- Sanitation systems

- Faecal sludge management (FSM)

- Faecal sludge transport (including emptying of pits and septic tanks, transfer stations)

- Improved Pit Emptying Technology

Improved Pit Emptying Technology

39.7k views

- gsmikhael

-

- Georges MIkhael

Less- Posts: 11

- Likes received: 7

Re: Improved Pit Emptying Technology

Hello Nicola,

Interesting question! Just a quick preamble though, I'm not sure how you would go about reaching the market without at some point establishing a company to be the 'technology champion'. It does not have to manufacture the technology (there are plenty of folks that the 'tech champion' could partner with for that), but it would have to as a minimum oversee marketing and sales.

One way to go about it is:

1. identify influential market leaders in different regions (e.g. SSA and Asia) that can prove a strong business case for the technology as *innovators*. Provide them with the technology (for free?) in return for getting hard financial and operational data (partner with a research university?), and allowing access to visitors. There are only a handful of those, so probably very easy to find! They may be social enterprises, utilities, businesses, etc. If they don't have the capacity to give you what you need (data and access), and need some technical support, I'm sure there are non-profits that are keen to help.

2. Define your upcoming customers - both *early adopters* and *major adopters*. Are they existing local businesses, local governments, utilities, foundations, IFIs, all? The challenge with the first category of customer (local businesses) is that even if they do believe in the business case, they may not be willing to take the investment risk required. However, I still think they should be your 'early adopters' - their advantage is that (a) they are much easier to target in the short-term compared to the other customer categories, and (b) you have the opportunity (and thus retain control) to interview / assess their capacity and pick them. Unless there is something wrong with the technology, they would become the foundation necessary for building a good brand (early adopters). To address and mitigate the risk of investment by the business, you might consider designing an enticing financing product. For instance, something like the Rent-to-Own model (rtoafrica.com/).

3. I would target the rest of those customers (major adopters: local government, utilities, foundations, IFIs, non-profits) later, because (a) you have little control of your brand at the crucial time when you're trying to build it (easier to blame the technology rather than the user), and (b) their funding cycles are challenging to align with. You would probably want to start considering them 6 - 12 months before you're hoping for some kind of deal.

I guess all this will need to be put into the business plan of a 'technology champion'. The market assessment you're currently working on could explore these issues (innovators, profile of 'early adopters', risk appetite, potential manufacturing partners, etc.), building the basis for an investible business plan.

Did that come close to answering your question, or did I completely miss the point?

Best,

Georges

Interesting question! Just a quick preamble though, I'm not sure how you would go about reaching the market without at some point establishing a company to be the 'technology champion'. It does not have to manufacture the technology (there are plenty of folks that the 'tech champion' could partner with for that), but it would have to as a minimum oversee marketing and sales.

One way to go about it is:

1. identify influential market leaders in different regions (e.g. SSA and Asia) that can prove a strong business case for the technology as *innovators*. Provide them with the technology (for free?) in return for getting hard financial and operational data (partner with a research university?), and allowing access to visitors. There are only a handful of those, so probably very easy to find! They may be social enterprises, utilities, businesses, etc. If they don't have the capacity to give you what you need (data and access), and need some technical support, I'm sure there are non-profits that are keen to help.

2. Define your upcoming customers - both *early adopters* and *major adopters*. Are they existing local businesses, local governments, utilities, foundations, IFIs, all? The challenge with the first category of customer (local businesses) is that even if they do believe in the business case, they may not be willing to take the investment risk required. However, I still think they should be your 'early adopters' - their advantage is that (a) they are much easier to target in the short-term compared to the other customer categories, and (b) you have the opportunity (and thus retain control) to interview / assess their capacity and pick them. Unless there is something wrong with the technology, they would become the foundation necessary for building a good brand (early adopters). To address and mitigate the risk of investment by the business, you might consider designing an enticing financing product. For instance, something like the Rent-to-Own model (rtoafrica.com/).

3. I would target the rest of those customers (major adopters: local government, utilities, foundations, IFIs, non-profits) later, because (a) you have little control of your brand at the crucial time when you're trying to build it (easier to blame the technology rather than the user), and (b) their funding cycles are challenging to align with. You would probably want to start considering them 6 - 12 months before you're hoping for some kind of deal.

I guess all this will need to be put into the business plan of a 'technology champion'. The market assessment you're currently working on could explore these issues (innovators, profile of 'early adopters', risk appetite, potential manufacturing partners, etc.), building the basis for an investible business plan.

Did that come close to answering your question, or did I completely miss the point?

Best,

Georges

Please Log in to join the conversation.

You need to login to reply- nicolag

-

Topic Author

Topic Author- Sanitation Engineer - Consultant

Less- Posts: 46

- Karma: 4

- Likes received: 13

Two great points here....

When our pit emptiers in South Africa used an early version of the evac they didnt like it as it took longer to set up and made a lot of mess in the bakkie and in peoples gardens when you disconnected hoses and containers, they preferred manual emptying. You need to look at how emptiers will use the tech beyond operation how the parts fit in and how the come apart, how you clean and store it (sanitation safety planning) and the capex and opex costs.

We had the exact same issue in Rwanda. I actually never ended up totally convinced that the eVac was actually more efficient or cleaner than buckets but we persevered because it brought us legitimacy both in the eyes of the Government and from the customer..and actually that worked out well BUT that won't play in every market right? In Rwanda, this was essential for permission to operate; in Kisumu, Kenya, it was not. As we try to convince Governments to find legalise methods of dealing with pit latrine emptying; the machine can end up a bit tokenistic, but it does the job. I just don't know how 'valuable' that is (I know for sure its of no value without a business case!)

P.S.You're right, the hoses are certainly an issue...and this is not solved.

It might be worth linking with a finance institution or local government who can make the capital investment and rent to pit emptiers. This was one advantage of the a franchise model we could buy the technology and rent it at a monthly fee and if it wasnt fit for purpose the franchisee had not had a major capital outlay. Also with the franchise model it gave us a bulk buy advantage for materials and machinery.

This is also spot on ...but here is my question: this is a technology developed in a University ...without establishing a company directly centred on marketing, manufacturing and selling this, who are likely to be these 'technology champions'? It would take a lot of time, effort and money to set up these systems...and I don't know that I work with many local governments that would be capable of it Would this 'champion' type need to vary country to country based on circumstance. Any thoughts?

When our pit emptiers in South Africa used an early version of the evac they didnt like it as it took longer to set up and made a lot of mess in the bakkie and in peoples gardens when you disconnected hoses and containers, they preferred manual emptying. You need to look at how emptiers will use the tech beyond operation how the parts fit in and how the come apart, how you clean and store it (sanitation safety planning) and the capex and opex costs.

We had the exact same issue in Rwanda. I actually never ended up totally convinced that the eVac was actually more efficient or cleaner than buckets but we persevered because it brought us legitimacy both in the eyes of the Government and from the customer..and actually that worked out well BUT that won't play in every market right? In Rwanda, this was essential for permission to operate; in Kisumu, Kenya, it was not. As we try to convince Governments to find legalise methods of dealing with pit latrine emptying; the machine can end up a bit tokenistic, but it does the job. I just don't know how 'valuable' that is (I know for sure its of no value without a business case!)

P.S.You're right, the hoses are certainly an issue...and this is not solved.

It might be worth linking with a finance institution or local government who can make the capital investment and rent to pit emptiers. This was one advantage of the a franchise model we could buy the technology and rent it at a monthly fee and if it wasnt fit for purpose the franchisee had not had a major capital outlay. Also with the franchise model it gave us a bulk buy advantage for materials and machinery.

This is also spot on ...but here is my question: this is a technology developed in a University ...without establishing a company directly centred on marketing, manufacturing and selling this, who are likely to be these 'technology champions'? It would take a lot of time, effort and money to set up these systems...and I don't know that I work with many local governments that would be capable of it Would this 'champion' type need to vary country to country based on circumstance. Any thoughts?

Please Log in to join the conversation.

You need to login to reply- eshaylor

-

- I am a WASH engineer who loves nothing more than talking Sh*t. I am currently working for UNICEF on innovation products in the WASH sector that can support the impact of programmes with a focus on children and women.

Less- Posts: 102

- Karma: 10

- Likes received: 61

Hi Nicola,

I like your approach and I think this is a really well considered bit of kit but from my experience the key thing most of these approaches miss is the infield application after testing, as a purchased product. As you say the number of parts will reduce and new versions are developed and with capital investment in the production. But often in focusing on the technology and a known problem a key use group is missed and that is the purchaser of the tech.

Yes there is rubbish in the pits and most pit emptier's are well aware of the issue and have a system they are using. When our pit emptiers in South Africa used an early version of the evac they didnt like it as it took longer to set up and made a lot of mess in the bakkie and in peoples gardens when you disconnected hoses and containers, they preferred manual emptying. You need to look at how emptiers will use the tech beyond operation how the parts fit in and how the come apart, how you clean and store it (sanitation safety planning) and the capex and opex costs.

It might be worth linking with a finance institution or local government who can make the capital investment and rent to pit emptiers. This was one advantage of the a franchise model we could buy the technology and rent it at a monthly fee and if it wasnt fit for purpose the franchisee had not had a major capital outlay. Also with the franchise model it gave us a bulk buy advantage for materials and machinery.

Hope that helps

Esther

I like your approach and I think this is a really well considered bit of kit but from my experience the key thing most of these approaches miss is the infield application after testing, as a purchased product. As you say the number of parts will reduce and new versions are developed and with capital investment in the production. But often in focusing on the technology and a known problem a key use group is missed and that is the purchaser of the tech.

Yes there is rubbish in the pits and most pit emptier's are well aware of the issue and have a system they are using. When our pit emptiers in South Africa used an early version of the evac they didnt like it as it took longer to set up and made a lot of mess in the bakkie and in peoples gardens when you disconnected hoses and containers, they preferred manual emptying. You need to look at how emptiers will use the tech beyond operation how the parts fit in and how the come apart, how you clean and store it (sanitation safety planning) and the capex and opex costs.

It might be worth linking with a finance institution or local government who can make the capital investment and rent to pit emptiers. This was one advantage of the a franchise model we could buy the technology and rent it at a monthly fee and if it wasnt fit for purpose the franchisee had not had a major capital outlay. Also with the franchise model it gave us a bulk buy advantage for materials and machinery.

Hope that helps

Esther

Esther Shaylor

Innovation specialist - WASH and Education

UNICEF Supply Division

Innovation specialist - WASH and Education

UNICEF Supply Division

The following user(s) like this post: gsmikhael

Please Log in to join the conversation.

You need to login to reply

Probably worth getting into contact with these people also:

forum.susana.org/99-faecal-sludge-transp...ort-from-pit-to-road

Similar system though (minus the build-in auger), so there might be some competing commercial interest?

forum.susana.org/99-faecal-sludge-transp...ort-from-pit-to-road

Similar system though (minus the build-in auger), so there might be some competing commercial interest?

Please Log in to join the conversation.

You need to login to reply- nicolag

-

Topic Author

Topic Author- Sanitation Engineer - Consultant

Less- Posts: 46

- Karma: 4

- Likes received: 13

In particular, any of you who have seen technology come and go in the past ...do let us know the vital lessons to learn.

Lesson 1, is of course, know your market before you design your tech..but unfortunately this is a little back to front, and the reality of where we are at. So, I do wonder if we have an 'in' at this point.

Lesson 1, is of course, know your market before you design your tech..but unfortunately this is a little back to front, and the reality of where we are at. So, I do wonder if we have an 'in' at this point.

Please Log in to join the conversation.

You need to login to reply- nicolag

-

Topic Author

Topic Author- Sanitation Engineer - Consultant

Less- Posts: 46

- Karma: 4

- Likes received: 13

Thanks for the responses.

The high solid waste content in pits is exactly why the Flexcrevator came about as a concept; of course as you noted it needs a lot more streamlining on design work - better trash rejection, less parts, easier to clean. I don't mean to dismiss this at is the whole root of the problem and I agree that stopping waste getting in there is absolutely the way to go

HOWEVER, what I am wondering in your context(s); say we get close to 'perfect' operation from a technical perspective and get to a functional trash rejecting pit emptying machine. Where and how would you see such a unit being distributed? Who, in your context, might be the purchasers of such a machine?

As for cost, that's a bit tricky during this prototype phase and it depends on a lot of what I ask above.

The material cost may come in at somewhere around $2-3,000

HOWEVER, the cost of selling a unit in the early stages for an independent outlet would actually be quite high as it would involve 'service provider behaviour change' - an expensive process. This might include:

- a visit to explain the machine to a service provider

- a demonstration empty to show it's use

- a sample business plan for how to incorporate it in one's business

- a follow up maintenance assistance guarantee

All in all, an outlet would need probably need to recoup $10,000/unit (completely off the top of my head) - to make it worth their while to sell, which then crushes the business model. The service provider might also have some more expenses e.g. licenses, if they were a new entrant to the business.

The alternative end of the scale is that, much like NGOs support behaviour change in communities to create markets for sanitation products; an organisation could 'adopt' the Flexcrevator in each country (in the early years) and absorb the cost of marketing/sales/adoption of this technology; charging service providers a tokenistic amount for the sake of getting it out there and in use.

Obviously, even the basic price tag, and required maintenance means this won't be targeted at the every day manual emptier - it could be an add on for a vacuum truck owner, or even a pick up owner, to enable them to start removing waste via a vacuum.

Otherwise, you sell to social enterprises only, who often operate in a world where capital cost is less of an issue as long as the OpEx works out - though that is an extremely limited market for now.

What do you think is the realistic way to get improved equipment to market, given that the reality is it needs to be coupled with significant systematic change?

The high solid waste content in pits is exactly why the Flexcrevator came about as a concept; of course as you noted it needs a lot more streamlining on design work - better trash rejection, less parts, easier to clean. I don't mean to dismiss this at is the whole root of the problem and I agree that stopping waste getting in there is absolutely the way to go

HOWEVER, what I am wondering in your context(s); say we get close to 'perfect' operation from a technical perspective and get to a functional trash rejecting pit emptying machine. Where and how would you see such a unit being distributed? Who, in your context, might be the purchasers of such a machine?

As for cost, that's a bit tricky during this prototype phase and it depends on a lot of what I ask above.

The material cost may come in at somewhere around $2-3,000

HOWEVER, the cost of selling a unit in the early stages for an independent outlet would actually be quite high as it would involve 'service provider behaviour change' - an expensive process. This might include:

- a visit to explain the machine to a service provider

- a demonstration empty to show it's use

- a sample business plan for how to incorporate it in one's business

- a follow up maintenance assistance guarantee

All in all, an outlet would need probably need to recoup $10,000/unit (completely off the top of my head) - to make it worth their while to sell, which then crushes the business model. The service provider might also have some more expenses e.g. licenses, if they were a new entrant to the business.

The alternative end of the scale is that, much like NGOs support behaviour change in communities to create markets for sanitation products; an organisation could 'adopt' the Flexcrevator in each country (in the early years) and absorb the cost of marketing/sales/adoption of this technology; charging service providers a tokenistic amount for the sake of getting it out there and in use.

Obviously, even the basic price tag, and required maintenance means this won't be targeted at the every day manual emptier - it could be an add on for a vacuum truck owner, or even a pick up owner, to enable them to start removing waste via a vacuum.

Otherwise, you sell to social enterprises only, who often operate in a world where capital cost is less of an issue as long as the OpEx works out - though that is an extremely limited market for now.

What do you think is the realistic way to get improved equipment to market, given that the reality is it needs to be coupled with significant systematic change?

Please Log in to join the conversation.

You need to login to reply- hajo

-

- retired in Germany... but still interested in water and sanitation... especially in OSS... and especially in Africa...

Less- Posts: 288

- Karma: 15

- Likes received: 156

Dear all,

I had the opportunity observing three different pumps emptying latrine pits in Lusaka peri-urban compounds (high density, low income areas) in last quarter of 2017, namely the Gulper, the eVac and the FlexCravator. I want to share with you two major observations I made during the exercises.

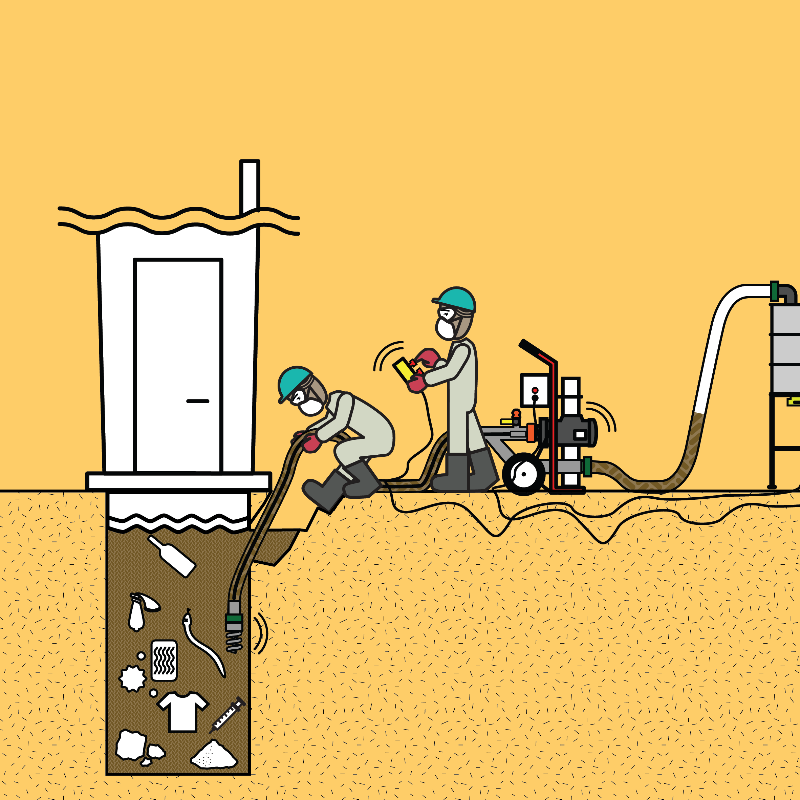

A major problem of pit emptying in Lusaka is the high content of solid waste in the pits which obstructs every mechanized emptying, no matter whether manual (Gulper) or motorized (eVac, Flexcravator). And the problem is not the real solid waste like brooms, bottles, tins, shoes, bones which are either easily rejected by a cage at the suction pipe inlet or by the auger of the FlexCravator, but the immense quantity of plastic bags (and rags and cloths).

These get into the pit either as wrapping of kitchen waste, baby diapers, MHM remains or as anal cleansing material. And every of the three pumps tested was heavily affected by all the plastic which sooner than later blocks any cage, auger or suction pipe. Then the pump has to be pulled out and cleaned of the plastic which inevitably leads to spillage of FS at the site.

It is not fair blaming the pumps failing to handle the plastic but it is an immediate effect of its presence and before we think about using any type of pump emptying latrine pits in Lusaka we have to solve the problem of solid waste/plastic going into the pits which is caused also by the failing solid waste management system. The current pit emptiers in Lusaka use long arm buckets and rakes to empty pits from FS and solid waste, which seems so far the most appropriate technology.

In this context it may be interesting to hear how the SSG from Kampala who presented the Gulper in Lusaka deal with the problem: 1) they convince customers having a SATO pan installed which by its smaller opening reduces the chance of dumping solid waste/filled plastic bags in the pit and 2) they charge an extra amount for every drum of solid waste retrieved from a pit which they empty. They say both measures have already helped reducing solid waste in pits of their customers easing and economizing their business. By the way: SSG lives of pit emptying, which impressed me heavily!

My second observation was that the more bits, pieces and pipes a specific emptying technology (pump) consists of, the more pieces need to be cleaned after pit emptying which again leads to spillage of FS on site because normally the bits and pipes are just washed down on site. Therefore I would prefer a technology which comprises as few as possible parts which get into contact with the FS and which require cleaning before moving to the next site.

I describe these observations in detail because before I observed it in the field I had no idea how much plastic could be in a pit and how it could affect any mechanical emptying. And I had no idea how much FS can be spilled on site in the process of emptying which is in sheer discrepancy of the purpose of toilets: separating people from their shit.

Ciao

Hajo

I had the opportunity observing three different pumps emptying latrine pits in Lusaka peri-urban compounds (high density, low income areas) in last quarter of 2017, namely the Gulper, the eVac and the FlexCravator. I want to share with you two major observations I made during the exercises.

A major problem of pit emptying in Lusaka is the high content of solid waste in the pits which obstructs every mechanized emptying, no matter whether manual (Gulper) or motorized (eVac, Flexcravator). And the problem is not the real solid waste like brooms, bottles, tins, shoes, bones which are either easily rejected by a cage at the suction pipe inlet or by the auger of the FlexCravator, but the immense quantity of plastic bags (and rags and cloths).

These get into the pit either as wrapping of kitchen waste, baby diapers, MHM remains or as anal cleansing material. And every of the three pumps tested was heavily affected by all the plastic which sooner than later blocks any cage, auger or suction pipe. Then the pump has to be pulled out and cleaned of the plastic which inevitably leads to spillage of FS at the site.

It is not fair blaming the pumps failing to handle the plastic but it is an immediate effect of its presence and before we think about using any type of pump emptying latrine pits in Lusaka we have to solve the problem of solid waste/plastic going into the pits which is caused also by the failing solid waste management system. The current pit emptiers in Lusaka use long arm buckets and rakes to empty pits from FS and solid waste, which seems so far the most appropriate technology.

In this context it may be interesting to hear how the SSG from Kampala who presented the Gulper in Lusaka deal with the problem: 1) they convince customers having a SATO pan installed which by its smaller opening reduces the chance of dumping solid waste/filled plastic bags in the pit and 2) they charge an extra amount for every drum of solid waste retrieved from a pit which they empty. They say both measures have already helped reducing solid waste in pits of their customers easing and economizing their business. By the way: SSG lives of pit emptying, which impressed me heavily!

My second observation was that the more bits, pieces and pipes a specific emptying technology (pump) consists of, the more pieces need to be cleaned after pit emptying which again leads to spillage of FS on site because normally the bits and pipes are just washed down on site. Therefore I would prefer a technology which comprises as few as possible parts which get into contact with the FS and which require cleaning before moving to the next site.

I describe these observations in detail because before I observed it in the field I had no idea how much plastic could be in a pit and how it could affect any mechanical emptying. And I had no idea how much FS can be spilled on site in the process of emptying which is in sheer discrepancy of the purpose of toilets: separating people from their shit.

Ciao

Hajo

We can't solve problems by using the same kind of thinking we used when we created them.

Albert Einstein

Any intelligent fool can make things bigger and more complex... It takes a touch of a genius - and a lot of courage to move in the opposite direction.

E.F. Schumacher

Everything should be made as simple as possible, but not simpler.

Albert Einstein

Albert Einstein

Any intelligent fool can make things bigger and more complex... It takes a touch of a genius - and a lot of courage to move in the opposite direction.

E.F. Schumacher

Everything should be made as simple as possible, but not simpler.

Albert Einstein

Attachments:

-

gulperbloc...stic.jpg

(Filesize: 75KB)

gulperbloc...stic.jpg

(Filesize: 75KB)

-

plasticbags.jpg

(Filesize: 66KB)

plasticbags.jpg

(Filesize: 66KB)

-

modifiedhandtools.jpg

(Filesize: 87KB)

modifiedhandtools.jpg

(Filesize: 87KB)

The following user(s) like this post: JKMakowka

Please Log in to join the conversation.

You need to login to reply

Dear Ms. Nicola Greene,

Thank you for sharing your interesting project. Do you have all the information in pdf format? That will be helpful.

What is the capital; and operation and maintenance cost of the system?

Regards,

F H Mughal

Thank you for sharing your interesting project. Do you have all the information in pdf format? That will be helpful.

What is the capital; and operation and maintenance cost of the system?

Regards,

F H Mughal

F H Mughal (Mr.)

Karachi, Pakistan

Karachi, Pakistan

Please Log in to join the conversation.

You need to login to reply- nicolag

-

Topic Author

Topic Author- Sanitation Engineer - Consultant

Less- Posts: 46

- Karma: 4

- Likes received: 13

Great- thanks @JKMakowka. You are right. Though not the initial aim of the product, it seems like a more straightforward market to tap into could be the humanitarian one. I will follow up on those leads....and suggest a darker hose!

@Snehit - there is a big effort to streamline the machine to reduce parts and improve cleaning now. We used the eVac (similar scale vacuum device in Rwanda) and cleaning certainly is a bit labour intensive. Not solved for now quite honestly.

"As for markets, or positioning, one strategy could be positioning it as a auxiliary product for a service provider who has a larger mechanised unit capable of collecting higher volumes, but can't quite access smaller or narrower areas. Depends on the economics".

This is exactly what I am trying to figure out. At what point do the more "straighforward" jobs end for the vac trucks and what would incentivise them to take on the pit latrines or harder to access waste with this service. As you say, the local economics would determine quite a bit. In many African cities, the pits offer a significant scale business opportunity, but often not a lucrative one (low margin, high volume rarely works here). Therefore, as the makers of a machine that needs complimentary systems change to function well, we either face into taking the easier wins (e.g. humanitarian, industrial) and waiting for the systems to change; or be the 'pioneers' in changing the system.....an expensive and time consuming process!

@Snehit - there is a big effort to streamline the machine to reduce parts and improve cleaning now. We used the eVac (similar scale vacuum device in Rwanda) and cleaning certainly is a bit labour intensive. Not solved for now quite honestly.

"As for markets, or positioning, one strategy could be positioning it as a auxiliary product for a service provider who has a larger mechanised unit capable of collecting higher volumes, but can't quite access smaller or narrower areas. Depends on the economics".

This is exactly what I am trying to figure out. At what point do the more "straighforward" jobs end for the vac trucks and what would incentivise them to take on the pit latrines or harder to access waste with this service. As you say, the local economics would determine quite a bit. In many African cities, the pits offer a significant scale business opportunity, but often not a lucrative one (low margin, high volume rarely works here). Therefore, as the makers of a machine that needs complimentary systems change to function well, we either face into taking the easier wins (e.g. humanitarian, industrial) and waiting for the systems to change; or be the 'pioneers' in changing the system.....an expensive and time consuming process!

Please Log in to join the conversation.

You need to login to reply- Snehit

-

- High Altitude FSM Professional

Less- Posts: 5

- Likes received: 1

Re: Improved Pit Emptying Technology

Hi Nicola,

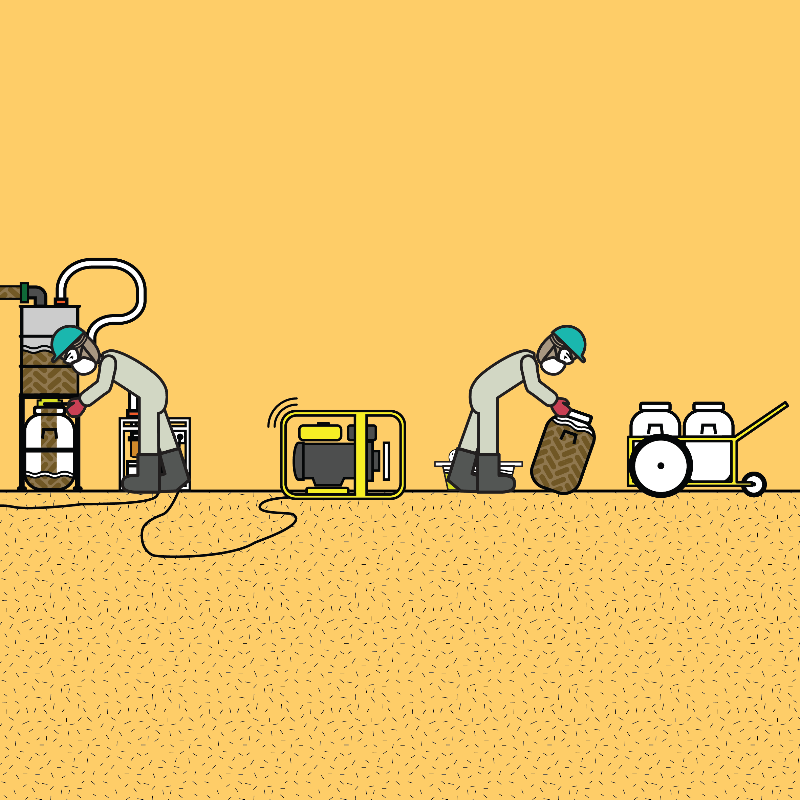

For a private player the issue that might immediately strikes me that there are so many parts, and more parts mean more repair and management. Also there seems to be requirement of 2-3 people to run this system?

As for markets, or positioning, one strategy could be positioning it as a auxiliary product for a service provider who has a larger mechanised unit capable of collecting higher volumes, but can't quite access smaller or narrower areas. Depends on the economics.

Do you have a video of the cleaning process?

Seems very interesting.

For a private player the issue that might immediately strikes me that there are so many parts, and more parts mean more repair and management. Also there seems to be requirement of 2-3 people to run this system?

As for markets, or positioning, one strategy could be positioning it as a auxiliary product for a service provider who has a larger mechanised unit capable of collecting higher volumes, but can't quite access smaller or narrower areas. Depends on the economics.

Do you have a video of the cleaning process?

Seems very interesting.

Please Log in to join the conversation.

You need to login to reply

Looks like a nice system, although I hope there are different color suction pipes in the final product

As for potential customers: humanitarian aid agencies might find this interesting, especially if it comes in a reasonably priced and easy to airlift complete package, i.e. everything out of the box incl. personal safety equipment.

The usecase would be refugee settlements and urban host communities that are difficult to serve by conventional vacuum trucks (over crowding and difficult road conditions). So something that can fit on a larger 4wheel drive pickup would fit the bill.

Butyl products is usually the reference supplier for this (small) market:

www.butylproducts.co.uk/

So worth talking to them.

Otherwise send a mail to William Carter from IFRC ( This email address is being protected from spambots. You need JavaScript enabled to view it. ), who I know is currently looking together with the British Red Cross into such products.

As for potential customers: humanitarian aid agencies might find this interesting, especially if it comes in a reasonably priced and easy to airlift complete package, i.e. everything out of the box incl. personal safety equipment.

The usecase would be refugee settlements and urban host communities that are difficult to serve by conventional vacuum trucks (over crowding and difficult road conditions). So something that can fit on a larger 4wheel drive pickup would fit the bill.

Butyl products is usually the reference supplier for this (small) market:

www.butylproducts.co.uk/

So worth talking to them.

Otherwise send a mail to William Carter from IFRC ( This email address is being protected from spambots. You need JavaScript enabled to view it. ), who I know is currently looking together with the British Red Cross into such products.

Please Log in to join the conversation.

You need to login to reply- nicolag

-

Topic Author

Topic Author- Sanitation Engineer - Consultant

Less- Posts: 46

- Karma: 4

- Likes received: 13

Hi Everyone

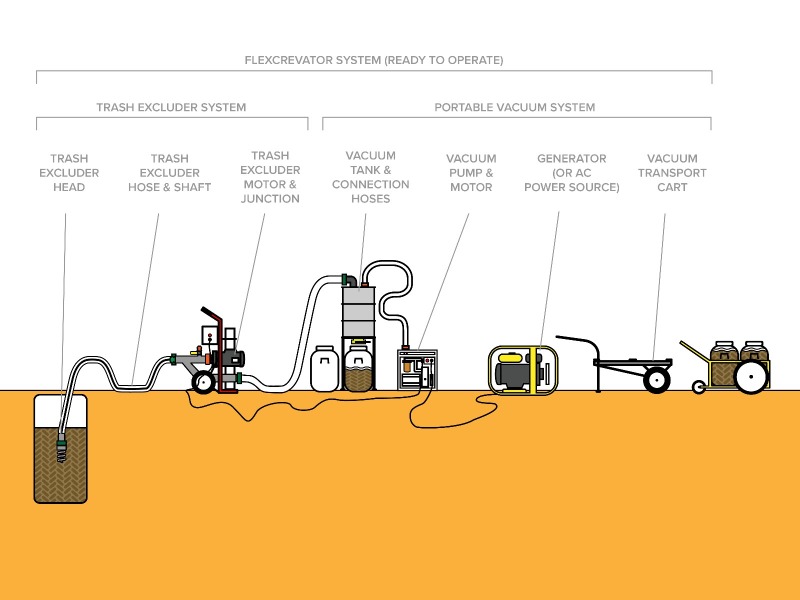

As you may know, North Carolina State University has been developing the Flexcrevator: A safe and cost-effective system for emptying pit latrines that aims to eliminate the need for manual pit emptying. The project began in 2011 with funding from the Bill and Melinda Gates Foundation. (see here: www.susana.org/en/knowledge-hub/projects/database/details/542 and here: www.susana.org/en/knowledge-hub/projects/database/details/85 in the SuSanA project database; added by moderator)

Since then, more than four iterations of the design have been tested with support from our partners in South Africa, Malawi, India, and Zambia. The most recent version of the Flexcrevator system includes a small, mobile vacuum system coupled with our trash rejection system that allows pits with high trash content to be emptied effectively. Our most recent phase of funding began in September 2017 and includes a partnership with Catapult Design. This phase of the project aims to perfect the design, validate in several target countries, and identify the potential markets for entry.

I've attached some photos and illustrations of the current system - do let me know if you have questions on it's function.

As we approach a functional unit, the question around how to get this machine to market is at the forefront of our minds. The type of questions we need to address are:

(i) who are the potential (immediate and long term) customers for this unit and what support would they need to acquire it?

(ii) how could the existence of such a unit be promoted to the right people?

(iii) without formal industries emptying pit latrines, how do we convey both the business model and enable access to the machine itself - via whom, and with what support services?

(iv) what is the potential demand country to country - is there an easier or more receptive market in some places?

Right now we are completely open. We are assessing 10 countries to gain an understanding of the market that exists and if penetration strategies may vary from place to place e.g. in Zambia the market could be reached via the Utility; in Kenya it might be social enterprises, in Ghana NGOs may pioneer the tech. Some countries also are strong candidates to manufacture in; but we are very aware that a manufacturer would need a lot of support to make sales.

Many 'improved pit latrine emptying' technologies have fallen by the way-side before...we do appreciate this group's knowledge in helping us to avoid the same pitfalls...no matter how labour intensive the route to market may be!

What would be your advice for reaching market with this machine?

Nicola

As you may know, North Carolina State University has been developing the Flexcrevator: A safe and cost-effective system for emptying pit latrines that aims to eliminate the need for manual pit emptying. The project began in 2011 with funding from the Bill and Melinda Gates Foundation. (see here: www.susana.org/en/knowledge-hub/projects/database/details/542 and here: www.susana.org/en/knowledge-hub/projects/database/details/85 in the SuSanA project database; added by moderator)

Since then, more than four iterations of the design have been tested with support from our partners in South Africa, Malawi, India, and Zambia. The most recent version of the Flexcrevator system includes a small, mobile vacuum system coupled with our trash rejection system that allows pits with high trash content to be emptied effectively. Our most recent phase of funding began in September 2017 and includes a partnership with Catapult Design. This phase of the project aims to perfect the design, validate in several target countries, and identify the potential markets for entry.

I've attached some photos and illustrations of the current system - do let me know if you have questions on it's function.

As we approach a functional unit, the question around how to get this machine to market is at the forefront of our minds. The type of questions we need to address are:

(i) who are the potential (immediate and long term) customers for this unit and what support would they need to acquire it?

(ii) how could the existence of such a unit be promoted to the right people?

(iii) without formal industries emptying pit latrines, how do we convey both the business model and enable access to the machine itself - via whom, and with what support services?

(iv) what is the potential demand country to country - is there an easier or more receptive market in some places?

Right now we are completely open. We are assessing 10 countries to gain an understanding of the market that exists and if penetration strategies may vary from place to place e.g. in Zambia the market could be reached via the Utility; in Kenya it might be social enterprises, in Ghana NGOs may pioneer the tech. Some countries also are strong candidates to manufacture in; but we are very aware that a manufacturer would need a lot of support to make sales.

Many 'improved pit latrine emptying' technologies have fallen by the way-side before...we do appreciate this group's knowledge in helping us to avoid the same pitfalls...no matter how labour intensive the route to market may be!

What would be your advice for reaching market with this machine?

Nicola

Attachments:

-

Flexcrevat...ion.jpeg

(Filesize: 53KB)

Flexcrevat...ion.jpeg

(Filesize: 53KB)

-

FlexOperation2.png

(Filesize: 162KB)

FlexOperation2.png

(Filesize: 162KB)

-

FlexOperation.png

(Filesize: 223KB)

FlexOperation.png

(Filesize: 223KB)

-

FlexSystem.jpg

(Filesize: 235KB)

FlexSystem.jpg

(Filesize: 235KB)

-

FlexTransp...hoto.jpg

(Filesize: 252KB)

FlexTransp...hoto.jpg

(Filesize: 252KB)

The following user(s) like this post: shaji

Please Log in to join the conversation.

You need to login to reply

Share this thread:

- Sanitation systems

- Faecal sludge management (FSM)

- Faecal sludge transport (including emptying of pits and septic tanks, transfer stations)

- Improved Pit Emptying Technology

Recently active users. Who else has been active?

Time to create page: 0.500 seconds