- Forum

- categories

- Sanitation systems

- Faecal sludge management (FSM)

- Faecal sludge treatment technologies

- Transfer tanks in dense slum area (for pit latrine waste) - and mobile dewatering units

Transfer tanks in dense slum area (for pit latrine waste) - and mobile dewatering units

34.5k views

- Elisabeth

-

- User is blocked

- Freelance consultant since 2012

Less- Posts: 3372

- Karma: 54

- Likes received: 932

Re: Transfer tanks in dense slum area (for pit latrine waste) - and mobile dewatering units

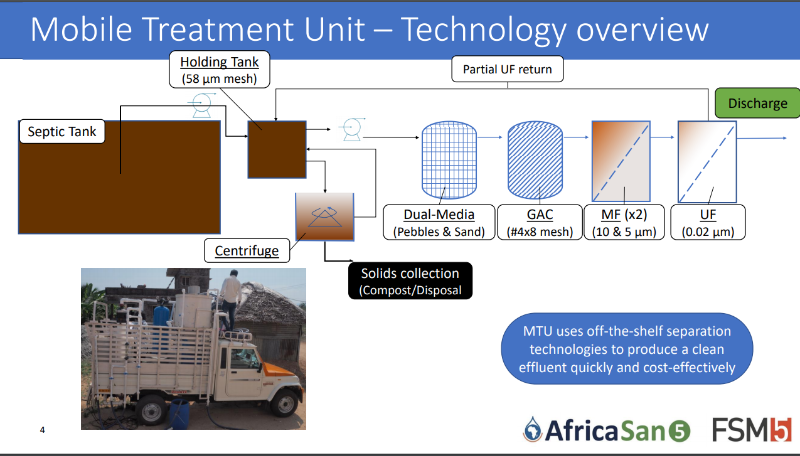

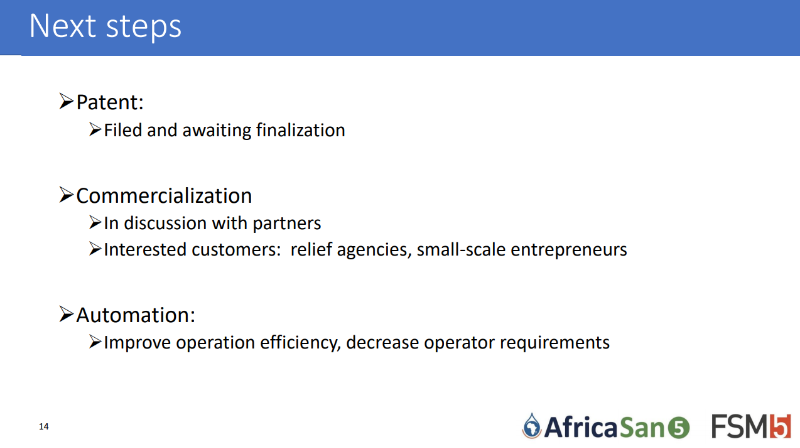

We have talked about mobile dewatering units in this thread. Check out this project: it is not just about dewatering but they are trying to treat the dewatering liquid to a level that is suitable for discharge into the environment on-site:

“Mobile Treatment Unit for Septage Emptying and Safe Disposal in Dindigul, India”, (India)

fsm5.susana.org/images/FSM_Conference_Ma...mptying-and-safe.pdf

Presented at FSM5: fsm5.susana.org/en/downloads/conference-materials

Authors: Aaron Forbis-Stokes 1,2 Arumugam Kalimuthu 3, L. Peter 3, Marc Deshusses 1

1 Duke University, Dept. of Civil & Environmental Engineering, Durham, NC, USA

2 Triangle Environmental, Durham, NC, USA

3 WASH Institute, Kodaikanal, India

The project was funded by - you guessed it - the Bill and Melinda Gates Foundation. We have it in our project database here:

www.susana.org/en/knowledge-hub/projects/database/details/491

The presentation doesn't mention anything about costs. I assume such a treatment unit is not cheap (and there would be no economies of scale compared to a large treatment plant)... But it would save fuel for transport of all that water, that's for sure. It's an interesting concept.

Regards,

Elisabeth

“Mobile Treatment Unit for Septage Emptying and Safe Disposal in Dindigul, India”, (India)

fsm5.susana.org/images/FSM_Conference_Ma...mptying-and-safe.pdf

Presented at FSM5: fsm5.susana.org/en/downloads/conference-materials

Authors: Aaron Forbis-Stokes 1,2 Arumugam Kalimuthu 3, L. Peter 3, Marc Deshusses 1

1 Duke University, Dept. of Civil & Environmental Engineering, Durham, NC, USA

2 Triangle Environmental, Durham, NC, USA

3 WASH Institute, Kodaikanal, India

The project was funded by - you guessed it - the Bill and Melinda Gates Foundation. We have it in our project database here:

www.susana.org/en/knowledge-hub/projects/database/details/491

The presentation doesn't mention anything about costs. I assume such a treatment unit is not cheap (and there would be no economies of scale compared to a large treatment plant)... But it would save fuel for transport of all that water, that's for sure. It's an interesting concept.

Regards,

Elisabeth

Dr. Elisabeth von Muench

Freelance consultant on environmental and climate projects

Freelance consultant on environmental and climate projects

The following user(s) like this post: Mawejje92

Please Log in to join the conversation.

You need to login to reply- Yvonne

-

- A FSM enthusiast fortunate to work in areas of sanitation with Water For people

Less- Posts: 4

- Likes received: 2

Re: Transfer tanks in dense slum area (for pit latrine waste) - and mobile dewatering units

Hello Andrew

My apologies or the late reply.

1. The gulpers have competition amongst themselves. There are now more gulping businesses operating in this space than before.

2. This is not accurate. The gulper entrepreneurs are actually able to empty more pit latrines with the transfer station. They can also work into the night since it has been fitted with floodlights until its capacity is filled.

3. While they might have more market demand with more time, it also depends on their ability to market themselves in the communities.

My apologies or the late reply.

1. The gulpers have competition amongst themselves. There are now more gulping businesses operating in this space than before.

2. This is not accurate. The gulper entrepreneurs are actually able to empty more pit latrines with the transfer station. They can also work into the night since it has been fitted with floodlights until its capacity is filled.

3. While they might have more market demand with more time, it also depends on their ability to market themselves in the communities.

The following user(s) like this post: Mawejje92

Please Log in to join the conversation.

You need to login to reply- Mawejje92

-

- civil engineer #Researcher

Less- Posts: 1

- Likes received: 0

Re: Transfer tanks in dense slum area (for pit latrine waste) - and mobile dewatering units

Hello Nicola,

We are keen for any updates (successes and failures) in your transfer tanks project especially regarding the business models and impact to the pit emptying so far. Are you dewatering at the transfer stations.

Thanks

Martin

We are keen for any updates (successes and failures) in your transfer tanks project especially regarding the business models and impact to the pit emptying so far. Are you dewatering at the transfer stations.

Thanks

Martin

Martin Nyanzi Mawejje

Please Log in to join the conversation.

You need to login to replyRe: Transfer tanks in dense slum area (for pit latrine waste) - and mobile dewatering units

Hi Yvonne,

Thanks for the response. Is it accurate to say the gulper operators 1) have no competition in the area, 2) that they are unable to empty more pits per day, even with the transfer station reducing their transportation time, and 3) If they have more time, would they have market demand to meet?

Thanks,

Andrew

Thanks for the response. Is it accurate to say the gulper operators 1) have no competition in the area, 2) that they are unable to empty more pits per day, even with the transfer station reducing their transportation time, and 3) If they have more time, would they have market demand to meet?

Thanks,

Andrew

Andrew Whitesell

President/Founder of Beaumont

President/Founder of Beaumont

Please Log in to join the conversation.

You need to login to reply- Yvonne

-

- A FSM enthusiast fortunate to work in areas of sanitation with Water For people

Less- Posts: 4

- Likes received: 2

Re: Transfer tanks in dense slum area (for pit latrine waste) - and mobile dewatering units

Hello Andrew

The unwillingness to reduce the cost of emptying was primarily out of the stubbornness of the gulpers so that they could make more profit.

With the transfer tank, the costs of transportation of sludge is greatly reduced since there are fewer trips to the treatment plant and therefore less costs on fuel.

Yes the transfer tank does reduce on the time spent transporting and disposing of collected waste since fewer trips are made and more waste is collected in one go and this can potentially increase the number of pits emptied per day.

The unwillingness to reduce the cost of emptying was primarily out of the stubbornness of the gulpers so that they could make more profit.

With the transfer tank, the costs of transportation of sludge is greatly reduced since there are fewer trips to the treatment plant and therefore less costs on fuel.

Yes the transfer tank does reduce on the time spent transporting and disposing of collected waste since fewer trips are made and more waste is collected in one go and this can potentially increase the number of pits emptied per day.

The following user(s) like this post: Mawejje92

Please Log in to join the conversation.

You need to login to reply- edna

-

Less

Less- Posts: 12

- Karma: 1

- Likes received: 2

Good to hear this, i know this model has been tried in Nakuru's low income areas by the utility's collaborating with trained manual emptiers. However it seems not to work after the trial. Maybe will be good to learn from their experience.

Young water professional with developed interest on strategic sanitation planning and service provision and innovation systems in developing countries.

Please Log in to join the conversation.

You need to login to replyRe: Transfer tanks in dense slum area (for pit latrine waste) - and mobile dewatering units

Hi Elizabeth,

Thanks for posting this. I'm very interested in hearing more details about the transfer station project. All the reports I've read in the past, and my own economic study, indicate that they aren't financially viable but I reckon if you have the variables figured out it can work.

The bullet point in the slide deck that really caught my eye is this one:

Unwillingness by gulpers to lower the pit emptying charges

If I understand the presentation correctly, the emptiers cut their costs by 1/3 but they are unwilling to lower their fees. Is that correct? Do they have competition in the area?

Does the use of the transfer station reduce the time they spend transporting and disposing of the collected waste? If so, can they increase the number of pits they empty per day?

Cheers,

Andrew

Thanks for posting this. I'm very interested in hearing more details about the transfer station project. All the reports I've read in the past, and my own economic study, indicate that they aren't financially viable but I reckon if you have the variables figured out it can work.

The bullet point in the slide deck that really caught my eye is this one:

Unwillingness by gulpers to lower the pit emptying charges

If I understand the presentation correctly, the emptiers cut their costs by 1/3 but they are unwilling to lower their fees. Is that correct? Do they have competition in the area?

Does the use of the transfer station reduce the time they spend transporting and disposing of the collected waste? If so, can they increase the number of pits they empty per day?

Cheers,

Andrew

Andrew Whitesell

President/Founder of Beaumont

President/Founder of Beaumont

Please Log in to join the conversation.

You need to login to reply- Elisabeth

-

- User is blocked

- Freelance consultant since 2012

Less- Posts: 3372

- Karma: 54

- Likes received: 932

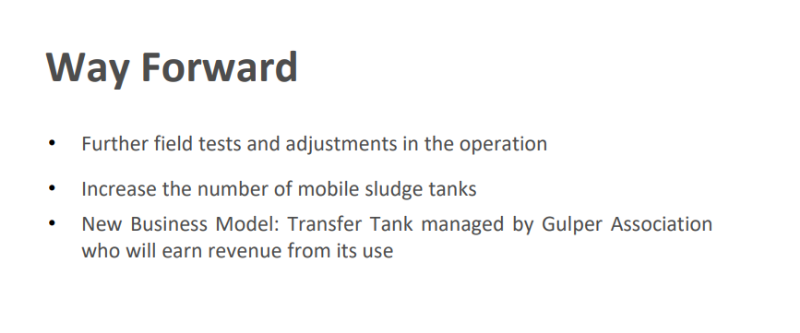

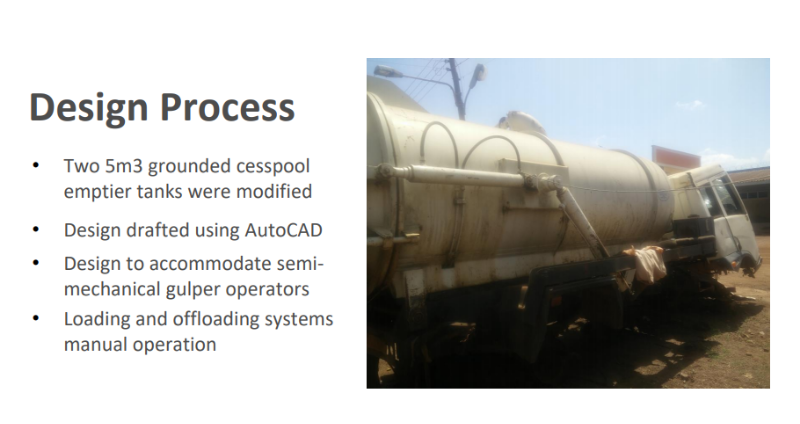

Re: Transfer tanks in dense slum area (for pit latrine waste) - and mobile dewatering units

For those of you following this thread I wonder what you think of this one:

Mobile Faecal Sludge Stations in Urban FSM: A case of two pilots in Kampala City

by Yvonne Lugali, Brenda Achiro, Cate. Z. Nimanya

Water For People

fsm5.susana.org/images/FSM_Conference_Ma...ntation_05.02.19.pdf

Presented at FSM5 Conference in Feb 2019.

Three slides from their presentation:

Regards,

Elisabeth

Mobile Faecal Sludge Stations in Urban FSM: A case of two pilots in Kampala City

by Yvonne Lugali, Brenda Achiro, Cate. Z. Nimanya

Water For People

fsm5.susana.org/images/FSM_Conference_Ma...ntation_05.02.19.pdf

Presented at FSM5 Conference in Feb 2019.

Three slides from their presentation:

Regards,

Elisabeth

Dr. Elisabeth von Muench

Freelance consultant on environmental and climate projects

Freelance consultant on environmental and climate projects

Attachments:

-

waterforpeople3.png

(Filesize: 75KB)

waterforpeople3.png

(Filesize: 75KB)

-

waterforpeople1.png

(Filesize: 99KB)

waterforpeople1.png

(Filesize: 99KB)

-

waterforpeople2.png

(Filesize: 246KB)

waterforpeople2.png

(Filesize: 246KB)

The following user(s) like this post: Mawejje92

Please Log in to join the conversation.

You need to login to reply- tgurksi

-

Less

Less- Posts: 14

- Karma: 2

- Likes received: 6

Hi Nicola,

Thought I'd respond to your questions here in advance of our conversation so that the greater community can chime in (likely to correct me!).

In my experience, you start getting floc formation well below the ideal dose of flocculant...maybe at something like 25% of that dose. As you add more and approach the ideal dose, the fraction of the solids that are captured in flocs compared to the fraction that remains suspended increases. This results in a larger number of larger flocs, and a clearer liquid fraction. When performing well, you get corn to grape-sized flocs and very slightly cloudy liquid. When you add too much, the biggest problem is wasting flocculant, but if you significantly overdose the flocs seem to weaken and either break apart or not form as well. The liquid at this point feels "syrupy" to the touch. Complete ballpark swag here, but I'd say you get fairly effective flocculation between something like 2/3 and 4/3 of the ideal dose.

Regarding what you use downstream, you would need to use something very different to separate flocc'd and unflocc'd sludge. Your mesh size for flocc'd will be on the order of 1mm. Unflocc'd would strain right through that with essentially no separation. The mesh size to get decent permeate quality from unflocc'd sludge is on the order of 1 micron or smaller. Not only does this require a significantly larger product of area and pressure, but you also need a mechanism to prevent blinding. Sludge is a colloidal suspension, so there are tiny charged particles that deposit on the filter media and repulse other particles, clogging it almost instantly. Flocculant both counteracts the charge on the particles, eliminating this tendency and their mutual repulsion, and provides a scaffolding for them to agglomerate around, forming larger particles that are more easily separated.

You can run raw septage through the screw press, but it won't separate if it was designed for traditional dewatering. You won't damage it, but what you get out of both streams will be essentially identical to what you put in. Pumping 5% sludge shouldn't be a problem for anything other than a clear water pump. You risk clogging with hair and other debris, but you are unlikely to damage anything.

Once flocc'd, it's more typical to run through a thickener before a screw press, but you might be able to go straight to the press, especially if your starting solids are quite high. Other mechanical presses may be less likely to require thickening.

To your last question, a polymer flocculant does both...it prevents clogging by counteracting the charge on the particles, and it causes the formation of larger particles which are easier to separate.

Cheers!

Tom

Thought I'd respond to your questions here in advance of our conversation so that the greater community can chime in (likely to correct me!).

In my experience, you start getting floc formation well below the ideal dose of flocculant...maybe at something like 25% of that dose. As you add more and approach the ideal dose, the fraction of the solids that are captured in flocs compared to the fraction that remains suspended increases. This results in a larger number of larger flocs, and a clearer liquid fraction. When performing well, you get corn to grape-sized flocs and very slightly cloudy liquid. When you add too much, the biggest problem is wasting flocculant, but if you significantly overdose the flocs seem to weaken and either break apart or not form as well. The liquid at this point feels "syrupy" to the touch. Complete ballpark swag here, but I'd say you get fairly effective flocculation between something like 2/3 and 4/3 of the ideal dose.

Regarding what you use downstream, you would need to use something very different to separate flocc'd and unflocc'd sludge. Your mesh size for flocc'd will be on the order of 1mm. Unflocc'd would strain right through that with essentially no separation. The mesh size to get decent permeate quality from unflocc'd sludge is on the order of 1 micron or smaller. Not only does this require a significantly larger product of area and pressure, but you also need a mechanism to prevent blinding. Sludge is a colloidal suspension, so there are tiny charged particles that deposit on the filter media and repulse other particles, clogging it almost instantly. Flocculant both counteracts the charge on the particles, eliminating this tendency and their mutual repulsion, and provides a scaffolding for them to agglomerate around, forming larger particles that are more easily separated.

You can run raw septage through the screw press, but it won't separate if it was designed for traditional dewatering. You won't damage it, but what you get out of both streams will be essentially identical to what you put in. Pumping 5% sludge shouldn't be a problem for anything other than a clear water pump. You risk clogging with hair and other debris, but you are unlikely to damage anything.

Once flocc'd, it's more typical to run through a thickener before a screw press, but you might be able to go straight to the press, especially if your starting solids are quite high. Other mechanical presses may be less likely to require thickening.

To your last question, a polymer flocculant does both...it prevents clogging by counteracting the charge on the particles, and it causes the formation of larger particles which are easier to separate.

Cheers!

Tom

The following user(s) like this post: Elisabeth

Please Log in to join the conversation.

You need to login to reply- nicolag

-

Topic Author

Topic Author- Sanitation Engineer - Consultant

Less- Posts: 46

- Karma: 4

- Likes received: 13

Thanks for the follow up Tom

A fairly basic investigation seems to suggest that we are pretty light on external contaminants so no hassle there; even if they were they'd get diluted with the other sources of sludge that get mixed at the treatment site.

I guess my concerns are not so much the quality of the output, it is finding the most cost effective way to separate a reasonable amount of solids - it does not need to approach perfection.

My concerns are:

(a) getting the floc to work at all given that some sludge is old, some is new, some are lined pits, some unlined etc.

(b) getting the dosage right for optimum floculation given this varying input - mostly from a financial view

I wonder if any of you have some insights on the following.....::

1. Mechanisms of floc: Maybe I don't really understand how floc works....is the relationship between amount added and degree of separation linear...or do you just keep adding until you reach a kind of 'tipping point' where floculation occurs? Do you meet a certain maximum where the floc stops having effectiveness and then you just start wasting money - or does over floculation have a different impact e.g. slippy sludge? The Uganda report above seems to suggest a linear relationship.

I ask because I imagine we will first need to do experiments to see how the sludge and the floc reacts, and how consistent that reaction is given how variable the sludge is. Then try to draw up our own curve of cost of more floc vs effectiveness of separation...but perhaps someone here has better insight to what you win/lose by adding more/less.

Simultaneous to this we'll need to downstream experiments around how well the sludge settles with and without floc; but also how a screw press( that we already own from a different projects) or basic dewatering membrane, reacts to the sludge (with and without floc)

2. Failure mode of the screw press - we have a screw press, we have sludge, we are tempted to just run it through but the sludge can be ~5% and tricky to pump. Do you have any idea if there is a risk of us damaging the screw press with the sludge as is (given that is out of its design limits), and if so, what the failure mode right be? or is the risk merely up front with clogging the pump? Would it be a matter of slowing down the intake pump? I don't know if screw presses are designed around L/s input; or kg/s of solids within the liquid.

3. Mechanical methods with floc - with floc+ screw press are we adding floc allowing to FS to separate, and running the remaining liquid portion through the screw press, or keeping it mixed right up to the point of entry and the floc aids separation within the screw press (same question to mechanical presses etc).

4. How non-floc sludge reacts with membranes - mechanised or other - is the floc more to aid separation; or does it help the sludge kind of cling together so that it doesn't just coat the membranes and stick in the pores really fast? I saw some WSUP research in Bangladesh that seemed to suggest the floc was worth it from a clogging perspective as much as from a separation perspective. I ask this because I would like to try to avoid floc given the high solids content of the sludge and the risky supply chains here; BUT it may be that I need it for anything membrane based purely for the clogging issue (geobags, dewatering box, presses etc)

Nicola

A fairly basic investigation seems to suggest that we are pretty light on external contaminants so no hassle there; even if they were they'd get diluted with the other sources of sludge that get mixed at the treatment site.

I guess my concerns are not so much the quality of the output, it is finding the most cost effective way to separate a reasonable amount of solids - it does not need to approach perfection.

My concerns are:

(a) getting the floc to work at all given that some sludge is old, some is new, some are lined pits, some unlined etc.

(b) getting the dosage right for optimum floculation given this varying input - mostly from a financial view

I wonder if any of you have some insights on the following.....::

1. Mechanisms of floc: Maybe I don't really understand how floc works....is the relationship between amount added and degree of separation linear...or do you just keep adding until you reach a kind of 'tipping point' where floculation occurs? Do you meet a certain maximum where the floc stops having effectiveness and then you just start wasting money - or does over floculation have a different impact e.g. slippy sludge? The Uganda report above seems to suggest a linear relationship.

I ask because I imagine we will first need to do experiments to see how the sludge and the floc reacts, and how consistent that reaction is given how variable the sludge is. Then try to draw up our own curve of cost of more floc vs effectiveness of separation...but perhaps someone here has better insight to what you win/lose by adding more/less.

Simultaneous to this we'll need to downstream experiments around how well the sludge settles with and without floc; but also how a screw press( that we already own from a different projects) or basic dewatering membrane, reacts to the sludge (with and without floc)

2. Failure mode of the screw press - we have a screw press, we have sludge, we are tempted to just run it through but the sludge can be ~5% and tricky to pump. Do you have any idea if there is a risk of us damaging the screw press with the sludge as is (given that is out of its design limits), and if so, what the failure mode right be? or is the risk merely up front with clogging the pump? Would it be a matter of slowing down the intake pump? I don't know if screw presses are designed around L/s input; or kg/s of solids within the liquid.

3. Mechanical methods with floc - with floc+ screw press are we adding floc allowing to FS to separate, and running the remaining liquid portion through the screw press, or keeping it mixed right up to the point of entry and the floc aids separation within the screw press (same question to mechanical presses etc).

4. How non-floc sludge reacts with membranes - mechanised or other - is the floc more to aid separation; or does it help the sludge kind of cling together so that it doesn't just coat the membranes and stick in the pores really fast? I saw some WSUP research in Bangladesh that seemed to suggest the floc was worth it from a clogging perspective as much as from a separation perspective. I ask this because I would like to try to avoid floc given the high solids content of the sludge and the risky supply chains here; BUT it may be that I need it for anything membrane based purely for the clogging issue (geobags, dewatering box, presses etc)

Nicola

Please Log in to join the conversation.

You need to login to reply- tgurksi

-

Less

Less- Posts: 14

- Karma: 2

- Likes received: 6

Hi Nicola,

Andrew brings up a good point that I forgot to mention when we talked...chemistry variations and their effect on flocculation. To the best of my knowledge, this has never been explored (doing so was one of the main recommendations that came out of my OI project), so at best we can say that it is a potential problem. My experience is with a constantly changing supply of US septage, and all 3 flocculants we used (including organically derived chitosan) worked every time. My suspicion is that as long as you're talking about relatively uncontaminated fecal sludge, it won't be an issue for a fixed location (region to region or country to country may require changes). The bigger concern, in my opinion, would be the effect of a contaminant, such as diesel or industrial chemicals. It's not KNOWN if they pose a significant risk to floc chemisty, but they might. I would suggest that having a relatively small "batch" size and a contingency plan in case of periodic contamination would be sufficient mitigations.

Cheers,

Tom

Andrew brings up a good point that I forgot to mention when we talked...chemistry variations and their effect on flocculation. To the best of my knowledge, this has never been explored (doing so was one of the main recommendations that came out of my OI project), so at best we can say that it is a potential problem. My experience is with a constantly changing supply of US septage, and all 3 flocculants we used (including organically derived chitosan) worked every time. My suspicion is that as long as you're talking about relatively uncontaminated fecal sludge, it won't be an issue for a fixed location (region to region or country to country may require changes). The bigger concern, in my opinion, would be the effect of a contaminant, such as diesel or industrial chemicals. It's not KNOWN if they pose a significant risk to floc chemisty, but they might. I would suggest that having a relatively small "batch" size and a contingency plan in case of periodic contamination would be sufficient mitigations.

Cheers,

Tom

Please Log in to join the conversation.

You need to login to reply

Please find attached a recent study on dewatering fecal sludge in Uganda using geotextiles (and Chitosan). Might be a good start and should be quite robust to varying inputs.

This message has an attachment file.

Please log in or register to see it.

The following user(s) like this post: cecile

Please Log in to join the conversation.

You need to login to reply

Share this thread:

- Forum

- categories

- Sanitation systems

- Faecal sludge management (FSM)

- Faecal sludge treatment technologies

- Transfer tanks in dense slum area (for pit latrine waste) - and mobile dewatering units

Recently active users. Who else has been active?

Time to create page: 0.272 seconds