- Sanitation systems

- Faecal sludge management (FSM)

- Pit or vault content research, accumulation rates and faecal sludge characteristics

- Measuring the physical strength of faecal sludge/pit latrine contents

Measuring the physical strength of faecal sludge/pit latrine contents

9526 views

- Elisabeth

-

- User is blocked

- Freelance consultant since 2012

Less- Posts: 3372

- Karma: 54

- Likes received: 932

Re: Measuring the physical strength of faecal sludge/pit latrine contents

Jamie, could you perhaps post some photos to show the penetrometer in action on a pit latrine?

I only found this photo in your presentation from last year, but am not sure if it is representative?

I found it in this presentation:

www.susana.org/docs_ccbk/susana_download...rfaeca---lsludge.pdf

I only found this photo in your presentation from last year, but am not sure if it is representative?

I found it in this presentation:

www.susana.org/docs_ccbk/susana_download...rfaeca---lsludge.pdf

Dr. Elisabeth von Muench

Freelance consultant on environmental and climate projects

Freelance consultant on environmental and climate projects

Attachments:

-

photoofpen...tion.png

(Filesize: 199KB)

photoofpen...tion.png

(Filesize: 199KB)

Please Log in to join the conversation.

You need to login to reply- RadfordJT

-

Topic Author

Topic Author- Civil engineer with a particular interest in sanitation and faecal sludge management.

Less- Posts: 10

- Karma: 3

- Likes received: 8

Re: Measuring the physical strength of faecal sludge/pit latrine contents

For latrines directly over the pit it is quite straightforward - the penetrometer shaft goes down through the squat hole from within the toilet building. For pour-flush systems with an offset pit you would need to remove part of the cover over the pit to gain access.

Please Log in to join the conversation.

You need to login to reply- wambuak

-

Less

- Posts: 16

- Likes received: 2

Re: Measuring the physical strength of faecal sludge/pit latrine contents

Measuring the physical strength of human sludge is quiet a novel idea. But I am wondering how one gets to insert a penetrometer into a pit latrine!

James Wambua Kaluli

JKUAT

Kenya

JKUAT

Kenya

Please Log in to join the conversation.

You need to login to reply- RadfordJT

-

Topic Author

Topic Author- Civil engineer with a particular interest in sanitation and faecal sludge management.

Less- Posts: 10

- Karma: 3

- Likes received: 8

Re: Measuring the physical strength of faecal sludge/pit latrine contents

Strength has a strong influence on "pumpability" although debris does complicate matters. The sludge can either flow around/through the debris or suspend the debris and move that through the sludge - whichever happens will depend on what offers the least resistance and is controlled by size, shape and weight of the debris, and strength of the sludge. This is equally true of a ball pushing down through the sludge, or some form of pressure gradient causing the sludge to flow during emptying. Although the exact impact of debris won't be the same on the penetrometer and on "pumpability" they should be correlated, so a high strength will be harder to pump.

Perhaps the biggest issue is not around strength (which we can now measure), but tangling or binding of moving mechanical parts - particularly by long, stringy debris like hair, rope, wire and rags. Although they may not have much of an impact on strength, they often prove most challenging and are one of the most common reasons for promising new technologies that have been developed on some kind of simulant for "pure" sludge failing on real latrines.

To try and address this we've developed a simulant (see: forum.susana.org/forum/categories/99-fae...mit=12&start=24#8326) that contains these materials for early-stage technology testing, more details to follow soon.

We're also working on a pump benchmarking exercise (see: forum.susana.org/forum/categories/99-fae...l-companies-usa#8364) to measure the performance of different technologies on simulants with and without solid waste/debris which should provide more clarity on how different types of pumps perform and therefore which are best suited to latrines in different areas.

The foreign objects we use are based on average data from UKZN PRG's Mechanical Properties of FS study where samples were manually sorted and debris classified. We're including things like bottles and stones but no large, unusual items found where pits are used for solid waste disposal.

Perhaps the biggest issue is not around strength (which we can now measure), but tangling or binding of moving mechanical parts - particularly by long, stringy debris like hair, rope, wire and rags. Although they may not have much of an impact on strength, they often prove most challenging and are one of the most common reasons for promising new technologies that have been developed on some kind of simulant for "pure" sludge failing on real latrines.

To try and address this we've developed a simulant (see: forum.susana.org/forum/categories/99-fae...mit=12&start=24#8326) that contains these materials for early-stage technology testing, more details to follow soon.

We're also working on a pump benchmarking exercise (see: forum.susana.org/forum/categories/99-fae...l-companies-usa#8364) to measure the performance of different technologies on simulants with and without solid waste/debris which should provide more clarity on how different types of pumps perform and therefore which are best suited to latrines in different areas.

The foreign objects we use are based on average data from UKZN PRG's Mechanical Properties of FS study where samples were manually sorted and debris classified. We're including things like bottles and stones but no large, unusual items found where pits are used for solid waste disposal.

Please Log in to join the conversation.

You need to login to reply- joeturner

-

Less

Less- Posts: 717

- Karma: 23

- Likes received: 185

Re: Measuring the physical strength of faecal sludge/pit latrine contents

Ah-ha, that's very interesting, thanks for the information.

One further thought though - what is the relation between the strength of the sludge and the difficulty (or otherwise) of extracting it from a latrine? In your example above, the ball might move apart hair fairly easily in the penetrometer experiment, but (perhaps) restrict the movement of the sludge.

Also, presumably, there is a limit to the size of foreign objects in your lab experiment, is there a good understanding of how the size and shape of objects in the latrine affect the strength of the sludge?

One further thought though - what is the relation between the strength of the sludge and the difficulty (or otherwise) of extracting it from a latrine? In your example above, the ball might move apart hair fairly easily in the penetrometer experiment, but (perhaps) restrict the movement of the sludge.

Also, presumably, there is a limit to the size of foreign objects in your lab experiment, is there a good understanding of how the size and shape of objects in the latrine affect the strength of the sludge?

Please Log in to join the conversation.

You need to login to reply- RadfordJT

-

Topic Author

Topic Author- Civil engineer with a particular interest in sanitation and faecal sludge management.

Less- Posts: 10

- Karma: 3

- Likes received: 8

Re: Measuring the physical strength of faecal sludge/pit latrine contents

Krischan,

We actually submitted a funding proposal in partnership with Jeroen and LSHTM to use the penetrometer as part of the next phase of their study a couple of years ago, sadly unsuccessfully. The issue with only using pit (volumetric) fill-up rate as a measure of performance is that it doesn't distinguish between a pit full of water (perhaps seasonally, probably indicative of poor performance) and one full of strong sludge. We are now trying to get a similar long-term study off the ground with Water for People.

We're also looking at similar applications for testing dewatering performance as part of the Omni-Processor project - particularly the spatial strength distribution which would give some indication of how effectively water is leaving the sludge.

With regards to "dealing with" debris - it doesn't cause a problem for the test as ultimately the penetrometer is an electronic ball on a stick and pushes straight through. Some of the latrines we tested in Kampala had significant amounts of solid waste in them. The challenge is interpreting the data that comes out and understanding whether a 'strong' layer in the pit is due to higher solids content sludge, or the presence of debris. Layered plastic bags in particular are picked up as they are anchored horizontally and extrude around the ball, eventually puncturing. We have done some initial testing on simulant in the lab to generate example traces for different types of debris (eg flat plastic bags, knotted bags of simulant, hard solid objects like bottles stones etc) which should help with interpreting data from real pits. We do need to bear in mind the purpose of the testing though, and actually for pit emptying purposes, knowing that a given latrine has layers of thick sludge and plastic bags overlying watery material is actually quite useful.

Fluidisation - My thesis touched on this, generating a 3-fold drop in strength for relatively weak sludges (perhaps equivalent to a 1 year old latrine?) at small scale (50L bucket) by just blowing in 'gulps' of air at 0.3bar from a vacuum cleaner-powered rig.

Link to my thesis:

susana.org/lang-en/library/library?view=...eitem&type=2&id=2008

A follow-up project last year looked at spatial distribution (over a 1x1m grid using the penetrometer) of fluidisation in two different consolidated sludges with higher air pressure. We're still processing the data with a view to publish, but shall share it here ASAP. The results were a little disappointing though - whereas at low strength the entire mixture heaves, churns and mixes, at higher strength (around 3kPa, you could probably stand on it) and higher pressure it simply fractured and any fluidising effect was very local to the hose, which additionally had to be 'built in' at the bottom of the tank to get a good seal around it from the sludge and enable the pressure to build up.

Joe,

The penetrometer measures resistance to pushing a ball through the sludge, so will give you the composite of whatever's in the pit. It won't pick up small debris like hair extensions or small amounts of rags which will just be pushed out the way of the ball, but if there's sufficient to form a matted reinforcing matrix for the sludge then that will register. That effect will depend on the strength of the surrounding sludge and therefore how easy it is for debris to be pushed out the way of the ball - think water vs mashed potato. A 'direct hit' on a bottle, for example, shows up as a spike in strength at a given depth.

There are limitations with comparing to wastewater treatment works sludge (for which there is indeed more information on rheology) as it tends to be at a different water content, perhaps with a lower proportion of faecal matter (eg activated sludge vs a rapidly filling latrine with a high proportion of fresh faeces) and tends not to have large foreign objects which are removed by sewage screening before the sludge is produced.

We actually submitted a funding proposal in partnership with Jeroen and LSHTM to use the penetrometer as part of the next phase of their study a couple of years ago, sadly unsuccessfully. The issue with only using pit (volumetric) fill-up rate as a measure of performance is that it doesn't distinguish between a pit full of water (perhaps seasonally, probably indicative of poor performance) and one full of strong sludge. We are now trying to get a similar long-term study off the ground with Water for People.

We're also looking at similar applications for testing dewatering performance as part of the Omni-Processor project - particularly the spatial strength distribution which would give some indication of how effectively water is leaving the sludge.

With regards to "dealing with" debris - it doesn't cause a problem for the test as ultimately the penetrometer is an electronic ball on a stick and pushes straight through. Some of the latrines we tested in Kampala had significant amounts of solid waste in them. The challenge is interpreting the data that comes out and understanding whether a 'strong' layer in the pit is due to higher solids content sludge, or the presence of debris. Layered plastic bags in particular are picked up as they are anchored horizontally and extrude around the ball, eventually puncturing. We have done some initial testing on simulant in the lab to generate example traces for different types of debris (eg flat plastic bags, knotted bags of simulant, hard solid objects like bottles stones etc) which should help with interpreting data from real pits. We do need to bear in mind the purpose of the testing though, and actually for pit emptying purposes, knowing that a given latrine has layers of thick sludge and plastic bags overlying watery material is actually quite useful.

Fluidisation - My thesis touched on this, generating a 3-fold drop in strength for relatively weak sludges (perhaps equivalent to a 1 year old latrine?) at small scale (50L bucket) by just blowing in 'gulps' of air at 0.3bar from a vacuum cleaner-powered rig.

Link to my thesis:

susana.org/lang-en/library/library?view=...eitem&type=2&id=2008

A follow-up project last year looked at spatial distribution (over a 1x1m grid using the penetrometer) of fluidisation in two different consolidated sludges with higher air pressure. We're still processing the data with a view to publish, but shall share it here ASAP. The results were a little disappointing though - whereas at low strength the entire mixture heaves, churns and mixes, at higher strength (around 3kPa, you could probably stand on it) and higher pressure it simply fractured and any fluidising effect was very local to the hose, which additionally had to be 'built in' at the bottom of the tank to get a good seal around it from the sludge and enable the pressure to build up.

Joe,

The penetrometer measures resistance to pushing a ball through the sludge, so will give you the composite of whatever's in the pit. It won't pick up small debris like hair extensions or small amounts of rags which will just be pushed out the way of the ball, but if there's sufficient to form a matted reinforcing matrix for the sludge then that will register. That effect will depend on the strength of the surrounding sludge and therefore how easy it is for debris to be pushed out the way of the ball - think water vs mashed potato. A 'direct hit' on a bottle, for example, shows up as a spike in strength at a given depth.

There are limitations with comparing to wastewater treatment works sludge (for which there is indeed more information on rheology) as it tends to be at a different water content, perhaps with a lower proportion of faecal matter (eg activated sludge vs a rapidly filling latrine with a high proportion of fresh faeces) and tends not to have large foreign objects which are removed by sewage screening before the sludge is produced.

The following user(s) like this post: JKMakowka, joeturner

Please Log in to join the conversation.

You need to login to reply- joeturner

-

Less

Less- Posts: 717

- Karma: 23

- Likes received: 185

Re: Measuring the physical strength of faecal sludge/pit latrine contents

I'm pretty sure a penetrometer is not going to be measuring foreign objects in the sludge, but only the physical properties of the sludge.

I'd think there must be data regarding the measured flow of different sludges (there are a lot of electronic flowmeters in use at sludge treatment works around the world) - would this not be related to the 'sludge strength' and give a better 'real life' understanding of the material, including foreign objects?

I'd think there must be data regarding the measured flow of different sludges (there are a lot of electronic flowmeters in use at sludge treatment works around the world) - would this not be related to the 'sludge strength' and give a better 'real life' understanding of the material, including foreign objects?

Please Log in to join the conversation.

You need to login to replyRe: Measuring the physical strength of faecal sludge/pit latrine contents

This might be a quite interesting devices to support testing various degradation hypothesis in-situ (for example the moisture-content to degradation ratio

as discussed here

).

How well does it deal with foreign waste objects like sanitary pads or rags etc.?

I would also love to see some tests comparing fluidisation of pit-latrine contents for pumping with water or alternatively with a pressurized air + little water mixture.

A bit OT: Has anyone ever heard of air-lift or venturi pumps for pit emptying? Might be a great way to combine pumping and solid sludge fluidisation in one step.

How well does it deal with foreign waste objects like sanitary pads or rags etc.?

I would also love to see some tests comparing fluidisation of pit-latrine contents for pumping with water or alternatively with a pressurized air + little water mixture.

A bit OT: Has anyone ever heard of air-lift or venturi pumps for pit emptying? Might be a great way to combine pumping and solid sludge fluidisation in one step.

Please Log in to join the conversation.

You need to login to reply- RadfordJT

-

Topic Author

Topic Author- Civil engineer with a particular interest in sanitation and faecal sludge management.

Less- Posts: 10

- Karma: 3

- Likes received: 8

Measuring the physical strength of faecal sludge/pit latrine contents

As many of you, I’m sure, will have found, there is very little data available on the physical strength of faecal sludge/pit latrine contents. Indeed, until a couple of years ago, virtually the only information in the literature was a 1986 study by IRCWD in Botswana, which was actually looking at pump performance not sludge strength (and therefore only gives a lower bound on the maximum strength of pit contents). Since then UKZN's PRG has been testing samples with a rheometer and Damian Seal's thesis (Cranfield, 2012) looked at variability in sludge strength, but given the acknowledged variations in faecal sludge properties around the world, we still have a negligible amount of data.

We therefore developed the penetrometer as a relatively cheap, man-portable research tool for measuring the in-situ strength of faecal sludge to try and help address this need. The penetrometer produces a continuous strength profile with depth, removing the need to empty the pit and extract samples, and therefore helps one to understand the physical characteristics of the sludge relatively quickly, without needing to empty the pit.

At a simplistic level, it works by driving a ball through the shaft at a controlled rate, and measuring the force required – the “resistance to penetration”. Through calibration this is converted into an undrained shear strength, in N/m2 or Pa.

There are various benefits of being able to test in-situ, including:

- Measure the actual strength of the sludge, before it is disturbed or "remoulded" by the sampling process

- Understand variability and 'layering' within the pit (and perhaps use this information to inform a sampling protocol so that you target the distinct layers within each pit)

- Enables repeated testing over time (eg every month to investigate seasonal variability in wet/dry seasons), or before/after some experiment (eg attempted fluidisation or pumping)

- Quicker than emptying the pit and removing samples for lab analysis

The most obvious drawback being that you are only collecting strength data (which almost certainly correlates closely to solids content - %TS) and don't have a sample for running other experiments such as the suite of characterisation tests that UKZN PRG is currently undertaking.

The results from a field trial of 30 pits in Kampala, Uganda, were published in Water SA earlier this year and are available open-access here:

www.ajol.info/index.php/wsa/article/view/100248

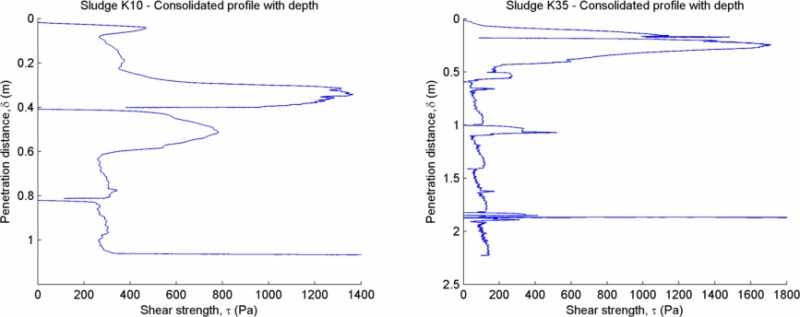

One of the interesting things we found is marked layering within the pit, confirming anecdotal experience, which underlines the value of having a continuous profile rather than just testing/sampling at set depths, which may miss some of the different layers. Here are a couple of examples:

We are currently trying to secure funding for the next phase of development - taking the penetrometer from a 1-off proof of concept, to a ruggedised, easy to use tool that other researchers can take into the field to support their own specific projects. The aim is to get there in the next couple of months, in time for NCSU's final field testing of the excrevator , as well as supporting work by UKZN and some of the SRFA-funded universities characterising faecal sludge .

Future studies that we're keen to develop include:

- Testing 100 pits in 10 different countries to start to develop a meaningful database on the "pumpability" of faecal sludge, supported by sampling and more complete lab-based characterisation

- A long-term monitoring study investigating sludge accumulation rates in pit latrines, and critical factors controlling pit fill-up, with repeated profiling of a small number of pits to track them through time.

- Performance testing of different pumps and injection systems for fluidising pit sludge to quantitatively measure performance of the various devices.

Now that there are so many more researchers working in this area, the intention is to get the penetrometer to the point that any research team can use it as a tool to support their work - whether that includes the ideas outlined above, or something else entirely. I shall keep you posted with updates as things progress.

We therefore developed the penetrometer as a relatively cheap, man-portable research tool for measuring the in-situ strength of faecal sludge to try and help address this need. The penetrometer produces a continuous strength profile with depth, removing the need to empty the pit and extract samples, and therefore helps one to understand the physical characteristics of the sludge relatively quickly, without needing to empty the pit.

At a simplistic level, it works by driving a ball through the shaft at a controlled rate, and measuring the force required – the “resistance to penetration”. Through calibration this is converted into an undrained shear strength, in N/m2 or Pa.

There are various benefits of being able to test in-situ, including:

- Measure the actual strength of the sludge, before it is disturbed or "remoulded" by the sampling process

- Understand variability and 'layering' within the pit (and perhaps use this information to inform a sampling protocol so that you target the distinct layers within each pit)

- Enables repeated testing over time (eg every month to investigate seasonal variability in wet/dry seasons), or before/after some experiment (eg attempted fluidisation or pumping)

- Quicker than emptying the pit and removing samples for lab analysis

The most obvious drawback being that you are only collecting strength data (which almost certainly correlates closely to solids content - %TS) and don't have a sample for running other experiments such as the suite of characterisation tests that UKZN PRG is currently undertaking.

The results from a field trial of 30 pits in Kampala, Uganda, were published in Water SA earlier this year and are available open-access here:

www.ajol.info/index.php/wsa/article/view/100248

One of the interesting things we found is marked layering within the pit, confirming anecdotal experience, which underlines the value of having a continuous profile rather than just testing/sampling at set depths, which may miss some of the different layers. Here are a couple of examples:

We are currently trying to secure funding for the next phase of development - taking the penetrometer from a 1-off proof of concept, to a ruggedised, easy to use tool that other researchers can take into the field to support their own specific projects. The aim is to get there in the next couple of months, in time for NCSU's final field testing of the excrevator , as well as supporting work by UKZN and some of the SRFA-funded universities characterising faecal sludge .

Future studies that we're keen to develop include:

- Testing 100 pits in 10 different countries to start to develop a meaningful database on the "pumpability" of faecal sludge, supported by sampling and more complete lab-based characterisation

- A long-term monitoring study investigating sludge accumulation rates in pit latrines, and critical factors controlling pit fill-up, with repeated profiling of a small number of pits to track them through time.

- Performance testing of different pumps and injection systems for fluidising pit sludge to quantitatively measure performance of the various devices.

Now that there are so many more researchers working in this area, the intention is to get the penetrometer to the point that any research team can use it as a tool to support their work - whether that includes the ideas outlined above, or something else entirely. I shall keep you posted with updates as things progress.

Attachments:

-

Penetromet...hoto.jpg

(Filesize: 45KB)

Penetromet...hoto.jpg

(Filesize: 45KB)

-

Fig3-Conso...iles.jpg

(Filesize: 19KB)

Fig3-Conso...iles.jpg

(Filesize: 19KB)

The following user(s) like this post: JKMakowka, PatrickBBB, fcharlesc

Please Log in to join the conversation.

You need to login to reply

Share this thread:

- Sanitation systems

- Faecal sludge management (FSM)

- Pit or vault content research, accumulation rates and faecal sludge characteristics

- Measuring the physical strength of faecal sludge/pit latrine contents

Recently active users. Who else has been active?

Time to create page: 0.251 seconds