- Forum

- categories

- Sanitation systems

- Faecal sludge management (FSM)

- Faecal sludge treatment technologies

- Development of a low tech carbonising process for management by small enterprises - Faecal sludge to biochar (South Africa)

Development of a low tech carbonising process for management by small enterprises - Faecal sludge to biochar (South Africa)

7514 views

- Oliver

-

Topic Author

Topic Author- Engineer - Water Services Specialist

Less- Posts: 4

- Likes received: 0

Re: Development of a Low Tech Carbonising Process for Management by Small Enterprises.

Hi Heiner,

Clearly if we are targeting the production and reuse of predominantly faecal sludge in producing a biochar for agricultural use, we will need to investigate further the nutrient value in the faecally derived biochar. This will add "value to the biochar as it can then be considered as having a fertiliser benefit in addition to soil amendment properties.

I did mention in my previous comments, that there is in the general research I have consulted, an observed benefit attributed to biochar use in soils whereby it locks in the soil the nitrogen (gas) thereby availing it to the plants. However, when we are dealing with the waste from on-site sanitation (particularly VIP latrines where both urine and faeces are collected together), particularly noting that the urine includes nitrogen in the form of ammonia, any residue of precipitated nitrogen forming a part of the ash content of the final product (e.g. struvite precipitation) will include nitrogen in a solid form which may be available to plants as nutrient for growth. More work will need to be done on this aspect of our piloting.

Regarding the carbonising temperatures, we are typically looking at a "slow pyrolysis" whereby higher char volumes are achieved (rather than driving off carbon as gas), and this is typically in the 350-550 deg C range. Much however depends on where you measure the temperature and we are still working on techniques to determine the best way to measure and manage the temperature whilst still retaining the "low-tech" design which we believe is essential to enable the plant to be operated in remote areas and by technically unqualified personnel.

Regards

Oliver

Clearly if we are targeting the production and reuse of predominantly faecal sludge in producing a biochar for agricultural use, we will need to investigate further the nutrient value in the faecally derived biochar. This will add "value to the biochar as it can then be considered as having a fertiliser benefit in addition to soil amendment properties.

I did mention in my previous comments, that there is in the general research I have consulted, an observed benefit attributed to biochar use in soils whereby it locks in the soil the nitrogen (gas) thereby availing it to the plants. However, when we are dealing with the waste from on-site sanitation (particularly VIP latrines where both urine and faeces are collected together), particularly noting that the urine includes nitrogen in the form of ammonia, any residue of precipitated nitrogen forming a part of the ash content of the final product (e.g. struvite precipitation) will include nitrogen in a solid form which may be available to plants as nutrient for growth. More work will need to be done on this aspect of our piloting.

Regarding the carbonising temperatures, we are typically looking at a "slow pyrolysis" whereby higher char volumes are achieved (rather than driving off carbon as gas), and this is typically in the 350-550 deg C range. Much however depends on where you measure the temperature and we are still working on techniques to determine the best way to measure and manage the temperature whilst still retaining the "low-tech" design which we believe is essential to enable the plant to be operated in remote areas and by technically unqualified personnel.

Regards

Oliver

Please Log in to join the conversation.

You need to login to reply- Heiner

-

- I am a retired organic farmer and interested in nutrient cycles. As an volunteer I now travel mainly to poor countries and together with locals I would like to find new ways of sustainable agriculture. This is beyond the regulations of IFOAM.

Less- Posts: 80

- Karma: 1

- Likes received: 67

Re: Development of a Low Tech Carbonising Process for Management by Small Enterprises.

Hi Jeff (and Elisabeth?),

just a question to understand the process of closing the nutrient loop via biochar production:

What is the temperature during production of biochar? And did you ever measure the loss of nitrogen during the process?

Thanks a lot,

Heiner

just a question to understand the process of closing the nutrient loop via biochar production:

What is the temperature during production of biochar? And did you ever measure the loss of nitrogen during the process?

Thanks a lot,

Heiner

Heiner, the old farmer.....

Please Log in to join the conversation.

You need to login to reply- Oliver

-

Topic Author

Topic Author- Engineer - Water Services Specialist

Less- Posts: 4

- Likes received: 0

Re: Development of a Low Tech Carbonising Process for Management by Small Enterprises.

Hi Elizabeth,

The photos I attached in my presentation show the stand alone kiln during pyrolysis, which discharges openly to atmosphere. This is where we started, as the initial challenge was to prove our ability to produce the char from the dried sludge feedstock by pyrolysis in the retort drums. This step needed proving at scale to give us the necessary confidence for the carbonising step. The next step has been to capture all the volatile gas (seen in the pictures in my presentation) and ensure this is burnt off in our progressive batch approach.

We have been testing the approach in a six kiln train and this has been yielding a far better result in reducing emission and the use of external energy sources for heating, by utilising the majority of the pyrolysis emissions in re-burning for heating the downstream kilns.

We have been self funding the upgrade and testing and are now sourcing additional funding so we can construct a scaled up plant which will include additional secondary drying, material handling and final product crushing and packing etc....see diagrammatic layout as attached. In addition, we hope to investigate further the application and benefit of the end product for agricultural use, and are working on twinning with a local university where regular monitoring of field trials can be done.

Thanks for your interest,

Oliver

The photos I attached in my presentation show the stand alone kiln during pyrolysis, which discharges openly to atmosphere. This is where we started, as the initial challenge was to prove our ability to produce the char from the dried sludge feedstock by pyrolysis in the retort drums. This step needed proving at scale to give us the necessary confidence for the carbonising step. The next step has been to capture all the volatile gas (seen in the pictures in my presentation) and ensure this is burnt off in our progressive batch approach.

We have been testing the approach in a six kiln train and this has been yielding a far better result in reducing emission and the use of external energy sources for heating, by utilising the majority of the pyrolysis emissions in re-burning for heating the downstream kilns.

We have been self funding the upgrade and testing and are now sourcing additional funding so we can construct a scaled up plant which will include additional secondary drying, material handling and final product crushing and packing etc....see diagrammatic layout as attached. In addition, we hope to investigate further the application and benefit of the end product for agricultural use, and are working on twinning with a local university where regular monitoring of field trials can be done.

Thanks for your interest,

Oliver

Attachments:

-

Sitemap4.jpg

(Filesize: 74KB)

Sitemap4.jpg

(Filesize: 74KB)

Please Log in to join the conversation.

You need to login to reply- Oliver

-

Topic Author

Topic Author- Engineer - Water Services Specialist

Less- Posts: 4

- Likes received: 0

Re: Development of a Low Tech Carbonising Process for Management by Small Enterprises.

Hi Jeff,

Thanks for your comment, and I do agree that we will need to focus on emission control/reduction to ensure as clean an emission as possible.

We have not yet investigated the ways of reducing the CO portion in the flue gas, but your suggestion to look at catalytic conversion is certainly worth further consideration.

The benefit of returning the carbon in the stable char form to the soils, rather than letting the uncharred sludge biodegrade into gas over time is beneficial from an overarching carbon balance perspective.

As you noted one of the advantages of the faecal sludge to biochar process is phosphate and nitrogen recovery and its re-use in agriculture. In my mind, this was one of the benefits which steered us towards the biochar production for soil amendment, rather than using the char for energy where there would be limited control of where and how the ash would be used after the burning of the char.

Thanks for your comment, and I do agree that we will need to focus on emission control/reduction to ensure as clean an emission as possible.

We have not yet investigated the ways of reducing the CO portion in the flue gas, but your suggestion to look at catalytic conversion is certainly worth further consideration.

The benefit of returning the carbon in the stable char form to the soils, rather than letting the uncharred sludge biodegrade into gas over time is beneficial from an overarching carbon balance perspective.

As you noted one of the advantages of the faecal sludge to biochar process is phosphate and nitrogen recovery and its re-use in agriculture. In my mind, this was one of the benefits which steered us towards the biochar production for soil amendment, rather than using the char for energy where there would be limited control of where and how the ash would be used after the burning of the char.

Please Log in to join the conversation.

You need to login to replyRe: Development of a Low Tech Carbonising Process for Management by Small Enterprises.

Elisabeth and Oliver,

High CO is a problem when making biochar. There are pollution control technologies such as catalysts that can reduce emissions.

Biochar is also important for nutrient recovery. In addition to the carbon, Phosphorus supply continues to be depleted and needs closed loop solutions like your process.

Thank you for sharing.

Jeff

High CO is a problem when making biochar. There are pollution control technologies such as catalysts that can reduce emissions.

Biochar is also important for nutrient recovery. In addition to the carbon, Phosphorus supply continues to be depleted and needs closed loop solutions like your process.

Thank you for sharing.

Jeff

Jeff Hallowell

Biomass Controls PBC

Biomass Controls PBC

Please Log in to join the conversation.

You need to login to reply- Elisabeth

-

- User is blocked

- Freelance consultant since 2012

Less- Posts: 3372

- Karma: 54

- Likes received: 932

Re: Development of a Low Tech Carbonising Process for Management by Small Enterprises.

Dear Oliver,

Thanks for your forum post.

I have the following questions:

1 - How do you feel about air pollution issues (see photo below), and how would you deal with that at a larger scale?

2 - How is this work funded?

And I am going to add some information below to draw more attention to it and also to ensure this thread is found with the relevant keyword searches (the searches can't search inside a pdf file):

+++++++++

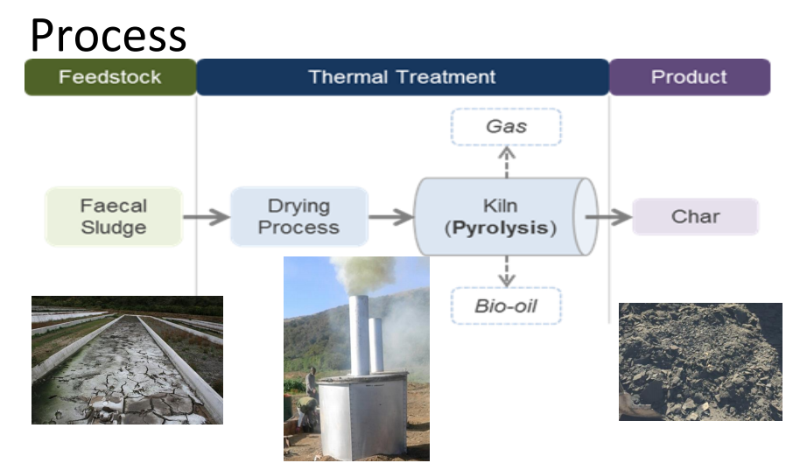

Faecal Sludge to “Biochar”.

• Biochar is the char product that is created

through the heating of organic biomass in a

low or no-oxygen environment through a

process called pyrolysis, and is then applied to

agricultural or forest soils

Why Biochar?

• Biochar supports agricultural sustainability,

food security and livelihoods for resourcepoor farmers in Africa and beyond

• Use of biochar is not only for soil enrichment

but also for the contribution as a carbon sink

and its value in carbon sequestration

Next Steps

• Improvements in the conservation of the energy

available from the pyrolysis of sludge together with

the downstream use of heat in the flue gasses can

provide additional benefit for drying

• Refining the kiln design to incorporate refractory

bricks or and insulation for heat retention would

allow for the reduction of wood fuel stock.

• Further refinements includes the addition of steel

ducting and pressure controls required to transfer

the heat from the pyrolysing kilns to be used in the

drying kilns or special developed drying chambers.

Way forward

• Prove process efficiency and effectiveness

• Field test product range – soil amendment

• Deregister processed faecal sludge

• Verify Economic and Agronomic data

• Add sludge drying stages

• Product testing and production quality

assurance

++++++

Regards,

Elisabeth

Thanks for your forum post.

I have the following questions:

1 - How do you feel about air pollution issues (see photo below), and how would you deal with that at a larger scale?

2 - How is this work funded?

And I am going to add some information below to draw more attention to it and also to ensure this thread is found with the relevant keyword searches (the searches can't search inside a pdf file):

+++++++++

Faecal Sludge to “Biochar”.

• Biochar is the char product that is created

through the heating of organic biomass in a

low or no-oxygen environment through a

process called pyrolysis, and is then applied to

agricultural or forest soils

Why Biochar?

• Biochar supports agricultural sustainability,

food security and livelihoods for resourcepoor farmers in Africa and beyond

• Use of biochar is not only for soil enrichment

but also for the contribution as a carbon sink

and its value in carbon sequestration

Next Steps

• Improvements in the conservation of the energy

available from the pyrolysis of sludge together with

the downstream use of heat in the flue gasses can

provide additional benefit for drying

• Refining the kiln design to incorporate refractory

bricks or and insulation for heat retention would

allow for the reduction of wood fuel stock.

• Further refinements includes the addition of steel

ducting and pressure controls required to transfer

the heat from the pyrolysing kilns to be used in the

drying kilns or special developed drying chambers.

Way forward

• Prove process efficiency and effectiveness

• Field test product range – soil amendment

• Deregister processed faecal sludge

• Verify Economic and Agronomic data

• Add sludge drying stages

• Product testing and production quality

assurance

++++++

Regards,

Elisabeth

Dr. Elisabeth von Muench

Freelance consultant on environmental and climate projects

Freelance consultant on environmental and climate projects

Attachments:

-

biochar1.png

(Filesize: 235KB)

biochar1.png

(Filesize: 235KB)

Please Log in to join the conversation.

You need to login to reply- Oliver

-

Topic Author

Topic Author- Engineer - Water Services Specialist

Less- Posts: 4

- Likes received: 0

Development of a Low Tech Carbonising Process for Management by Small Enterprises.

As presented at FSM5 Conference in Cape Town (Feb 2019) - We have been piloting a low-tech carbonising process suitable for use by the small local enterprises (operation under a social franchise) as an additional service offering for their on-site sanitation activities.

See link to presentation: fsm5.susana.org/images/FSM_Conference_Ma...bonising---Final.pdf

See link to presentation: fsm5.susana.org/images/FSM_Conference_Ma...bonising---Final.pdf

This message has an attachment file.

Please log in or register to see it.

Please Log in to join the conversation.

You need to login to reply

Share this thread:

- Forum

- categories

- Sanitation systems

- Faecal sludge management (FSM)

- Faecal sludge treatment technologies

- Development of a low tech carbonising process for management by small enterprises - Faecal sludge to biochar (South Africa)

Recently active users. Who else has been active?

Time to create page: 0.205 seconds