- Forum

- categories

- Resource recovery

- Resource recovery from excreta, faecal sludge or wastewater

- Launching of Fortifer in Ghana: Innovating Sanitation to feed the nation

Launching of Fortifer in Ghana: Innovating Sanitation to feed the nation

53.2k views

Re: Launching of Fortifer in Ghana: Innovating Sanitation to feed the nation

Partner, Kellogg Consultants

Hope for Africa: Director Sanitation Projects

Project 16,000: Reusable Menstrual Products (pads and cups) for Ghana

Please Log in to join the conversation.

You need to login to reply- Funke

-

- Research Scientist at IWMI, West Africa. Interested in the exploitation of the agriculture-water-sanitation nexus for livelihood improvements in rural-urban interface. With my team, we have developed faecal sludge-based fertilizer materials

Less- Posts: 11

- Karma: 1

- Likes received: 2

Re: Launching of Fortifer in Ghana: Innovating Sanitation to feed the nation

Yes, this is phase II of the project that we posted here. It is funded jointly by BMGF (with contribution from DFID) and Grand Challenge Canada.

The main customers are individual small-scale farmers. The private company that is managing the plant is in the process of completing off-takers contract with a company to purchase a large quantity of Fortifer for distribution to farmers. The sale of fertilizer has just started and cannot yet sustain the plant.

Regards

Funke

Principal Researcher, Resource Recovery and Reuse Group

Head, IWMI West Africa Office.

www.iwmi.cgiar.org/research/projects

Attachments:

-

Aerialview...IWMI.JPG (Filesize: 182KB)

-

FortiferPl...IWMI.jpg

(Filesize: 123KB)

FortiferPl...IWMI.jpg

(Filesize: 123KB)

-

A50kgbagof...IWMI.JPG (Filesize: 182KB)

-

PelletsofF...9-18.jpg

(Filesize: 135KB)

PelletsofF...9-18.jpg

(Filesize: 135KB)

Please Log in to join the conversation.

You need to login to reply- Funke

-

- Research Scientist at IWMI, West Africa. Interested in the exploitation of the agriculture-water-sanitation nexus for livelihood improvements in rural-urban interface. With my team, we have developed faecal sludge-based fertilizer materials

Less- Posts: 11

- Karma: 1

- Likes received: 2

Re: Launching of Fortifer in Ghana: Innovating Sanitation to feed the nation

Thanks and apologies for the delayed response. We have not tried this kind of feedstock yet. We will have to test first and assess the results before we can make any recommendation.

Yes, we would be glad to talk to your people. We are located in Accra which is not too far fromAshaiman. Feel free to contact me

via email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Regards.

Funke

Principal Researcher, Resource Recovery and Reuse Group

Head, IWMI West Africa Office.

www.iwmi.cgiar.org/research/projects

Please Log in to join the conversation.

You need to login to replyRe: Launching of Fortifer in Ghana: Innovating Sanitation to feed the nation

I would be interested in hearing from others about relevant experience using sanitary pads for composting. Please post.

Also, can we get my people talking to your people? I am in Ghana right now, if you'd like to email any contact information.

Partner, Kellogg Consultants

Hope for Africa: Director Sanitation Projects

Project 16,000: Reusable Menstrual Products (pads and cups) for Ghana

Please Log in to join the conversation.

You need to login to reply- Elisabeth

-

- User is blocked

- Freelance consultant since 2012

Less- Posts: 3372

- Karma: 54

- Likes received: 932

Re: Launching of Fortifer in Ghana: Innovating Sanitation to feed the nation

Thanks for informing us about this important milestone!

Is this work a follow-on component of the earlier work funded by the Bill & Melinda Gates Foundation which was posted here on the Forum (see thread above)?

The funding for that one ended two years ago. How is this ongoing work funded? Can it self-sustain itself based on the sales of the fertiliser (which would be great but is probably unlikely to be sufficient).

Who are your main customers for the Fortifer fertiliser?

Do you have some photos of the plant which you could post here?

Regards,

Elisabeth

Freelance consultant on environmental and climate projects

Please Log in to join the conversation.

You need to login to reply- Funke

-

- Research Scientist at IWMI, West Africa. Interested in the exploitation of the agriculture-water-sanitation nexus for livelihood improvements in rural-urban interface. With my team, we have developed faecal sludge-based fertilizer materials

Less- Posts: 11

- Karma: 1

- Likes received: 2

Re: Launching of Fortifer in Ghana: Innovating Sanitation to feed the nation

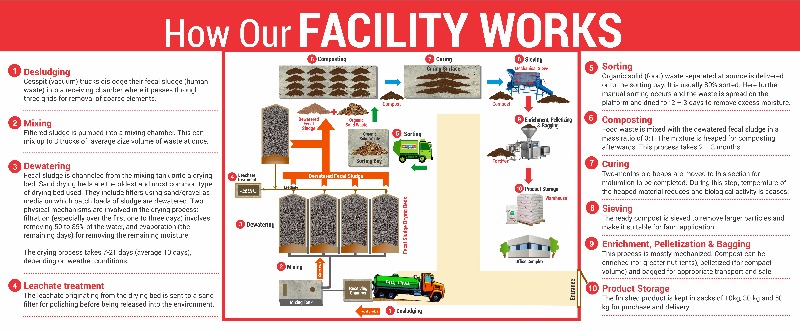

A new compost plant has opened in the greater Accra Region in Ghana which recycles human and food waste and turns it into Fortifer, a safe, nutrient rich fertilizer. Established in partnership with the Tema Metropolitan Assembly and Jekora Ventures Ltd, JVL Fortifer Compost Plant builds on years of research done by the International Water Management Institute (IWMI) to simultaneously improve sanitation services and food security through private-public partnerships. The plant will treat 12,500 cubic meters of fecal sludge and 700 tonnes of organic food waste in order to produce 500 tons of Fortifer in the next year.

www.iwmi.cgiar.org/News_Room/Press_Relea...f-ghanas-economy.pdf

wle.cgiar.org/year-wastewater

Principal Researcher, Resource Recovery and Reuse Group

Head, IWMI West Africa Office.

www.iwmi.cgiar.org/research/projects

Please Log in to join the conversation.

You need to login to reply- njosiane

-

Less

Less- Posts: 4

- Karma: 1

- Likes received: 3

Re: Developing fortified excreta pellets for use in agriculture - and From Waste to Food - Phase 1 and 2 (IWMI, Ghana)

The capacity of the plant (500 metric tons) that I have mentioned is the amount of composts (output) per year. Such a plant should be capable of processing about 13,000 m3 of fecal sludge from septic tanks per year (2/3rd from households and 1/3rd from public toilets) in addition to 720 metric tons of sorted organic wastes (depending on type of waste available, it could be food waste, market waste, etc.). If the capacity of the plant in terms of compost production increases to 1,000 MT, then, the processed amounts of wastes will follow the same pattern.

Assuming a fecal sludge generation of 0.1 m3 per capita per year for household septic tanks and of 0.55 m3 per capita per year for public toilet septic tanks, we theoretically get a coverage of more than 91,000 people. The difference in the amounts of fecal sludge generated per capita lies in the fact that the residence time at household level is in general much higher than that of public toilets.

The launching of the plant is slightly delayed, but I will certainly share photos and videos when they become available.

Best regards,

Josiane.

Researcher – Environmental Sciences

International Water Management Institute

West Africa Office

PMB CT 112, Cantonments

Accra, Ghana

Phone: (+233) 302 784 753/754

Fax: (+233) 302 784 752

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Please Log in to join the conversation.

You need to login to reply- Elisabeth

-

- User is blocked

- Freelance consultant since 2012

Less- Posts: 3372

- Karma: 54

- Likes received: 932

Re: Developing fortified excreta pellets for use in agriculture - and From Waste to Food - Phase 1 and 2 (IWMI, Ghana)

Thanks a lot for providing this update. It sounds very exciting! Finally something at a larger scale!

I have a question about the capacity of the plant. You said:

Is that tons of wet sludge entering the plant or tons of dry solids leaving the plant?The capacity of the plant is 500 Metric ton per year, which could be increased to 1,000 MT/year with further investment.

If you convert that figure to number of people served, how many people would that be (based on xx L of faecal sludge produced per person per day? What is your design figure for xx?).

Also, could you post some photos of the plant just before its commissioning (and then later after it has been commissioned)? With a lot of processes (like settling tanks and drying beds), it helps to see the tanks and structures empty to understand better how they will work.

Good luck with the start-up of the plant! Is it still on track to be started up this month?

Regards,

Elisabeth

Freelance consultant on environmental and climate projects

Please Log in to join the conversation.

You need to login to reply- njosiane

-

Less

Less- Posts: 4

- Karma: 1

- Likes received: 3

Re: Developing fortified excreta pellets for use in agriculture - and From Waste to Food - Phase 1 and 2 (IWMI, Ghana)

Taking this opportunity to update on you the recent developments related to this project. You will recall that in many West African cities, human excreta collected as fecal sludge (FS) from on-site sanitation systems are commonly discharged into the environment due to high treatment costs and missing incentives at various stages in the sanitation supply chain to provide safe and sustainable fecal sludge management services. This results in the contamination of urban land, waterways, and food supplies by fecal-borne pathogens. However, this dangerous waste flow is also rich in nutrients and organic matter which are valuable inputs in agricultural systems. Past studies by the International Water Management Institute (IWMI) resulted in different excreta-based fertilizer formulations (composted FS, composted and blended FS in powder or pellet). These are collectively described here as Fortifer©.

In particular, the GCE Phase I project resulted in knowledge on pelletizing dried excreta for easier transportation, placement, handling and marketing as well as a preliminary assessment of the market and supporting institutions.

This GCE Phase II project (called in short Wafo) was launched in March 2013. Its goal is to commercialize the Fortifier technology for agriculture in a manner that improves the sustainability of the sanitation value chain by generating a positive revenue stream, which measurably improves cities’ fecal sludge management.

A joint venture type of PPP between the Tema Metropolitan Assembly and Jekora Ventures Limited (JVL) was signed in 2014. JVL will be in charge of the management and operation of the Fortifer plant. They will also market the Fortifer in the Greater Accra region. TMA provided 1 hectare of land for the plant and will also provide supervisory services. The International Water Management Institute (IWMI) is providing technical support and supports JVL in the developing a marketing strategy. The Training Research and Networking for Development (TREND) facilitated the setting of the PPP and is leading additional activities involving engagement of public authorities, especially the certification of the Fortifer.

The capacity of the plant is 500 Metric ton per year, which could be increased to 1,000 MT/year with further investment.

The WaFo project has secured permit from the Environmental Protection Agency (EPA) in Ghana to construct the Fortifer plant. This followed the registration of the project with the EPA and satisfying all other subsequent requirements set by the EPA.

The construction of the plant is ongoing and should be completed in October, 2015.

The plant components include:

• 5 drying beds of 240 m2 of surface area per bed

• 1,475 m2 of composting platform (for windrow composting)

• Manual sorting bay

• Storage facilities for end products

• Pelletizing unit

• Office building

At this stage, field demonstration with selected farmers and users of Fortifer are planned. These are cereals and vegetable farmers in Accra. Demonstration will involve various formulations of Fortifer together with fertilizer materials that are commonly used by the farmers on maize, onion and sweet pepper. The demonstration will also involve MoFA extension agents.

Some links to various presentations/ publications / videos:

Presentation at FSM3 Conference workshop in Hanoi, Vietnam in January 2015:

www.susana.org/_resources/documents/defa...81-22-1425990893.pdf

(and also documents in SuSanA library: www.susana.org/en/resources/library/details/1781)

Presentation at WEDC Conference in Hanoi, Vietnam in 2014:

wedc.lboro.ac.uk/resources/conference/37/Impraim-2035.pdf

IWMI Publication on resource recovery and reuse:

www.iwmi.cgiar.org/Publications/wle/rrr/...d_reuse-series_2.pdf

Researcher – Environmental Sciences

International Water Management Institute

West Africa Office

PMB CT 112, Cantonments

Accra, Ghana

Phone: (+233) 302 784 753/754

Fax: (+233) 302 784 752

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Please Log in to join the conversation.

You need to login to reply- Funke

-

- Research Scientist at IWMI, West Africa. Interested in the exploitation of the agriculture-water-sanitation nexus for livelihood improvements in rural-urban interface. With my team, we have developed faecal sludge-based fertilizer materials

Less- Posts: 11

- Karma: 1

- Likes received: 2

Find some responses below and sorry for the delay.

Regards

Funke

++++++++++++++++++

Pit latrines are rarely used in urban Ghana. They are more prevalent in the rural areas and the sludge is unavailable for use. An improved pit latrine popularly known as Kumasi Ventilated Improved Pit latrines (KVIP) are often used in some public toilets. The sludge are stored in septic tanks and can be collected for use.Fredrick's question in the chat was missed out:

Fredrick: Funke: That leaves out sludge from pit latrines, or are they seldom used as a technology?

Faecal sludge is taken from pour-flush toilets. The plant is planned for Tema Metropolitan Area (TMA) within TMA many households and public toilet facilities are connected to septic tank .I had also wondered about solid waste. Are you strictly taking faecal sludge from septic tanks which are downstream of flush or pour-flush toilets and therefore you can be quite certain that there is no solid waste in the faecal sludge (not even menstrual hygiene products? Condoms? Toilet paper etc.?). What fraction of the city's population is connected to such septic tanks? Which city are you actually planning to build this treatment plant, is it in Tema (since you mentioned TMA in one of your slides). Why Tema and not Accra or Kumasi? (information about Tema: en.wikipedia.org/wiki/Tema)

We carried out a prefeasibility study of 5 cities (excluding Accra and Kumasi where there are already other arrangements for waste management). We settled for Tema as the most favourable in terms of:

• availability of raw materials

• willingness of municipality to contribute to the project

• willingness of our private sector partner to work in the city as well as their capacity to sell the products in the city.

Not included in the capital O&M costs for our Fortifer because there are existing ponds in the treatment plant. The cost of O&M is borne by the municipality that manages the existing treatment plant5. "The Fortifer is made from raw faecal sludge which they receive in liquid form. The first step is to remove excess liquid by drying beds. The excess liquid needs to be treated in some type of wastewater treatment plant, e.g. ponds."

My question: will the operation of such ponds be included in the capital and O&M costs for your Fortifer production plant? If not then who will take care of it? What is your experience with treating this excess liquid in ponds? What effluent quality are you achieving in those ponds?

I can imagine that financing will become easier but in the short term, some form of support is necessary.10." The project funding from the donors will bring financial support to construct the facility (neither TMA nor the private company would have the means to do it on their own)".

My question: Does that mean that also future Fortifer production plants would rely on outside donor support? Or would you expect that financing of such a production plant will become easier once the process is proven?

Principal Researcher, Resource Recovery and Reuse Group

Head, IWMI West Africa Office.

www.iwmi.cgiar.org/research/projects

Please Log in to join the conversation.

You need to login to reply- Elisabeth

-

- User is blocked

- Freelance consultant since 2012

Less- Posts: 3372

- Karma: 54

- Likes received: 932

Re: Developing fortified excreta pellets for use in agriculture - and From Waste to Food - Phase 1 and 2 (IWMI, Ghana)

While writing up the above information about your presentation during webinar 6, I had 3 follow-up questions with some sub-questions:

(1)

Fredrick's question in the chat was missed out:

Fredrick: Funke: That leaves out sludge from pit latrines, or are they seldom used as a technology?

I had also wondered about solid waste. Are you strictly taking faecal sludge from septic tanks which are downstream of flush or pour-flush toilets and therefore you can be quite certain that there is no solid waste in the faecal sludge (not even menstrual hygiene products? Condoms? Toilet paper etc.?). What fraction of the city's population is connected to such septic tanks? Which city are you actually planning to build this treatment plant, is it in Tema (since you mentioned TMA in one of your slides). Why Tema and not Accra or Kumasi? (information about Tema: en.wikipedia.org/wiki/Tema)

(2)

About my Point 5 above

5. The Fortifer is made from raw faecal sludge which they receive in liquid form. The first step is to remove excess liquid by drying beds. The excess liquid needs to be treated in some type of wastewater treatment plant, e.g. ponds.

My question: will the operation of such ponds be included in the capital and O&M costs for your Fortifer production plant? If not then who will take care of it? What is your experience with treating this excess liquid in ponds? What effluent quality are you achieving in those ponds?

(3)

About my point 10 above:

10. The project funding from the donors will bring financial support to construct the facility (neither TMA nor the private company would have the means to do it on their own).

My question: Does that mean that also future Fortifer production plants would rely on outside donor support? Or would you expect that financing of such a production plant will become easier once the process is proven?

Greetings,

Elisabeth

Freelance consultant on environmental and climate projects

Please Log in to join the conversation.

You need to login to reply- Elisabeth

-

- User is blocked

- Freelance consultant since 2012

Less- Posts: 3372

- Karma: 54

- Likes received: 932

Re: Developing fortified excreta pellets for use in agriculture - and From Waste to Food - Phase 1 and 2 (IWMI, Ghana)

This is my second write-up of a presentation at the sixth SuSanA-SEI webinar:

For the benefit of readers with slow internet connection (or unable to view Youtube videos), I am providing you here with a write-up of the presentation by Josiane Nikiema and the discussion on 25 February 2014 during webinar number 6 (*).

The topic of her presentation was:

Large scale production and commercialization of Fortifer - a fertilizer manufactured from faecal sludge - in Ghana

By Josiane Nikiema (IWMI-Ghana), IWMI (International Water Management Institute, West Africa Office, Accra, Ghana)

You can watch Josiane's presentation here (it is 8 minutes long): (**)

Powerpoint slides from her presentation are available here:

Please log in or register to see it.

Some key points from her presentation according to my notes:

- Slide 2 shows that they started already in the year 2000 (that’s 14 years ago! It shows that it pays off to be patient in sanitation…). From 2001 onwards, they had their first pilot plant in Kumasi, Ghana, and soon after they also started testing different ways to enrich the produced fertiliser.

- They have had quite a few donors over the years (also shown in slide 2), currently the funding comes from Bill & Melinda Gates Foundation, DFID (from UK) and GCC (Grand Challenges Canada).

- Right now they are trying to implement a full-scale production plant targeting 500 tons of product (Fortifer) per year.

- This Fortifer is the generic name for various fertiliser formulations (explained in her slides).

- The Fortifer is made from raw faecal sludge which they receive in liquid form. The first step is to remove excess liquid by drying beds. The excess liquid needs to be treated in some type of wastewater treatment plant, e.g. ponds.

- From previous research, they are confident that “we know how to make sure that the compost is safe by the end of the processing” (I can hear Joe Turner (forum.susana.org/forum/profile/userid-2608) saying: “how can you be sure; evidence, please!?”) ;-) – see reference below...

- The pellets are one of the high quality products that they can produce (see photo on slide 3 to the right). It is made from compost with the steps: grinding, enriching, adding binder to facilitate formation of pellets, pelletisation, drying. Then it can be applied in agriculture.

- Right now they are busy setting up a PPP (public private partnership), see slide 6. The public entity is TMA (Tema Municipal Authority) who will be responsibe to facilitate access to land and to faecal sludge.

- The private entity (they have already selected one) would bring all the financial resources for operating and maintaining the plant; they would also be responsible for marketing of the product.

- The project funding from the donors will bring financial support to construct the facility (neither TMA nor the private company would have the means to do it on their own).

- Expected revenues are: selling the compost, pellets or other fertilisers; and also the tipping fee from the truck operators that they normally have to pay when they discharge faecal sludge at a treatment plant in Ghana.

- They also have an advisory team: this is made up of high level people from different sectors in the country.

The question was by Laura Kimani: How long is composting time before pelletization and which and how much other organic feedstock is mixed into the fecal sludge during co-composting?

Answer by Josiane (see also chat below): “3 months of composting on average; we add saw dust, market waste, food waste to the faecal sludge for composting.”

For most of the discussion we used the chat function, as that was actually more efficient and faster. Due to the fact that the chat was recorded, it makes it easy for me: I just copy the chat recording below (I have asked the people concerned, i.e. the participants, and they agreed with this):

- Fredrick: Good presentation from Ghana. It would be interesting to know how project overcame regulation barriers.

- Fredrick: (Regulations on re-use, if any)

- Carol McCreary: Solid pit material? Because latrine no longer in use? Or UDDT?

- Funke: Generally re-use is accepted in the sanitation policy of Ghana provided it is safe. One of the expected outcome of our current project is to have FORTIFER registered and certified as a fertilizer material in Ghana

- Fredrick: @Funke: Thanks for response.

- Laura Kimani: How long is composting time before pelletization and which and how much other organic feedstock is mixed into the fecal sludge during co-composting?

- Funke: Composting time to maturity is about 3 months

- Funke: Laura, we mix fecal sludge with organic market waste or saw dust

- Andrew Jones: Funke, do you have to worry about heavy metal contamination?

- Laura Kimani: Besides Heavy metals, which other compost quality parameters are you testing your product for?

- Fredrick: Funke: Who defines 'safe'?

- Funke: Andrew, we don’t have to 'worry' about heavy metals but we analyse them anyway to be sure. We use sludge from household septic thank and from public toilets

- Funke: Laura. for compost quality parameters, we measure C, N, EC, temperature, and several other parameters in the time past to establish the procedures. subsequently we stick to helminth eggs, nitorgen, carbon, temperature.

- Fredrick: Funke: That leaves out sludge from pit latrines, or are they seldom used as a technology?

- Mohammad Mojtabaei: chemical hazard , biological hazard , parasite eggs and larvae for both operator, environment and users

- Laura Kimani: @ Funke: How do you mix and turn your feedstock?

- Funke: Laura, we mix manually with shovels and workers wear gloves + nose masks

- Laura Kimani: What's the NPK of your final product?

- Funke: I will provide some links here for additional information

- Laura Kimani: Thanks so much Funke!

- Funke: Laura, depending on the type of FORTIFER (enriched or not enriched) we have different values

- Funke: Laura, you may check out this for more information: Cofie Olufunke, et.al (2009). Co-composting of faecal sludge and organic solid waste for agriculture: Process dynamics. Water Research 43: 4665-4675.

- Funke: Laura, and this also. Nikiema, Josiane, Cofie, Olufunke, Impraim, Robert; Adamtey, N. 2013. Processing of fecal sludge to fertilizer pellets using a low-cost technology in Ghana. Environment and Pollution, 2(4): 70-87.

- Laura Kimani: Thanks so much Funke I will check it out. It would be great to be in touch in future.

- Jeremy Kohlitz: Funke, thank you for your and Josiane's presentation. How do you deal with large solids (e.g. pieces of rubbish) in the pit latrine sludge before you apply it to the drying beds?

- Funke: Jeremy, thanks. we are not using pit latrine sludge

- Funke: Jeremy, again we use sludge from septic tanks, discharged into the drying beds.

- Jeremy Kohlitz: Thank you for clarifying, Funke. I missed that part!

- Funke: Yes, the time was too short. If you need additional information, do not hesitate to get back to us

- Ofosu Budu: @Funke. What is your view about enriching the compost with N to about 5% N and P to meet the soil and nutrient demands in tropical soils

- Funke: Ofosu, indeed, we can enrich with N, P or K depending on the nutrient requirements. so far we did enrichment with N because we were targeting crops that require a lot of N. This year we are also starting some enrichment with P and K. We can modify the FORTIFER formulation depending on the need

- Dorothee Spuhler: @Funke: How much time does the treatment in the drying bed take and what is your moisture content before and after?

- Richard (Chip) Fisher: @ Josiane and Funke: Do you dry the waste prior to pelletization? If so, how?

- Funke: Dorothee, dewatering on the drying bed can take up to 2 weeks

- Funke: Dorothee, you can check this also: Cofie, et al. (2006) Solid-liquid separation of faecal sludge using drying beds in Ghana: Implications for nutrient recycling in urban agriculture. Water Research 40: 75-82

- Cofie, et al. (2006) Solid-liquid separation of faecal sludge using drying beds in Ghana: Implications for nutrient recycling in urban agriculture. Water Research 40: 75-82

- Cofie Olufunke, et.al (2009). Co-composting of faecal sludge and organic solid waste for agriculture: Process dynamics. Water Research 43: 4665-4675.

- Nikiema, Josiane, Cofie, Olufunke, Impraim, Robert; Adamtey, N. (2013). Processing of fecal sludge to fertilizer pellets using a low-cost technology in Ghana. Environment and Pollution, 2(4): 70-87. www.ccsenet.org/journal/index.php/ep/art...download/28987/17903

++++++++++++++++

+++++++++++++++++Yes, you can include the SuSanA case study (Co-composting of faecal sludge and organic solid waste Kumasi, Ghana, see: susana.org/lang-en/case-studies?view=ccbktypeitem&type=2&id=113). The plant is no longer there though but the experience/content is valid.

Indeed, the publications I mentioned in the chat and the appendix of the reports have copyright issues but the information I have provided should allow access to the abstracts through google search.

We are working on a series of downloadable publications which we plan to share very soon.

Hope this helps.

Kind regards

Funke

I hope you found this write-up useful (particularly if Youtube is banned in your country). Please don’t hesitate to put any follow-up questions, comments or clarifications into this thread. Thanks again to Josiane and Funke for preparing and giving this presentation at this webinar, and for answering all the questions!

Regards,

Elisabeth

(*) More information about these webinars is available in this thread here:

forum.susana.org/forum/categories/139-in...n-now-available#7519

A Playlist with all the videos from our webinars so far is available here:

www.youtube.com/playlist?list=PL0gMdVBup...ymOPomtqL_XYT5YtLTSK

(**) If you have any problems with displaying the videos, please take a look at this FAQ for a possible solution:

forum.susana.org/forum/categories/135-qu...--but-it-doesnt-work

Freelance consultant on environmental and climate projects

This message has an attachment file.

Please log in or register to see it.

Please Log in to join the conversation.

You need to login to reply- Forum

- categories

- Resource recovery

- Resource recovery from excreta, faecal sludge or wastewater

- Launching of Fortifer in Ghana: Innovating Sanitation to feed the nation