- Sanitation systems

- Faecal sludge management (FSM)

- Faecal sludge transport (including emptying of pits and septic tanks, transfer stations)

- The excrevator (power auger) to empty pits (North Carolina State University, USA) - now field testing

The excrevator (power auger) to empty pits (North Carolina State University, USA) - now field testing

70k views

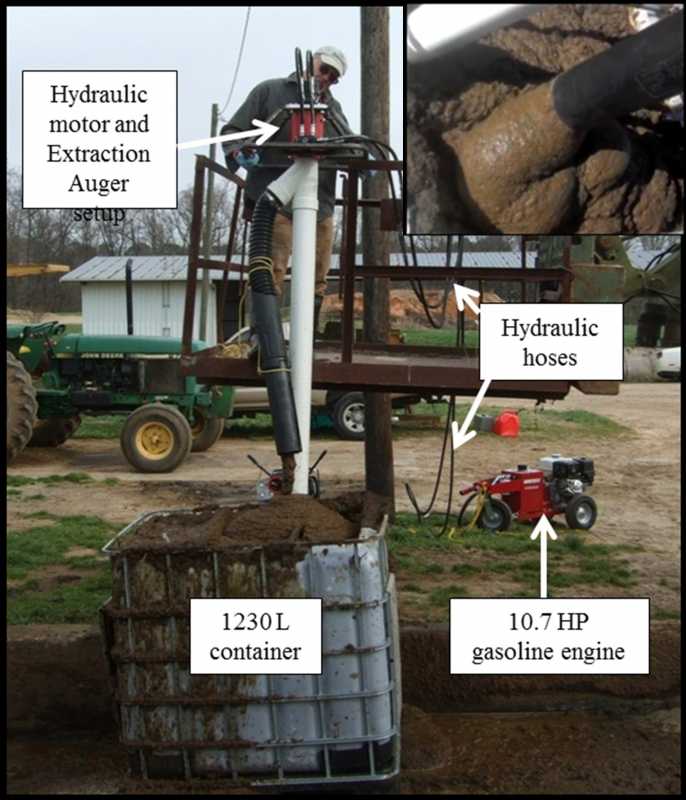

Hydraulic powered auger being tested on a simulated pit containing cattle manure:

Initial Prototype Development and Testing

Phase I involved development of an initial prototype and experimental facilities to evaluate the system. Our initial design was a simple modification of a standard earth auger with a machined coupling, PVC pipe and Tee.

Once a functional prototype was developed, the auger was tested to evaluate the effect of auger rotating speed (rpm), auger length, and waste viscosity on pumping rate and discharge head (pressure). The minimum speed to effectively pump the 5 and 6% bentonite simulant waste was 300 rpm, which is the maximum rotational speed of many earth augers. Based on this result, an alternative power drive was developed to generate higher rpm and increased flow.

Equipment Modification to Improve Performance

Based on the insights gained during RTTF and FSM2 conferences, we identified several modifications to improve the versatility and performance of our design. In fall 2012 and early winter 2013, these improvements were incorporated into our prototype and tested in the laboratory and in a simulated pit constructed on the NCSU farms. The improvements included:

1. The upper portion of the extraction auger was modified by replacing the ‘Tee’ fitting with a ‘Wye’ fitting and including a section of reversed flighting at the top of the auger. Together, these changes improved discharge of non-fecal material into the collection container.

2. Several different auger tips were developed to improve performance for a variety of site conditions including tips to reduce trash entry, reduce damage to concrete pit bottoms and break up compacted solids.

3. The auger body was modified allowing the auger to be shortened or extended depending on site conditions. When entering a building, the auger can be taken apart to negotiate tight areas, and then assembled to empty the pit. When dry solids are present, the outer pipe can also be shortened, exposing more auger to solids in the pit.

4. The standard mechanical drive was replaced with a hydraulic drive. This increased the pumping rate and allowed the auger to be easily reversed to discharge fecal material and/or trash that had entered the auger.

Hydraulic power is provided to the auger from a separate gasoline powered hydraulic pump. The hydraulic fluid travels through rubber hoses to the hydraulic motor that drives the auger. When the pit is located within 100 ft. of a vehicle, the hydraulic pump could remain on the vehicle and the hydraulic hoses would run from the vehicle to the pit. The hydraulic pump is also fitted with rubber tires allowing transport to more remote locations.

Video of the field testing on the farm with waste surrogate:

Initial Prototype Development and Testing

Phase I involved development of an initial prototype and experimental facilities to evaluate the system. Our initial design was a simple modification of a standard earth auger with a machined coupling, PVC pipe and Tee.

Once a functional prototype was developed, the auger was tested to evaluate the effect of auger rotating speed (rpm), auger length, and waste viscosity on pumping rate and discharge head (pressure). The minimum speed to effectively pump the 5 and 6% bentonite simulant waste was 300 rpm, which is the maximum rotational speed of many earth augers. Based on this result, an alternative power drive was developed to generate higher rpm and increased flow.

Equipment Modification to Improve Performance

Based on the insights gained during RTTF and FSM2 conferences, we identified several modifications to improve the versatility and performance of our design. In fall 2012 and early winter 2013, these improvements were incorporated into our prototype and tested in the laboratory and in a simulated pit constructed on the NCSU farms. The improvements included:

1. The upper portion of the extraction auger was modified by replacing the ‘Tee’ fitting with a ‘Wye’ fitting and including a section of reversed flighting at the top of the auger. Together, these changes improved discharge of non-fecal material into the collection container.

2. Several different auger tips were developed to improve performance for a variety of site conditions including tips to reduce trash entry, reduce damage to concrete pit bottoms and break up compacted solids.

3. The auger body was modified allowing the auger to be shortened or extended depending on site conditions. When entering a building, the auger can be taken apart to negotiate tight areas, and then assembled to empty the pit. When dry solids are present, the outer pipe can also be shortened, exposing more auger to solids in the pit.

4. The standard mechanical drive was replaced with a hydraulic drive. This increased the pumping rate and allowed the auger to be easily reversed to discharge fecal material and/or trash that had entered the auger.

Hydraulic power is provided to the auger from a separate gasoline powered hydraulic pump. The hydraulic fluid travels through rubber hoses to the hydraulic motor that drives the auger. When the pit is located within 100 ft. of a vehicle, the hydraulic pump could remain on the vehicle and the hydraulic hoses would run from the vehicle to the pit. The hydraulic pump is also fitted with rubber tires allowing transport to more remote locations.

Video of the field testing on the farm with waste surrogate:

Francis de los Reyes III

Professor/TED Fellow

Professor/TED Fellow

Attachments:

-

pic2.jpg

(Filesize: 61KB)

pic2.jpg

(Filesize: 61KB)

The topic has been locked.

The excrevator (power auger) to empty pits (North Carolina State University, USA) - now field testing

Here is a description of the grant from the Bill & Melinda Gates Foundation that I am leading:

Title of grant: Power Auger Modification to Empty Cess Pits

Subtitle: Developing a Pit Extraction Auger

Name of lead organization: North Carolina State University

Primary contact at lead organization: Robert Borden and Francis de los Reyes

Grantee location: Raleigh, North Carolina, USA

Country where the research is being or will be tested: South Africa

Goal(s):

The overall objective of the Phase I project was to modify and test a portable, gasoline powered earth auger that can be used to more efficiently and hygienically empty septic tanks, cesspits and latrines.

Start and end date: end date 31 December 2012, final report due 30 April 2013 (Phase 2 extension until early 2015)

Grant type: GCE Round 7

Funding for this research currently ongoing (yes/no): No

Research or implementation partners: Partners in Development, Pietermaritzburg, South Africa

Links, further readings – results to date:

Presentation at FSM-2 conference: www.susana.org/images/documents/07-cap-d...e-university-usa.pdf

Video of my presentation:

Our tests in South Africa has also been mentioned in this thread here on the forum:

forum.susana.org/forum/categories/53-fae...lper-and-others#3720

Francis L. de los Reyes III, Ph.D.

Professor

Department of Civil, Construction, and Environmental Engineering

North Carolina State University

Title of grant: Power Auger Modification to Empty Cess Pits

Subtitle: Developing a Pit Extraction Auger

Name of lead organization: North Carolina State University

Primary contact at lead organization: Robert Borden and Francis de los Reyes

Grantee location: Raleigh, North Carolina, USA

Country where the research is being or will be tested: South Africa

Goal(s):

The overall objective of the Phase I project was to modify and test a portable, gasoline powered earth auger that can be used to more efficiently and hygienically empty septic tanks, cesspits and latrines.

Start and end date: end date 31 December 2012, final report due 30 April 2013 (Phase 2 extension until early 2015)

Grant type: GCE Round 7

Funding for this research currently ongoing (yes/no): No

Research or implementation partners: Partners in Development, Pietermaritzburg, South Africa

Links, further readings – results to date:

Presentation at FSM-2 conference: www.susana.org/images/documents/07-cap-d...e-university-usa.pdf

Video of my presentation:

Our tests in South Africa has also been mentioned in this thread here on the forum:

forum.susana.org/forum/categories/53-fae...lper-and-others#3720

Francis L. de los Reyes III, Ph.D.

Professor

Department of Civil, Construction, and Environmental Engineering

North Carolina State University

Francis de los Reyes III

Professor/TED Fellow

Professor/TED Fellow

The following user(s) like this post: cecile

You need to login to reply

The topic has been locked.

Share this thread:

- Sanitation systems

- Faecal sludge management (FSM)

- Faecal sludge transport (including emptying of pits and septic tanks, transfer stations)

- The excrevator (power auger) to empty pits (North Carolina State University, USA) - now field testing

Recently active users. Who else has been active?

Time to create page: 0.116 seconds