- Forum

- categories

- Sanitation systems

- Faecal sludge management (FSM)

- Faecal sludge treatment technologies

- Guidance on dewatering sludge and separating solid waste from the solids

Guidance on dewatering sludge and separating solid waste from the solids

19.1k views

Re: Guidance on dewatering sludge and separating solid waste from the solids

Dear Jonathan,

"...Any sewage nearly without fecal sludge, as it is currently delivered by Dakar's "honey-suckers", would have no caloric/financial value for the biogas-service providers, therefore less payments. This means, in order to keep quality of delivered FS the "honey-suckers" are paid by the fecal sludge content (TS) delivered only.

Having an energy producing system with an open & transparent financial interests involved, will minimize illegal dumping, as the owner of "honeysuckers" would loos profit and additional it would avoid e.g. costly "gadget systems" of distrust like GIS-traking of the whereabouts of "honeysuckers" and avoid too high maintenance intensive de-watering of FS (Omni-Ingestor) at the spot. For the time being, not functional lance nozzle at nearly all Dakar's "honeysuckers", would be repaired by the owners (without "capacity building"), as functional lance nozzle would increase fecal sludge content during collection..."

In general terms, a "rolling" sewage collection system is always the most expensive system (total over the time) in comparison to piped and is mainly based on current very cheap energy costs for diesel (fossil energy) and cheap labor cost. At least energy prices will increase for sure as availability of fossil energy is shrinking. Keeping this in mind it is up most important to "design" systems for a long term future which most as possible less "rolling" transport costs, which means you can not avoid the hassle (as Christoph described rightly) having many decentralized treatment points for transported FS, regardless AD or Composting systems.

A decentralized treatment system like that should be in the hand of one operator/management (organization) only. Additional, having many smaller treatment systems might reduce the complexity and would be more resilient in comparison to one or two larger centralized treatment systems/points. If one of this decentralized and smaller treatment systems/points is temporary out of order it would not affect the whole system as it could be the problem of a centralized system with one/two point of treatment.

Just for a ponder, in Germany communal owned sanitation companies with sanitation systems in rural areas having large scale piped collection systems, already drafting plans, Universities and think tanks discussing about to cut down this pipe networks to go for more decentralized systems. By replacing then worn out sewage pump station against smaller wwtp's with a kind of DEWATS, in order to have less energy- and O&M costs. Existing large scale wwtp's will then be reduced partly and maybe used for others. They looking already now further for possible changes, last not least to avoid financial collapses.

This is just my opinion.

Detlef

I am guessing, maybe you are dealing with very similar problems like the colleagues in Dakar ?water is used for desludging and the septage is more like wastewater than fecal sludge.

"...Any sewage nearly without fecal sludge, as it is currently delivered by Dakar's "honey-suckers", would have no caloric/financial value for the biogas-service providers, therefore less payments. This means, in order to keep quality of delivered FS the "honey-suckers" are paid by the fecal sludge content (TS) delivered only.

Having an energy producing system with an open & transparent financial interests involved, will minimize illegal dumping, as the owner of "honeysuckers" would loos profit and additional it would avoid e.g. costly "gadget systems" of distrust like GIS-traking of the whereabouts of "honeysuckers" and avoid too high maintenance intensive de-watering of FS (Omni-Ingestor) at the spot. For the time being, not functional lance nozzle at nearly all Dakar's "honeysuckers", would be repaired by the owners (without "capacity building"), as functional lance nozzle would increase fecal sludge content during collection..."

In general terms, a "rolling" sewage collection system is always the most expensive system (total over the time) in comparison to piped and is mainly based on current very cheap energy costs for diesel (fossil energy) and cheap labor cost. At least energy prices will increase for sure as availability of fossil energy is shrinking. Keeping this in mind it is up most important to "design" systems for a long term future which most as possible less "rolling" transport costs, which means you can not avoid the hassle (as Christoph described rightly) having many decentralized treatment points for transported FS, regardless AD or Composting systems.

A decentralized treatment system like that should be in the hand of one operator/management (organization) only. Additional, having many smaller treatment systems might reduce the complexity and would be more resilient in comparison to one or two larger centralized treatment systems/points. If one of this decentralized and smaller treatment systems/points is temporary out of order it would not affect the whole system as it could be the problem of a centralized system with one/two point of treatment.

Just for a ponder, in Germany communal owned sanitation companies with sanitation systems in rural areas having large scale piped collection systems, already drafting plans, Universities and think tanks discussing about to cut down this pipe networks to go for more decentralized systems. By replacing then worn out sewage pump station against smaller wwtp's with a kind of DEWATS, in order to have less energy- and O&M costs. Existing large scale wwtp's will then be reduced partly and maybe used for others. They looking already now further for possible changes, last not least to avoid financial collapses.

This is just my opinion.

Detlef

www.aqua-verde.de, AquaVerde Ltd. Zanzibar

"simple" Sanitation-Solutions by gravity

Low-Tech Solutions with High-Tech Effects

"Inspired by Circular Economy and Cooperation"

www.flickr.com/photos/aqua-verde/

"simple" Sanitation-Solutions by gravity

Low-Tech Solutions with High-Tech Effects

"Inspired by Circular Economy and Cooperation"

www.flickr.com/photos/aqua-verde/

Please Log in to join the conversation.

You need to login to reply- jonpar

-

- As part of the Engineering team, my role at IMC is to lead on the delivery of projects requiring specific expertise on urban sanitation (including excreta/waste/wastewater/stormwater management) focusing on technical, institutional and financial aspects in project design and implementation.

Less- Posts: 223

- Karma: 24

- Likes received: 87

Re: Guidance on dewatering sludge and separating solid waste from the solids

Dear Christoph

You can clearly understand my line of thinking.. and sounds like you've already been there, which is good. This is what I like about the SuSanA forum... the more we are open about what we are thinking, the more we have the opportunity to interact and learn from eachother.

Like you I have looked at various technologies that might provide the solution and they all seem to be polymer based.. so not keen on those. I found information the SALSNES filter and was hoping that this would do the job but unfortunately not as the filter doesn't like septic waste waters. Perhaps planted drying beds are the best solution but that takes more land.....

Which leads to the next point that you raise.. which is why bother in the first place... well... the proposed treatment plant in Freetown is 25-30 km away. We've not done any detailed calculations but my gut feeling is that this is too far to be transporting septage .. especially because in many cases, water is used for desludging and the septage is more like wastewater than fecal sludge.

There are a couple of sites used by Freetown city council for solid waste disposal.. and these could potential be used for this purposed.. in due course, I'll tell you what we put forward in our recommendations to FCC.

I can't answer our questions about dry fermentation vs CSTR but will look into it. I will look more at hydraulic thickening too but as you say, it may not be worth it.

Thanks again for your useful reply.

best regards,

Jonathan

You can clearly understand my line of thinking.. and sounds like you've already been there, which is good. This is what I like about the SuSanA forum... the more we are open about what we are thinking, the more we have the opportunity to interact and learn from eachother.

Like you I have looked at various technologies that might provide the solution and they all seem to be polymer based.. so not keen on those. I found information the SALSNES filter and was hoping that this would do the job but unfortunately not as the filter doesn't like septic waste waters. Perhaps planted drying beds are the best solution but that takes more land.....

Which leads to the next point that you raise.. which is why bother in the first place... well... the proposed treatment plant in Freetown is 25-30 km away. We've not done any detailed calculations but my gut feeling is that this is too far to be transporting septage .. especially because in many cases, water is used for desludging and the septage is more like wastewater than fecal sludge.

There are a couple of sites used by Freetown city council for solid waste disposal.. and these could potential be used for this purposed.. in due course, I'll tell you what we put forward in our recommendations to FCC.

I can't answer our questions about dry fermentation vs CSTR but will look into it. I will look more at hydraulic thickening too but as you say, it may not be worth it.

Thanks again for your useful reply.

best regards,

Jonathan

Dr. Jonathan Parkinson

Principal Consultant – Water and Sanitation

IMC Worldwide Ltd, Redhill, United Kingdom

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Skype : jonathanparkinson1

Principal Consultant – Water and Sanitation

IMC Worldwide Ltd, Redhill, United Kingdom

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Skype : jonathanparkinson1

Please Log in to join the conversation.

You need to login to reply- BStalker

-

Topic AuthorLess

- Posts: 10

- Likes received: 2

Re: Guidance on dewatering sludge and separating solid waste from the solids

Dear Bob,

please have a look at this threat. forum.susana.org/forum/categories/35-bio...mit=12&start=12#6524

Thanks to Ben, he was very open on the results and experiences. I would consider the set up they had, much more elaborated than the pilot plant you are working on - even though it was critical. Have a look at the comments and concerns on his plant.

Yours

Christoph

please have a look at this threat. forum.susana.org/forum/categories/35-bio...mit=12&start=12#6524

Thanks to Ben, he was very open on the results and experiences. I would consider the set up they had, much more elaborated than the pilot plant you are working on - even though it was critical. Have a look at the comments and concerns on his plant.

Yours

Christoph

Please Log in to join the conversation.

You need to login to reply- BStalker

-

Topic AuthorLess

- Posts: 10

- Likes received: 2

Re: Guidance on dewatering sludge and separating solid waste from the solids

So i am back from the site now, yeah the press didnt work well, or at all to be honest it was an idea we had and thought we would try. The main reason was because of the top of the barrel is smaller than the main part of the barrel so you could not press the sludge fully.

But it was just an idea that was had so we thought to test and now it does not work rather than just presume it does not work. Rather annoying as i was working on a lifting and loading mechanism this morning providing we could separate the majority of the water in a barrel. Like mentioned i do not want to be re inventing the wheel but do not think we could use a commercial dewatering system at the pilot plot. Currently Osbert was putting all the sludge into an inlet tank and had made a metal filter for the water to pass through and then push the solids into a drying bed. IF that was working then i was supposed to design a lifting and loading device into this inlet tank.

However after today it seems that the design for the inlet tank is not working and it is getting blocked. So i do not think a lifting device will be needed. Do you know of any other small scale techniques for dewatering sludge or than the screw mechanisms?

Thanks again

Bob

But it was just an idea that was had so we thought to test and now it does not work rather than just presume it does not work. Rather annoying as i was working on a lifting and loading mechanism this morning providing we could separate the majority of the water in a barrel. Like mentioned i do not want to be re inventing the wheel but do not think we could use a commercial dewatering system at the pilot plot. Currently Osbert was putting all the sludge into an inlet tank and had made a metal filter for the water to pass through and then push the solids into a drying bed. IF that was working then i was supposed to design a lifting and loading device into this inlet tank.

However after today it seems that the design for the inlet tank is not working and it is getting blocked. So i do not think a lifting device will be needed. Do you know of any other small scale techniques for dewatering sludge or than the screw mechanisms?

Thanks again

Bob

Please Log in to join the conversation.

You need to login to replyRe: Guidance on dewatering sludge and separating solid waste from the solids

Looking forward to hear about the results, but I have my doubts the "french press" idea will work very well.

Somewhat related: The attached documents sheds some light on the difficulties of treating fecal sludge and especially the problems with pit-latrine contents. Definitely worth a read!

Somewhat related: The attached documents sheds some light on the difficulties of treating fecal sludge and especially the problems with pit-latrine contents. Definitely worth a read!

This message has an attachment file.

Please log in or register to see it.

Please Log in to join the conversation.

You need to login to reply- BStalker

-

Topic AuthorLess

- Posts: 10

- Likes received: 2

Re: Guidance on dewatering sludge and separating solid waste from the solids

Thanks to all for the responses and good information, i am very new to the world of sanitation and have only been working in it for 5 months. The pilot plot was not designed by me and i am still learning about how it works by my colleague. It was called a DEWATS system from the start but i supposed it has changed now. I will get my colleague to respond to the concerns about the actual treatment pilot.

For the concerns about re inventing the wheel, i totally understand it would be stupid to do this however for this pilot plot it would be way to expensive to purchase such a system by Bilfinger. This is because of it being a pilot plot so if it fails it will be hard to justify spending so much on a machine for separating.

The pilot was designed with not much thought into the loading of the sludge so the design stages i am in now can be pretty tricky with our given space and budget that we have to work in. Our quick solution is this "French Press" idea that i will be testing later today, i will record and take pictures to post hopefully later to day for you guys and you should gain an understanding of what we are working with. This is based on the idea of separating the water and solids within the barrel that are brought to the site and then loading this water into the system.

We have two options if this can be done, the first is separate the water and then lift and load the barrels with a device to be designed. And the second is to separate the water and then pump from the barrel using a diaphragm pump, that just arrived at the office today.

Another reason for this post was to get some help into our current system as for one i am not experienced within treatment of sludge, i am a more mechanical design engineer hired to design lifting devices for barrels.

I have attached a PDF of the technical drawings that were produced by Osbert the engineer that designed the pilot.

Thanks again for the advice

[attachment:1]C:\fakepath\STRUCTURAL DRAWINGS DFSTS.pdf[/attachment]

For the concerns about re inventing the wheel, i totally understand it would be stupid to do this however for this pilot plot it would be way to expensive to purchase such a system by Bilfinger. This is because of it being a pilot plot so if it fails it will be hard to justify spending so much on a machine for separating.

The pilot was designed with not much thought into the loading of the sludge so the design stages i am in now can be pretty tricky with our given space and budget that we have to work in. Our quick solution is this "French Press" idea that i will be testing later today, i will record and take pictures to post hopefully later to day for you guys and you should gain an understanding of what we are working with. This is based on the idea of separating the water and solids within the barrel that are brought to the site and then loading this water into the system.

We have two options if this can be done, the first is separate the water and then lift and load the barrels with a device to be designed. And the second is to separate the water and then pump from the barrel using a diaphragm pump, that just arrived at the office today.

Another reason for this post was to get some help into our current system as for one i am not experienced within treatment of sludge, i am a more mechanical design engineer hired to design lifting devices for barrels.

I have attached a PDF of the technical drawings that were produced by Osbert the engineer that designed the pilot.

Thanks again for the advice

This attachment is hidden for guests.

Please log in or register to see it.

Please log in or register to see it.

[attachment:1]C:\fakepath\STRUCTURAL DRAWINGS DFSTS.pdf[/attachment]

This message has an attachment file.

Please log in or register to see it.

Please Log in to join the conversation.

You need to login to replyRe: Guidance on dewatering sludge and separating solid waste from the solids

Vacuum assisted drying beds are an proven and relatively low-tech solution worth looking into.

A funny idea I just had for a makeshift solution: a batch centrifugal dryer made out of an old washing machine

A funny idea I just had for a makeshift solution: a batch centrifugal dryer made out of an old washing machine

Please Log in to join the conversation.

You need to login to replyRe: Guidance on dewatering sludge and separating solid waste from the solids

Hi Jonathan,

it seems that you are looking into a possibility to concentrate at decentralized points and than bring it to a central treatment. I know that there are solutions on the market which pump out a septic tank, dewater it on the way to the next tank, unload the water in the next station and pump up again sludge (I saw it at IFAT some years ago), but as they are way too expensive for my business, I never came deeper into the subject and I can imagine it is the same for your case.

Dewatering to 18-25 % without polimers is not possible I guess (never heard anything else) almost every dewatering even to 8% uses polimers.

Did you do a calculation from what distance on it is worthwhile to have a dewatering station in between treatment and septic tank? Because you need the space, you have to have somebody there for security reasons, you have a decentralized maintenance point, you need a decentralized sludgewater treatment, you have on and off loading of the sludge, therefore odor? Lots of hazel but I understand that it might be interesting from a certain distance on… what is that distance in your case? I know it depends very much on the set of criteria you use. I have always been wondering from what distance on it is worth it. The solution I almost did once, was just to pass on from small tanks to larger tanks, but even that has to have large distances to be viable as you have the large tanker waiting for the small ones, you need a palce to do so as you might spill some sludge, you have odor, etc.etc. We gave up quickly.

A solution which comes into my mind is just hydraulic thickening - but is it really worth it to come to about 4% of solids?

And for the treatment – I agree with you that it might be very,very interesting for composting, but for the anaerobic treatment – do you go for dry fermentation? Or do you think of feeding the dewatered sludge into a CSTR (Continuous Stirred Tank Reactor)?

Regards

Christoph

it seems that you are looking into a possibility to concentrate at decentralized points and than bring it to a central treatment. I know that there are solutions on the market which pump out a septic tank, dewater it on the way to the next tank, unload the water in the next station and pump up again sludge (I saw it at IFAT some years ago), but as they are way too expensive for my business, I never came deeper into the subject and I can imagine it is the same for your case.

Dewatering to 18-25 % without polimers is not possible I guess (never heard anything else) almost every dewatering even to 8% uses polimers.

Did you do a calculation from what distance on it is worthwhile to have a dewatering station in between treatment and septic tank? Because you need the space, you have to have somebody there for security reasons, you have a decentralized maintenance point, you need a decentralized sludgewater treatment, you have on and off loading of the sludge, therefore odor? Lots of hazel but I understand that it might be interesting from a certain distance on… what is that distance in your case? I know it depends very much on the set of criteria you use. I have always been wondering from what distance on it is worth it. The solution I almost did once, was just to pass on from small tanks to larger tanks, but even that has to have large distances to be viable as you have the large tanker waiting for the small ones, you need a palce to do so as you might spill some sludge, you have odor, etc.etc. We gave up quickly.

A solution which comes into my mind is just hydraulic thickening - but is it really worth it to come to about 4% of solids?

And for the treatment – I agree with you that it might be very,very interesting for composting, but for the anaerobic treatment – do you go for dry fermentation? Or do you think of feeding the dewatered sludge into a CSTR (Continuous Stirred Tank Reactor)?

Regards

Christoph

Please Log in to join the conversation.

You need to login to reply- jonpar

-

- As part of the Engineering team, my role at IMC is to lead on the delivery of projects requiring specific expertise on urban sanitation (including excreta/waste/wastewater/stormwater management) focusing on technical, institutional and financial aspects in project design and implementation.

Less- Posts: 223

- Karma: 24

- Likes received: 87

Hi

The title of this discussion thread could be better .. but the topic is very interested.

I couldn't agree more with Christoph when he talks about not reinventing the technological "wheel". I wonder if there has been a comprehensive review about existing technologies for FSM. That would be really useful.

I am working with GOAL to support Freetown City Council develop a strategy for fecal sludge management.... and we have been looking at dewatering which reduces transportation costs and makes the waste more suitable for treatment (anaerobic or composting) and we were looking at various options that are already on the market.

e.g.

www.nawt.org/symp/documents/ScrewPress-J...ellFKCScrewPress.pdf

www.fkcscrewpress.com/docs/septage2.pdf

But the addition of flocculant doesn't sounds like something that is viable for Freetown so we were looking at alternatives.. we looked at SALSNES filter but apparently that is not good for septic waste....

So - the question is... does anyone know of any effective equipment that can be used at medium scale in a city to dewater sludge without the additional of flocculant ?

best regards,

Jonathan

The title of this discussion thread could be better .. but the topic is very interested.

I couldn't agree more with Christoph when he talks about not reinventing the technological "wheel". I wonder if there has been a comprehensive review about existing technologies for FSM. That would be really useful.

I am working with GOAL to support Freetown City Council develop a strategy for fecal sludge management.... and we have been looking at dewatering which reduces transportation costs and makes the waste more suitable for treatment (anaerobic or composting) and we were looking at various options that are already on the market.

e.g.

www.nawt.org/symp/documents/ScrewPress-J...ellFKCScrewPress.pdf

www.fkcscrewpress.com/docs/septage2.pdf

But the addition of flocculant doesn't sounds like something that is viable for Freetown so we were looking at alternatives.. we looked at SALSNES filter but apparently that is not good for septic waste....

So - the question is... does anyone know of any effective equipment that can be used at medium scale in a city to dewater sludge without the additional of flocculant ?

best regards,

Jonathan

Dr. Jonathan Parkinson

Principal Consultant – Water and Sanitation

IMC Worldwide Ltd, Redhill, United Kingdom

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Skype : jonathanparkinson1

Principal Consultant – Water and Sanitation

IMC Worldwide Ltd, Redhill, United Kingdom

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Skype : jonathanparkinson1

Attachments:

-

septagescrewpress.JPG (Filesize: 52KB)

Please Log in to join the conversation.

You need to login to reply

Dear Bob,

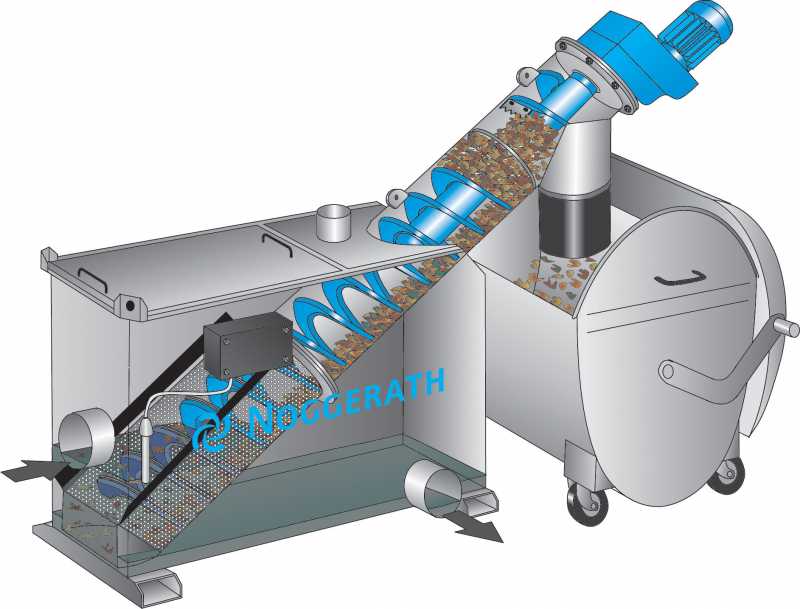

I don´t feel very comfortable with the attempts to reinvent something that is already on the market - in order to get to a cheaper base. In this case it might be better to look for a company which has a reliable product already developed. It is just too much of experience you have to gain to be able to design something which is really trustworthy and robust. Only if you are a genius with mechanical items it might make sense to test around.

Here is just one example www.water-passavant.bilfinger.com/produk...-spiral-sieve-nsi-fa of existing technology

and the corresponding picture.

I know it is too expensive, therefore I think it is not possible to go that way of separating in low budget contexts. I would go for a planted sludge mineralization bed and do a separation once you empty the bed. Saying this I do come to my other concern. When you talk about fecal sludge and especially the water you pretend to treat in a “DEWATS” System… I ask myself "What kind of DEWATS system?". Normally DEWATS is thought for fresh wastewater (therefore anaerobic pretreatment) not for fecal sludge effluent. This is a very difficult to treat liquor. A “normal” DEWATS system could not handle that. I think it is important to stress that as people reading might think this is a viable option. What kind of design did you do?

Regards

Christoph

I don´t feel very comfortable with the attempts to reinvent something that is already on the market - in order to get to a cheaper base. In this case it might be better to look for a company which has a reliable product already developed. It is just too much of experience you have to gain to be able to design something which is really trustworthy and robust. Only if you are a genius with mechanical items it might make sense to test around.

Here is just one example www.water-passavant.bilfinger.com/produk...-spiral-sieve-nsi-fa of existing technology

and the corresponding picture.

I know it is too expensive, therefore I think it is not possible to go that way of separating in low budget contexts. I would go for a planted sludge mineralization bed and do a separation once you empty the bed. Saying this I do come to my other concern. When you talk about fecal sludge and especially the water you pretend to treat in a “DEWATS” System… I ask myself "What kind of DEWATS system?". Normally DEWATS is thought for fresh wastewater (therefore anaerobic pretreatment) not for fecal sludge effluent. This is a very difficult to treat liquor. A “normal” DEWATS system could not handle that. I think it is important to stress that as people reading might think this is a viable option. What kind of design did you do?

Regards

Christoph

Attachments:

-

nsi-b.jpg

(Filesize: 42KB)

nsi-b.jpg

(Filesize: 42KB)

The following user(s) like this post: JKMakowka

Please Log in to join the conversation.

You need to login to replyRe: Guidence on dewatering sludge and seperating solid waste from the solids

The term I was actually looking for is "rotary drum strainer" (I learned these things in German, thus I sometimes struggle with the terms). Do a google search and you will find examples for advanced and less advanced setups of various kinds. Sometimes they also include an sort of internal archimedes screw to lift the solids a bit.

Given the pictures in your document I actually wasn't proposing to lift the liquid with the archimedes screw, but rather have a "leaky" setup that transports the solids to the drying bed while leaving the surplus liquid in the loading bay. From there the accumulating liquid could be pumped with for example a diaphragm pump (relative resistant to low strength liquid sludge) into the feeding tank.

Not sure if it will work, and I have never seen such a setup in a "low-tech" setting, but I guess it might be worth a try.

Given the pictures in your document I actually wasn't proposing to lift the liquid with the archimedes screw, but rather have a "leaky" setup that transports the solids to the drying bed while leaving the surplus liquid in the loading bay. From there the accumulating liquid could be pumped with for example a diaphragm pump (relative resistant to low strength liquid sludge) into the feeding tank.

Not sure if it will work, and I have never seen such a setup in a "low-tech" setting, but I guess it might be worth a try.

Please Log in to join the conversation.

You need to login to reply

Share this thread:

- Forum

- categories

- Sanitation systems

- Faecal sludge management (FSM)

- Faecal sludge treatment technologies

- Guidance on dewatering sludge and separating solid waste from the solids

Recently active users. Who else has been active?

Time to create page: 0.132 seconds