- Forum

- categories

- Sanitation systems

- Treatment of wastewater, sludges, organic waste, excreta

- Anaerobic treatment systems (biogas sanitation)

- Anaerobic baffled reactor (ABR)

- FYI: "Successful" R&D on ABRs at WWTPs in Northern Ireland and Southern California by UK based company Atkins?

FYI: "Successful" R&D on ABRs at WWTPs in Northern Ireland and Southern California by UK based company Atkins?

11k views

- kelldigest

-

Less

Less- Posts: 21

- Likes received: 4

- kelldigest

-

Less

Less- Posts: 21

- Likes received: 4

Re: FYI: "Successful" R&D on ABRs at WWTPs in Northern Ireland and Southern California by UK based company Atkins?

I work in the wastewater industry in Ireland and have operated WWTP and AD Plant from 10 to 80,000 p.e in size.*

Our systems are very energy hungry and I would like to promote low energy treatment systems.

ABR looks like a good option but for larger scale operations you would need a low energy way of removing ammonia. For discharges to water courses, ammonia is often the limiting nutrient in discharge licences.

I will post some thoughts on the thread you suggested.

This forum is new to me and I find it exciting to have people to share ideas with.

Kind Regards

Seamus Kelly

* Note by moderator: For novices: WWTP = wastewater treatment plant, AD = Anaerobic digestion, p.e. = person equivalent (sometimes also called EP or equivalent persons)

Please Log in to join the conversation.

You need to login to reply- Elisabeth

-

- User is blocked

- Freelance consultant since 2012

Less- Posts: 3372

- Karma: 54

- Likes received: 932

Re: FYI: "Successful" R&D on ABRs at WWTPs in Northern Ireland and Southern California by UK based company Atkins?

Yes, there is ammonia in the effluent from ABRs (anaerobic baffled reactors). But they are not normally connected to activated sludge plants, rather to a constructed wetland or to reuse activities.

I think you will find this thread interesting where we discussed ammonia in the effluent from ABRs:

forum.susana.org/forum/categories/35-bio...sed-treatment-plants

(any particular reason why you ask? Welcome to the forum!)

Regards,

Elisabeth

Freelance consultant on environmental and climate projects

Please Log in to join the conversation.

You need to login to reply- kelldigest

-

Less

Less- Posts: 21

- Likes received: 4

Re: FYI: "Successful" R&D on ABRs at WWTPs in Northern Ireland and Southern California by UK based company Atkins?

Please Log in to join the conversation.

You need to login to replyRe: Past sucessfull R&D's on ABRs at wwtp's in Northern Ireland and Southern California by UK based company ATKINS?

"Anaerobic Baffled Reactor - Minimising Sludge Production PB Clark WS Atkins Water 2001"

To my surprise, Methan emissions been not considered at all during 2001!

books.google.de/books?id=V6K_CsugV7EC&pg...ed%20Reactor&f=false

"simple" Sanitation-Solutions by gravity

Low-Tech Solutions with High-Tech Effects

"Inspired by Circular Economy and Cooperation"

www.flickr.com/photos/aqua-verde/

Please Log in to join the conversation.

You need to login to replyRe: Past sucessfull R&D's on ABRs at wwtp's in Northern Ireland and Southern California by UK based company ATKINS?

Dear Mr. Schwager,

While we did invent the ABR many years ago, I have not followed applications well enough to offer any new information to you. I know there are several available in warmer climates such as Africa, but have no information to offer on colder region applications.

If you really want to reduce energy consumption and biosolids production you might consider the anaerobic membrane bioreactor. I am attaching a copy of a paper accepted for publication in Water Science and Technology to treat settled domestic wastewater. With temperature down to 10 oC and with only a 2.5 h HRT, effluent BOD was in the range of only about 5 mg/L and biosolids generation was only 0.03 kg VSS/kg COD removed. We have been operating a pilot plant for the past year on this process in South Korea at 7 to 10 m3/d and a total HRT of 4.5 h, and are currently obtaining effluent BOD of about 5 mg/L as well. We had just started the system as winter temperature approached, but still obtained effluent BOD less than 40 mg/L at 8 oC, but will be going through the same temperatures in a couple of months. Now that the system is well acclimated we are expecting to see removals as in the paper attached. While operating over a year, we have not yet had to remove the membranes for cleaning. Biosolids production has been 0.08 kg/kg COD removed, but we expect that to drop soon to levels similar to laboratory studies. Just thought you might be interested in seeing what is possible today.

Sincerely,

Perry L. McCarty

In my opinion, information found in different reports are not consistent, despite favorable R&D results and proposals to install at wwtp's further ABRs in larger scale. After 2005-6 further ABR-developments ceased, I am wondering why?

Abstract: LARGE-SCALE PILOT TRIAL OF ANAEROBIC BAFFLED REACTOR: ASSESSMENT OF KEY PERFORMANCE PARAMETERS AND COST-BENEFIT ANALYSIS OF FULL-SCALE RETRO...It was observed that the soluble BOD fraction of the ABR effluent increased when compared to the primary tank effluent soluble BOD, an observation that had not been made in previous ABR studies in the UK....

"simple" Sanitation-Solutions by gravity

Low-Tech Solutions with High-Tech Effects

"Inspired by Circular Economy and Cooperation"

www.flickr.com/photos/aqua-verde/

This message has an attachment file.

Please log in or register to see it.

Please Log in to join the conversation.

You need to login to replyRe: Past sucessfull R&D's on ABRs at wwtp's in Northern Ireland and Southern California by UK based company ATKINS?

That is the critical and open discussion I am looking for at Forum-susana. Therefore, I appreciating very much your input.

I had as well the impression "or did I get something wrong?", reading 2-3 reports about "successes". Maybe one of more reasons is the very low organic load at the OCSD wwpt, because of "Mischwasser". I could not find clear information whether sewage and storm-water flowing separated.

Much details about the smaller R&D-ABR at Ellesmere Port wwtp and full-scale ABR-pilot installation at Culmore wwtp, Northern Ireland not given. This two European pre-treatment plants do not have the same design concept. I am still digging for details about at ATKINS. I hope for an "Open Source".

You are right the success is questionable. In my opinion, information found in different reports are not consistent.

See e.g.: www.ocsd.com/Home/ShowDocument?id=10335

page 3-4 3.3 ABR

"...Several cost assessments indicated that full-scale ABR use could reduce OCSD’s expected capital and operational costs. OCSD’s biosolids processing cost model, which does not include liquid stream (primary or secondary) treatment costs, indicated 20-year present value savings exceeding $35,000,000 for solids handling at either treatment plant if ABRs were used. A simpler model, but one that considers both capital and operating costs for the entire treatment process, suggested that ABRs could provide overall net cost savings compared to using conventional primary clarifiers.

The ABR results were sufficiently positive to justify continuing with plans to retrofit a full-scale primary clarifier. The goals of a retrofit will be to obtain an accurate assessment of the capital costs and subsequently to obtain full-scale operating experience and data at conditions that will be most relevant for OCSD. The planning and construction activities are expected to extend over three years starting in FY 2004/05."

But after that, no further developments I could find in UK and USA... I am wondering too. I am guessing reasons are your a) to c) and main reason probably related Methane emissions!?

By viewing the location of test at wwtp No. 2 of OCSD you may get a good understanding of intended scaling up: goo.gl/maps/rTe72

But only from mistakes we are all learning...

All the Best

Detlef

"simple" Sanitation-Solutions by gravity

Low-Tech Solutions with High-Tech Effects

"Inspired by Circular Economy and Cooperation"

www.flickr.com/photos/aqua-verde/

Please Log in to join the conversation.

You need to login to replyRe: Past sucessfull R&D's on ABRs at wwtp's in Northern Ireland and Southern California by UK based company ATKINS?

Thanks for the report by Atkins, very interesting indeed. The EPA report does not contain relevant information about ABR I would say.

Interesting as well how much information is out there which one does not look at.

You said

so I will comment on some aspects which caught my attention.Any suggestions are highly welcome

You write

.Reading through the report I would not call the installations successful. In contrary, I think the report shows a serious of aspects how it not should be done and why ABR in larger size are not recommendable.two successful full-scale installations (pilot's)

a) Example England and Northern Ireland – 6 hrs hydraulic retention time (HRT).

For a treatment plant 6 hours for a pretreatment is a lot of volume, so high cost. The report says:

I don´t know the primary tanks in the UK, but for the parts of the world I´have been working in, the typical retention times for primary treatment are in between 30 min (before nutrient removal plants), 1-1,5 hours typical pre-treatment and up to 2 hours for plants where only primary treatment is done. So the costs of an ABR would be 4-6 times higher, beside the need for baffles.similar to a conventional primary tank in the UK

b) The methane is not captured, the tank seemed to be open. This will lead to a lot of odor problems and the methane aspect you discussed here quite often. For a large plant I don´t see this as adequate.

c) In the US the plant had very low COD removal, much lower than the regular settler which was operated in parallel – as the typical task of the primary treatment is to bring down the organic load without energy – this would be a complete failure for the ABR. Beside the aspect b).

So 3 different aspects which hint to … not successful … or did I get something wrong?

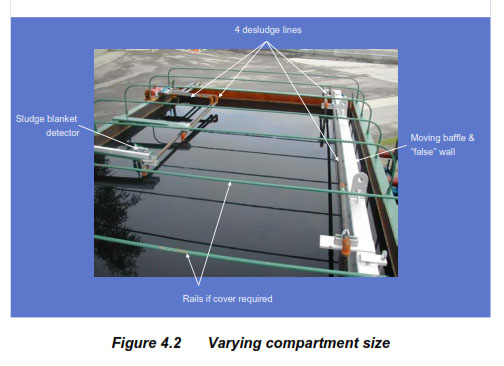

My experience with ABR (I wrote it before) is – up to about 2000 pe. an interesting technology as far better than a septic tank and less volume, past that - not recommendable. And it is important not to do too many baffles, to simplify construction and not to have high upstream velocities (in order not to lose sludge, apparently a problem in many ABR which use a anaerobic filter after the ABR to retain the sludge). The Atkins report discusses the velocity aspect in several parts (example):

.Previous demonstrations have been designed to create multiple compartments using baffles such that the upflow velocity in each compartment does not cause substantial wash-out of the solids blanket

One additional observation. The report discusses the methane content which went up to 80%.

We observed in several UASB as well contents of a about 80%, as other researchers in Brazil as well. A high methane concentration seems to be a chacracteristic of biogas produced in the main stream. The probable explanation is mentioned in the report as wellUsually in anaerobic digestion methane is produced at 60 to 65% by volume and this would be the anticipated level in gas exiting the ABR.

Thanks again for the interesting report.It should be noted that the solubility of carbon dioxide in water is 90ml/100ml which may explain maximum readings of methane that exceeded 80% volume.

Christoph

Please Log in to join the conversation.

You need to login to replyFYI: "Successful" R&D on ABRs at WWTPs in Northern Ireland and Southern California by UK based company Atkins?

Again "only" about Anaerobic Baffled Reactor's (ABR)...

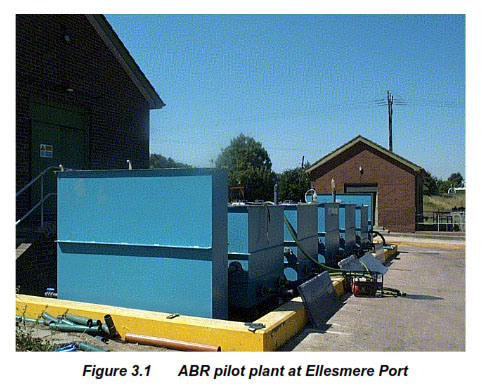

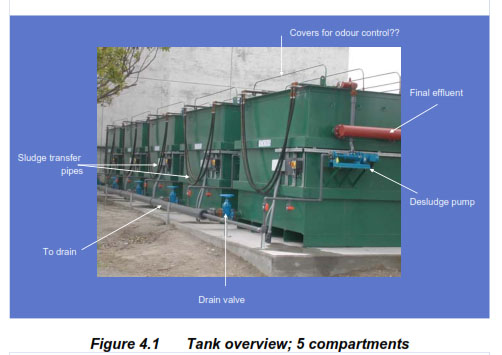

Please find attached final R&D-report by Mr. Rupert Kruger, ATKINS, from 2005 about pilot plant demonstrations via full-scale installations in Northern Ireland and in Southern California, USA, from 2001 - 2004.

2005: www.ocsd.com/Home/ShowDocument?id=11016 81 pages

and

2007: Emerging Technologies for Wastewater Biosolids Management

water.epa.gov/scitech/wastetech/upload/2...tb_epa-biosolids.pdf

only page 53 & 54 4-4

OCSD's use of ABR in short: Not for bio-gas production! Just for COD/BOD- and sludge reductions for pre-treatment in large scale centralized wwtp, in order to reduce total costs for energy- and space- demand of aeration for activated sludge reactors.

Do any body know about further developments, progress and further scaling up, after this two successful full-scale installations (pilot's)?

Any suggestions are highly welcome.

Thanks in advance.

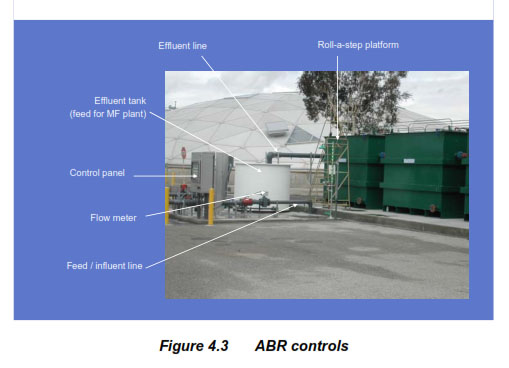

R&D-ABR at Ellesmere Port wwtp, near Liverpool: ORL 2-4 kg COD/m3/d

goo.gl/maps/3HOZA

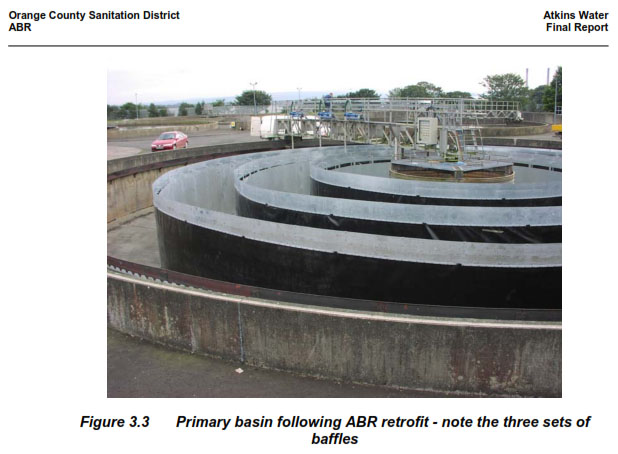

full-scale ABR-pilot installation at Culmore wwtp, Northern Ireland, near Belfast: 6 hours HRT at 12.8 °C

goo.gl/maps/gFhRO

made out of Primary Basin prior to ABR retrofit

full-scale ABR-pilot installation at OCSD, Southern California, USA: 610 - 890 m3/d, only 3 hours HRT at 23.9 °C goo.gl/maps/rTe72

Best Regards,

Detlef SCHWAGER

"simple" Sanitation-Solutions by gravity

Low-Tech Solutions with High-Tech Effects

"Inspired by Circular Economy and Cooperation"

www.flickr.com/photos/aqua-verde/

Please Log in to join the conversation.

You need to login to reply- Forum

- categories

- Sanitation systems

- Treatment of wastewater, sludges, organic waste, excreta

- Anaerobic treatment systems (biogas sanitation)

- Anaerobic baffled reactor (ABR)

- FYI: "Successful" R&D on ABRs at WWTPs in Northern Ireland and Southern California by UK based company Atkins?