Dr Mike Allen

Plymouth Marine Laboratory

Website: www.pml.ac.uk

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Twitter: twitter.com/mike_j_allen

www.pml.ac.uk/about_us/the_pml_team/staf...tory/mike_allen.aspx

Attachments:

-

REACTOR1.jpg

(Filesize: 26KB)

REACTOR1.jpg

(Filesize: 26KB)

-

REACTOR2.jpg

(Filesize: 29KB)

REACTOR2.jpg

(Filesize: 29KB)

-

REACTOR3.jpg

(Filesize: 22KB)

REACTOR3.jpg

(Filesize: 22KB)

-

RESULTS1.jpg

(Filesize: 27KB)

RESULTS1.jpg

(Filesize: 27KB)

-

results2.jpg

(Filesize: 24KB)

results2.jpg

(Filesize: 24KB)

-

WIDERPLACE.jpg

(Filesize: 26KB)

WIDERPLACE.jpg

(Filesize: 26KB)

The following user(s) like this post: christoph

Please Log in to join the conversation.

You need to login to reply

Share this thread:

- Sanitation systems

- Various topics related to sanitation systems

- Vortex bioreactors for the processing of contaminated wastewater (Plymouth Marine Laboratory, UK)

Recently active users. Who else has been active?

Time to create page: 0.305 seconds