- Sanitation systems

- Faecal sludge management (FSM)

- Faecal sludge transport (including emptying of pits and septic tanks, transfer stations)

- The Excrevator, e-Vac, and Gulper for our project in Myanmar – and the answer is …

The Excrevator, e-Vac, and Gulper for our project in Myanmar – and the answer is …

7426 views

I wonder though what effect the lime might have on the water permeability of the pit walls. Maybe that's something to look out for in slow draining soils.

For the pump:

If you go mechanized, the locally made diaphragm pumps they use here in the Philippines for the vacuum trucks seems to work relatively well (see attached pictures, They can be used under the CC-by-SA license).

Maybe one could also experiment with an air-lift pump, utilizing an off the shelf air-compressor with a large enough pressure tank? I imagine that sludge like this could be pumped quite well through raising air bubbles and the pressurized air could also be used to break up the solids at the bottom.

Edit: Note though that the air-lift pump will not allow full desludging, but only 1/2 or 2/3s or so of the liquid content, not quite sure how much as the viscose sludge will likely hold more air than a air/water mix that is usually used for such pumps (the density difference it what makes the pump work; for pure water it pumps about the same hight as it is submerged into the liquid). But you could add more water to dilute the remaining sludge during later stages of the pumping to keep a certain water level in the pit.

Edit2: On a second thought: I guess an airlift pump would be more feasible for septic-tanks, as pit-latrines might require way too much water to be added before the sludge can be pumped this way.

For the pump:

If you go mechanized, the locally made diaphragm pumps they use here in the Philippines for the vacuum trucks seems to work relatively well (see attached pictures, They can be used under the CC-by-SA license).

Maybe one could also experiment with an air-lift pump, utilizing an off the shelf air-compressor with a large enough pressure tank? I imagine that sludge like this could be pumped quite well through raising air bubbles and the pressurized air could also be used to break up the solids at the bottom.

Edit: Note though that the air-lift pump will not allow full desludging, but only 1/2 or 2/3s or so of the liquid content, not quite sure how much as the viscose sludge will likely hold more air than a air/water mix that is usually used for such pumps (the density difference it what makes the pump work; for pure water it pumps about the same hight as it is submerged into the liquid). But you could add more water to dilute the remaining sludge during later stages of the pumping to keep a certain water level in the pit.

Edit2: On a second thought: I guess an airlift pump would be more feasible for septic-tanks, as pit-latrines might require way too much water to be added before the sludge can be pumped this way.

Attachments:

-

diaphragm_pump1.jpg

(Filesize: 34KB)

diaphragm_pump1.jpg

(Filesize: 34KB)

-

diaphragm_pump2.jpg

(Filesize: 55KB)

diaphragm_pump2.jpg

(Filesize: 55KB)

Please Log in to join the conversation.

You need to login to reply- dmrobbins10

-

Topic Author

Topic Author- Improving life and livelihood through decentralized wastewater management

Less- Posts: 56

- Karma: 10

- Likes received: 33

The Excrevator, e-Vac, and Gulper for our project in Myanmar – and the answer is …

Dear friends,

First thanks so much for the detailed feedback you gave me about this project (forum.susana.org/forum/categories/53-fae...idp-camps-in-myanmar). Based on your input, and our scenario, it is likely that our sludge will be too thick for pumping. While augering might work, we think we have a better solution, which is an in-pit lime stabilization process, first demonstrated by Irina Chakraborty at IDE in Cambodia back in 2015. In this scenario, workers treat the septage in the pit with the lime, and dilute it so it can be easily pumped. The idea would be that the workers would:

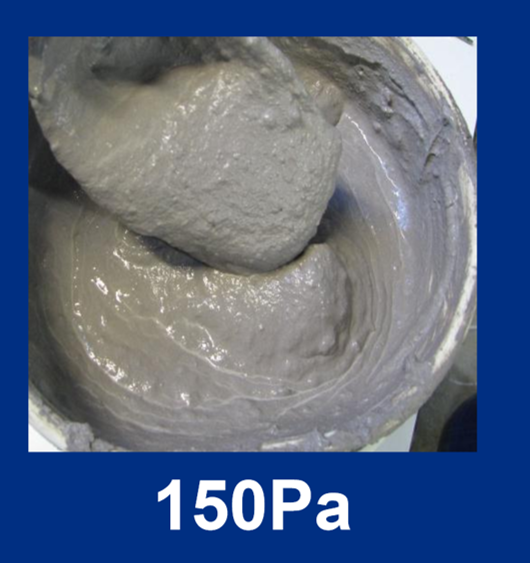

a) Mix a slurry of hydrated lime in water into the pit using hand tools. They will use enough water in the slurry to bring the sludge to a consistency of about 100 – 150 Pa. This will be thin enough to be able to be pumped;

b) The workers will use long handle metal digging bars to thoroughly mix the contents of the lime slurry with contents of the pit. 20 Kg of lime per pit will be used during the initial trials. It may need to be increased depending upon the quality of the hydrated lime. Workers will monitor pH to verify pH of 12 is met for at least 30 minutes;

c) This should significantly reduce the odors common with desludging, which is reportedly the reason the septage workers do their services at night;

d) The action of the mixing as well as the chemical reaction achieved by the lime will help to loosen up the very dense and compacted layers of sludge. It may not be possible to get all of that compact sludge the first time. But over time, it will become easier to achieve complete cleaning;

e) The workers will then use either the Gulper, Excravator, e-Vac, or perhaps a non-clog centrifugal sludge pump to pump the now stabilized septage from the pit. They will fill specially designed trays 2’ by 2’ by 6” deep made of black plastic. Perfect for air drying in the sun. The trays are designed to easily stack on the motorcycle septage transport vehicle;

f) They use the transport vehicle to bring the now filled trays over to the processing area. The vehicle is the same one they already use for solid waste collection. The trays fit right on top of the sand drying bed with its underdrain system to collect whatever moisture that drains out during the drying process. The workers will easily be able to handle the trays without contacting the stabilized sludge;

g) After two to three weeks, the biosolids in the trays should be dry to about 25% solids. The material is then dumped from the trays and either stockpiled or composted.

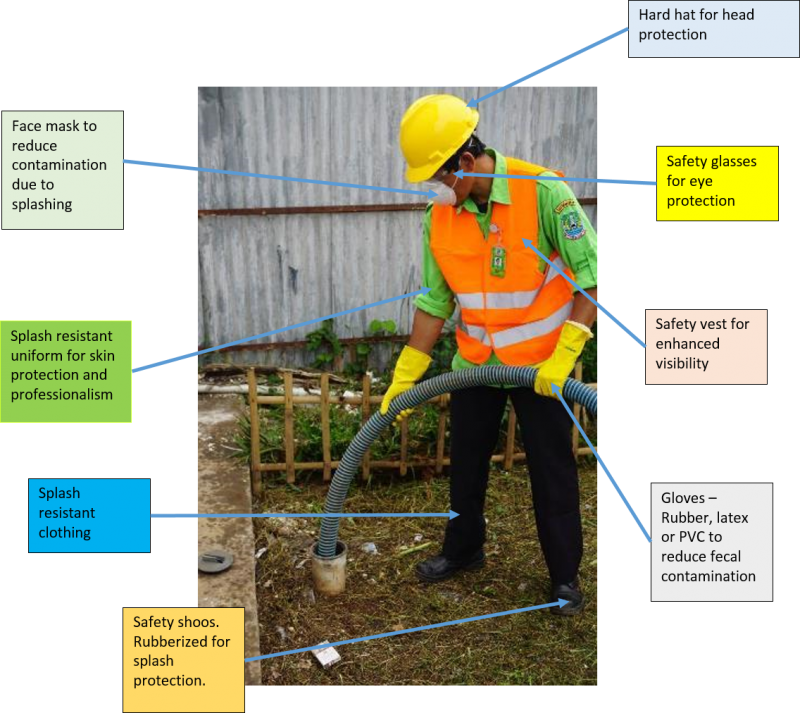

What makes this approach particularly appealing is that the workers will only be processing sludge that is already stabilized. This is important as in Myanmar, septage workers are typically treated as an underclass of citizens due to the poor hygienic practices common in this profession. We are trying to turn this around. In this scenario, the workers will be doing their work during the full light of day, and will be seen as professionals doing an important service, a message that will be reinforced by the workers wearing their personal protective equipment.

h. There will be a promotions campaign with the camp leader acting as spokesperson that will raise the awareness of the program amongst the camp residents. It is a small camp so this can be achieved through a series of meetings and interpersonal communications, along with a poster campaign. There is a strong WASH working group which will spearhead this effort.

i. Key to the success will be an anti trash throwing campaign that will reduce the amount of solid waste being put into the pits. Each latrine will be equipped with a woven trash receptacle (made by camp residents as a micro enterprise) attached to the wall of the latrine and fitted with a tight fitting lid and the contents will be collected along with the rest of the camp’s solid waste twice a week. There will be a poster campaign with posters installed inside each latrine. The current “shaming” campaign will continue where solid waste fished out of the latrine is left on site for a few days for the whole camp to see.

Small is beautiful. We hope that this project demonstrates how small-scale decentralized FSM projects may be a viable alternative to truck based large community style programs. But it is still just a proposal. In the next couple of weeks, we will finalize our plan and then present it to the village leader and the WASH Working Group to see what they think. If they want to give it a try, we will likely begin sometime in May.

For more information or to get involved, just let us know. If you have any comments or ideas for improvement, please email or respond to this post. Thanks!

First thanks so much for the detailed feedback you gave me about this project (forum.susana.org/forum/categories/53-fae...idp-camps-in-myanmar). Based on your input, and our scenario, it is likely that our sludge will be too thick for pumping. While augering might work, we think we have a better solution, which is an in-pit lime stabilization process, first demonstrated by Irina Chakraborty at IDE in Cambodia back in 2015. In this scenario, workers treat the septage in the pit with the lime, and dilute it so it can be easily pumped. The idea would be that the workers would:

a) Mix a slurry of hydrated lime in water into the pit using hand tools. They will use enough water in the slurry to bring the sludge to a consistency of about 100 – 150 Pa. This will be thin enough to be able to be pumped;

b) The workers will use long handle metal digging bars to thoroughly mix the contents of the lime slurry with contents of the pit. 20 Kg of lime per pit will be used during the initial trials. It may need to be increased depending upon the quality of the hydrated lime. Workers will monitor pH to verify pH of 12 is met for at least 30 minutes;

c) This should significantly reduce the odors common with desludging, which is reportedly the reason the septage workers do their services at night;

d) The action of the mixing as well as the chemical reaction achieved by the lime will help to loosen up the very dense and compacted layers of sludge. It may not be possible to get all of that compact sludge the first time. But over time, it will become easier to achieve complete cleaning;

e) The workers will then use either the Gulper, Excravator, e-Vac, or perhaps a non-clog centrifugal sludge pump to pump the now stabilized septage from the pit. They will fill specially designed trays 2’ by 2’ by 6” deep made of black plastic. Perfect for air drying in the sun. The trays are designed to easily stack on the motorcycle septage transport vehicle;

f) They use the transport vehicle to bring the now filled trays over to the processing area. The vehicle is the same one they already use for solid waste collection. The trays fit right on top of the sand drying bed with its underdrain system to collect whatever moisture that drains out during the drying process. The workers will easily be able to handle the trays without contacting the stabilized sludge;

g) After two to three weeks, the biosolids in the trays should be dry to about 25% solids. The material is then dumped from the trays and either stockpiled or composted.

What makes this approach particularly appealing is that the workers will only be processing sludge that is already stabilized. This is important as in Myanmar, septage workers are typically treated as an underclass of citizens due to the poor hygienic practices common in this profession. We are trying to turn this around. In this scenario, the workers will be doing their work during the full light of day, and will be seen as professionals doing an important service, a message that will be reinforced by the workers wearing their personal protective equipment.

h. There will be a promotions campaign with the camp leader acting as spokesperson that will raise the awareness of the program amongst the camp residents. It is a small camp so this can be achieved through a series of meetings and interpersonal communications, along with a poster campaign. There is a strong WASH working group which will spearhead this effort.

i. Key to the success will be an anti trash throwing campaign that will reduce the amount of solid waste being put into the pits. Each latrine will be equipped with a woven trash receptacle (made by camp residents as a micro enterprise) attached to the wall of the latrine and fitted with a tight fitting lid and the contents will be collected along with the rest of the camp’s solid waste twice a week. There will be a poster campaign with posters installed inside each latrine. The current “shaming” campaign will continue where solid waste fished out of the latrine is left on site for a few days for the whole camp to see.

Small is beautiful. We hope that this project demonstrates how small-scale decentralized FSM projects may be a viable alternative to truck based large community style programs. But it is still just a proposal. In the next couple of weeks, we will finalize our plan and then present it to the village leader and the WASH Working Group to see what they think. If they want to give it a try, we will likely begin sometime in May.

For more information or to get involved, just let us know. If you have any comments or ideas for improvement, please email or respond to this post. Thanks!

David M. Robbins

This email address is being protected from spambots. You need JavaScript enabled to view it.

This email address is being protected from spambots. You need JavaScript enabled to view it.

Attachments:

-

picb.jpg.png

(Filesize: 454KB)

picb.jpg.png

(Filesize: 454KB)

-

pic2.jpg

(Filesize: 49KB)

pic2.jpg

(Filesize: 49KB)

-

pic3.jpg

(Filesize: 96KB)

pic3.jpg

(Filesize: 96KB)

-

pic4.png

(Filesize: 600KB)

pic4.png

(Filesize: 600KB)

-

picb.jpg

(Filesize: 56KB)

picb.jpg

(Filesize: 56KB)

Please Log in to join the conversation.

You need to login to reply

Share this thread:

- Sanitation systems

- Faecal sludge management (FSM)

- Faecal sludge transport (including emptying of pits and septic tanks, transfer stations)

- The Excrevator, e-Vac, and Gulper for our project in Myanmar – and the answer is …

Recently active users. Who else has been active?

Time to create page: 0.380 seconds