- Resource recovery

- Vermitechnology

- Vermifilters (or vermi-digesters)

- Promote VERMIFILTRATION Technology for WASTEWATER PURIFICATION by EARTHWORMS to produce clean water

Promote VERMIFILTRATION Technology for WASTEWATER PURIFICATION by EARTHWORMS to produce clean water

60.4k views

- hajo

-

- retired in Germany... but still interested in water and sanitation... especially in OSS... and especially in Africa...

Less- Posts: 288

- Karma: 15

- Likes received: 156

Re: Promote VERMIFILTRATION Technology for WASTEWATER PURIFICATION by EARTHWORMS to produce clean water

Hi Heiner,

to start with your last sentence, a Ghanaian friend once said to me: what we miss most in Ghana is maintenance and management.

Reading your post, i feel we have to go a long way trying to understand each other and finding the links between your and my 'profession' between your and my ‘dreams’.

I am a water & sanitation engineer. My latest ambition is finding solutions through this discussion to improve (human excreta) sanitation at various levels, i.e.

• for wastewater treatment plants of centralised sewer systems

• for de-centralised small scale sewer systems at institutions and housing estates,

• for faecal sludge treatment works in communities for septage and FS

• for household toilets in small towns and peri-urban areas

I have learned that human excreta SHOULD NEVER be regarded as waste but IS a resource and MUST be brought back on the land and into the soil. And vermi-culture may be one technology which can possibly help to achieve this. I need your advice what has to be observed with this technology to make the best possible use of human excreta for agriculture.

Vermi-culture alone will not make perfect organic farming and that is not even my aim … but yours. You may have to add a number of other 'ingredients' or 'processes' to put into practice organic farming. But you can advise me/us how vermi-culture should work best to contribute its share to organic farming.

Ciao Hajo

to start with your last sentence, a Ghanaian friend once said to me: what we miss most in Ghana is maintenance and management.

Reading your post, i feel we have to go a long way trying to understand each other and finding the links between your and my 'profession' between your and my ‘dreams’.

I am a water & sanitation engineer. My latest ambition is finding solutions through this discussion to improve (human excreta) sanitation at various levels, i.e.

• for wastewater treatment plants of centralised sewer systems

• for de-centralised small scale sewer systems at institutions and housing estates,

• for faecal sludge treatment works in communities for septage and FS

• for household toilets in small towns and peri-urban areas

I have learned that human excreta SHOULD NEVER be regarded as waste but IS a resource and MUST be brought back on the land and into the soil. And vermi-culture may be one technology which can possibly help to achieve this. I need your advice what has to be observed with this technology to make the best possible use of human excreta for agriculture.

Vermi-culture alone will not make perfect organic farming and that is not even my aim … but yours. You may have to add a number of other 'ingredients' or 'processes' to put into practice organic farming. But you can advise me/us how vermi-culture should work best to contribute its share to organic farming.

Ciao Hajo

We can't solve problems by using the same kind of thinking we used when we created them.

Albert Einstein

Any intelligent fool can make things bigger and more complex... It takes a touch of a genius - and a lot of courage to move in the opposite direction.

E.F. Schumacher

Everything should be made as simple as possible, but not simpler.

Albert Einstein

Albert Einstein

Any intelligent fool can make things bigger and more complex... It takes a touch of a genius - and a lot of courage to move in the opposite direction.

E.F. Schumacher

Everything should be made as simple as possible, but not simpler.

Albert Einstein

Please Log in to join the conversation.

You need to login to reply- Heiner

-

- I am a retired organic farmer and interested in nutrient cycles. As an volunteer I now travel mainly to poor countries and together with locals I would like to find new ways of sustainable agriculture. This is beyond the regulations of IFOAM.

Less- Posts: 80

- Karma: 1

- Likes received: 67

Re: Promote VERMIFILTRATION Technology for WASTEWATER PURIFICATION by EARTHWORMS to produce clean water

Hajo,

you mentioned a few ideas which are very interesting for me. As an organic farmer I think in rotations and in subarid climates I can't imagine food production without hedgerows or windbrakes (agroforestry of all different kinds). So here is the place to use compost of "second quality". The cutoffs of these plants can be used as mulch, feed or compost material depending of the pathogens remained in the organic stuff and the needs of the farm.

From managing a little aquaponic system I know that the big plants use UV lights for sterilisation. I wonder if there is a chance to use natural UV radiation in liquid substrates (not compost of course)when exposed to the sun???

Using the elements (drought, heat, sun), changing aerobic and anaerobic conditions and a rich biology (humus quality and quantity) in the soil should put up a cascade of deadly environments for the pathogens. Thats how nature works and we can assist

I think the fields/gardens where the output is used must be a part of the crack down chain. Though a fairly strict management is required.

Ciao

you mentioned a few ideas which are very interesting for me. As an organic farmer I think in rotations and in subarid climates I can't imagine food production without hedgerows or windbrakes (agroforestry of all different kinds). So here is the place to use compost of "second quality". The cutoffs of these plants can be used as mulch, feed or compost material depending of the pathogens remained in the organic stuff and the needs of the farm.

From managing a little aquaponic system I know that the big plants use UV lights for sterilisation. I wonder if there is a chance to use natural UV radiation in liquid substrates (not compost of course)when exposed to the sun???

Using the elements (drought, heat, sun), changing aerobic and anaerobic conditions and a rich biology (humus quality and quantity) in the soil should put up a cascade of deadly environments for the pathogens. Thats how nature works and we can assist

I think the fields/gardens where the output is used must be a part of the crack down chain. Though a fairly strict management is required.

Ciao

Heiner, the old farmer.....

The following user(s) like this post: HarryTams

Please Log in to join the conversation.

You need to login to reply- hajo

-

- retired in Germany... but still interested in water and sanitation... especially in OSS... and especially in Africa...

Less- Posts: 288

- Karma: 15

- Likes received: 156

Re: Promote VERMIFILTRATION Technology for WASTEWATER PURIFICATION by EARTHWORMS to produce clean water

Hi Dean,

I do not fully agree that there is not much life in SuSanA: membership is constantly increasing and every month there are between 15 and 25,000 posts. It may be that vermi-culture hasn’t received the attention yet, which it deserves also in my opinion. But we are working on it, isn’t it?

Money is definitely a problem in sanitation in Africa. In general users don’t want to spend on constructing a toilet – a new smartphone is always more ‘sexy’ and don’t want to pay for sanitation services neither for collection from on-site facilities nor for sewer charges if they are connected. It is one big obstacle.

Another problem is the ignorance of people regarding pathogens in sanitation. Why do not all school toilets in Africa have hand washing facilities? Why do people dig shallow wells even in vicinity of pit latrines and even when piped water is available? Why is the highest incidence of cholera in an African city just around the central wastewater treatment plants? Is it partially financial desperation and partially ignorance?

Behaviour change is the most difficult thing to achieve. And especially in sanitation where the consequences of behaviour change are not felt immediately. If I touch a hot pot, I burn my fingers, thus I won’t do it again. If I touch a dirty toilet (and don’t wash my fingers before eating), I get sick a day later: I don’t even know that it is related to that toilet visit. If a farmer fertilises his carrots with effluent from the central wastewater treatment plant, the customers of his customers get cholera. The farmer does not know it, the consumers don’t know what the farmer used. Germans needed almost 20 years (1964 to 1984) to accept the use of safety belts when driving and only accepted it once stiff penalties were introduced for not wearing belts.

Therefore, I agree a bit to the approach trying to ‘nuke’ the pathogens. Unfortunately, also vermi-culture does not kill ascaris – which I had so much hoped for. Because of the desperation, the ignorance, the wrong behaviour, and the greed of people, we have to try our best, that humus and effluent which leaves the community treatment plant is as safe as possible for reuse. And we only need one more step after the vermi-culture (digester and filter) to achieve this! Which one?

This applies to community treatment plants where septage from septic tanks and humus from VC household toilets are being processed for public sale and reuse. In community TP the operator has the responsibility that pathogens from single households (not every ‘supplier’ is infected) are not spread by the reuse of VC humus and effluent.

This may be seen a bit different where households reuse their own humus and effluent. Here the pathogens are ‘recycled’ within the same group of people. And they can observe, maybe learn and improve and start using the same precautions which you use: windrowing, humus only at trees, under-ground percolation, or else. If I remember well even the official (WHO?) safety requirements for household reuse of faecal matter are lower than for ‘public’ reuse.

I think we must adapt our ideas, judgements and solutions to the different tasks: household sanitation, decentralised systems and central sewers may require different approaches also if they are all build on VC.

Ciao

Hajo

I do not fully agree that there is not much life in SuSanA: membership is constantly increasing and every month there are between 15 and 25,000 posts. It may be that vermi-culture hasn’t received the attention yet, which it deserves also in my opinion. But we are working on it, isn’t it?

Money is definitely a problem in sanitation in Africa. In general users don’t want to spend on constructing a toilet – a new smartphone is always more ‘sexy’ and don’t want to pay for sanitation services neither for collection from on-site facilities nor for sewer charges if they are connected. It is one big obstacle.

Another problem is the ignorance of people regarding pathogens in sanitation. Why do not all school toilets in Africa have hand washing facilities? Why do people dig shallow wells even in vicinity of pit latrines and even when piped water is available? Why is the highest incidence of cholera in an African city just around the central wastewater treatment plants? Is it partially financial desperation and partially ignorance?

Behaviour change is the most difficult thing to achieve. And especially in sanitation where the consequences of behaviour change are not felt immediately. If I touch a hot pot, I burn my fingers, thus I won’t do it again. If I touch a dirty toilet (and don’t wash my fingers before eating), I get sick a day later: I don’t even know that it is related to that toilet visit. If a farmer fertilises his carrots with effluent from the central wastewater treatment plant, the customers of his customers get cholera. The farmer does not know it, the consumers don’t know what the farmer used. Germans needed almost 20 years (1964 to 1984) to accept the use of safety belts when driving and only accepted it once stiff penalties were introduced for not wearing belts.

Therefore, I agree a bit to the approach trying to ‘nuke’ the pathogens. Unfortunately, also vermi-culture does not kill ascaris – which I had so much hoped for. Because of the desperation, the ignorance, the wrong behaviour, and the greed of people, we have to try our best, that humus and effluent which leaves the community treatment plant is as safe as possible for reuse. And we only need one more step after the vermi-culture (digester and filter) to achieve this! Which one?

This applies to community treatment plants where septage from septic tanks and humus from VC household toilets are being processed for public sale and reuse. In community TP the operator has the responsibility that pathogens from single households (not every ‘supplier’ is infected) are not spread by the reuse of VC humus and effluent.

This may be seen a bit different where households reuse their own humus and effluent. Here the pathogens are ‘recycled’ within the same group of people. And they can observe, maybe learn and improve and start using the same precautions which you use: windrowing, humus only at trees, under-ground percolation, or else. If I remember well even the official (WHO?) safety requirements for household reuse of faecal matter are lower than for ‘public’ reuse.

I think we must adapt our ideas, judgements and solutions to the different tasks: household sanitation, decentralised systems and central sewers may require different approaches also if they are all build on VC.

Ciao

Hajo

We can't solve problems by using the same kind of thinking we used when we created them.

Albert Einstein

Any intelligent fool can make things bigger and more complex... It takes a touch of a genius - and a lot of courage to move in the opposite direction.

E.F. Schumacher

Everything should be made as simple as possible, but not simpler.

Albert Einstein

Albert Einstein

Any intelligent fool can make things bigger and more complex... It takes a touch of a genius - and a lot of courage to move in the opposite direction.

E.F. Schumacher

Everything should be made as simple as possible, but not simpler.

Albert Einstein

The following user(s) like this post: goeco

Please Log in to join the conversation.

You need to login to replyRe: Promote VERMIFILTRATION Technology for WASTEWATER PURIFICATION by EARTHWORMS to produce clean water

Hi Hajo, I have given your posts some thought and have also waited for others to contribute. Seems there isn't much life in the susana forum, which is a real shame given the plight of so many developing nations to undertake basic sanitation that avoids infection... especially with respect to such easily controlled pathogens such as round worms, where the cycle just needs breaking. I'm not familiar with conditions in Rwanda but I understand wages are very low, and we all know that sanitation does cost money, perhaps the biggest obstacle? Faeces in the environment (open defecation) means helminth re-infection in humans, as does using faecal sludge for fertilising gardens growing vegetables to be consumed raw, or handling raw sludge without wearing gloves. I'm not sure whether centrally treated sewage sludge (from a conventional larger plant) poses such risk, but there may be risk around disposing of that sludge in Rwanda if not wind-rowed, composted and rested?

So the first world solution is to "nuke" the contaminated mass, to kill all pathogens. A bit like Donald Trump wanting to nuke hurricanes, that'll sort them. This could be achieved by such means as well controlled composting to ensure all compost has been treated via thermophilic means. Other solutions may include solar heating or urea/ash treatment. To be successful these methods become specialised and higher cost to be foolproof and guaranteed. The black box, on the other hand, fixes everything - the contaminated sludge goes in one end and out the other, so that it's foolproof and safe. But is this really the best solution for developing countries? Why is the easiest and low cost method (time) out of the question? Because poor people will "cheat" and in desperation put contaminated compost in their vegetable garden and thereby not break the helminth cycle? So is it really not possible to address this as a cultural issue?

I don't believe expensive solutions will work in poor countries. Most of the black box contraptions Bill Gates is funding won't apply to poor communities... foolproof sanitation, flush and forget, but at a high cost. But for poor communities, surely cultural change, being free, could accompany low cost technological solutions - moving from open defecation and pits and even septic tanks into technological solutions that work, but that depend on behaviour change. Is it too much to ask that communities take charge of their own health and let faecal humus rest for a prescribed time before using in vegetable gardens? Or that a community treatment plant has prescribed rest periods for wind-rowed faecal humus after removal from the digester, before it can be taken away? Or that workers handling faecal humus must wear gloves? What would the community itself prefer? Low cost solutions that involve simple procedures to follow, or expensive black box solutions?

cheers

Dean

So the first world solution is to "nuke" the contaminated mass, to kill all pathogens. A bit like Donald Trump wanting to nuke hurricanes, that'll sort them. This could be achieved by such means as well controlled composting to ensure all compost has been treated via thermophilic means. Other solutions may include solar heating or urea/ash treatment. To be successful these methods become specialised and higher cost to be foolproof and guaranteed. The black box, on the other hand, fixes everything - the contaminated sludge goes in one end and out the other, so that it's foolproof and safe. But is this really the best solution for developing countries? Why is the easiest and low cost method (time) out of the question? Because poor people will "cheat" and in desperation put contaminated compost in their vegetable garden and thereby not break the helminth cycle? So is it really not possible to address this as a cultural issue?

I don't believe expensive solutions will work in poor countries. Most of the black box contraptions Bill Gates is funding won't apply to poor communities... foolproof sanitation, flush and forget, but at a high cost. But for poor communities, surely cultural change, being free, could accompany low cost technological solutions - moving from open defecation and pits and even septic tanks into technological solutions that work, but that depend on behaviour change. Is it too much to ask that communities take charge of their own health and let faecal humus rest for a prescribed time before using in vegetable gardens? Or that a community treatment plant has prescribed rest periods for wind-rowed faecal humus after removal from the digester, before it can be taken away? Or that workers handling faecal humus must wear gloves? What would the community itself prefer? Low cost solutions that involve simple procedures to follow, or expensive black box solutions?

cheers

Dean

Dean Satchell, M For. Sc.

Vermifilter.com

www.vermifilter.com

Vermifilter.com

www.vermifilter.com

Please Log in to join the conversation.

You need to login to reply- hajo

-

- retired in Germany... but still interested in water and sanitation... especially in OSS... and especially in Africa...

Less- Posts: 288

- Karma: 15

- Likes received: 156

Re: Reply: Promote VERMIFILTRATION Technology for WASTEWATER PURIFICATION by EARTHWORMS to produce clean water

Hi Dean,

I like it how you are always concerned about low cost solutions for developing countries... and I will think about how I can clad your latest proposal nicely so it does not look so much DIY... and I like the proposal, it may be feasible...

I want to emphasis again that at the beginning when we want to convince partners and financiers, the technology must look as professional and 'shiny' as possible. Once the technology is accepted by the authorities (local governments, W&S utilities, banks) and we want to upscale it (not necessarily making bigger but spreading to more users), we will need cheaper solutions, most likely even to the level that households build their own VC facilities. Then we will definitely come back to all your good proposals.

For promotion it must not be as cheap as possible - which may be even contra-productive - but only be cheaper than standard, state-of-art technologies....

I found the fruit crates on the internet in 0.7m3 from China/India at 80 to 100 USD per piece. We have to find out at what price they can be produced locally, the machines should be here as for producing water tanks, thus 'only' the forms are needed for rotary moulding.

ciao

Hajo

We can't solve problems by using the same kind of thinking we used when we created them.

Albert Einstein

Any intelligent fool can make things bigger and more complex... It takes a touch of a genius - and a lot of courage to move in the opposite direction.

E.F. Schumacher

Everything should be made as simple as possible, but not simpler.

Albert Einstein

Albert Einstein

Any intelligent fool can make things bigger and more complex... It takes a touch of a genius - and a lot of courage to move in the opposite direction.

E.F. Schumacher

Everything should be made as simple as possible, but not simpler.

Albert Einstein

Please Log in to join the conversation.

You need to login to replyRe: Reply: Promote VERMIFILTRATION Technology for WASTEWATER PURIFICATION by EARTHWORMS to produce clean water

Hi Hajo,

The fruit bins cost about $250 here in New Zealand, with a capacity of approximately 0.7 m3, or over $300 per cubic metre of capacity, which would be fine for the domestic setting but is quite high for the community scale.

I'd like to suggest that the drainage panel option doesn't actually need a "box". I don't see sides and roof as necessary. The panels could be set up as a robust and durable modular structure using cable ties. The main cost would be labour, tying the panels together as a framework or scaffold. Once the framework is constructed a textile "sock" would be lowered into each cavity, then filled with media. The whole unit could even be deconstructed if necessary and then put back together. In terms of maintenance, I don't believe there is any maintenance apart from topping up the media, checking for influent blockages (if you use nozzles) and eventually removing surplus humus from the top of vermifilter modules.

What the drainage panels offer is a very low cost option for aerating the media, perhaps not much more than $50 per cubic metre of capacity, my choice for a developing country.

For secondary treatment I don't think you'd be concerned with vermin, but if cockroaches took a liking to the secondary treatment environment you could wrap the structure in netting. Rain wouldn't be a problem because you are building upwards, therefore rainfall per cubic metre of capacity is minimised.

cheers

Dean

The fruit bins cost about $250 here in New Zealand, with a capacity of approximately 0.7 m3, or over $300 per cubic metre of capacity, which would be fine for the domestic setting but is quite high for the community scale.

I'd like to suggest that the drainage panel option doesn't actually need a "box". I don't see sides and roof as necessary. The panels could be set up as a robust and durable modular structure using cable ties. The main cost would be labour, tying the panels together as a framework or scaffold. Once the framework is constructed a textile "sock" would be lowered into each cavity, then filled with media. The whole unit could even be deconstructed if necessary and then put back together. In terms of maintenance, I don't believe there is any maintenance apart from topping up the media, checking for influent blockages (if you use nozzles) and eventually removing surplus humus from the top of vermifilter modules.

What the drainage panels offer is a very low cost option for aerating the media, perhaps not much more than $50 per cubic metre of capacity, my choice for a developing country.

For secondary treatment I don't think you'd be concerned with vermin, but if cockroaches took a liking to the secondary treatment environment you could wrap the structure in netting. Rain wouldn't be a problem because you are building upwards, therefore rainfall per cubic metre of capacity is minimised.

cheers

Dean

Dean Satchell, M For. Sc.

Vermifilter.com

www.vermifilter.com

Vermifilter.com

www.vermifilter.com

The following user(s) like this post: hajo, HarryTams

Please Log in to join the conversation.

You need to login to reply- hajo

-

- retired in Germany... but still interested in water and sanitation... especially in OSS... and especially in Africa...

Less- Posts: 288

- Karma: 15

- Likes received: 156

Re: Reply: Promote VERMIFILTRATION Technology for WASTEWATER PURIFICATION by EARTHWORMS to produce clean water

Hi all,

In a parallel thread discussion about compost toilets, Geoff Hill presents two research papers which look at the destruction of ascaris in VC digesters . The result of this research is that vermi-digestion does not destruct ascaris, which is in contradiction to other researches done earlier by Eastman and Boxmann and which are quoted in these two papers.

If this research by Hill et al. is proved correct, it means that humus from VC digesters cannot be used without restrictions or without further treatment. For the time being we must assume this.

I have also contacted Prof. Sinha (see author of this thread) because his research indicated that the humus from VC treatment would be fully safe. He now concedes that the humus may require additional treatment getting rid of the ascaris.

Because I anticipate that under our conditions multi-barrier approaches (use of humus only for fruit trees, windrowing of humus before further use) may not be observed, the humus leaving the VC TP must be safe! Here I agree with Joe who voiced similar concerns in the above mentioned thread.

Which is the most economical treatment destructing the ascaris in the humus? I read about urea and ash treatment, which would require additional input materials. Another possibility can be heating the humus to above 40C or higher for a given time (the hotter, the shorter, sun drying?). Any comments on these two alternatives? Or any other proposal? Don’t forget that we discuss about ‘central’ community VC TP not about household applications!

Ciao

Hajo

In a parallel thread discussion about compost toilets, Geoff Hill presents two research papers which look at the destruction of ascaris in VC digesters . The result of this research is that vermi-digestion does not destruct ascaris, which is in contradiction to other researches done earlier by Eastman and Boxmann and which are quoted in these two papers.

If this research by Hill et al. is proved correct, it means that humus from VC digesters cannot be used without restrictions or without further treatment. For the time being we must assume this.

I have also contacted Prof. Sinha (see author of this thread) because his research indicated that the humus from VC treatment would be fully safe. He now concedes that the humus may require additional treatment getting rid of the ascaris.

Because I anticipate that under our conditions multi-barrier approaches (use of humus only for fruit trees, windrowing of humus before further use) may not be observed, the humus leaving the VC TP must be safe! Here I agree with Joe who voiced similar concerns in the above mentioned thread.

Which is the most economical treatment destructing the ascaris in the humus? I read about urea and ash treatment, which would require additional input materials. Another possibility can be heating the humus to above 40C or higher for a given time (the hotter, the shorter, sun drying?). Any comments on these two alternatives? Or any other proposal? Don’t forget that we discuss about ‘central’ community VC TP not about household applications!

Ciao

Hajo

We can't solve problems by using the same kind of thinking we used when we created them.

Albert Einstein

Any intelligent fool can make things bigger and more complex... It takes a touch of a genius - and a lot of courage to move in the opposite direction.

E.F. Schumacher

Everything should be made as simple as possible, but not simpler.

Albert Einstein

Albert Einstein

Any intelligent fool can make things bigger and more complex... It takes a touch of a genius - and a lot of courage to move in the opposite direction.

E.F. Schumacher

Everything should be made as simple as possible, but not simpler.

Albert Einstein

Please Log in to join the conversation.

You need to login to reply- hajo

-

- retired in Germany... but still interested in water and sanitation... especially in OSS... and especially in Africa...

Less- Posts: 288

- Karma: 15

- Likes received: 156

Re: Reply: Promote VERMIFILTRATION Technology for WASTEWATER PURIFICATION by EARTHWORMS to produce clean water

Hi Harry, welcome to the club!

Hi Dean,

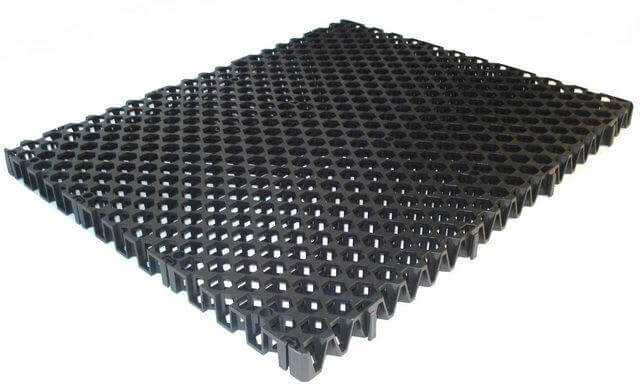

Thanks for taking your time proposing another design for the upscaled vermi-filter. We currently look at three different designs: the stacks of fruit crates, the upright HDPE culvert pipes and the concrete/block box with the drainage cell panels (your last post).

If we plan designing a (scalable) VC filter for community use, I feel the fruit crates are still the best solution. Let me try to summarise the pros and cons:

Fruit crates:

• The filter structure only requires the crates, windbreak cloth, media, wall sheathing and roof;

• The structure is easily set up, adjusted in size or set-up, and easily maintained;

• Looks professional;

• Fruit crates may not be easily available and may be expensive (compared to second-hand DIY material but not compared to ‘state of the art’ standard designs).

HDPE culverts:

• 600mm culvert with slotted pipes inside provides only 0.15m2 effective filter area, thus, many more culverts are needed than fruit crates providing the required filter area;

• Culverts can only be filled with media once they are in position and I wonder how the media can eventually be maintained/exchanged if necessary;

• Setting up multiple culverts with slotted pipes inside, plastic mesh and windbreak cloth inside a 3m long, 600mm culvert is not as easy as the fruit crates with windbreak cloth inside only.

Box with drainage panels (described in Dean’s last posting):

• Once it is built it cannot be adjusted in size if found necessary;

• As for culverts, the fixing of the panels covered with windbreak cloth to a depth of 3 (or 4) m and at 60cm distance will not be easy;

• As for culverts, the maintenance and exchange of media will be difficult (if not impossible) unless the whole inside structure of the box is removed;

• The costs of this alternative are mostly in the outside wall structure which makes it not necessarily economical.

As said, I still tend to the fruit crates if we can get them in Rwanda. They may not be the cheapest solution (of the 3), but I rather look for functionality, including adaptability and maintenance as well as ‘looks’. Because I assume that any of above solution will be cheaper than the ‘state of the art’ standard design, we must choose the most ‘professional’ solution convincing partner and financier.

I know, Dean, this is not what you are aiming at but please consider that (at this stage) we are not designing household facilities but community size infrastructure which must be appreciated by water & sanitation administrators and be financed by international development banks. And I need your professional input designing them right.

We will come to designing household facilities, those to be financed by banks and those to be built by the users… 😊

Dean, what do you pay for the fruit crates in NZ?

Ciao

Hajo

Hi Dean,

Thanks for taking your time proposing another design for the upscaled vermi-filter. We currently look at three different designs: the stacks of fruit crates, the upright HDPE culvert pipes and the concrete/block box with the drainage cell panels (your last post).

If we plan designing a (scalable) VC filter for community use, I feel the fruit crates are still the best solution. Let me try to summarise the pros and cons:

Fruit crates:

• The filter structure only requires the crates, windbreak cloth, media, wall sheathing and roof;

• The structure is easily set up, adjusted in size or set-up, and easily maintained;

• Looks professional;

• Fruit crates may not be easily available and may be expensive (compared to second-hand DIY material but not compared to ‘state of the art’ standard designs).

HDPE culverts:

• 600mm culvert with slotted pipes inside provides only 0.15m2 effective filter area, thus, many more culverts are needed than fruit crates providing the required filter area;

• Culverts can only be filled with media once they are in position and I wonder how the media can eventually be maintained/exchanged if necessary;

• Setting up multiple culverts with slotted pipes inside, plastic mesh and windbreak cloth inside a 3m long, 600mm culvert is not as easy as the fruit crates with windbreak cloth inside only.

Box with drainage panels (described in Dean’s last posting):

• Once it is built it cannot be adjusted in size if found necessary;

• As for culverts, the fixing of the panels covered with windbreak cloth to a depth of 3 (or 4) m and at 60cm distance will not be easy;

• As for culverts, the maintenance and exchange of media will be difficult (if not impossible) unless the whole inside structure of the box is removed;

• The costs of this alternative are mostly in the outside wall structure which makes it not necessarily economical.

As said, I still tend to the fruit crates if we can get them in Rwanda. They may not be the cheapest solution (of the 3), but I rather look for functionality, including adaptability and maintenance as well as ‘looks’. Because I assume that any of above solution will be cheaper than the ‘state of the art’ standard design, we must choose the most ‘professional’ solution convincing partner and financier.

I know, Dean, this is not what you are aiming at but please consider that (at this stage) we are not designing household facilities but community size infrastructure which must be appreciated by water & sanitation administrators and be financed by international development banks. And I need your professional input designing them right.

We will come to designing household facilities, those to be financed by banks and those to be built by the users… 😊

Dean, what do you pay for the fruit crates in NZ?

Ciao

Hajo

We can't solve problems by using the same kind of thinking we used when we created them.

Albert Einstein

Any intelligent fool can make things bigger and more complex... It takes a touch of a genius - and a lot of courage to move in the opposite direction.

E.F. Schumacher

Everything should be made as simple as possible, but not simpler.

Albert Einstein

Albert Einstein

Any intelligent fool can make things bigger and more complex... It takes a touch of a genius - and a lot of courage to move in the opposite direction.

E.F. Schumacher

Everything should be made as simple as possible, but not simpler.

Albert Einstein

Please Log in to join the conversation.

You need to login to reply- HarryTams

-

Less

- Posts: 31

- Likes received: 14

Re: Reply: Promote VERMIFILTRATION Technology for WASTEWATER PURIFICATION by EARTHWORMS to produce clean water

The drainage panels if they are universally available appear to be a multipurpose material even inside a UDDT chamber.

I like the modular possibilities and the ability to scale this concept up or down.

Harry

I like the modular possibilities and the ability to scale this concept up or down.

Harry

The following user(s) like this post: goeco

Please Log in to join the conversation.

You need to login to replyRe: Reply: Promote VERMIFILTRATION Technology for WASTEWATER PURIFICATION by EARTHWORMS to produce clean water

Hi Hajo,

For a pilot you'd want to choose materials and products which together create the most cost-effective setup possible to make the case for further deployment. The big plastic forklift fruit crates are not cheap but they are convenient in that they can form the structure, so require only cladding. The large plastic culverts are also quite expensive in terms of cost per unit volume of media capacity. The plastic pallets are a cost-effective base for primary digesters and also secondary plants because they handle weight and are durable. In order to have a utilisable depth of media in a larger-capacity reactor, there needs to be a method to get air into the media so the full depth of media remains aerobic. Plastic drainage cell panels could be used for this:

500mm x 600mm x 20mm panels. These cost about $3 each

They could be used for ventilation inside the outer wall of the reactor and also as vertical dividers that provide ventilation through the media. They could be set up as an "x pattern" grid that provides ventilation right through the media from bottom to top every 60cm. So the reactor shell might be square and made with structural walls, say 3.6m x 3.6m x 3m high, with a grid inside made from 600 mm squares, six high. These would form 36 three metre high 600mm wide "square tubes" each lined with windbreak cloth and filled with media. That would be 504 panels costing $1500 for a capacity of approximately 38 cubic metres of media. The reactor would be built on top of plastic pallets ventilating the grid from underneath.

The whole point of these designs are so that the media can be deep, but still well aerated. A deep aerated media provides better treatment and only one pump is required to lift the water from the sump of the primary vermi-digester to the top of the secondary vermifilter, which can even have the OUTLET elevated to gravity feed the surface irrigation system.

The key innovation is to cost effectively utilise the full capacity of the media. Deep media reduces the cost and increases the treatment efficiency per unit of capacity. BUT only if the media remains fully aerobic. AND only if the cost is not too high, otherwise the standard-practice wide shallow vermifilter beds win the day. So we need something that is professional looking, durable and long-lasting, but also low cost...

cheers

Dean

For a pilot you'd want to choose materials and products which together create the most cost-effective setup possible to make the case for further deployment. The big plastic forklift fruit crates are not cheap but they are convenient in that they can form the structure, so require only cladding. The large plastic culverts are also quite expensive in terms of cost per unit volume of media capacity. The plastic pallets are a cost-effective base for primary digesters and also secondary plants because they handle weight and are durable. In order to have a utilisable depth of media in a larger-capacity reactor, there needs to be a method to get air into the media so the full depth of media remains aerobic. Plastic drainage cell panels could be used for this:

500mm x 600mm x 20mm panels. These cost about $3 each

They could be used for ventilation inside the outer wall of the reactor and also as vertical dividers that provide ventilation through the media. They could be set up as an "x pattern" grid that provides ventilation right through the media from bottom to top every 60cm. So the reactor shell might be square and made with structural walls, say 3.6m x 3.6m x 3m high, with a grid inside made from 600 mm squares, six high. These would form 36 three metre high 600mm wide "square tubes" each lined with windbreak cloth and filled with media. That would be 504 panels costing $1500 for a capacity of approximately 38 cubic metres of media. The reactor would be built on top of plastic pallets ventilating the grid from underneath.

The whole point of these designs are so that the media can be deep, but still well aerated. A deep aerated media provides better treatment and only one pump is required to lift the water from the sump of the primary vermi-digester to the top of the secondary vermifilter, which can even have the OUTLET elevated to gravity feed the surface irrigation system.

The key innovation is to cost effectively utilise the full capacity of the media. Deep media reduces the cost and increases the treatment efficiency per unit of capacity. BUT only if the media remains fully aerobic. AND only if the cost is not too high, otherwise the standard-practice wide shallow vermifilter beds win the day. So we need something that is professional looking, durable and long-lasting, but also low cost...

cheers

Dean

Dean Satchell, M For. Sc.

Vermifilter.com

www.vermifilter.com

Vermifilter.com

www.vermifilter.com

Attachments:

-

20mm-drain...cell.jpg

(Filesize: 32KB)

20mm-drain...cell.jpg

(Filesize: 32KB)

The following user(s) like this post: HarryTams

Please Log in to join the conversation.

You need to login to reply- hajo

-

- retired in Germany... but still interested in water and sanitation... especially in OSS... and especially in Africa...

Less- Posts: 288

- Karma: 15

- Likes received: 156

Re: Reply: Promote VERMIFILTRATION Technology for WASTEWATER PURIFICATION by EARTHWORMS to produce clean water

Hi Dean,

I like the discussion with you…. Always new ideas to digest… Thanks!

Budget: we are currently in discussions with our financier about the on-site sanitation package of our program. Thus, it is more about functionality of the technology and whether they are willing to ‘risk’ some money on a pilot, rather than making it cheap.

Inlet pipes: yes, I agree that it is more practicable having the vacuum truck off-loading at the place where septage/food is needed just ‘now’. We will not have a continues flow of septage coming in. The manifold distribution pipe may be needed once we connect a VC primary digester to a sewer pipe (of a (semi-)centralised system). I will foresee an access road along the VC digester where the truck can pass and pump onto the digester at any place.

Weight: the pallets which I selected can carry up to 4000 kg static load and you also get them for 5000 and 6000kg.The media plus septage may weigh (2500 kg/m3) at 60cm height (max) about 1500 kg, or?

Cockroaches: this is definitely a topic for household VC digesters but not only for them. When I open manholes of waste pipe or septic tank on my plot, there are lots of them. I wonder whether we must bother about them when we have a ‘central’ VC FSTP and not close to residential places?

Mosquito netting: that is meant to keep flies, cockroaches and rodents out from the top of the VC digester, preventing them from feeding on the septage and carrying contamination to the neighbourhood. Needs to be discussed further whether needed.

VC filter: I agree that the VC filter cartridges can be made from either these PE culverts or from plastic drums, but both approaches give me too much impression of DIY … which is ok for you and me running our private VC plant but more difficult to sell to a development bank being asked to invest into a pilot … your previous proposal of ‘pods’ of 36 fruit crates will look more ‘professional’ and will therefore be easier to sell, don’t you agree? Did you not install such filter at a commercial place in India? I thought I saw a video of you where the filter looks very professional, that is what we need in order to sell it.

Ciao

Hajo

I like the discussion with you…. Always new ideas to digest… Thanks!

Budget: we are currently in discussions with our financier about the on-site sanitation package of our program. Thus, it is more about functionality of the technology and whether they are willing to ‘risk’ some money on a pilot, rather than making it cheap.

Inlet pipes: yes, I agree that it is more practicable having the vacuum truck off-loading at the place where septage/food is needed just ‘now’. We will not have a continues flow of septage coming in. The manifold distribution pipe may be needed once we connect a VC primary digester to a sewer pipe (of a (semi-)centralised system). I will foresee an access road along the VC digester where the truck can pass and pump onto the digester at any place.

Weight: the pallets which I selected can carry up to 4000 kg static load and you also get them for 5000 and 6000kg.The media plus septage may weigh (2500 kg/m3) at 60cm height (max) about 1500 kg, or?

Cockroaches: this is definitely a topic for household VC digesters but not only for them. When I open manholes of waste pipe or septic tank on my plot, there are lots of them. I wonder whether we must bother about them when we have a ‘central’ VC FSTP and not close to residential places?

Mosquito netting: that is meant to keep flies, cockroaches and rodents out from the top of the VC digester, preventing them from feeding on the septage and carrying contamination to the neighbourhood. Needs to be discussed further whether needed.

VC filter: I agree that the VC filter cartridges can be made from either these PE culverts or from plastic drums, but both approaches give me too much impression of DIY … which is ok for you and me running our private VC plant but more difficult to sell to a development bank being asked to invest into a pilot … your previous proposal of ‘pods’ of 36 fruit crates will look more ‘professional’ and will therefore be easier to sell, don’t you agree? Did you not install such filter at a commercial place in India? I thought I saw a video of you where the filter looks very professional, that is what we need in order to sell it.

Ciao

Hajo

We can't solve problems by using the same kind of thinking we used when we created them.

Albert Einstein

Any intelligent fool can make things bigger and more complex... It takes a touch of a genius - and a lot of courage to move in the opposite direction.

E.F. Schumacher

Everything should be made as simple as possible, but not simpler.

Albert Einstein

Albert Einstein

Any intelligent fool can make things bigger and more complex... It takes a touch of a genius - and a lot of courage to move in the opposite direction.

E.F. Schumacher

Everything should be made as simple as possible, but not simpler.

Albert Einstein

The following user(s) like this post: HarryTams

Please Log in to join the conversation.

You need to login to replyRe: Reply: Promote VERMIFILTRATION Technology for WASTEWATER PURIFICATION by EARTHWORMS to produce clean water

Hi Hajo,

If that sized primary plant is within your budget then it looks like a good size to pilot the technology. You might scale up or down for 500 users and there will be lessons to learn as with anything pioneering. Not sure if you'd need the fixed inlet pipes, wouldn't you just be pumping in septage from the collection truck on to the surface where it needs it?

Once the worms are established and busy digesting the 30cm layer of solids, you'd top up at regular intervals, ensuring you always have a layer of fresh stuff on top. It will be a weight thing, the applied septage will be heavy with water and the water will drain with time - so let it drain and then add more - the pallets will only handle so much weight. Eventually you would need to remove the buildup of humus. But never all of it, a layer of humus would always be left as the drainage base/worm habitat.

Because it is semi-treated (septic tank) septage/sludge rather than fresh sewage, you might not have problems with cockroaches and vermin? Certainly raw sewage solids will attract vermin and a primary digester shouldn't allow cockroach and vermin entry. I have heard of examples where the biofil vermidigester toilet was not sufficiently vermin proof to keep cockroaches out... sounds pretty gross and unsanitary that they could come out from the shit pile and crawl into the kitchen only metres away! I provide 2mm gauze ventilation in domestic vermidigesters, which only gives small (beneficial) insects access. You certainly don't want any pooling water under your false floor that will attract mosquitos, but other than that I doubt you'd need mosquito netting for primary septage/sludge treatment. Yes to a roof, you are trying to drain the septage... and rainwater is best kept off it and would just add to the liquid effluent. Perhaps a polythene roof and simple "greenhouse" structure with windbreak walls to stop dogs and rodents.

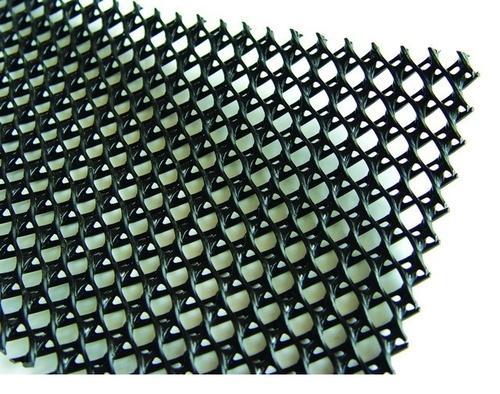

For secondary digesters you can use plastic culvert pipe, here is a photo:

2-3m height would be adequate and they could be set up as towers strapped together, each with vents at the bottom and top.

Tall narrow water tanks made from plastic culvert pipe

Inside you'd make the ventilation cavity from twenty or so evenly spaced pieces of vertical polyethylene tubing or slotted draincoil attached to the inside wall of the culvert. A plastic mesh "tube" lined with textile (windbreak cloth) would fit inside the cavity and hold the media. You can even source lids for the 600 mm culvert.

Sturdy plastic mesh used for geotextile drainage

Alternatively stack 40 gallon plastic drums on top of each other if they are free or cheap. Recycle where you can!

cheers

Dean

If that sized primary plant is within your budget then it looks like a good size to pilot the technology. You might scale up or down for 500 users and there will be lessons to learn as with anything pioneering. Not sure if you'd need the fixed inlet pipes, wouldn't you just be pumping in septage from the collection truck on to the surface where it needs it?

Once the worms are established and busy digesting the 30cm layer of solids, you'd top up at regular intervals, ensuring you always have a layer of fresh stuff on top. It will be a weight thing, the applied septage will be heavy with water and the water will drain with time - so let it drain and then add more - the pallets will only handle so much weight. Eventually you would need to remove the buildup of humus. But never all of it, a layer of humus would always be left as the drainage base/worm habitat.

Because it is semi-treated (septic tank) septage/sludge rather than fresh sewage, you might not have problems with cockroaches and vermin? Certainly raw sewage solids will attract vermin and a primary digester shouldn't allow cockroach and vermin entry. I have heard of examples where the biofil vermidigester toilet was not sufficiently vermin proof to keep cockroaches out... sounds pretty gross and unsanitary that they could come out from the shit pile and crawl into the kitchen only metres away! I provide 2mm gauze ventilation in domestic vermidigesters, which only gives small (beneficial) insects access. You certainly don't want any pooling water under your false floor that will attract mosquitos, but other than that I doubt you'd need mosquito netting for primary septage/sludge treatment. Yes to a roof, you are trying to drain the septage... and rainwater is best kept off it and would just add to the liquid effluent. Perhaps a polythene roof and simple "greenhouse" structure with windbreak walls to stop dogs and rodents.

For secondary digesters you can use plastic culvert pipe, here is a photo:

2-3m height would be adequate and they could be set up as towers strapped together, each with vents at the bottom and top.

Tall narrow water tanks made from plastic culvert pipe

Inside you'd make the ventilation cavity from twenty or so evenly spaced pieces of vertical polyethylene tubing or slotted draincoil attached to the inside wall of the culvert. A plastic mesh "tube" lined with textile (windbreak cloth) would fit inside the cavity and hold the media. You can even source lids for the 600 mm culvert.

Sturdy plastic mesh used for geotextile drainage

Alternatively stack 40 gallon plastic drums on top of each other if they are free or cheap. Recycle where you can!

cheers

Dean

Dean Satchell, M For. Sc.

Vermifilter.com

www.vermifilter.com

Vermifilter.com

www.vermifilter.com

Attachments:

-

LargePEculverts.jpg

(Filesize: 166KB)

LargePEculverts.jpg

(Filesize: 166KB)

-

drainage-n...x500.jpg

(Filesize: 54KB)

drainage-n...x500.jpg

(Filesize: 54KB)

-

H10108H10107-2.jpg

(Filesize: 63KB)

H10108H10107-2.jpg

(Filesize: 63KB)

The following user(s) like this post: HarryTams

Please Log in to join the conversation.

You need to login to reply

Share this thread:

- Resource recovery

- Vermitechnology

- Vermifilters (or vermi-digesters)

- Promote VERMIFILTRATION Technology for WASTEWATER PURIFICATION by EARTHWORMS to produce clean water

Recently active users. Who else has been active?

Time to create page: 0.283 seconds