- Resource recovery

- Resource recovery from excreta, faecal sludge or wastewater

- Production of biochar, fuel or electricity

- Faecal sludge to biodiesel (Columbia University, USA and Kumasi, Ghana)

Faecal sludge to biodiesel (Columbia University, USA and Kumasi, Ghana)

31.9k views

Re: Faecal sludge to biodiesel (Columbia University, USA and Kumasi, Ghana)

Dear Melani,

As a professional working in biogas, I am always very interested in projects involving anaerobic fermentation.

One thing that does not really become clear to me from the process schematic that you included.

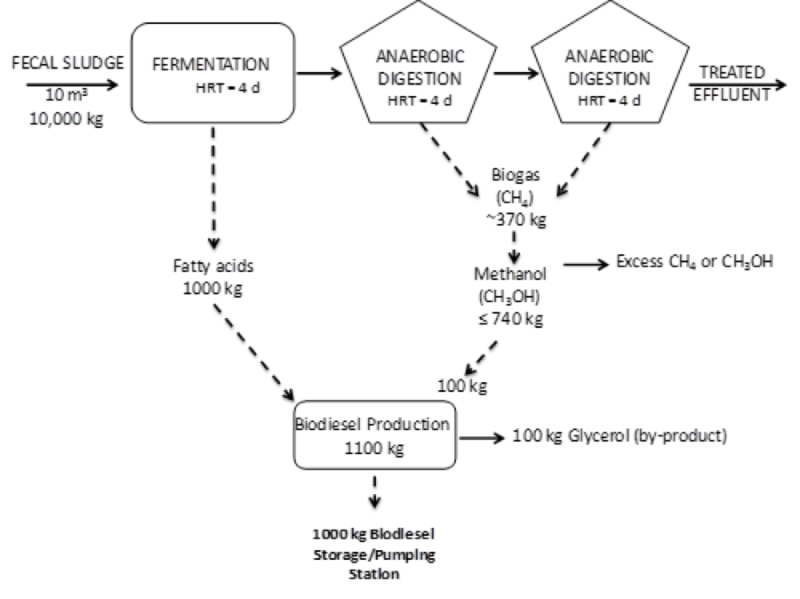

As I understand you propose to separate part of the VFAs (a precursor to biogas), from the fermenting sludge. Also you propose to turn the biogas made from the remaining VFAs into Methanol and then combine VFAs and Methanol to biodiesel. Correct?

My question is how this process will be more efficient than just producing biogas from all VFAs and using it to generate electricity?

I am sure I have missed some important point and would like to understand the tinking behind the project better.

Kind regards

Marijn Zandee

As a professional working in biogas, I am always very interested in projects involving anaerobic fermentation.

One thing that does not really become clear to me from the process schematic that you included.

As I understand you propose to separate part of the VFAs (a precursor to biogas), from the fermenting sludge. Also you propose to turn the biogas made from the remaining VFAs into Methanol and then combine VFAs and Methanol to biodiesel. Correct?

My question is how this process will be more efficient than just producing biogas from all VFAs and using it to generate electricity?

I am sure I have missed some important point and would like to understand the tinking behind the project better.

Kind regards

Marijn Zandee

Marijn Zandee

E: This email address is being protected from spambots. You need JavaScript enabled to view it.

E: This email address is being protected from spambots. You need JavaScript enabled to view it.

Please Log in to join the conversation.

You need to login to reply- mv2368

-

- FS2BD team page

Less- Posts: 7

- Karma: 3

- Likes received: 2

Re: Biofuels: The "Food vs. Fuel" Debate, can Human Waste be the answer?

Hi Esther! I am so glad your post got moved here. That is exactly the research question of FS2BD. I hope you can read some of the updated information above and in our library.

Biofuel has definitely gotten a bad reputation among environmentalists and public health workers. I get very mixed reactions when I explain that I am working on biodiesel production-until I describe that the feedstock we are using is fecal sludge - although currently we are analyzing our options for including other feedstocks, such as food waste-.

I am currently in Kumasi as a summer researcher trying to develop an environmental and public health assessment of what the plant is doing in terms of emissions as well as pathogen removal. I am working with KNUST students setting up colilert to determine the pathogen removal from our treatment (the primary public health objective, although protecting our food supply and reducing air pollution from fossil fuels are also pretty high up on the list).

We will soon have more information to share with everyone in the forum about our results!

Biofuel has definitely gotten a bad reputation among environmentalists and public health workers. I get very mixed reactions when I explain that I am working on biodiesel production-until I describe that the feedstock we are using is fecal sludge - although currently we are analyzing our options for including other feedstocks, such as food waste-.

I am currently in Kumasi as a summer researcher trying to develop an environmental and public health assessment of what the plant is doing in terms of emissions as well as pathogen removal. I am working with KNUST students setting up colilert to determine the pathogen removal from our treatment (the primary public health objective, although protecting our food supply and reducing air pollution from fossil fuels are also pretty high up on the list).

We will soon have more information to share with everyone in the forum about our results!

FS2BD team

Please Log in to join the conversation.

You need to login to reply- EstherGlotzbach

-

- I am currently working on a sanitation competition called "What to do with poo?" This challenge is part of a larger programme called the Nakuru County Sanitation Programme, which aims to put a sanitation value chain in place in Nakuru County, Kenya.

Less- Posts: 6

- Likes received: 2

Re: Biofuels: The "Food vs. Fuel" Debate, can Human Waste be the answer?

(note by moderator (EvM): I have moved this post to here because it fits perfectly into this thread)

+++++++++++++++++++

Food vs. fuel is the dilemma regarding the risk of diverting farmland or crops for biofuels production in detriment of the food supply on a global scale. The "food vs. fuel" or "food or fuel" debate is international in scope, with valid arguments on all sides of the issue. There is disagreement about how significant the issue is, what is causing it, and what can or should be done about it.

Biofuel production has increased in recent years. Some commodities like maize (corn), sugar cane or vegetable oil can be used either as food, feed, or to make biofuels.

With global demand for biofuels on the increase due to the oil price increases taking place since 2003 and the desire to reduce oil dependency as well as reduce GHG emissions from transportation, there is also fear of the potential destruction of natural habitats by being converted into farmland. Environmental groups have raised concerns about this trade-off for several years,but now the debate reached a global scale due to the 2007–2008 world food price crisis. While recent research by the World Bank and OECD has shown that the impacts of biofuels on food prices are much smaller than originally thought, there is still an issue; the demand for fuel in rich countries is now competing against demand for food in poor countries.

Can biofuel made from Human Waste be an alternative solution?

+++++++++++++++++++

Food vs. fuel is the dilemma regarding the risk of diverting farmland or crops for biofuels production in detriment of the food supply on a global scale. The "food vs. fuel" or "food or fuel" debate is international in scope, with valid arguments on all sides of the issue. There is disagreement about how significant the issue is, what is causing it, and what can or should be done about it.

Biofuel production has increased in recent years. Some commodities like maize (corn), sugar cane or vegetable oil can be used either as food, feed, or to make biofuels.

With global demand for biofuels on the increase due to the oil price increases taking place since 2003 and the desire to reduce oil dependency as well as reduce GHG emissions from transportation, there is also fear of the potential destruction of natural habitats by being converted into farmland. Environmental groups have raised concerns about this trade-off for several years,but now the debate reached a global scale due to the 2007–2008 world food price crisis. While recent research by the World Bank and OECD has shown that the impacts of biofuels on food prices are much smaller than originally thought, there is still an issue; the demand for fuel in rich countries is now competing against demand for food in poor countries.

Can biofuel made from Human Waste be an alternative solution?

Esther Umutoni Glotzbach

ESA WASH and Local Organizer

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.snvworld.org

www.whattodowithpoo.com

ESA WASH and Local Organizer

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.snvworld.org

www.whattodowithpoo.com

The following user(s) like this post: mv2368

Please Log in to join the conversation.

You need to login to reply- hanutime

-

Less

- Posts: 1

- Likes received: 2

Re: Faecal sludge to biodiesel. Work in Kumasi and New York (Columbia University, USA and Ghana)

hello,

my name is Hanan,i am from Ethiopia.I am very glad to hear this as someone from low income country and i hope it will be very helpfull for most countries as far as energy is the heart of one's country economic development ...so i would to congradulate the founders.

my name is Hanan,i am from Ethiopia.I am very glad to hear this as someone from low income country and i hope it will be very helpfull for most countries as far as energy is the heart of one's country economic development ...so i would to congradulate the founders.

The following user(s) like this post: mv2368, SusannahClemence

Please Log in to join the conversation.

You need to login to reply- mv2368

-

- FS2BD team page

Less- Posts: 7

- Karma: 3

- Likes received: 2

Re: Faecal sludge to biodiesel (Columbia University, USA and Kumasi, Ghana)

Hello!

We want to introduce our grant here:

Title of grant: Fecal Sludge-Fed Biodiesel Plants: The Next-Generation Urban Sanitation Facility

Subtitle: Creating a next-generation urban sanitation facility by transforming fecal sludge into biodiesel and methane.

Name of lead organization: Columbia University

Primary contact at lead organization: Kartik Chandran (his faculty website) and Ashley Murray

Grantee location: New York, USA

Developing country where the research is being tested: Ghana

Short description of the project:

This project focuses on the development of a resource-recovery based sanitation technology. which uses fecal sludge as a feedstock for producing biodiesel and biogas. The technology development is being conducted by a team of nine American and Ghanaian engineers based in Kumasi, with the oversight of Prof. Kartik Chandran of Columbia University. Technology development is accompanied by development of a social business model that aims to use revenue from energy products to help finance and incentivize complete and sustained urban sanitation.

Goal(s):

1) To develop a bioprocess technology based on anaerobic fermentation and digestion to convert faecal sludge into biodiesel precursors and biogas

2) To develop an associated social enterprise model that reinvests the revenues into improving sanitation for the urban poor and is widely transferrable.

Objectives (or activities or key research components):

1) Developing a bioprocess technology to convert the organic compounds present in fecal sludge to biodiesel and biogas.

2) Piloting the technology in Kumasi, Ghana at a design capacity of 10,000 L fecal sludge per day

3) Integrating the bioprocess technology component into a social enterprise business model that will further promote widespread implementation of this approach and technology across the globe.

Start and end date: May 2011 - December 2013 (Phase 2 extension until December 2015)

Grant type: Other

Grant size: $ 1,525,979 (Phase 1, see here on grant database), followed by $ 273,083 (Phase 2 in 2013, see here in grant database)

Funding for this research currently ongoing: yes

Research or implementation partners: Kartik Chandran Laboratories at Columbia University School of Engineering, Kwame Nkrumah University of Science and Technology (KNUST), the Kumasi Metropolitan Assembly, and the Ghanaian company Waste Enterprisers Ltd.

Current state of affairs:

1) Phase 1 of the project, which includes the pilot-scale fermentation units (total volume of 120 m3, design capacity of 10 m3 of faecal sludge per day) was commissioned in November 2012. The plant is now being operated at 50% of the design capacity and its performance is being monitored with the use of advanced techniques and assays. The local engineering students from KNUST have been trained in the use of these advanced methods.

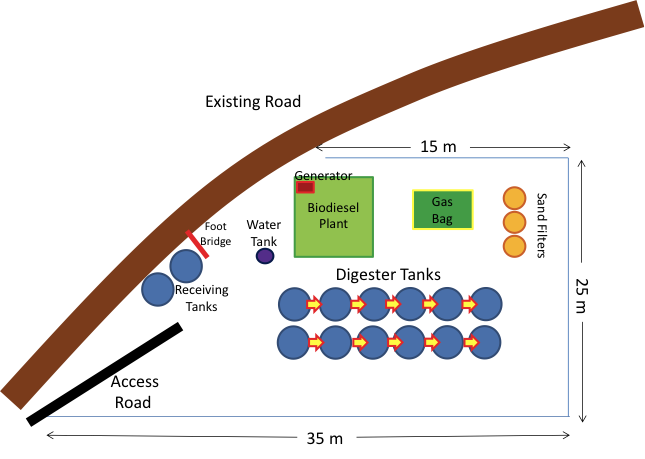

Figure 1: 6 digesters connected in series in Kumasi.

Figure 2: General plant schematic

2) A chemical and analytical laboratory has been constructed in Kumasi specifically for this purpose, under the auspices of this project.

3) Phase 2 of the piloting effort, which includes the biodiesel plant will be commissioned in June 2013.

4) A comprehensive survey of fecal sludge characteristics from different sources around Kumasi was conducted. This survey included approximately hundred samples, gathered over a period of six months. The samples were characterized for not only typical state variables including the particulate, carbonaceous and nitrogenous content, but also specific variables pertaining to the production of biodiesel, including lipid content and free-fatty acid content. These added variables have not been quantified in faecal sludge thus far and therefore, these results are rather novel and informative.

5) In addition to pilot-scale research and development, the team is also undertaking extensive bench-scale work. The bench-scale work to date has been primarily conducted in Kumasi, Ghana in the newly built project-lab. Select activities have been conducted in the Chemistry lab at KNUST and the plant biology lab at the Council for Scientific and industrial Research in Kumasi. The bench-scale work address the following topics:

a. Determination of faecal sludge fermentation kinetics, when subjected to different feedstocks and inocula. These studies were instrumental in informing our pilot-scale startup operations.

b. Development of protocols for testing different wet and dry procedures for extracting lipids from faecal sludge and for converting the inherent lipids present in faecal sludge to biodiesel.

c. Cultivation and integration of axenic yeast cultures into the faecal sludge to biodiesel pipeline. Parallel studies with yeast cultures are also underway at Columbia.

d. Prior to their implementation, project engineer, Jeremy Rushlow conducted extensive testing at the Kartik Chandran labs at Columbia University to determine the impact of free-fatty acids on esterficiation and transesterification yields, different procedures for extracting lipids from food waste (due to the non-availability of faecal sludge in New York) and procedures for extracting lipids from biomass.

6) Although not funded directly by this project, engineers in the Kartik Chandran labs have been developing technologies to biologically convert biogas into methanol. If successful, this technology can serve to reduce the operating costs of converting faecal sludge to biodiesel, by providing an internal source of methanol. Based on our progress, we will explore the integration of this new technology into this faecal sludge to biodiesel project. A paper on this topic was recently published by us in Environmental Science and Technology and reported substantially higher biokinetics and yields of biomethanol from methane than previously documented .

Figure 3: Schematic of fecal sludge to biodiesel conversion process

Publications, presentations, links, further readings, etc:

• Presentation at the 2nd International Conference on Faecal Sludge Management (FSM2) as a foundation for urban sustainability

Powerpoint slides: www.susana.org/images/documents/07-cap-d...a-university-usa.pdf

Video of the presentation by Kartik Chandran:

• TEDx talk on Resource recovery as a foundation for urban sustainability:

• Journal paper: High-Rate, High-Yield Production of Methanol by Ammonia-Oxidizing Bacteria (April 2013) dx.doi.org/10.1021/es3042912

• Press release of the Columbia University (Nov 19 2012)

Website of Waste Enterprisers Ltd.: www.waste-enterprisers.com

Check out our page on the susana library! We will be posting more documents there soon.

We want to introduce our grant here:

Title of grant: Fecal Sludge-Fed Biodiesel Plants: The Next-Generation Urban Sanitation Facility

Subtitle: Creating a next-generation urban sanitation facility by transforming fecal sludge into biodiesel and methane.

Name of lead organization: Columbia University

Primary contact at lead organization: Kartik Chandran (his faculty website) and Ashley Murray

Grantee location: New York, USA

Developing country where the research is being tested: Ghana

Short description of the project:

This project focuses on the development of a resource-recovery based sanitation technology. which uses fecal sludge as a feedstock for producing biodiesel and biogas. The technology development is being conducted by a team of nine American and Ghanaian engineers based in Kumasi, with the oversight of Prof. Kartik Chandran of Columbia University. Technology development is accompanied by development of a social business model that aims to use revenue from energy products to help finance and incentivize complete and sustained urban sanitation.

Goal(s):

1) To develop a bioprocess technology based on anaerobic fermentation and digestion to convert faecal sludge into biodiesel precursors and biogas

2) To develop an associated social enterprise model that reinvests the revenues into improving sanitation for the urban poor and is widely transferrable.

Objectives (or activities or key research components):

1) Developing a bioprocess technology to convert the organic compounds present in fecal sludge to biodiesel and biogas.

2) Piloting the technology in Kumasi, Ghana at a design capacity of 10,000 L fecal sludge per day

3) Integrating the bioprocess technology component into a social enterprise business model that will further promote widespread implementation of this approach and technology across the globe.

Start and end date: May 2011 - December 2013 (Phase 2 extension until December 2015)

Grant type: Other

Grant size: $ 1,525,979 (Phase 1, see here on grant database), followed by $ 273,083 (Phase 2 in 2013, see here in grant database)

Funding for this research currently ongoing: yes

Research or implementation partners: Kartik Chandran Laboratories at Columbia University School of Engineering, Kwame Nkrumah University of Science and Technology (KNUST), the Kumasi Metropolitan Assembly, and the Ghanaian company Waste Enterprisers Ltd.

Current state of affairs:

1) Phase 1 of the project, which includes the pilot-scale fermentation units (total volume of 120 m3, design capacity of 10 m3 of faecal sludge per day) was commissioned in November 2012. The plant is now being operated at 50% of the design capacity and its performance is being monitored with the use of advanced techniques and assays. The local engineering students from KNUST have been trained in the use of these advanced methods.

Figure 1: 6 digesters connected in series in Kumasi.

Figure 2: General plant schematic

2) A chemical and analytical laboratory has been constructed in Kumasi specifically for this purpose, under the auspices of this project.

3) Phase 2 of the piloting effort, which includes the biodiesel plant will be commissioned in June 2013.

4) A comprehensive survey of fecal sludge characteristics from different sources around Kumasi was conducted. This survey included approximately hundred samples, gathered over a period of six months. The samples were characterized for not only typical state variables including the particulate, carbonaceous and nitrogenous content, but also specific variables pertaining to the production of biodiesel, including lipid content and free-fatty acid content. These added variables have not been quantified in faecal sludge thus far and therefore, these results are rather novel and informative.

5) In addition to pilot-scale research and development, the team is also undertaking extensive bench-scale work. The bench-scale work to date has been primarily conducted in Kumasi, Ghana in the newly built project-lab. Select activities have been conducted in the Chemistry lab at KNUST and the plant biology lab at the Council for Scientific and industrial Research in Kumasi. The bench-scale work address the following topics:

a. Determination of faecal sludge fermentation kinetics, when subjected to different feedstocks and inocula. These studies were instrumental in informing our pilot-scale startup operations.

b. Development of protocols for testing different wet and dry procedures for extracting lipids from faecal sludge and for converting the inherent lipids present in faecal sludge to biodiesel.

c. Cultivation and integration of axenic yeast cultures into the faecal sludge to biodiesel pipeline. Parallel studies with yeast cultures are also underway at Columbia.

d. Prior to their implementation, project engineer, Jeremy Rushlow conducted extensive testing at the Kartik Chandran labs at Columbia University to determine the impact of free-fatty acids on esterficiation and transesterification yields, different procedures for extracting lipids from food waste (due to the non-availability of faecal sludge in New York) and procedures for extracting lipids from biomass.

6) Although not funded directly by this project, engineers in the Kartik Chandran labs have been developing technologies to biologically convert biogas into methanol. If successful, this technology can serve to reduce the operating costs of converting faecal sludge to biodiesel, by providing an internal source of methanol. Based on our progress, we will explore the integration of this new technology into this faecal sludge to biodiesel project. A paper on this topic was recently published by us in Environmental Science and Technology and reported substantially higher biokinetics and yields of biomethanol from methane than previously documented .

Figure 3: Schematic of fecal sludge to biodiesel conversion process

Publications, presentations, links, further readings, etc:

• Presentation at the 2nd International Conference on Faecal Sludge Management (FSM2) as a foundation for urban sustainability

Powerpoint slides: www.susana.org/images/documents/07-cap-d...a-university-usa.pdf

Video of the presentation by Kartik Chandran:

• TEDx talk on Resource recovery as a foundation for urban sustainability:

• Journal paper: High-Rate, High-Yield Production of Methanol by Ammonia-Oxidizing Bacteria (April 2013) dx.doi.org/10.1021/es3042912

• Press release of the Columbia University (Nov 19 2012)

Website of Waste Enterprisers Ltd.: www.waste-enterprisers.com

Check out our page on the susana library! We will be posting more documents there soon.

FS2BD team

Attachments:

-

fermenters.png

(Filesize: 667KB)

fermenters.png

(Filesize: 667KB)

-

plantschematic.png

(Filesize: 64KB)

plantschematic.png

(Filesize: 64KB)

-

mechanisms.png

(Filesize: 110KB)

mechanisms.png

(Filesize: 110KB)

The following user(s) like this post: rahul, susu

Please Log in to join the conversation.

You need to login to replyRequest for proposals: use of biodiesel research facility in Kumasi, Ghana

This attachment is hidden for guests.

Please log in or register to see it.

Please log in or register to see it.

-PLEASE CIRCULATE—

Please find an RfP attached for use of the biodiesel research facility in Kumasi, Ghana (short summary below). Please circulate this call to colleagues and networks.

This is a really incredible research opportunity for partners who might be interested in conducting biogas and/or fermentation field research. FS is delivered to the “door”. The project anticipates finding a reliable organization to take over the site and equipment. In the event reliable applicants are not identified, the team will have to formally decommission the plant otherwise.

Roshan Shrestha,PhD

Senior Program Officer

Global Development Division

Water, Sanitation and Hygiene

Seattle - WA

Tel: +206 770 2453

email: This email address is being protected from spambots. You need JavaScript enabled to view it.

www.gatesfoundation.org

Senior Program Officer

Global Development Division

Water, Sanitation and Hygiene

Seattle - WA

Tel: +206 770 2453

email: This email address is being protected from spambots. You need JavaScript enabled to view it.

www.gatesfoundation.org

This message has an attachment file.

Please log in or register to see it.

The following user(s) like this post: tmsinnovation, susu

Please Log in to join the conversation.

You need to login to reply

Share this thread:

- Resource recovery

- Resource recovery from excreta, faecal sludge or wastewater

- Production of biochar, fuel or electricity

- Faecal sludge to biodiesel (Columbia University, USA and Kumasi, Ghana)

Recently active users. Who else has been active?

Time to create page: 0.308 seconds