- Sanitation systems

- Treatment of wastewater, sludges, organic waste, excreta

- Various other technologies and comparisons of treatment technologies

- Designing and building grey water filter for reuse in flush toilets at the tourist hostel in the Carpathian mountains (Ukraine)

Designing and building grey water filter for reuse in flush toilets at the tourist hostel in the Carpathian mountains (Ukraine)

15.5k views

Re: Designing and building grey water filter for reuse in flush toilets at the tourist hostel in the Carpathian mountains (Ukraine)

This is very interesting goeco. I have one question, can the worms live directly in the zeolite? don't you need something like sawdust or humus? Maybe I didn't get it just right. Thanks for any clarification you can provide.

Gustavo Heredia

Director

AGUATUYA Bolivia

www.aguatuya.org

Director

AGUATUYA Bolivia

www.aguatuya.org

The following user(s) like this post: goeco

Please Log in to join the conversation.

You need to login to reply- AjitSeshadri

-

- Marine Chief Engineer by profession (1971- present) and at present Faculty in Marine Engg. Deptt. Vels University, Chennai, India. Also proficient in giving Environmental solutions , Designation- Prof. Ajit Seshadri, Head- Environment, The Vigyan Vijay Foundation, NGO, New Delhi, INDIA , Consultant located at present at Chennai, India

Re: Designing and building grey water filter for reuse in flush toilets at the tourist hostel in the Carpathian mountains (Ukraine)

Dear Goeco.

Grey water is once used water from certain cleaning up operation.

In kitchen , bath . laundry wash waters optimise the use of detergents and soaps - awareness in communities.

If you have control in the community and can ensure use of bio-soaps and hot water with degreaser.

Then the effluent in the last stage can have phyto remediation ie use of appropriate plants foliage etc..

This wwtp plant can be effective.

Well wishes

Prof Ajit Seshadri

Vels Unversity. Chennai .

Grey water is once used water from certain cleaning up operation.

In kitchen , bath . laundry wash waters optimise the use of detergents and soaps - awareness in communities.

If you have control in the community and can ensure use of bio-soaps and hot water with degreaser.

Then the effluent in the last stage can have phyto remediation ie use of appropriate plants foliage etc..

This wwtp plant can be effective.

Well wishes

Prof Ajit Seshadri

Vels Unversity. Chennai .

Prof. Ajit Seshadri, Faculty in Marine Engg. Deptt. Vels University, and

Head-Environment , VigyanVijay Foundation, Consultant (Water shed Mngmnt, WWT, WASH, others)Located at present at Chennai, India

Head-Environment , VigyanVijay Foundation, Consultant (Water shed Mngmnt, WWT, WASH, others)Located at present at Chennai, India

Please Log in to join the conversation.

You need to login to replyRe: Designing and building grey water filter for reuse in flush toilets at the tourist hostel in the Carpathian mountains (Ukraine)

Hi Bogdan, I'm assuming this greywater system is only for washwater rather than kitchen wastewater. A kitchen wastewater vermifilter needs a much larger surface area.

The only way to stop the stink is to ensure dissolved oxygen (DO) levels remain high. There will be demand on that very limited oxygen in the greywater by organisms in the process of breaking down the organics. Your system does not add oxygen to the water so the water in the receiving tank will be very low in DO or even devoid of it. Indeed the system might even operate anaerobically, depending on the levels of organics present and the flow.

Next, the capacity of your receiving tank (and received water volume) will be greater than what you use for flushing. Therefore you will need an overflow to soakage. Importantly, the longer this "stored" water remains therein the tank depleted of oxygen, the more it will stink as the anaerobic organisms work on the remaining dissolved organics.

Vermifiltration, on the other hand, oxygenates the water at the same time as the aerobic organisms are working on the organics. The oxygen demand is reduced at the same time as oxygen is being dissolved into the water, in one simple process. Most people don't understand this which is why outdated technologies continue to be used and promoted.

With vermifiltration your receiving water tank will hold oxygenated water with a greatly reduced oxygen demand. Provided you don't hold it for too long, the water will not stink. That is, there will still be a residual oxygen demand and dissolved organics, so DO will reduce over time. What I would suggest is to limit the capacity of your receiving water tank so that the flush-water doesn't sit there too long and is being replenished with "fresh" well oxygenated water from your vermifilter.

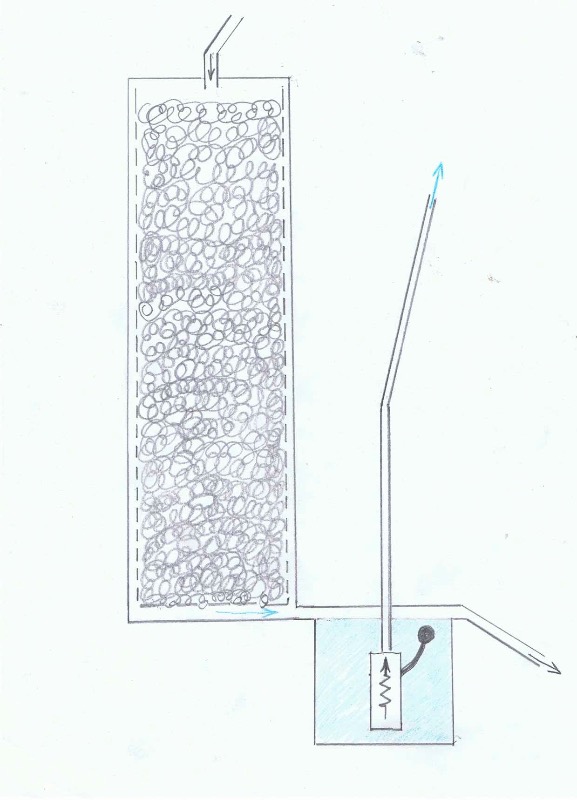

This design has a fairly small diameter (maybe 1m) but as much depth as you can provide. Note the air cavity between the wall of the vessel and the media, and there also needs to be good ventilation so this air can be constantly replenished. Zeolite will be fine as the medium, but of more importance than the composition is the size. Powdered zeolite will not have sufficient flow for 1 cubic metre per hour unless the vermifilter vessel is much much wider. Coarse granules would have too much flow and therefore not reduce the oxygen demand sufficiently with one pass. Sieved to be small-granular will be fine and layering with different sizes is not necessary when packing the vermifilter. Test the zeolite granules first in a bucket with flows equivalent to the actual system and (unlike in my diagram) allow capacity at the top of the vermifilter so the maximum dose volume doesn't overflow.

The only way to stop the stink is to ensure dissolved oxygen (DO) levels remain high. There will be demand on that very limited oxygen in the greywater by organisms in the process of breaking down the organics. Your system does not add oxygen to the water so the water in the receiving tank will be very low in DO or even devoid of it. Indeed the system might even operate anaerobically, depending on the levels of organics present and the flow.

Next, the capacity of your receiving tank (and received water volume) will be greater than what you use for flushing. Therefore you will need an overflow to soakage. Importantly, the longer this "stored" water remains therein the tank depleted of oxygen, the more it will stink as the anaerobic organisms work on the remaining dissolved organics.

Vermifiltration, on the other hand, oxygenates the water at the same time as the aerobic organisms are working on the organics. The oxygen demand is reduced at the same time as oxygen is being dissolved into the water, in one simple process. Most people don't understand this which is why outdated technologies continue to be used and promoted.

With vermifiltration your receiving water tank will hold oxygenated water with a greatly reduced oxygen demand. Provided you don't hold it for too long, the water will not stink. That is, there will still be a residual oxygen demand and dissolved organics, so DO will reduce over time. What I would suggest is to limit the capacity of your receiving water tank so that the flush-water doesn't sit there too long and is being replenished with "fresh" well oxygenated water from your vermifilter.

This design has a fairly small diameter (maybe 1m) but as much depth as you can provide. Note the air cavity between the wall of the vessel and the media, and there also needs to be good ventilation so this air can be constantly replenished. Zeolite will be fine as the medium, but of more importance than the composition is the size. Powdered zeolite will not have sufficient flow for 1 cubic metre per hour unless the vermifilter vessel is much much wider. Coarse granules would have too much flow and therefore not reduce the oxygen demand sufficiently with one pass. Sieved to be small-granular will be fine and layering with different sizes is not necessary when packing the vermifilter. Test the zeolite granules first in a bucket with flows equivalent to the actual system and (unlike in my diagram) allow capacity at the top of the vermifilter so the maximum dose volume doesn't overflow.

Dean Satchell, M For. Sc.

Vermifilter.com

www.vermifilter.com

Vermifilter.com

www.vermifilter.com

Attachments:

-

CCI20112018.jpg

(Filesize: 73KB)

CCI20112018.jpg

(Filesize: 73KB)

The following user(s) like this post: gustavo, BPopov, AjitSeshadri

Please Log in to join the conversation.

You need to login to reply- BPopov

-

Topic Author

- Ecologist involved with ecosanitation in Ukrainian Carpathians

Less- Posts: 147

- Karma: 7

- Likes received: 50

Re: Designing and building grey water filter for reuse in flush toilets at the tourist hostel in the Carpathian mountains (Ukraine)

Hi Elisabeth!

Thanks for the responce!

I suggest upflow design mainly because it seems to allow effective non-pressurized backwashing as opposed to down flow one.

This kind of roughing filter had been suggested in many resources like for instance here www.aqsolutions.org/images/2016/12/2000LPD_English.pdf

Actually now I am not too sure if zeolite is the best material for the media.. Maybe regular gravel all is needed. The single goal is to have flush water for the toilet. It should not clog the toilet cistern flush valves , have more or less nice appearance (some turbidity is probably ok) and most important do not stink too strong while rests for some time in the toilet cistern or in the receiving tank after the roughing filter below. The nitrogen content is not an issue at all I guess. Maybe actually UV would deal with the odor but this involves electricity which quite limited in that mountain hostel. What about batch chlorination?

I think a servicesable mesh filter before the equalizing/pressure tank would be good to get read of hairs and fibres

Best wishes,

Bogdan

Thanks for the responce!

I suggest upflow design mainly because it seems to allow effective non-pressurized backwashing as opposed to down flow one.

This kind of roughing filter had been suggested in many resources like for instance here www.aqsolutions.org/images/2016/12/2000LPD_English.pdf

Actually now I am not too sure if zeolite is the best material for the media.. Maybe regular gravel all is needed. The single goal is to have flush water for the toilet. It should not clog the toilet cistern flush valves , have more or less nice appearance (some turbidity is probably ok) and most important do not stink too strong while rests for some time in the toilet cistern or in the receiving tank after the roughing filter below. The nitrogen content is not an issue at all I guess. Maybe actually UV would deal with the odor but this involves electricity which quite limited in that mountain hostel. What about batch chlorination?

I think a servicesable mesh filter before the equalizing/pressure tank would be good to get read of hairs and fibres

Best wishes,

Bogdan

Bogdan Popov

The Ecosolutions Forge

www.ecoforge.org

The Ecosolutions Forge

www.ecoforge.org

Please Log in to join the conversation.

You need to login to reply- Elisabeth

-

- Moderator

- Freelance consultant since 2012 (former roles: program manager at GIZ and SuSanA secretariat, lecturer, process engineer for wastewater treatment plants)

Less- Posts: 3372

- Karma: 54

- Likes received: 931

Re: Designing and building grey water filter for reuse in flush toilets at the tourist hostel in the Carpathian mountains (Ukraine)

Hi Bogdan,

Thanks for sharing this! I am just wondering why you chose an upflow configuration rather than downflow? Is that to save on space?

Also that's interesting that you have zeolite available. It might help you also with ammonia removal, have you considered that?

Would your filter require any periodic backwashing to prevent clogging? Would you add some sieves before the filter or at the outlet of the shower maybe?

Regards,

Elisabeth

Thanks for sharing this! I am just wondering why you chose an upflow configuration rather than downflow? Is that to save on space?

Also that's interesting that you have zeolite available. It might help you also with ammonia removal, have you considered that?

Would your filter require any periodic backwashing to prevent clogging? Would you add some sieves before the filter or at the outlet of the shower maybe?

Regards,

Elisabeth

Dr. Elisabeth von Muench

Freelance consultant on environmental and climate projects

Freelance consultant on environmental and climate projects

Please Log in to join the conversation.

You need to login to reply- BPopov

-

Topic Author

- Ecologist involved with ecosanitation in Ukrainian Carpathians

Less- Posts: 147

- Karma: 7

- Likes received: 50

Designing and building grey water filter for reuse in flush toilets at the tourist hostel in the Carpathian mountains (Ukraine)

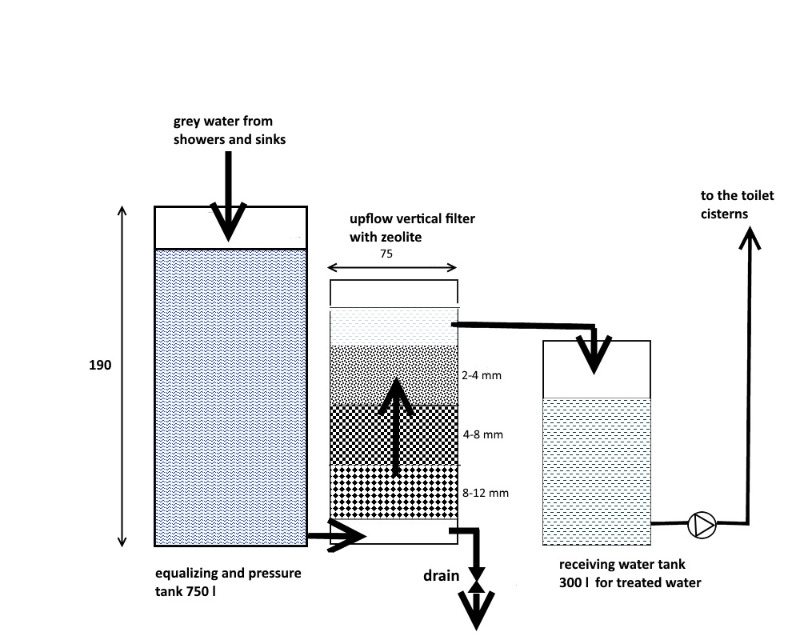

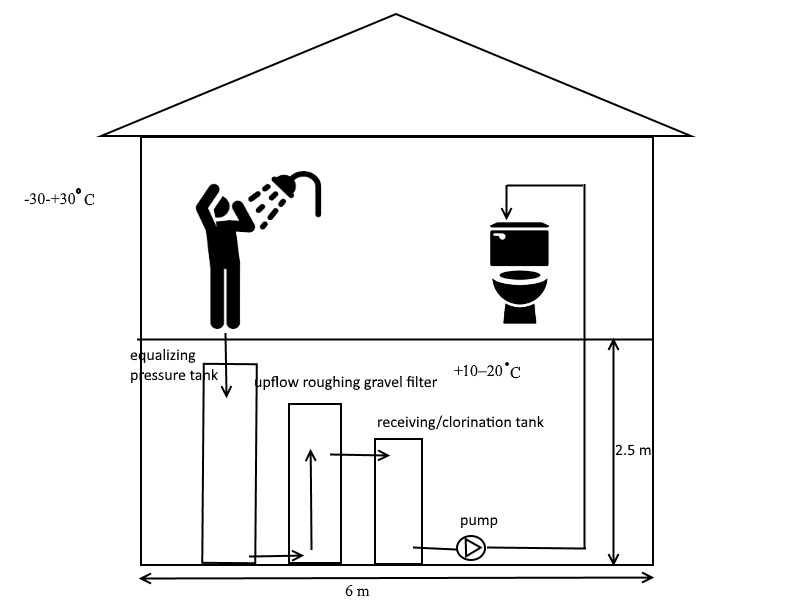

Hello everyone!

I am helping to design a rain water harvesting and sanitation system for the tourist hostel up in the Carpathian mountains. The situation with water supply there is rather complicated -- rain water is the main source. There is an idea to reuse the grey water from showers and sinks for the water flush toilets. However grey water needs basic treatment and filtration before pumped back to the toilet cisterns. One of the challenges is that treatment and filtration system has to be installed indoors protected from freezing temperatures thus it should be relatively compact. There are some factory made grey water filters that can do the job but being produced in Scandinavian countries they are too expensive for Ukrainian context and need constant and regular replacement of special filtration material also to be imported and being expensive.

There is a need to design a self built system form locally available materials and components with moderate maintenance input

I would be interested to discuss possible design of this filter and later next year post the reports on building process as I did this before with my public toilets projects. This can be quite an interesting project!

The main issues to consider:

1. The filter can be located on the ground floor directly underneath the showers, sinks and toilets (4 points of each) on the second floor. The grey water should feed filter by gravity and then pumped back to the toilet cisterns. The height of the ground floor to the ceiling is 2.3 m.

2. The grey wat can be rather hot from the showers.

3. The flow can be highly variable from 50 l up to 1 cubic meter per hour.

At the moment I am thinking about using there a vertical up flow filter made in 500 l polyethylene tank filled with 30 cm layers of zeolite with progressively smaller grain size each (8-12mm, 4-8 mm and 2-4 mm) Zeolite is used because it is mined nearby and hopefully will provide better treatment than ordinary gravel. Upflow design is thought since this will allow hydraulic cleaning by draining. Concept sketch is attached.

Looking forward to hear you suggestions and ideas!

I am helping to design a rain water harvesting and sanitation system for the tourist hostel up in the Carpathian mountains. The situation with water supply there is rather complicated -- rain water is the main source. There is an idea to reuse the grey water from showers and sinks for the water flush toilets. However grey water needs basic treatment and filtration before pumped back to the toilet cisterns. One of the challenges is that treatment and filtration system has to be installed indoors protected from freezing temperatures thus it should be relatively compact. There are some factory made grey water filters that can do the job but being produced in Scandinavian countries they are too expensive for Ukrainian context and need constant and regular replacement of special filtration material also to be imported and being expensive.

There is a need to design a self built system form locally available materials and components with moderate maintenance input

I would be interested to discuss possible design of this filter and later next year post the reports on building process as I did this before with my public toilets projects. This can be quite an interesting project!

The main issues to consider:

1. The filter can be located on the ground floor directly underneath the showers, sinks and toilets (4 points of each) on the second floor. The grey water should feed filter by gravity and then pumped back to the toilet cisterns. The height of the ground floor to the ceiling is 2.3 m.

2. The grey wat can be rather hot from the showers.

3. The flow can be highly variable from 50 l up to 1 cubic meter per hour.

At the moment I am thinking about using there a vertical up flow filter made in 500 l polyethylene tank filled with 30 cm layers of zeolite with progressively smaller grain size each (8-12mm, 4-8 mm and 2-4 mm) Zeolite is used because it is mined nearby and hopefully will provide better treatment than ordinary gravel. Upflow design is thought since this will allow hydraulic cleaning by draining. Concept sketch is attached.

Looking forward to hear you suggestions and ideas!

Bogdan Popov

The Ecosolutions Forge

www.ecoforge.org

The Ecosolutions Forge

www.ecoforge.org

Attachments:

-

greywaterf...eng2.jpg

(Filesize: 113KB)

greywaterf...eng2.jpg

(Filesize: 113KB)

-

3_2018-11-22.jpg

(Filesize: 51KB)

3_2018-11-22.jpg

(Filesize: 51KB)

The following user(s) like this post: cecile, gustavo, HarryTams

Please Log in to join the conversation.

You need to login to reply

Share this thread:

- Sanitation systems

- Treatment of wastewater, sludges, organic waste, excreta

- Various other technologies and comparisons of treatment technologies

- Designing and building grey water filter for reuse in flush toilets at the tourist hostel in the Carpathian mountains (Ukraine)

Recently active users. Who else has been active?

Time to create page: 0.098 seconds