- Sanitation systems

- Treatment of wastewater, sludges, organic waste, excreta

- Anaerobic treatment systems (biogas sanitation)

- Anaerobic baffled reactor (ABR)

- Pathogen destruction in biogas plant vs ABR (Anaerobic Baffled Reactor)

Pathogen destruction in biogas plant vs ABR (Anaerobic Baffled Reactor)

21.1k views

- joeturner

-

Less

Less- Posts: 717

- Karma: 23

- Likes received: 185

- Elisabeth

-

- User is blocked

- Freelance consultant since 2012

Less- Posts: 3372

- Karma: 54

- Likes received: 932

Re: Pathogen destruction in biogas plant vs ABR

I think your assumption is correct:

I can only assume that this is because biogas plants may usually have longer retention times.

Biogas plants have much much longer retention times than ABRs (many days compared to just hours or a few days).

Perhaps another reason could be that biogas plants can be operated at higher temperatures which would also lead to faster pathogen kill.

One publication that came to mind (because I was involved in creating it) is this Technology Review of GIZ on biogas plants:

Mang, H.-P., Li, Z. (2010). Technology review of biogas sanitation (draft) - Biogas sanitation for blackwater, brown water or for excreta and organic household waste treatment and reuse in developing countries. Deutsche Gesellschaft für Internationale Zusammenarbeit GmbH (GIZ)

www.susana.org/en/resources/library/details/877

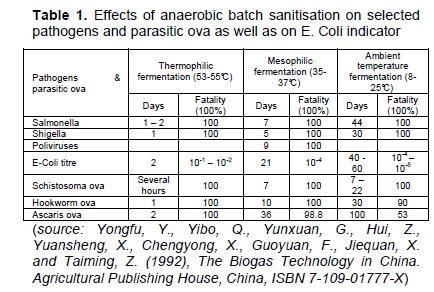

There is a section in there on pathogen destruction, I copy a bit:

3.2.1 Incomplete pathogen removal

Human excreta are contaminated with all kinds of pathogens

and hence a reliable technology is necessary for their

inactivation. During anaerobic digestion an inactivation of

most animal and plant pathogens is obtained under

thermophillic conditions (>55°C for several days). Several

studies on wet fermentation report that also mesophilic and

lower temperature operation inactivates pathogens; further

findings indicate that reactors with retention times of at least

60 days at 20oC to 15 days and 35-55oC reduce significantly

any type of pathogens (Michael H. Gerardi 2005).

Many studies reveal also that under fully mixed mesophilic

conditions, pathogens are not completely inactivated.

Therefore recommendations on the use of the not posttreated

slurry should limit irrigation only to fruit trees, and

exclude spray irrigation to vegetables. Effluent water could be

post-treated with UV desinfection by natural sunlight in

shallow polishing ponds. Post-composting of sludge may be

required for a one year period. If the effluent is directly

worked into the soil as soil conditionner no further restriction

applies.

Two main factors regulating the inactivation of pathogens

have been identified, namely the temperature and the concentration

of free ammonia as a function of the time of treatment/

exposure.

When it comes to helminth eggs (my most favourite topic), then I think they are pretty much just settled out but not destroyed in biogas plants. I could not imagine which mechanism should destroy them in a biogas plant given that they are so hardy that they can survive in the digetive tract of humans? (about helminths: en.wikipedia.org/wiki/Helminths - another page that I have been working on).

So when the sludge from a biogas digester is used for reuse activities you still need to keep those helminth eggs in mind and put treatment steps in place (or other safety precautions during reuse).

There is also this presentation from Heinz-Peter Mang about reuse of digestate in China which is very interesting:

forum.susana.org/forum/categories/174-sa...fertilizer-bioslurry

Perhaps my little input here will prompt others to share their experiences (or questions) on this important aspect of pathogen destruction in biogas sanitation systems.

And how about yourself, Marijn: As you work on a biogas programme in Nepal, what are your experiences with pathogen destruction in biogas plants, and reuse activities? Or is your work not dealing with human faecal matter?

Regards,

Elisabeth

Freelance consultant on environmental and climate projects

Attachments:

-

table.png

(Filesize: 33KB)

table.png

(Filesize: 33KB)

Please Log in to join the conversation.

You need to login to replyRe: Pathogen destruction in biogas plant vs ABR (Anaerobic Baffled Reactor)

During a recent conversation a question came-up regarding pathogen destruction in biogas plants vs ABRs. In this case either was to be considered as primary treatment followed by a secondary step (probably a CW). Someone in the discussion claimed that in this set-up the biogas plant would offer a better pathogen destruction than the ABR.

I can only assume that this is because biogas plants may usually have longer retention times. As I don't have the time to dive into the subject in detail I would like to ask if any one here is familiar with this argument and or has an explanation to offer?

Thanks

Marijn

E: This email address is being protected from spambots. You need JavaScript enabled to view it.

Please Log in to join the conversation.

You need to login to reply- Elisabeth

-

- User is blocked

- Freelance consultant since 2012

Less- Posts: 3372

- Karma: 54

- Likes received: 932

Re: Hygienic aspects of sewage sludge after AD

In my role as moderator, I have moved your topic from the original location of "biogas systems" to the category "faecal sludge management", because your question does not really relate to biogas systems but to the downstream processing of the sludge. (hope that is OK by you)

Just for the benefit of all: With AD he means anaerobic digestion.

Did you see that I mentioned in another topic (same category as this one), the sludge pelletiser in South Africa (eThekwini)? This would be one option for hygienisation. It works on heat, not on composting. See the video link which I posted. (I don't have more details on it, but could obtain it via Chris Buckley for example)

The other point I want to raise is this: don't get too hung up about destroying each and every helminth egg to make your sludge perfectly safe for reuse. Think rather of the WHO Guidelines from 2006 which promote a multiple-barrier approach. A technology to reduce pathogens is just one barrier. Other possible barriers are the handling of the sludge, education, personal protective equipment, the type of crops which you plant (does not necessarily have to be edible crops - cotton is a great example), and so forth. If you don't know these guidelines yet, you can find them in the SuSanA library (www.susana.org/lang-en/library?view=ccbktypeitem&type=2&id=1004)

Remember, any technology may fail (especially in developing countries), so think from the start of multiple barriers, not just the treatment barrier.

I wish you lots of success for your project!

Regards,

Elisabeth

Freelance consultant on environmental and climate projects

Please Log in to join the conversation.

You need to login to reply- daneric

-

Topic AuthorLess

- Posts: 4

- Likes received: 0

Hygienic aspects of sewage sludge after AD

I'd like to see if anybody have any advice on hygienizaion of faecal sludge (from toilets using less than one liter water per flushing) after 40 days retention time in batch AD. The location is Ngong, Kenya so the main issue is to get rid of parasite eggs. Since the AD process has probably metabolized large share of the organic compounds much heat will probably not be generated when composting. From what I've read these eggs can stay intact for 15 years. The intention is to make the sludge safe to use as bio-fertilizer. Anybody got advice or good ideas?

The idea is actually to use solar heaters to kill all pathogens before the AD process but seems we might not have enough funding for this. Read more about the project here: twowheelssouth.emulsionen.org/#post21

Regards,

//Dan-Eric

Please Log in to join the conversation.

You need to login to reply- Sanitation systems

- Treatment of wastewater, sludges, organic waste, excreta

- Anaerobic treatment systems (biogas sanitation)

- Anaerobic baffled reactor (ABR)

- Pathogen destruction in biogas plant vs ABR (Anaerobic Baffled Reactor)