- Sanitation systems

- Faecal sludge management (FSM)

- Faecal sludge treatment technologies

- Biogenic Refinery Demonstrations in India for treatment of faecal sludge

Biogenic Refinery Demonstrations in India for treatment of faecal sludge

4344 views

- Elisabeth

-

- User is blocked

- Freelance consultant since 2012

Less- Posts: 3372

- Karma: 54

- Likes received: 932

Re: Biogenic Refinery Demonstrations in India for treatment of faecal sludge

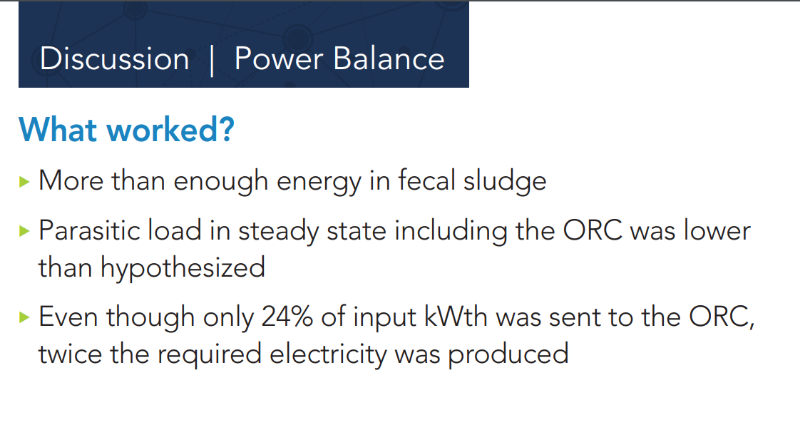

If you are interested to learn more about the Biogenic Refinery (BR) technology that Stuart introduced in this thread then you'll enjoy reading this presentation from the

FSM5 Conference

in February 2019:

Demonstrating Pathogen-Free Thermal Treatment Solutions Towards ISO/PC 318 Energy Neutrality Requirements

by Edgard Ngaboyamahina, August Frechette, Taylor Myers, Lars Schoebitz

fsm5.susana.org/images/FSM_Conference_Ma...19_final-version.pdf

The presentation looked at the consumption and production of thermal and electrical power during the treatment of fecal sludge (although wood pellets were used in this research: Run with wood pellets equivalent to fecal sludge energy).

I think (but am not totally sure) that ORC stands for Organic Rankine Cycle (en.wikipedia.org/wiki/Organic_Rankine_cycle)

Regards,

Elisabeth

Demonstrating Pathogen-Free Thermal Treatment Solutions Towards ISO/PC 318 Energy Neutrality Requirements

by Edgard Ngaboyamahina, August Frechette, Taylor Myers, Lars Schoebitz

fsm5.susana.org/images/FSM_Conference_Ma...19_final-version.pdf

The presentation looked at the consumption and production of thermal and electrical power during the treatment of fecal sludge (although wood pellets were used in this research: Run with wood pellets equivalent to fecal sludge energy).

I think (but am not totally sure) that ORC stands for Organic Rankine Cycle (en.wikipedia.org/wiki/Organic_Rankine_cycle)

Regards,

Elisabeth

Dr. Elisabeth von Muench

Freelance consultant on environmental and climate projects

Freelance consultant on environmental and climate projects

Attachments:

-

biogenicrefinery.png

(Filesize: 120KB)

biogenicrefinery.png

(Filesize: 120KB)

Please Log in to join the conversation.

You need to login to reply- Elisabeth

-

- User is blocked

- Freelance consultant since 2012

Less- Posts: 3372

- Karma: 54

- Likes received: 932

Re: Biogenic Refinery Demonstrations in India for treatment of faecal sludge

Dear Stuart,

I have now moved the information about your process to this separate thread, like we discussed. With the new thread title, it might also generate more interest by others to learn about your process.

One thing that is not clear to me yet: Is this a subidized operation (paid for by money from the Bill & Melinda Gates Foundation) or is this process already able to stand on its own feet financially? Are there clients willing to pay for this kind of faecal sludge treatment process yet? I think that's the hard part as you are competing with the "do nothing" solution or the "dump it somewhere" solution, so it's hard to find water utilities willing to pay for it. If yes, who are your clients exactly?

I think this was one of the problems that stopped the LaDePa process for faecal sludge treatment from getting off the ground properly. (see: forum.susana.org/forum/categories/280-fa...-in-ethekwini-durban)

Regards,

Elisabeth

I have now moved the information about your process to this separate thread, like we discussed. With the new thread title, it might also generate more interest by others to learn about your process.

One thing that is not clear to me yet: Is this a subidized operation (paid for by money from the Bill & Melinda Gates Foundation) or is this process already able to stand on its own feet financially? Are there clients willing to pay for this kind of faecal sludge treatment process yet? I think that's the hard part as you are competing with the "do nothing" solution or the "dump it somewhere" solution, so it's hard to find water utilities willing to pay for it. If yes, who are your clients exactly?

I think this was one of the problems that stopped the LaDePa process for faecal sludge treatment from getting off the ground properly. (see: forum.susana.org/forum/categories/280-fa...-in-ethekwini-durban)

Regards,

Elisabeth

Dr. Elisabeth von Muench

Freelance consultant on environmental and climate projects

Freelance consultant on environmental and climate projects

Please Log in to join the conversation.

You need to login to replyRe: Biogenic Refinery Demonstrations in India for treatment of faecal sludge

Dear Pawan,

Thanks for your message! I hope you don't mind if I break up the message to reply to the different questions individually.

Is your FSTP in Warangal and Bangalore is in operational stage or at planning stage?

The FSTP is in operation at 3 of the 4 sites mentioned. The Biogenic Refinery (the thermal treatment component) has 2000+ hours on it at the oldest site.

Your attachment does not mention any functional detail of the system.

Apologies; the attachment was merely meant to serve as a quick overview of the project and a conversation starter. What specific functional details would you be interested in?

Kindly elaborate information on CAPEX , OPEX, land requirement, volume of septage treated daily, system of collection and transportation of septage to the site.

CAPEX & OPEX: We're trying to make CAPEX and OPEX easier to manage for clients by transitioning towards leasing models, where the CAPEX, OPEX, and operational support services can be bundled into a monthly payment. As mentioned to Elisabeth in a new post, a solution on this scale would cost $ 5 000 per month over 10 years, for 10 000 users (INR 1.12 per user per day). We provide modular solutions, so that we can provide tailored solutions through combinations of different modules for processes such as dewatering, drying, thermal treatment, emissions treatment and electrical energy generation. The exact pricing will obviously depend on the combination of modules used for a specific solution and the level of service selected, but I hope that ballpark figure gives you an idea of the costs.

Land Requirement: Our pyrolyser and dryer can fit into a 20 foot container. The land requirement for the treatment process itself is therefore quite small, but the land requirements of the final site will depend on the delivery method of the sludge, the scale of the operation, and any additional pre-processing requirements dependent on the type of sludge.

Volume of septage treated daily: Approximately 15 000 litres of septage per day.

Septage Collection and Transportation: These sites receive the septage from septage tankers/trucks. A receiving station and holding tank has been included in these sites.

You are using pyrolysis technology only to convert dried / semi dried sludge (after planted filter beds) into ashes at high temperature- above 5000C. Quantity of such ashes should be around 10% only.

For these specific sites, we are dewatering the sludge, drying sludge with thermal energy from the pyrolysis unit, and then pyrolysing the dried sludge at around 650°C. The planted beds remediate the dewatered component after pasteurization (again, using thermal energy). The pyrolyzer can process organic matter at 65% solids (35% moisture) directly, and the thermal energy is enough to dry sludge from 15-20% solids (80-85% moisture) to the required 65% solids.

We limit the amount of oxygen to the process and operate below 900°C, so we produce biochar rather than ash, with a volume reduction of approximately 85% on a dry basis, and 88% - 95% mass reduction on a dry basis.

Requirement of electricity to maintain the system should be very high.

Fortunately not! The Biogenic Refinery uses only 350 Watts at steady-state, including sensors and remote monitoring and operations. Mechanical dewatering and pumping in pre-treatment processes may also require energy, but overall it has been designed to be a very energy-efficient operation.

It appears too difficult to make the system sustainable for a state / country where government is struggling to provide electricity for domestic purpose.

We are also currently testing a module for energy generation from excess thermal energy, and aim to use this energy to power the pyrolysis and dewatering process. The implication is that we would then be able to deliver an off-grid solution that requires no input electrical energy, but this is not being used on these sites yet. This is difficult, but we seem to be getting to a point where technology is now advanced enough for us to start developing these solutions.

I am failing to understand that you are using pyrolysis only to make sludge pathogen / bacteria free and converting it into ashes. Such ashes don’t have plant nutrient value and thus can’t be used for agriculture purpose.

The sites use the pyrolysis unit to pasteurize effluent, and thermally decompose the dried sludge into biochar. We have had several analyses done on the output product, and we can see that we are producing biochar, rather than ash. Biochar has many reuse applications, and I have attached a white paper on biochar reuse that we wrote, should you be interested in more information.

Further, there are chances of obnoxious gases produced from the system that can cause environmental pollution.

Quite correct! Our background is in emissions controls, and most of the development of the Biogenic Refinery is related to emissions controls, particularly through automated software controls and catalysts. We've set this up to be automated and not require skilled staff to ensure our emissions are controlled, to make sure we're compliant with environmental standards, even in remote locations.

I realise that the previously attached flyer was brief and contained no technical information, but I hope these answers have started to fill in that gap. Please let me know if you have any fallow up questions!

Thanks for your message! I hope you don't mind if I break up the message to reply to the different questions individually.

Is your FSTP in Warangal and Bangalore is in operational stage or at planning stage?

The FSTP is in operation at 3 of the 4 sites mentioned. The Biogenic Refinery (the thermal treatment component) has 2000+ hours on it at the oldest site.

Your attachment does not mention any functional detail of the system.

Apologies; the attachment was merely meant to serve as a quick overview of the project and a conversation starter. What specific functional details would you be interested in?

Kindly elaborate information on CAPEX , OPEX, land requirement, volume of septage treated daily, system of collection and transportation of septage to the site.

CAPEX & OPEX: We're trying to make CAPEX and OPEX easier to manage for clients by transitioning towards leasing models, where the CAPEX, OPEX, and operational support services can be bundled into a monthly payment. As mentioned to Elisabeth in a new post, a solution on this scale would cost $ 5 000 per month over 10 years, for 10 000 users (INR 1.12 per user per day). We provide modular solutions, so that we can provide tailored solutions through combinations of different modules for processes such as dewatering, drying, thermal treatment, emissions treatment and electrical energy generation. The exact pricing will obviously depend on the combination of modules used for a specific solution and the level of service selected, but I hope that ballpark figure gives you an idea of the costs.

Land Requirement: Our pyrolyser and dryer can fit into a 20 foot container. The land requirement for the treatment process itself is therefore quite small, but the land requirements of the final site will depend on the delivery method of the sludge, the scale of the operation, and any additional pre-processing requirements dependent on the type of sludge.

Volume of septage treated daily: Approximately 15 000 litres of septage per day.

Septage Collection and Transportation: These sites receive the septage from septage tankers/trucks. A receiving station and holding tank has been included in these sites.

You are using pyrolysis technology only to convert dried / semi dried sludge (after planted filter beds) into ashes at high temperature- above 5000C. Quantity of such ashes should be around 10% only.

For these specific sites, we are dewatering the sludge, drying sludge with thermal energy from the pyrolysis unit, and then pyrolysing the dried sludge at around 650°C. The planted beds remediate the dewatered component after pasteurization (again, using thermal energy). The pyrolyzer can process organic matter at 65% solids (35% moisture) directly, and the thermal energy is enough to dry sludge from 15-20% solids (80-85% moisture) to the required 65% solids.

We limit the amount of oxygen to the process and operate below 900°C, so we produce biochar rather than ash, with a volume reduction of approximately 85% on a dry basis, and 88% - 95% mass reduction on a dry basis.

Requirement of electricity to maintain the system should be very high.

Fortunately not! The Biogenic Refinery uses only 350 Watts at steady-state, including sensors and remote monitoring and operations. Mechanical dewatering and pumping in pre-treatment processes may also require energy, but overall it has been designed to be a very energy-efficient operation.

It appears too difficult to make the system sustainable for a state / country where government is struggling to provide electricity for domestic purpose.

We are also currently testing a module for energy generation from excess thermal energy, and aim to use this energy to power the pyrolysis and dewatering process. The implication is that we would then be able to deliver an off-grid solution that requires no input electrical energy, but this is not being used on these sites yet. This is difficult, but we seem to be getting to a point where technology is now advanced enough for us to start developing these solutions.

I am failing to understand that you are using pyrolysis only to make sludge pathogen / bacteria free and converting it into ashes. Such ashes don’t have plant nutrient value and thus can’t be used for agriculture purpose.

The sites use the pyrolysis unit to pasteurize effluent, and thermally decompose the dried sludge into biochar. We have had several analyses done on the output product, and we can see that we are producing biochar, rather than ash. Biochar has many reuse applications, and I have attached a white paper on biochar reuse that we wrote, should you be interested in more information.

Further, there are chances of obnoxious gases produced from the system that can cause environmental pollution.

Quite correct! Our background is in emissions controls, and most of the development of the Biogenic Refinery is related to emissions controls, particularly through automated software controls and catalysts. We've set this up to be automated and not require skilled staff to ensure our emissions are controlled, to make sure we're compliant with environmental standards, even in remote locations.

I realise that the previously attached flyer was brief and contained no technical information, but I hope these answers have started to fill in that gap. Please let me know if you have any fallow up questions!

Stuart Woolley

This message has attachments files.

Please log in or register to see it.

Please Log in to join the conversation.

You need to login to reply

Hi Elisabeth,

Sure, we can start a page on the technology itself if you think it would be a useful post on the forums.

The specific project you've referenced is the Gates Foundation project with Tide Technocrats. Tide are operating several FSSTPs (Faecal Sludge / Septage Treatment Plants) in several areas. This is a Tide Technocrats operation and the Biomass Controls Biogenic Refinery is simply a component of their project and solution. The FSSTPs were designed by Tide Technocrats and treat septage.

The attached leaflet is a high-level information brief on the ongoing project, to get the conversation going. Regarding costing information:

To replicate a similar project we would suggest a leasing model around $ 5000 per month over 10 years, for 10 000 users (this is less than $ 0.02 per user per day). We provide modular solutions, so that we can provide tailored solutions through combinations of different modules for processes such as dewatering, drying, thermal treatment, emissions treatment and electrical energy generation. The exact pricing will obviously depend on the combination of modules used for a specific solution and the level of service selected, but I hope that ballpark figure gives you an idea of the costs.

Sure, we can start a page on the technology itself if you think it would be a useful post on the forums.

The specific project you've referenced is the Gates Foundation project with Tide Technocrats. Tide are operating several FSSTPs (Faecal Sludge / Septage Treatment Plants) in several areas. This is a Tide Technocrats operation and the Biomass Controls Biogenic Refinery is simply a component of their project and solution. The FSSTPs were designed by Tide Technocrats and treat septage.

The attached leaflet is a high-level information brief on the ongoing project, to get the conversation going. Regarding costing information:

To replicate a similar project we would suggest a leasing model around $ 5000 per month over 10 years, for 10 000 users (this is less than $ 0.02 per user per day). We provide modular solutions, so that we can provide tailored solutions through combinations of different modules for processes such as dewatering, drying, thermal treatment, emissions treatment and electrical energy generation. The exact pricing will obviously depend on the combination of modules used for a specific solution and the level of service selected, but I hope that ballpark figure gives you an idea of the costs.

Stuart Woolley

Please Log in to join the conversation.

You need to login to reply

Dear Stuart

Is your FSTP in Warangal and Bangalore is in operational stage or at planning stage? Your attachment does not mention any functional detail of the system. Kindly elaborate information on CAPEX , OPEX, land requirement, volume of septage treated daily, system of collection and transportation of septage to the site.

You are using pyrolysis technology only to convert dried / semi dried sludge (after planted filter beds) into ashes at high temperature- above 5000C. Quantity of such ashes should be around 10% only. Requirement of electricity to maintain the system should be very high. For treatment of effluent you will be using conventional system, as specific / any innovative technology is not mentioned in your brochure. I am failing to understand that you are using pyrolysis only to make sludge pathogen / bacteria free and converting it into ashes. Such ashes don’t have plant nutrient value and thus can’t be used for agriculture purpose. There are low cost options to make sludge pathogen free and that can be safely reused for agricultural purposes. Where you are disposing / using such ashes? Further, there are chances of obnoxious gases produced from the system that can cause environmental pollution. It appears too difficult to make the system sustainable for a state / country where government is struggling to provide electricity for domestic purpose.

Best

Pawan

Is your FSTP in Warangal and Bangalore is in operational stage or at planning stage? Your attachment does not mention any functional detail of the system. Kindly elaborate information on CAPEX , OPEX, land requirement, volume of septage treated daily, system of collection and transportation of septage to the site.

You are using pyrolysis technology only to convert dried / semi dried sludge (after planted filter beds) into ashes at high temperature- above 5000C. Quantity of such ashes should be around 10% only. Requirement of electricity to maintain the system should be very high. For treatment of effluent you will be using conventional system, as specific / any innovative technology is not mentioned in your brochure. I am failing to understand that you are using pyrolysis only to make sludge pathogen / bacteria free and converting it into ashes. Such ashes don’t have plant nutrient value and thus can’t be used for agriculture purpose. There are low cost options to make sludge pathogen free and that can be safely reused for agricultural purposes. Where you are disposing / using such ashes? Further, there are chances of obnoxious gases produced from the system that can cause environmental pollution. It appears too difficult to make the system sustainable for a state / country where government is struggling to provide electricity for domestic purpose.

Best

Pawan

Pawan Jha

Chairman

Foundation for Environment and Sanitation

Mahavir Enclave

New Delhi 110045, India

Web: www.foundation4es.org

Linked: linkedin.com/in/drpkjha

Chairman

Foundation for Environment and Sanitation

Mahavir Enclave

New Delhi 110045, India

Web: www.foundation4es.org

Linked: linkedin.com/in/drpkjha

Please Log in to join the conversation.

You need to login to reply- Elisabeth

-

- User is blocked

- Freelance consultant since 2012

Less- Posts: 3372

- Karma: 54

- Likes received: 932

Re: FSM in Extreme Hilly Area with Winter Conditions

Dear Stuart,

Very interesting information that you posted here. I suggest we start a new thread about your product so that it doesn't get lost & overlooked in this thread. OK?

I didn't understand this part (the first sentence):

Also you didn't say anything about the costs?

Is this funded by the Gates Foundation? It is probably part of this project, right?:

Small Pyrolysis Unit Product Development and Commercialization Planning

2016 - 2018 • Tide Technocrats Private Limited

www.susana.org/en/knowledge-hub/projects/database/details/395

Would love to hear more about this.

Regards,

Elisabeth

Very interesting information that you posted here. I suggest we start a new thread about your product so that it doesn't get lost & overlooked in this thread. OK?

I didn't understand this part (the first sentence):

Septage from local communities is delivered to the FSSTP, conceptualized, developed, and operated by Tide

Technocrats. The Biomass Controls Biogenic Refinery provides the final treatment of the sludge in the FSSTP.

Also you didn't say anything about the costs?

Is this funded by the Gates Foundation? It is probably part of this project, right?:

Small Pyrolysis Unit Product Development and Commercialization Planning

2016 - 2018 • Tide Technocrats Private Limited

www.susana.org/en/knowledge-hub/projects/database/details/395

Would love to hear more about this.

Regards,

Elisabeth

Dr. Elisabeth von Muench

Freelance consultant on environmental and climate projects

Freelance consultant on environmental and climate projects

Please Log in to join the conversation.

You need to login to replyBiogenic Refinery Demonstrations in India for treatment of faecal sludge

Dear Bharat, *

I work at Biomass Controls , who currently produces a Biogenic Refinery, for the off-site treatment of organic materials and faecal matter. Briefly looking at the information you've provided, it ticks some of the boxes that you've mentioned:

- It's a thermal treatment process, so we're capable of serving as a cold climate solution. We have a cold climate demonstration in Alaska where we've seen temperatures of -40°C.

- It's a small footprint operation (the refinery is housed in a 20' shipping container), so it would be appropriate for mountainous regions where space is limited due to the terrain or currently existing infrastructure.

- The 'users served' in terms of sanitation service delivery is highly dependent on the type of sludge used, but we're in the range of 10 000 people per day.

The Refinery is currently in operation at Tide Technocrats sites in Wai, Bangalore, Narsapur and Waranagal, and a visit can be arranged if you're interested in visiting an active site. These sites each treat 15 000+ litres of septage per day. A small brief on this is attached here.

Please let me know if you're interested in more information!

Elisabeth and Esther are admin/moderators on the forums here, and may be able to point you in the direction of other solutions too!

Many Thanks,

Stuart

* Note by moderator: this post was originally in this thread: forum.susana.org/53-faecal-sludge-manage...hal-pradesh-in-india

"FSM in Extreme Hilly Area with Winter Conditions - City Sanitation Plan for Northeastern state of Arunachal Pradesh in India"

I work at Biomass Controls , who currently produces a Biogenic Refinery, for the off-site treatment of organic materials and faecal matter. Briefly looking at the information you've provided, it ticks some of the boxes that you've mentioned:

- It's a thermal treatment process, so we're capable of serving as a cold climate solution. We have a cold climate demonstration in Alaska where we've seen temperatures of -40°C.

- It's a small footprint operation (the refinery is housed in a 20' shipping container), so it would be appropriate for mountainous regions where space is limited due to the terrain or currently existing infrastructure.

- The 'users served' in terms of sanitation service delivery is highly dependent on the type of sludge used, but we're in the range of 10 000 people per day.

The Refinery is currently in operation at Tide Technocrats sites in Wai, Bangalore, Narsapur and Waranagal, and a visit can be arranged if you're interested in visiting an active site. These sites each treat 15 000+ litres of septage per day. A small brief on this is attached here.

Please let me know if you're interested in more information!

Elisabeth and Esther are admin/moderators on the forums here, and may be able to point you in the direction of other solutions too!

Many Thanks,

Stuart

* Note by moderator: this post was originally in this thread: forum.susana.org/53-faecal-sludge-manage...hal-pradesh-in-india

"FSM in Extreme Hilly Area with Winter Conditions - City Sanitation Plan for Northeastern state of Arunachal Pradesh in India"

Stuart Woolley

This message has an attachment file.

Please log in or register to see it.

Please Log in to join the conversation.

You need to login to reply

Share this thread:

- Sanitation systems

- Faecal sludge management (FSM)

- Faecal sludge treatment technologies

- Biogenic Refinery Demonstrations in India for treatment of faecal sludge

Recently active users. Who else has been active?

Time to create page: 0.369 seconds