- Forum

- categories

- Sanitation systems

- Faecal sludge management (FSM)

- Faecal sludge transport (including emptying of pits and septic tanks, transfer stations)

- Silt Trap Design for Tanker Discharge Station

Silt Trap Design for Tanker Discharge Station

5797 views

- AjitSeshadri

-

- Marine Chief Engineer by profession (1971- present) and at present Faculty in Marine Engg. Deptt. Vels University, Chennai, India. Also proficient in giving Environmental solutions , Designation- Prof. Ajit Seshadri, Head- Environment, The Vigyan Vijay Foundation, NGO, New Delhi, INDIA , Consultant located at present at Chennai, India

Dear SuSanA Member Mr Patrick and other keen Members:

Sewage is definitely liquid enough to flow, when gradient is given less than 1:50,

Removals of silt per se, will be difficult, in a tank if left undisturbed for a few hours, van settle sludges heavier than sg say 1.5.

It is possible to separate silt matter if the flush water in sewage liquid flow is copious.

However, if silt says in the FS mixture, it means no harm, as it is earth matter and can return to soil.

Well wishes

Prof Ajit Seshadri

Sewage is definitely liquid enough to flow, when gradient is given less than 1:50,

Removals of silt per se, will be difficult, in a tank if left undisturbed for a few hours, van settle sludges heavier than sg say 1.5.

It is possible to separate silt matter if the flush water in sewage liquid flow is copious.

However, if silt says in the FS mixture, it means no harm, as it is earth matter and can return to soil.

Well wishes

Prof Ajit Seshadri

Prof. Ajit Seshadri, Faculty in Marine Engg. Deptt. Vels University, and

Head-Environment , VigyanVijay Foundation, Consultant (Water shed Mngmnt, WWT, WASH, others)Located at present at Chennai, India

Head-Environment , VigyanVijay Foundation, Consultant (Water shed Mngmnt, WWT, WASH, others)Located at present at Chennai, India

Please Log in to join the conversation.

You need to login to reply- Muda

-

Topic AuthorLess

- Posts: 5

- Likes received: 1

Re: Silt Trap Design for Tanker Discharge Station

Good day JK

The sewage is liquid enough yes. The client is insisting on silt removal. I have some basic detail from some one who put up one. I am still developing it and I will share once it has been fully developed. I ntend to put it after the grit removal system (vortex) .

Regards

Patrick

The sewage is liquid enough yes. The client is insisting on silt removal. I have some basic detail from some one who put up one. I am still developing it and I will share once it has been fully developed. I ntend to put it after the grit removal system (vortex) .

Regards

Patrick

The following user(s) like this post: AjitSeshadri

Please Log in to join the conversation.

You need to login to reply

The sewerage entering the system is liquid enough for something like a vortex separator / hydro-cyclone to work?

en.wikipedia.org/wiki/Hydrocyclone

en.wikipedia.org/wiki/Hydrocyclone

Please Log in to join the conversation.

You need to login to reply- ronmartinjr

-

- Environmental Engineer performing process design of water and wastewater treatment systems and water and sanitation solutions.

Less- Posts: 2

- Likes received: 1

Hi Patrick,

If the grit chamber is designed with a longer detention time and lower flow-through velocity some of the silt should be removed in the grit chamber. But too long of a detention time will allow more unwanted organics to also collect in the grit chamber.

I think the idea of an anaerobic pond following the grit chamber is a good idea because you can make it deep enough to allow for accumulation of the silt and anaerobic treatment of the organic matter adhering to the silt. Plus, it will reduce the high organic loading from the latrines and septage. Just be aware that anaerobic ponds can produce offensive odors, the anaerobic process can sometimes be easily upset, and it usually takes a long time to start up.

You may be able to discharge the washwater from grit cleaning into the anaerobic pond since it will contain organics and pathogens and probably some silt.

I do have not direct experience dealing with silt, so this is speculation based on design work for larger sized grit.

Hope this helps.

Ron

If the grit chamber is designed with a longer detention time and lower flow-through velocity some of the silt should be removed in the grit chamber. But too long of a detention time will allow more unwanted organics to also collect in the grit chamber.

I think the idea of an anaerobic pond following the grit chamber is a good idea because you can make it deep enough to allow for accumulation of the silt and anaerobic treatment of the organic matter adhering to the silt. Plus, it will reduce the high organic loading from the latrines and septage. Just be aware that anaerobic ponds can produce offensive odors, the anaerobic process can sometimes be easily upset, and it usually takes a long time to start up.

You may be able to discharge the washwater from grit cleaning into the anaerobic pond since it will contain organics and pathogens and probably some silt.

I do have not direct experience dealing with silt, so this is speculation based on design work for larger sized grit.

Hope this helps.

Ron

Ron Martin

The following user(s) like this post: JKMakowka

Please Log in to join the conversation.

You need to login to reply- Muda

-

Topic AuthorLess

- Posts: 5

- Likes received: 1

Re: Silt Trap Design for Tanker Discharge Station

Thanks Ron.

The information is very helpful. I already have the grit removal system design as well as the screens. Grit is heavier than silt so is easy to remove. For silt I am considering some pond after the grit removal where the sewage settles and allows silt to also settle. The problem is the organic materials. I may end up designing an anaerobic pond for the system which will act as a pretreatment unit.

Any comments on this approach?

Patrick

The information is very helpful. I already have the grit removal system design as well as the screens. Grit is heavier than silt so is easy to remove. For silt I am considering some pond after the grit removal where the sewage settles and allows silt to also settle. The problem is the organic materials. I may end up designing an anaerobic pond for the system which will act as a pretreatment unit.

Any comments on this approach?

Patrick

Please Log in to join the conversation.

You need to login to reply- Muda

-

Topic AuthorLess

- Posts: 5

- Likes received: 1

- ronmartinjr

-

- Environmental Engineer performing process design of water and wastewater treatment systems and water and sanitation solutions.

Less- Posts: 2

- Likes received: 1

Hi Patrick and Johannes,

I think you need a grit chamber. This should reduce silting of the channel/pipe to the ponds and reduces the amount of silt filling up the ponds. There are a few types of grit chambers: horizontal flow (square or rectangular), aerated, and vortex being the most common. A good design manual (e.g. Metcalf and Eddy: Wastewater Engineering) describes the design, operation, and maintenance of these. I would guess a rectangular horizontal flow grit chamber would be the easiest to design, operate, and maintain.

If you are dealing with silt or very fine sand, then you will need a longer detention time (slower flow through the tank) when compared to coarse sand; the fine particles have a lower settling velocity so will settle more slowly.

You also need to consider removal, treatment, and disposal of the silt (and other grit particles) which will be contaminated with pathogens and other organic matter. Not necessarily very pleasant if done manually.

Here are some examples of literature on grit chambers:

nepis.epa.gov/Exe/ZyPDF.cgi/P1000S7N.PDF?Dockey=P1000S7N.PDF

sswm.info/sanitation-systems/sanitation-...eatment-technologies

greentribunal.gov.in/sites/default/files/news_updates/321.pdf

www.researchgate.net/profile/Anthony-Qua...Municipal-Sewage.pdf

ncrpb.nic.in/NCRBP%20ADB-TA%207055/Toolk...0Designs%20Hapur.pdf

www.tandfonline.com/doi/full/10.1080/23311916.2020.1723782

Hope this is of some help,

Ron

I think you need a grit chamber. This should reduce silting of the channel/pipe to the ponds and reduces the amount of silt filling up the ponds. There are a few types of grit chambers: horizontal flow (square or rectangular), aerated, and vortex being the most common. A good design manual (e.g. Metcalf and Eddy: Wastewater Engineering) describes the design, operation, and maintenance of these. I would guess a rectangular horizontal flow grit chamber would be the easiest to design, operate, and maintain.

If you are dealing with silt or very fine sand, then you will need a longer detention time (slower flow through the tank) when compared to coarse sand; the fine particles have a lower settling velocity so will settle more slowly.

You also need to consider removal, treatment, and disposal of the silt (and other grit particles) which will be contaminated with pathogens and other organic matter. Not necessarily very pleasant if done manually.

Here are some examples of literature on grit chambers:

nepis.epa.gov/Exe/ZyPDF.cgi/P1000S7N.PDF?Dockey=P1000S7N.PDF

sswm.info/sanitation-systems/sanitation-...eatment-technologies

greentribunal.gov.in/sites/default/files/news_updates/321.pdf

www.researchgate.net/profile/Anthony-Qua...Municipal-Sewage.pdf

ncrpb.nic.in/NCRBP%20ADB-TA%207055/Toolk...0Designs%20Hapur.pdf

www.tandfonline.com/doi/full/10.1080/23311916.2020.1723782

Hope this is of some help,

Ron

Ron Martin

Please Log in to join the conversation.

You need to login to reply- EnviVac

-

- User

Less- Likes received: 1

Re: Reply: Silt Trap Design for Tanker Discharge Station

Hi,I am also working on the Maun System but the Vacuum Sewerage Section. We are facing the same problems, sand and unwanted items. If you want to talk to me see my contact details in Botswana.

Best Regards

Johannes Selke

ProSan Consultant

Am Laubloch 6a

56841 Traben Trarbach

Germany

Tel. +49 6541 8181 596

WhatsApp +49 175 254 3604

Botswana +267 7401 0782

This email address is being protected from spambots. You need JavaScript enabled to view it.

Skype: vacuumsewerage

Best Regards

Johannes Selke

ProSan Consultant

Am Laubloch 6a

56841 Traben Trarbach

Germany

Tel. +49 6541 8181 596

WhatsApp +49 175 254 3604

Botswana +267 7401 0782

This email address is being protected from spambots. You need JavaScript enabled to view it.

Skype: vacuumsewerage

The following user(s) like this post: Muda

Please Log in to join the conversation.

You need to login to reply- Muda

-

Topic AuthorLess

- Posts: 5

- Likes received: 1

Re: Silt Trap Design for Tanker Discharge Station

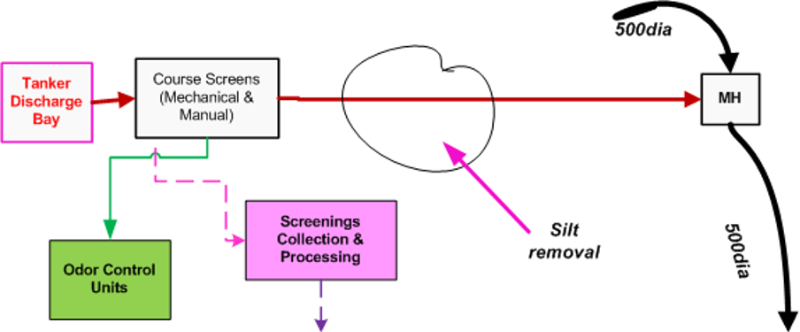

Thanks for the response. The situation is like this. There is a wastewater treatment plant that has been designed (Waste Stabilisation Ponds). At the ponds inlet works we have been asked to design a vacuum tanker discharge bay. Now, the tanker discharge bay has capacity for 2 vacuum tankers discharging at the same time. Discharge from the tankers passes through course screens before flowing into the main channel taking sewage from an outfall sewer from the village.

The village of Maun is in the desert and there is a lot of sand that finds its way into the sewer systems, including in the pit latrines and conservancy tank. When vacuum tankers empty the pits and conservancy tanks the sludge is mostly sand which in turn is discharged at the tanker discharge bay when offloading the vacuum tankers. The client does not want the sand from the tankers to be taken to the ponds and therefore requires a grit removal unit to be installed to capture the sand and silt before the sewage goes into the mainstream flow feeding the plant. Because most of the grit is from fine sand, a silt trap or any suitble silt removal system is preferred.

The village of Maun is in the desert and there is a lot of sand that finds its way into the sewer systems, including in the pit latrines and conservancy tank. When vacuum tankers empty the pits and conservancy tanks the sludge is mostly sand which in turn is discharged at the tanker discharge bay when offloading the vacuum tankers. The client does not want the sand from the tankers to be taken to the ponds and therefore requires a grit removal unit to be installed to capture the sand and silt before the sewage goes into the mainstream flow feeding the plant. Because most of the grit is from fine sand, a silt trap or any suitble silt removal system is preferred.

Attachments:

-

Picture1_2...0-26.png

(Filesize: 68KB)

Picture1_2...0-26.png

(Filesize: 68KB)

Please Log in to join the conversation.

You need to login to reply

Dear Patrick,

Please describe the problem in more detail. I do not understand how silt could enter the Fecal Sludge, nor how it could be separated from it.

What does the treatment consist of at the site where you are working?

Are you applying techniques that are described in the Faecal Sludge Management book (Strande, et al., downloadable from the IWA website)?

I think that the Planted Drying Bed is one of the most sustainable options (which could also receive silt without any problem).

Best wishes,

Chris

Please describe the problem in more detail. I do not understand how silt could enter the Fecal Sludge, nor how it could be separated from it.

What does the treatment consist of at the site where you are working?

Are you applying techniques that are described in the Faecal Sludge Management book (Strande, et al., downloadable from the IWA website)?

I think that the Planted Drying Bed is one of the most sustainable options (which could also receive silt without any problem).

Best wishes,

Chris

Conservation Biologist and EcoSan Promoter

Omaere Ethnobotanical Park

Puyo, Pastaza, Ecuador, South America

inodoroseco.blogspot.com

Omaere Ethnobotanical Park

Puyo, Pastaza, Ecuador, South America

inodoroseco.blogspot.com

The following user(s) like this post: Fahim1988

Please Log in to join the conversation.

You need to login to reply- Muda

-

Topic AuthorLess

- Posts: 5

- Likes received: 1

Silt Trap Design for Tanker Discharge Station

I am working on a 5.5ML/d sewage treatment works in Botswana. A lot of silt enters the sewerage system and needs to be removed from the sewage before it enters the plant. This is especially too much at the tanker discharge station where a lot of pit latrine and septic tank contents are discharged. If anyone has designed silt traps for wastewater treatment plants or discharge stations kindly share how to design the silt trap. Any literature will also be most welcome.

Thanks

Patrick

Thanks

Patrick

Please Log in to join the conversation.

You need to login to reply

Share this thread:

- Forum

- categories

- Sanitation systems

- Faecal sludge management (FSM)

- Faecal sludge transport (including emptying of pits and septic tanks, transfer stations)

- Silt Trap Design for Tanker Discharge Station

Recently active users. Who else has been active?

Time to create page: 0.226 seconds