- Forum

- categories

- Sanitation systems

- Treatment of wastewater, sludges, organic waste, excreta

- Septic tanks (conventional or upgraded)

- Using Cocopeat for Treating Septic Tank Effluent (RTI, USA - Philippines, Indonesia, Vietnam and other countries)

Using Cocopeat for Treating Septic Tank Effluent (RTI, USA - Philippines, Indonesia, Vietnam and other countries)

61.7k views

- dmrobbins10

-

Topic Author

Topic Author- Improving life and livelihood through decentralized wastewater management

Less- Posts: 56

- Karma: 10

- Likes received: 33

Re: Using Cocopeat for Treating Septic Tank Effluent (RTI, USA - Philippines, Indonesia, Vietnam and other countries)

Thanks for your very good questions. I will address them one-by-one in the order you present them, but first, lets harmonize our definitions:

Fecal sludge is the undigested or partially digested slurry or solids that results from the storage or treatment of blackwater or excreta. It is the heavy solids that are pumped out of latrines when the pits are full, or the accumulated solids in septic tanks (septage).

Sewage is liquid waste containing some solids produced by humans, which typically consists of washing water, feces, urine, laundry wastes, and other material that flows down drains and toilets from households and other buildings.

In your questions, you are asking about the mechanisms of fecal sludge treatment in the cocopeat. It is important to point out that the cocopeat system as described in these posts is a technology for the treatment of effluent from primary treatment devices such as septic tanks or ABRs, and not for the treatment of fecal sludge. Fecal Sludge is characterized as high strength wastewater with typical BOD values of 5,000 mg/l (Manila Water, 2010). Raw sewage on the other hand, following the above definition may have BOD levels ranging from 200 to 600 mg/l on average, which is much better suited to systems that use primary treatment followed by biofiltration. Cocopeat technology is intended as a secondary treatment technology, meaning that sewage must first undergo pretreatment as needed, and then primary treatment through septic tanks, ABRs or biodigesters. It is the effluent from these primary treatment devices that can be applied to cocopeat biofilters for additional treatment to the point where it may be reused, recycled or in some cases, discharged.

Now, your questions:

1. What is causing the treatment in the cocopeat biofilter? The cocopeat system provides for both physical filtration and biofiltration. The physical filtration occurs when the larger suspended solids in the wastewater become trapped within the cocopeat media. Cocopeat is quite fine, and therefore is efficient in removing suspended solids. Our tests indicate that 85% to 95% removal of suspended solids is typical. As for the biofiltration, as you know, wastewater is biologically active, supporting a host of bacteria and other microbes. When applied to the cocopeat filter, the biota form a bio-slime that attaches to the cocopeat particles. As the wastewater passes through the media, it comes into contact with the bio-slime where the hungry microbes consume the organic matter as food. This is the same bio-slime that covers gravel in constructed wetlands or the plastic media in rotating biological contactors. While there may be some fungi in the cocopeat that helps, it is these naturally occurring organisms in the wastewater itself that accomplishes most of the treatment.

2. Coffee pulp waste as a treatment medium. This is an interesting hypothesis. I think the key would be to determine how well the material holds up in the wastewater environment. For some reason, cocopeat is very resilient and quite slow to break down. If the same is true for coffee pulp waste, you may be on to something. One note though, is that color is often an important consideration for final effluent quality. Cocopeat if unwashed will leave a residual "tea" color to the effluent for some weeks after the system is started up. Coffee waste may also leave an undesired color which should be evaluated prior to full scale implementation.

3. ABRs as primary treatment devices. ABRs, when properly designed, built, loaded and maintained can often remove 70% of the BOD in the wastewater (and even as much as 85% as reported in some cases). This may not be good enough in some cases to meet discharge standards. If your incoming BOD of the raw sewage is 600 mg/l for example, and your ABR removal efficiency is 85%, that still leaves 90 mg/l of BOD in the ABR effluent, which is too high for discharge in many areas. In the Philippines for example, sources discharging into Class C waters (highly polluted) are not allowed more than 50 mg/l of BOD in the discharged effluent. The other point to note is that ABRs like septic tanks are not disinfecting devices. Effluent from ABRs may be significant sources of pathogens. It is for these reasons that secondary treatment is often required. The cocopeat systems we tested reduced fecal coliform bacteria by between 95% and 99%. While this is still not enough reduction for some end uses, it makes full disinfection through chlorination or UV light much more feasible.

One more point. In the cocopeat related posts you will see an interesting project from Bangladesh where cocopeat is used in conjunction with sand filters for treating fecal sludge. In this instance, the cocopeat units are used to purify the drainage from the sand filters after the solids are left behind. This seems like a good use for cocopeat technology, but some checks are still required. Our testing suggested that cocopeat is a viable biofilter technology for wastewater influent of 350 mg/l or less. While it might work for higher strength influent, there is no testing to support that. High strength influent should be subjected to additional primary treatment to minimize the chance for overloading.

Hope this helps.

Cheers,

Dave Robbins

This email address is being protected from spambots. You need JavaScript enabled to view it.

This email address is being protected from spambots. You need JavaScript enabled to view it.

Please Log in to join the conversation.

You need to login to reply- srikanth

-

Less

- Posts: 4

- Likes received: 0

Re: Using Cocopeat for Treating Septic Tank Effluent (RTI, USA - Philippines, Indonesia, Vietnam and other countries)

I am back again with few more questions for you.

1) What exactly is treating the fecal sludge in Cocopeat? Any fungi or bacteria? My search on literature gave me an idea that Trichoderma- a fungi is present in Cocopeat. Is that what treating fecal sludge?

2) There is a good amount of coffee pulp waste in Africa, so i was just wondering if any studies done with coffee pulp waste as a medium to treat fecal sludge?

3)I understand from your previous posts, that it is advisable to use ABR as a primary treatment unit to meet the influent BOD load to cocopeat filter. If i am not wrong, ABR is very effective in removing BOD. So, what is the reason in going for ABR as the primary treatment unit only, instead using it as the only treatment option (no cocopeat).

Looking forward for your reply.

Thanks again for disseminating the knowledge and your thoughts to the world.

Srikanth.

Please Log in to join the conversation.

You need to login to reply- dmrobbins10

-

Topic Author

Topic Author- Improving life and livelihood through decentralized wastewater management

Less- Posts: 56

- Karma: 10

- Likes received: 33

Re: Using Cocopeat for Treating Septic Tank Effluent (RTI, USA - Philippines, Indonesia, Vietnam and other countries)

Thanks for checking the math. I rechecked our toolkit output and it came back with just under .2 kg of BOD per square meter of surface area per day. It was rounding, so your value of 175 grams of BOD per day is supported. The BOD calculator we use, by the way is a module from our source characterization tool (still under development) which you can download and test at: watsanexp.ning.com/page/design-tools-for-engineers

As for your other questions and comments, I will offer this. The recirculating system in my opinion is more robust and represents a better option over intermittent systems for larger point sources, where there is access to electricity and management has access to personnel with greater technical abilities. There are a number of reasons, but highest on the list is that the recirculating systems provide more treatment capacity for smaller spaces, while building in a mechanism for flow equalization. Flow equalization uses pumps and tanks to enable the designer to size the system for average flows rather than peak flows. Consider this for a church, mosque or public market, where flows throughout the week may be widely variable. Flow equalization in these examples can reduce the design flow by more than 50% in many cases with savings that often more than make up for the additional costs for the pump and tankage. This aspect of recirculating systems limits the potential for hydraulic or organic overloading, which often is the culprit behind clogged systems.

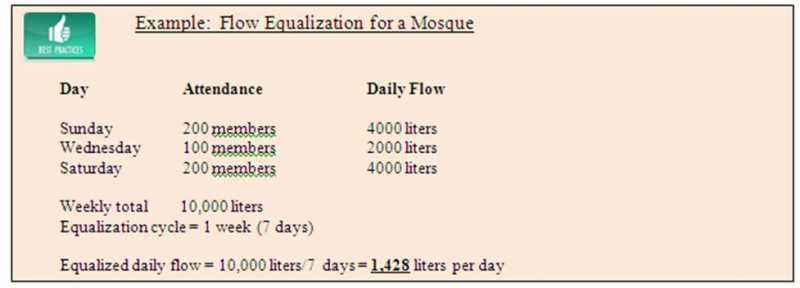

Here is an example of how flow equalization works (from our forthcoming IWA manual: Designing Wastewater Systems In Accordance with Local Conditions)

Example: Flow Equalization for a Church

NOTE: I haven't been able to figure out the "table" feature of this site, so you will have to click on the image attached to see the case study I have provided at the end of this post. Hope you find it useful. But here is the conclusion:

The equalized daily flow = 10,000 liters/7 days = 1,428 liters per day. In this case the design flow of 1,428 is well below 50% of the design flow of 4,000 liters per day that would be required without flow equalization.

Cheers, Christoph and best regards,

Dave Robbins,

Manila, Philippines

This email address is being protected from spambots. You need JavaScript enabled to view it.

Attachments:

-

Screen1.jpg

(Filesize: 18KB)

Screen1.jpg

(Filesize: 18KB)

Please Log in to join the conversation.

You need to login to replyRe: Using Cocopeat for Treating Septic Tank Effluent (RTI, USA - Philippines, Indonesia, Vietnam and other countries)

500 l/m²,d x 350 mg BOD/l /1000 mg/g = 175 g BOD/m².

This is an interesting number (I understand that is the highest) as it leeda to up to 4 pe/m². After conventional pretreatment (when low hydraulic figures). With anaerobic pretreatment (baffled) there chould be the possibility to go to almost 6 pe. But this would be a hydraulic challange?

Did you see a difference between recirculating and not recirculating?

When a system blocks (due to overload) did you test to rest it for some days for recovery? Might work, works quite well in weltands.

When you just recycle a system (same organic load but double the hydraulic load) what happens. And what about peaks?

Does the filter act really doing a retention of sludge (as in wetlands) or do you have to have a secondary clarifier.

Thanks

Christoph

Please Log in to join the conversation.

You need to login to reply- dmrobbins10

-

Topic Author

Topic Author- Improving life and livelihood through decentralized wastewater management

Less- Posts: 56

- Karma: 10

- Likes received: 33

Re: Using Cocopeat for Treating Septic Tank Effluent (RTI, USA - Philippines, Indonesia, Vietnam and other countries)

Thank you for your comments. As for the frequency of changing the cocopeat, our testing indicates that every 5 years, the cocopeat should be removed and replaced. Additionally, we found that after the first few months, there is quite a bit of settling. At the Putatan elementary school project in the Philippines, the cocopeat settled about 25 cm in the first several months, and we simply added new material on top of that to bring the level back to where it started. Routine operation and maintenance would be to rake the cocopeat bed surface every 3 months, add new material as needed to address settling, and completely replace the material every 5 years. The spent cocopeat material should be a great bulking agent for small compost piles (maybe mixed with biosolids from septic tanks or ABRs), although we have not performed studies on that yet.

Your second question relates to the organic loading on the filter. For single pass intermittent systems, the highest organic loading we tested was at the Institut Teknology Bandung (ITB) in Indonesia, where we applied as much as 500 liters of septic tank effluent (350 mg/l BOD on average) per square meter of filter surface area daily. If I am doing my math correctly, that equates to just over .2 kg of BOD per square meter of filter surface area per day. Please check and let me know if my math needs work.

Finally, we have not distinguished between high and low organic loading filters, but we did distinguish between high hydraulic and low hydraulic loading through the filter configuration. For our testing at Can Tho University in Vietnam, a recirculating filter configuration (multiple pass) was used, which allowed almost a three fold increase in the volume of septic tank effluent that could be treated daily. While a pump and timer system is required for recirculating systems, the higher treatment volume efficiency per unit of space might make up for the difference in component costs.

Your points are good, and for the next iteration of our toolkit, I think we should add the organic and hydraulic loading variables as you suggest.

Hope this helps. Thanks again for your suggestions and interest in this technology,

Best,

Dave Robbins

Manila, Philippines

This email address is being protected from spambots. You need JavaScript enabled to view it.

Please Log in to join the conversation.

You need to login to replyRe: Using Cocopeat for Treating Septic Tank Effluent (RTI, USA - Philippines, Indonesia, Vietnam and other countries)

I really appreciate the way of displaying clearly the information. Should be an example for everybody.

I find the solution interesting. Looking at the pictures I do ask myself about the frequency you have to exchange the material?

And what is the BOD load / m³? Do you distinguish between high load and low load biofilters?

Sorry if the information is available and I just did not find it.

Yours

Christoph

Please Log in to join the conversation.

You need to login to reply- dmrobbins10

-

Topic Author

Topic Author- Improving life and livelihood through decentralized wastewater management

Less- Posts: 56

- Karma: 10

- Likes received: 33

Re: Using Cocopeat for Treating Septic Tank Effluent (RTI, USA - Philippines, Indonesia, Vietnam and other countries)

Thank you for your additional questions on the cocopeat technology. If there are larger solids in the untreated wastewater flow, screening is required. In San Fernando City, La Union Province in the Philippines, at their Fecal Sludge Management facility, they have a very nice screen system (I have attached a photo). The truck directs its discharge directly into the screen, and after each load, the operator can tip the mechanism forward on a hinge that dumps the solids right into a bin, which is later collected and hauled to the landfill.

Important to realize though, that screening is considered pre-treatment, and you will still need some type of primary treatment system, like a septic tank or anaerobic baffled reactor (ABR) to lower the organic matter and solids concentration so that secondary treatment, through the cocopeat (or other media filter) will be possible.

There are two concerns: the first one is that the ABR is sized correctly to reduce the BOD and TSS in the wastewater to "acceptable" levels. For our cocopeat trials, 200 - 250 mg/l for each is considered OK for influent wastewater strength on the filter, although one of our systems operated at an influent strength of 350 mg/l. For domestic wastewater, this shouldn't be a problem, but for fecal sludge, it might be. Recommend you take some samples of the raw wastewater, which should give you some good inputs for designing the primary treatment system. If you go with an ABR for primary treatment, consider longer retention times and more baffled compartments to address higher strength wastewater.

The second point is that cocopeat (or other media filters) are generally sized based on loading, or how much volume of wastewater can be applied to a given area of filter. For the single pass cocopeat systems, we tested them at 200 to 500 liters per day per square meter of cocopeat surface area and obtained good results. You can increase the application rate if you go to a recirculating system, but that is another story. Your system at 2.2 square meters for 1 cubic meter of waste per day provides an application rate of 454 liters per square meter per day, which is within our tested range.

An additional note. Cocopeat systems should still be considered experimental until much more data is available. From a practical standpoint, this means that while you can still promote and install systems, you should disclose the experimental nature of the technology to the client and they should understand that if the system fails, installation of a more "recognized" technology would be required. Hope this doesn't dissuade you as receiving more data from additional installations is exactly what is needed to continue to mainstream the technology.

Good luck,

Dave

This email address is being protected from spambots. You need JavaScript enabled to view it.

Attachments:

-

P1030527.JPG (Filesize: 66KB)

Please Log in to join the conversation.

You need to login to reply- srikanth

-

Less

- Posts: 4

- Likes received: 0

Re: Using Cocopeat for Treating Septic Tank Effluent (RTI, USA - Philippines, Indonesia, Vietnam and other countries)

I also forgot to ask about the retention time of the sludge in the coco-peat biofilter. I used a 3 stack of coco-peat filter (with a total thickness of 0.6 m coco-peat layers in all 3 stacks, 1m wide and 2.2 m long)for 1 cubic meter per day influent and that gave me 1.32 day as the retention time. Does that seem reasonable?

Sorry for bugging you.

Thank you.

Srikanth.

Please Log in to join the conversation.

You need to login to reply- srikanth

-

Less

- Posts: 4

- Likes received: 0

Re: Using Cocopeat for Treating Septic Tank Effluent (RTI, USA - Philippines, Indonesia, Vietnam and other countries)

Thanks for the immediate reply and ofcourse very useful information on costs. I really appreciate your interest in disseminating the information, knowledge and results.

I had another question after reading Elisabeth's comments. I am particularly working on Fecal sludge treatment in Uganda. (the sludge there seems to be of very liquid type and people are even throwing some trash and sanitary pads into the pits). So, i am looking into bar screens (manual) as a pre-treatment option instead of Anaerobic Baffled Reactor. (Also would like to state here that the sludge is living for 6 months-2 years in the pits). So, would bar screens be a good substitute of ABR or septic tanks as pre-treatment?

Regards,

Srikanth.

Please Log in to join the conversation.

You need to login to reply- dmrobbins10

-

Topic Author

Topic Author- Improving life and livelihood through decentralized wastewater management

Less- Posts: 56

- Karma: 10

- Likes received: 33

Re: Using Cocopeat for Treating Septic Tank Effluent (RTI, USA - Philippines, Indonesia, Vietnam and other countries)

Thanks for your questions. I will try and answer them one at a time.

1. Cost breakdown table for cocopeat. I don't have one, but it is a good idea. For our pilot projects, the main cost categories are the filter box itself, the piping and the cocopeat material. For our test systems, we used septic tank effluent pumping systems (STEP) to provide more even dosing, but the system can be gravity based. Here is a posting that provides some of the details on the construction process: watsanexp.ning.com/profiles/blogs/how-we...ter-by-jet-pabilonia

2.Pretreatment, clogging and odor. Cocopeat systems, like constructed wetlands are secondary treatment systems. They require primary treatment such as a septic tank or anaerobic baffled reactor to precede them. Additionally, if a commercial facility conducts activities that include food service, food manufacturing, utensil washing or laundry washing, appropriate pretreatment devices, such as lint traps or grease traps are required. In the test programs we initiated, clogging has not been a problem. Standard O&M activities include raking the surface of the filter every 3 months, and perhaps this limited clogging in our tests. As for odors, we did experience them and one of our researchers came up with a simple solution. Just place a 12 cm layer of the coco fibers (Coir) over the cocopeat bed, and the odors were eliminated. That solution came from our Bandung Indonesia test site, and more about that one can be found here: watsanexp.ning.com/profiles/blogs/itb-la...t-their-bandung-indo

3.The decision model you mentioned is based on the very simple concept: That prior to making technology decisions, you must first adequately characterize the wastewater source in terms of volume, strength, and variability, and then evaluate the site in terms of soils, land area available,groundwater and surface water, land use of surrounding parcels, etc. While this may sound logical (which it is), in developing country settings, it is not frequently used. I can attest to this in my own work in the Philippines where our program frequently "pushed" the technology we were comfortable with and tried to adapt it to each situation we encountered, at the expense of other technologies that may have been better suited to the specific needs of the client. RTI is writing a manual on this topic to be published by IWA and that one should come out in a few months. In the mean time, here is a paper that describes the model in more detail: api.ning.com/files/p7ANfYc4uM2KSlNzioteG...ementofDEWATS_a_.pdf

4. As for the tools, we decided to place them on line as works in progress, to encourage collaboration. We are encouraging people to check them out and let us know what they think, and make suggestions for improvement. The tools are not intended as substitutes for actual engineering, which should be utilized for all wastewater systems, but instead as a means of providing additional information to service providers or end users. The tools can be accessed at this link and we encourage people to provide any feedback they may want to give (positive or negative) which would be appreciated: watsanexp.ning.com/page/design-tools-for-engineers

As for BORDA, they do appear in our documentation from time to time only as they are in my mind the most significant organization working in this space. They are doing incredible work, and their level of innovation is most impressive. I did have the great opportunity to work closely with BORDA while I was with the Philippine Sanitation Alliance. That was a USAID program implemented by AECOM. During those 4 years, BORDA was our implementing partner and constructed and operated many of the wastewater systems we developed in consultation with local government. I am hoping that I may be able to continue working with BORDA to promote onsite and decentralized wastewater management at scale.

Finally, you asked about RTI and why we are giving our information for free. RTI is a non profit organization dedicated to turning knowledge into practice and improving the human conditions. Knowledge sharing, capacity building and technology transfer are all means that we are trying to utilize to achieve these goals.

Thanks again Elizabeth for your comments and questions.

Dave Robbins

This email address is being protected from spambots. You need JavaScript enabled to view it.

Please Log in to join the conversation.

You need to login to reply- Elisabeth

-

- User is blocked

- Freelance consultant since 2012

Less- Posts: 3372

- Karma: 54

- Likes received: 932

Re: Using Cocopeat for Treating Septic Tank Effluent

Thanks for all the information on this research grant and the cocopeat technology itself - which seems pretty mature if you are already building full-scale installations. (I had never heard of it before, I must admit)

Your website is providing a heap of information which is great!

I had the same question about costs as Srikanth. You have given some cost data now, but do you also have more details (like a cost-breakdown table)? Maybe it is included in some of your case studies?

My other question is about the pre-treatment required, issues with clogging and odour? (it is probably detailed on your website somewhere, you can just direct me to the right place).

And one more question: I saw in your posting from 25 January 2012 (please scrol up) that you mention a wastewater treatment decision model and associated tools. This is the link you gave:

watsanexp.ning.com/dewats-illustration-model

I had a bit of a look at the model and tools and it looks pretty interesting and comprehensive (for sewer-based systems that is; non-sewer based systems are not part of it; fine). For example it includes a constructed wetlands sizing tool, which could be interesting for many people - if it works well.

Could you tell me more about this decision making tool so that I can understand it better:

- What is the feedback you got from people who have used it?

- How have you developed it, over how many years and with what input data or cases?

- For which countries is it most applicable?

- Why has RTI decided to put it online? I think it is good to do so, but am just wondering, since RTI also wants to make money with consulting services?

- Who were your collaborators?

- Have you used it in teaching/training?

- What working relationships do you have with BORDA (I see them mentioned every now and again on your website)? Were they involved with this tool?

Regards,

Elisabeth

Freelance consultant on environmental and climate projects

Please Log in to join the conversation.

You need to login to reply- dmrobbins10

-

Topic Author

Topic Author- Improving life and livelihood through decentralized wastewater management

Less- Posts: 56

- Karma: 10

- Likes received: 33

Thanks for your kind words. We tested the cocopeat system in the Philippines at an elementary school that provided good data on costs. The system was installed for about $2,500 and serves 700 students. Assuming a system life of 10 years, changing the cocopeat every 5 years, and pumping the septic tank every 3 years, the full lifecycle costs are just under 1 US cent per student per day. For residential housing the math doesn't work out quite as well. Full life cycle costs for residential housing are estimated at about 3.7 US cents per user per day using the cocopeat technology. This is generally because residents in homes on average use much more water per day than students in schools. Commercialization of the technology could help drive costs down further.

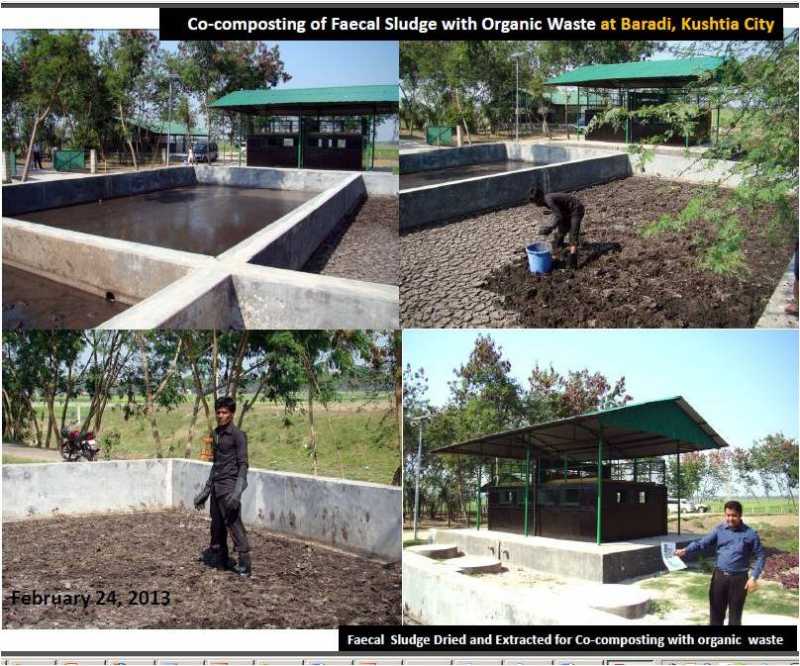

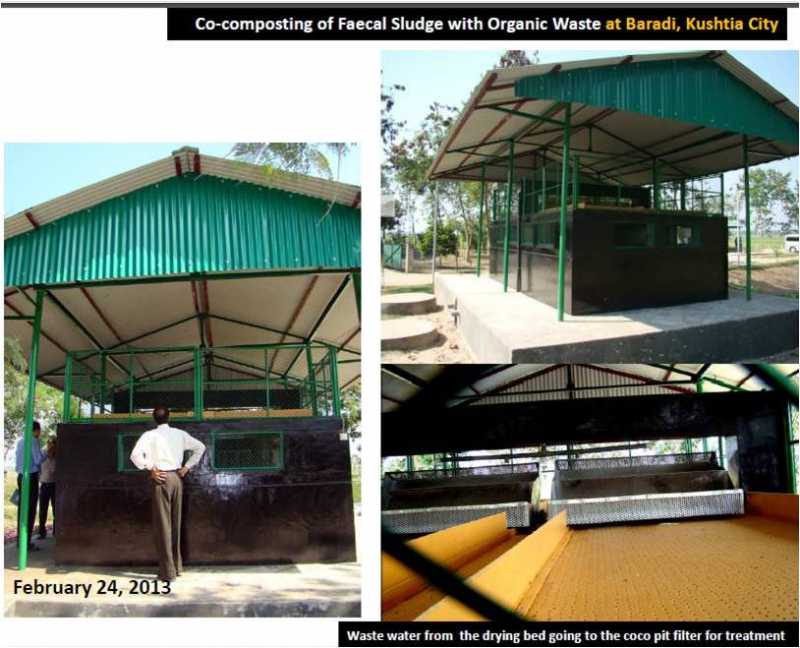

I do appreciate your interest in the cocopeat technology. Earlier this week, I learned of two new installations where the technology is being commercialized. Both are in Bangladesh, and this is just in from the installer:

Dear Dave,

Thanks for your interest and reply. The systems we built treat a water mixture of human toilet waste and water. The client is City Corporation of Kustia city. The project serves a school, office, private houses and other establishments of this small city. The process can be explained in this way:

1. The human discharge is collected from different septic tanks of the city by municipal workers.

2. Transported by some special vehicles called Vaccu-Tug & discharged it in a settlement tank called drying bed which is the part of the project.

3. The water is slowly transferred to another reservoir leaving the solid for natural drying.

4. From the reservoir water is transferred to the coco peat filter through tipping pans and discharged to the open field after filtration.

5. Next in time dried solids are transferred to a shed and mixed with compost from waste plants for making Bio-fertilizer.

Soon I will mail you about BOD & TSS including project Cost.

Thanks with Regards,

Md. Nazul Hasan

Here are some pictures from Hasan (attached):

Dave Robbins

Sr. Water and Sanitation Specialist

RTI International

Web: www.rti.org

This email address is being protected from spambots. You need JavaScript enabled to view it.

Attachments:

-

Hasan-1.jpg

(Filesize: 68KB)

Hasan-1.jpg

(Filesize: 68KB)

-

Hasan-2.jpg

(Filesize: 86KB)

Hasan-2.jpg

(Filesize: 86KB)

-

Hasan-3.jpg

(Filesize: 60KB)

Hasan-3.jpg

(Filesize: 60KB)

-

Hasan-4.jpg

(Filesize: 101KB)

Hasan-4.jpg

(Filesize: 101KB)

Please Log in to join the conversation.

You need to login to reply- Forum

- categories

- Sanitation systems

- Treatment of wastewater, sludges, organic waste, excreta

- Septic tanks (conventional or upgraded)

- Using Cocopeat for Treating Septic Tank Effluent (RTI, USA - Philippines, Indonesia, Vietnam and other countries)