- Resource recovery

- Vermitechnology

- Vermifilters for blackwater treatment, "worm toilets", "Tiger worm toilet"

- Re: Micro flush toilet training in Ethiopia

Re: Micro flush toilet training in Ethiopia

115k views

Re: Prototype Microflush-Biofil Toilet Facilities (Ghana Sustainable Aid Project, USA and Ghana)

I'm sympathetic to why GSAP wants to be there for face-to-face training when a toilet-maker receives the manual for the first time. I suspect GSAP is in "learn as you go" mode and is updating as you work in new cultures and in settings with new environmental challenges. What might need to be different for an open source manual to be possible? Thank you for all you are doing.

Diane M. Kellogg

Partner, Kellogg Consultants

Hope for Africa: Director Sanitation Projects

Project 16,000: Reusable Menstrual Products (pads and cups) for Ghana

Partner, Kellogg Consultants

Hope for Africa: Director Sanitation Projects

Project 16,000: Reusable Menstrual Products (pads and cups) for Ghana

The following user(s) like this post: Carol McCreary

Please Log in to join the conversation.

You need to login to replyRe: Prototype Microflush-Biofil Toilet Facilities (Ghana Sustainable Aid Project, USA and Ghana)

Thanks for this and several previous postings that have been very helpful, Dean. I'm sympathetic to why Dr. Mecca prefers to train people when he introduces them to the training manual. None of us would want people to fail at producing a good system because they downloaded it from the web and didn't really understand what they were doing or the science behind it. People could end up bad-mouthing a product and creating resistance to an excellent toilet.

Much better to get it out there and working properly in thousands of situations first, so neighbors end up educating, persuading and eventually training neighbors. Maybe open source could be possible eventually? Your idea of an open source, updatable, manual is really appealing. GSAP is creating a network of experienced toilet makers so might be in a position to collect expertise and wisdom that emerges.

Much better to get it out there and working properly in thousands of situations first, so neighbors end up educating, persuading and eventually training neighbors. Maybe open source could be possible eventually? Your idea of an open source, updatable, manual is really appealing. GSAP is creating a network of experienced toilet makers so might be in a position to collect expertise and wisdom that emerges.

Diane M. Kellogg

Partner, Kellogg Consultants

Hope for Africa: Director Sanitation Projects

Project 16,000: Reusable Menstrual Products (pads and cups) for Ghana

Partner, Kellogg Consultants

Hope for Africa: Director Sanitation Projects

Project 16,000: Reusable Menstrual Products (pads and cups) for Ghana

Please Log in to join the conversation.

You need to login to replyRe: The potential of subsurface infiltration for the treatment of vermibed effluents generated by the Biofil toilet. (UNESCO-IHE/KNUST, Kumasi, Ghana)

Dear Adane,

that was really an interesting work, i congratulate you dear for your hard work. i remember all your efforts.

that was really an interesting work, i congratulate you dear for your hard work. i remember all your efforts.

Lakachew Yihunie Alemneh

Water,Sanitation and Hygiene(WaSH)Specialist

Bahir Dar University-Institute of Technology.

Po.BOX 1322

Bahir Dar

Ethiopia

www.linkedin.com/pub/lakachew-yhunie/48/671/69/

Email- This email address is being protected from spambots. You need JavaScript enabled to view it.

Alt- email This email address is being protected from spambots. You need JavaScript enabled to view it.

Water,Sanitation and Hygiene(WaSH)Specialist

Bahir Dar University-Institute of Technology.

Po.BOX 1322

Bahir Dar

Ethiopia

www.linkedin.com/pub/lakachew-yhunie/48/671/69/

Email- This email address is being protected from spambots. You need JavaScript enabled to view it.

Alt- email This email address is being protected from spambots. You need JavaScript enabled to view it.

The following user(s) like this post: Carol McCreary, DianeKellogg, MirekuGh

Please Log in to join the conversation.

You need to login to reply- adanesew

-

Less

- Posts: 4

- Likes received: 7

Re: The potential of subsurface infiltration for the treatment of vermibed effluents generated by the Biofil toilet. (UNESCO-IHE/KNUST, Kumasi, Ghana)

As promissed in the 2013 post about the Biofil toilets, my work has already been published, you can download it here

Happy New Year

Happy New Year

Adane Sewhunegn Molla, Environmental Engineer(MSc)

Lecturer, Dept. of Public and Environmental Health

Hawassa University, College of Health Sciences

Hawassa, Ethiopia

This email address is being protected from spambots. You need JavaScript enabled to view it. OR

This email address is being protected from spambots. You need JavaScript enabled to view it.

Lecturer, Dept. of Public and Environmental Health

Hawassa University, College of Health Sciences

Hawassa, Ethiopia

This email address is being protected from spambots. You need JavaScript enabled to view it. OR

This email address is being protected from spambots. You need JavaScript enabled to view it.

This message has an attachment file.

Please log in or register to see it.

The following user(s) like this post: Carol McCreary, lakachewyihunie, DianeKellogg, MirekuGh

Please Log in to join the conversation.

You need to login to reply- former member

-

Less

- Posts: 101

- Likes received: 3

Re: Prototype Microflush-Biofil Toilet Facilities (Ghana Sustainable Aid Project, USA and Ghana)

Dean,

We have trained toilet GSAP Micorflush toilet MAKERs in 15 countries using the 80+ page fabrication guide, which is now set in both English and Spanish. The toilet is best made by a trained MAKER which is why we don't post the training guide on the net. Anyone wishing to be trained should contact me; basic masonry skills is all that is required. The program gives the trained MAKER an opportunity to have a small enterprise in her/his community while helping to solve the menacing condition of sanitation in the community.

Re: ground water infiltration to the filter-digester, we are very clear about placement of the system taking site water table conditions into account. We do this to be sure the digester cannot be flooded. For impossible situations, we have developed a filtrate processing system when ground water is at ground level (a swamp); the system is being tested in the field and we will be preparing instructional materials on this in the year ahead. I believe it will result in the first effectively closed toilet in the world, one that can even be installed on a swamp!

Re: deep testing of the filtrate that goes into a soak hole in normal installations, our lab is well along with doing deep DNA analysis of our products, a costly process that must be carefully carried out. We have months of work left on this after which we will publish the results. Please contact me if you are working in a community and wish to have a MAKER trained to properly fabricate the GSAP Microflush toilet.

Happy New Year.

++++++++

Note by moderators: This post was made by a former user with the login name smecca who is no longer a member of this discussion forum.

We have trained toilet GSAP Micorflush toilet MAKERs in 15 countries using the 80+ page fabrication guide, which is now set in both English and Spanish. The toilet is best made by a trained MAKER which is why we don't post the training guide on the net. Anyone wishing to be trained should contact me; basic masonry skills is all that is required. The program gives the trained MAKER an opportunity to have a small enterprise in her/his community while helping to solve the menacing condition of sanitation in the community.

Re: ground water infiltration to the filter-digester, we are very clear about placement of the system taking site water table conditions into account. We do this to be sure the digester cannot be flooded. For impossible situations, we have developed a filtrate processing system when ground water is at ground level (a swamp); the system is being tested in the field and we will be preparing instructional materials on this in the year ahead. I believe it will result in the first effectively closed toilet in the world, one that can even be installed on a swamp!

Re: deep testing of the filtrate that goes into a soak hole in normal installations, our lab is well along with doing deep DNA analysis of our products, a costly process that must be carefully carried out. We have months of work left on this after which we will publish the results. Please contact me if you are working in a community and wish to have a MAKER trained to properly fabricate the GSAP Microflush toilet.

Happy New Year.

++++++++

Note by moderators: This post was made by a former user with the login name smecca who is no longer a member of this discussion forum.

The following user(s) like this post: DianeKellogg

Please Log in to join the conversation.

You need to login to replyRe: Prototype Microflush-Biofil Toilet Facilities (Ghana Sustainable Aid Project, USA and Ghana)

The 2013 report Application of GSAP Microflush toilets: a sustainable development approach to rural and peri-urban sanitation can be downloaded

here

For those of you interested in Adane Molla's report which discusses subsurface infiltration of effluent from vermicomposting toilets, this can be downloaded here

I agree with Steve Mecca that the digested solids component (vermicast) needs to be tested for pathogens, if anybody knows about this being undertaken please post to the forum, as this "manure" would be very useful as fertiliser.

I'm wondering why I cannot yet find the plans for constructing the locally sourced and fabricated version of the GSAP microflush toilet. If these are not yet available perhaps this would explain why the "open-source" system has not gone "viral", meanwhile the aggregate filter manufactured system (Biofil) has grant-funded market consultants working hard on securing market share and expanding production.

However, its great to see the locally made version (onsite fabrication approach) of the microflush valve mechanism and the vermi-biofiltration system on youtube:

Microflush toilet

It needs to be kept in mind that the system shown here is an "outhouse type" where the low flush waste goes straight into the digester below. The low flush mechanism allows direct discharge of filtered liquid effluent to a gravel pit ("soak-away").

For a flush toilet to work inside a house the flush volume needs to be much greater so the waste travels down the pipe to exit at the digester effectively. Then, as Adane Moller points out, the liquid effluent needs a proper sub-surface infiltration system.

As Steve Mecca points out in his video presentation, the open source approach of putting it out there and letting it self improve, perhaps means the "manual" on how to fabricate the unit needs to be in an updatable form. Looking at the design in this video, I'd point out that by having the filtered liquid ("urinal pit") under ground and directly draining to the gravel pit, that if soil infiltration was not sufficient or the water table raised, the whole digester would start filling with water and kill the worms. Also, it appears that the "urinal pit" cannot be accessed easily and sediment buildup might become a problem over time.

Dean

For those of you interested in Adane Molla's report which discusses subsurface infiltration of effluent from vermicomposting toilets, this can be downloaded here

I agree with Steve Mecca that the digested solids component (vermicast) needs to be tested for pathogens, if anybody knows about this being undertaken please post to the forum, as this "manure" would be very useful as fertiliser.

I'm wondering why I cannot yet find the plans for constructing the locally sourced and fabricated version of the GSAP microflush toilet. If these are not yet available perhaps this would explain why the "open-source" system has not gone "viral", meanwhile the aggregate filter manufactured system (Biofil) has grant-funded market consultants working hard on securing market share and expanding production.

However, its great to see the locally made version (onsite fabrication approach) of the microflush valve mechanism and the vermi-biofiltration system on youtube:

Microflush toilet

It needs to be kept in mind that the system shown here is an "outhouse type" where the low flush waste goes straight into the digester below. The low flush mechanism allows direct discharge of filtered liquid effluent to a gravel pit ("soak-away").

For a flush toilet to work inside a house the flush volume needs to be much greater so the waste travels down the pipe to exit at the digester effectively. Then, as Adane Moller points out, the liquid effluent needs a proper sub-surface infiltration system.

As Steve Mecca points out in his video presentation, the open source approach of putting it out there and letting it self improve, perhaps means the "manual" on how to fabricate the unit needs to be in an updatable form. Looking at the design in this video, I'd point out that by having the filtered liquid ("urinal pit") under ground and directly draining to the gravel pit, that if soil infiltration was not sufficient or the water table raised, the whole digester would start filling with water and kill the worms. Also, it appears that the "urinal pit" cannot be accessed easily and sediment buildup might become a problem over time.

Dean

Dean Satchell, M For. Sc.

Vermifilter.com

www.vermifilter.com

Vermifilter.com

www.vermifilter.com

The following user(s) like this post: DianeKellogg

Please Log in to join the conversation.

You need to login to reply- former member

-

Less

- Posts: 101

- Likes received: 3

Re: Prototype Microflush-Biofil Toilet Facilities (Ghana Sustainable Aid Project, USA and Ghana)

[Start of Page 2 of the discussion]

Christian,

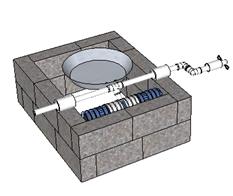

I need to clarify your post and one assertion in the video clip. The Biofil aggregate filter was 'invented' by Mr. Anno. However, the Microflush valve was developed at my lab, the S-Lab in the Department of Engineering-Physics-Systems. The two technologies were brought together and field tested as part of a Grand Challenges Explorations award from the Bill & Melinda Gates Foundation to the Ghana Sustainable Aid Project (GSAP). The Microflush technology was shared with Biofilcom, which was given the rights to use it in their toilets by me. The Biofil prototype toilets cost $1200 for a single stall and, while the price for these will likely fall a bit, they are not financially accessible to the rural poor. GSAP and my lab have been working on a low cost locally sourced and locally fabricated version of the technology and have successfully demonstrated a single stall GSAP Microflush toilet that is sold by the local Maker for ~ $300 US which makes it accessible to households in the lowest quintile of the household income spectrum. A few photos of a GSAP Microflush toilet are attached.

We are currently training what we call MAKERS in Ghana and around the world in the fabrication and installation of these toilets. Interested sanitation-missioned NGOs and organizations who wish to work with us in this effort should contact me at This email address is being protected from spambots. You need JavaScript enabled to view it.

..Steve Mecca

++++++++++++

Note by moderator: Further information about the GSAP microflush toilet is available here:

forum.susana.org/forum/categories/105-pr...king-steady-progress

++++++++

Note by moderators: This post was made by a former user with the login name smecca who is no longer a member of this discussion forum.

Christian,

I need to clarify your post and one assertion in the video clip. The Biofil aggregate filter was 'invented' by Mr. Anno. However, the Microflush valve was developed at my lab, the S-Lab in the Department of Engineering-Physics-Systems. The two technologies were brought together and field tested as part of a Grand Challenges Explorations award from the Bill & Melinda Gates Foundation to the Ghana Sustainable Aid Project (GSAP). The Microflush technology was shared with Biofilcom, which was given the rights to use it in their toilets by me. The Biofil prototype toilets cost $1200 for a single stall and, while the price for these will likely fall a bit, they are not financially accessible to the rural poor. GSAP and my lab have been working on a low cost locally sourced and locally fabricated version of the technology and have successfully demonstrated a single stall GSAP Microflush toilet that is sold by the local Maker for ~ $300 US which makes it accessible to households in the lowest quintile of the household income spectrum. A few photos of a GSAP Microflush toilet are attached.

We are currently training what we call MAKERS in Ghana and around the world in the fabrication and installation of these toilets. Interested sanitation-missioned NGOs and organizations who wish to work with us in this effort should contact me at This email address is being protected from spambots. You need JavaScript enabled to view it.

..Steve Mecca

++++++++++++

Note by moderator: Further information about the GSAP microflush toilet is available here:

forum.susana.org/forum/categories/105-pr...king-steady-progress

++++++++

Note by moderators: This post was made by a former user with the login name smecca who is no longer a member of this discussion forum.

Attachments:

-

DSC01329.JPG (Filesize: 49KB)

-

DSC01330.JPG (Filesize: 35KB)

-

DSC01331.JPG (Filesize: 30KB)

Please Log in to join the conversation.

You need to login to reply- christian.rieck

-

- Moderator

Less- Posts: 118

- Karma: 7

- Likes received: 41

Re: Prototype Microflush-Biofil Toilet Facilities (Ghana Sustainable Aid Project, USA and Ghana)

Dear all,

I just found a nice video which shows the micro flushing mechanism in action. It seems simple and easy to be handled. Great low-cost technology invented in Africa

Cheers

Christian

[End of Page 1 of the discussion]

I just found a nice video which shows the micro flushing mechanism in action. It seems simple and easy to be handled. Great low-cost technology invented in Africa

Cheers

Christian

[End of Page 1 of the discussion]

GIZ Uganda

Enhanced Water Security and Sanitation (ENWASS)

Sanitation for Millions

This email address is being protected from spambots. You need JavaScript enabled to view it.

Enhanced Water Security and Sanitation (ENWASS)

Sanitation for Millions

This email address is being protected from spambots. You need JavaScript enabled to view it.

The following user(s) like this post: HAPitot

Please Log in to join the conversation.

You need to login to reply- former member

-

Less

- Posts: 101

- Likes received: 3

Re: The potential of subsurface infiltration for the treatment of vermibed effluents generated by the Biofil toilet. (UNESCO-IHE/KNUST, Kumasi, Ghana)

We are delighted that you have undertaken this study and look forward to the full report. The S-Lab at Providence College in the US has been studying several options for blackwater treatment from our digester. We expect publishable results in the first quarter of 2014; I will keep you posted on this.

..Steve Mecca

++++++++

Note by moderators: This post was made by a former user with the login name smecca who is no longer a member of this discussion forum.

..Steve Mecca

++++++++

Note by moderators: This post was made by a former user with the login name smecca who is no longer a member of this discussion forum.

The following user(s) like this post: adanesew

Please Log in to join the conversation.

You need to login to reply- adanesew

-

Less

- Posts: 4

- Likes received: 7

Re: The potential of subsurface infiltration for the treatment of vermibed effluents generated by the Biofil toilet. (UNESCO-IHE/KNUST, Kumasi, Ghana)

Dear SuSanA Community

In an effort to promote sustainable sanitation for the developing world, and as a requirement for my MSc thesis for the 2011/13 double degree MSc programme in Sanitary Engineering by UNESCO-IHE and KNUST, Kumasi, A study has been done on the full flush Biofil Toilet in Ghana. Biofil toilet has two versions, the microflush system in this topic by the Ghana Sustainable aid project which uses very little water and the Full flush system. In my study the full flush system has been considered to look for its environmental impact of the infiltrating wastewater to the underground system. This is therefore to share you our experience and to initiate discussion for further improvement and promotion of the technology in the future.

The full report will soon be made available. We highly acknowledge any valuable comments, suggestions, discussions and recommendations that can be forwarded.

Thanks for your attention

In an effort to promote sustainable sanitation for the developing world, and as a requirement for my MSc thesis for the 2011/13 double degree MSc programme in Sanitary Engineering by UNESCO-IHE and KNUST, Kumasi, A study has been done on the full flush Biofil Toilet in Ghana. Biofil toilet has two versions, the microflush system in this topic by the Ghana Sustainable aid project which uses very little water and the Full flush system. In my study the full flush system has been considered to look for its environmental impact of the infiltrating wastewater to the underground system. This is therefore to share you our experience and to initiate discussion for further improvement and promotion of the technology in the future.

This attachment is hidden for guests.

Please log in or register to see it.

Please log in or register to see it.

The full report will soon be made available. We highly acknowledge any valuable comments, suggestions, discussions and recommendations that can be forwarded.

Thanks for your attention

Adane Sewhunegn Molla, Environmental Engineer(MSc)

Lecturer, Dept. of Public and Environmental Health

Hawassa University, College of Health Sciences

Hawassa, Ethiopia

This email address is being protected from spambots. You need JavaScript enabled to view it. OR

This email address is being protected from spambots. You need JavaScript enabled to view it.

Lecturer, Dept. of Public and Environmental Health

Hawassa University, College of Health Sciences

Hawassa, Ethiopia

This email address is being protected from spambots. You need JavaScript enabled to view it. OR

This email address is being protected from spambots. You need JavaScript enabled to view it.

This message has an attachment file.

Please log in or register to see it.

The following user(s) like this post: bipin, ayele

Please Log in to join the conversation.

You need to login to reply- Elisabeth

-

- User is blocked

- Freelance consultant since 2012

Less- Posts: 3372

- Karma: 54

- Likes received: 932

Re: Prototype Microflush-Biofil Toilet Facilities (Ghana Sustainable Aid Project, USA and Ghana)

I recieved the following information and photos from Steve about his project by e-mail:

+++++++++++++++

Attached are photos of: one of our Makers just finishing a new toilet for a user last month, the owner (a woman) and the bowl before it was cleaned, another photo of an owner (a man) and the Microflush toilet from 3 years ago.

I don't have any photos of "maintenance", e.g. fixing a broken valve or handle or door as we haven't observed much of this; maintenance for us is the 2-3 year need to harvest compost and restart the system and, no, this is not harder than construction. I think you are focused on the traditional pit latrine and the ritual of sludge removal. Yes, our makers are being trained to do the 2 year harvesting and restarting and they will be paid by users for the service. They remove a couple of wheelbarrows of useful compost; in the factory-made versions, the charge has been ~ 30-40 GHC ($20) but it occurs every 2 - 3 years.

+++++++++++

He has mentioned in one of his posts above that about 1000 factory-made toilets have been installed in Ghana (this is separate to his project). I asked him which company is behind that, and he told me they are called:

Biofilcom (www.biofilcom.org/)

This is a Ghanaian company, who are serving more the high-end market in Ghana, whereas Steve's project is targeting the low-income housholds.

+++++++++++++++

Attached are photos of: one of our Makers just finishing a new toilet for a user last month, the owner (a woman) and the bowl before it was cleaned, another photo of an owner (a man) and the Microflush toilet from 3 years ago.

I don't have any photos of "maintenance", e.g. fixing a broken valve or handle or door as we haven't observed much of this; maintenance for us is the 2-3 year need to harvest compost and restart the system and, no, this is not harder than construction. I think you are focused on the traditional pit latrine and the ritual of sludge removal. Yes, our makers are being trained to do the 2 year harvesting and restarting and they will be paid by users for the service. They remove a couple of wheelbarrows of useful compost; in the factory-made versions, the charge has been ~ 30-40 GHC ($20) but it occurs every 2 - 3 years.

+++++++++++

He has mentioned in one of his posts above that about 1000 factory-made toilets have been installed in Ghana (this is separate to his project). I asked him which company is behind that, and he told me they are called:

Biofilcom (www.biofilcom.org/)

This is a Ghanaian company, who are serving more the high-end market in Ghana, whereas Steve's project is targeting the low-income housholds.

Dr. Elisabeth von Muench

Freelance consultant on environmental and climate projects

Freelance consultant on environmental and climate projects

Attachments:

-

P5110171.JPG (Filesize: 17KB)

-

P5110172.JPG (Filesize: 28KB)

-

20130616_125155.jpg

(Filesize: 65KB)

20130616_125155.jpg

(Filesize: 65KB)

-

20130616_124023.jpg

(Filesize: 61KB)

20130616_124023.jpg

(Filesize: 61KB)

-

20130616_122508.jpg

(Filesize: 25KB)

20130616_122508.jpg

(Filesize: 25KB)

Please Log in to join the conversation.

You need to login to reply- former member

-

Less

- Posts: 101

- Likes received: 3

Re: Prototype Microflush-Biofil Toilet Facilities (Ghana Sustainable Aid Project, USA and Ghana)

The locally sourced and fabricated version is a fairly simple pan valve held in place by gravity through a counterbalance made from used water bottles. A sketch of the valve in a part of the user interface is below. We are producing an the 2nd version of an elaborate training guide for building our locally sourced and fabricated GSAP Microflush toilets. We use this for training our toilet Makers. If you have potential local community tradesmen that are interested in our training program, let me know.

..Steve

++++++++

Note by moderators: This post was made by a former user with the login name smecca who is no longer a member of this discussion forum.

..Steve

++++++++

Note by moderators: This post was made by a former user with the login name smecca who is no longer a member of this discussion forum.

Attachments:

-

Clipboard0...8-15.jpg

(Filesize: 7KB)

Clipboard0...8-15.jpg

(Filesize: 7KB)

The following user(s) like this post: christian.rieck

Please Log in to join the conversation.

You need to login to reply

Share this thread:

- Resource recovery

- Vermitechnology

- Vermifilters for blackwater treatment, "worm toilets", "Tiger worm toilet"

- Re: Micro flush toilet training in Ethiopia

Recently active users. Who else has been active?

Time to create page: 0.384 seconds