- Forum

- categories

- Sanitation systems

- Faecal sludge management (FSM)

- Faecal sludge treatment technologies

- Key documents for Category 1 "Design and Technologies" (Decentralised Treatment Facilities)

Key documents for Category 1 "Design and Technologies" (Decentralised Treatment Facilities)

25.4k views

- ogeda

-

Less

Less- Posts: 4

- Likes received: 1

Re: Key documents for Category 1 "Design and Technologies" (Decentralised Treatment Facilities)

Hello,

Thanks for the post. Happy to see the machakos plant operating well. I was there when it first received the faecal sludge.

Thanks for the post. Happy to see the machakos plant operating well. I was there when it first received the faecal sludge.

The following user(s) like this post: AlexandraDubois

Please Log in to join the conversation.

You need to login to reply- AlexandraDubois

-

- Administrator

- Technical advisor specialized in water, sanitation and hygiene. I work for GIZ since 2012 and have gathered experience in the sub-Saharan region mainly. Since January 2022, I work as an advisor for the “Water Policy Sector Programme - Innovations for Resilience” in Bonn and I am part of the SuSanA secretariat.

Less- Posts: 66

- Karma: 6

- Likes received: 47

Re: Key documents for Category 1 "Design and Technologies" (Decentralised Treatment Facilities)

I am adding some pictures of the DTF in operation to illustrate my previous post:

Aerial shot DTF Chuka © WSTF/GIZ

DTF Machakos © WSTF/GIZ

Faecal sludge discharge in Nakuru DTF © WSTF/GIZ

Anaerobic Baffled Reactor in DTF Chuka © WSTF/GIZ

Sludge drying bed in Machakos DTF © WSTF/GIZ

Vertical flow constructed wetland in Homa Bay DTF © WSTF/GIZ

Operator office in Chuka DTF © WSTF/GIZ

Samples in Chuka DTF: incoming vs treated effluent © WSTF/GIZ

Aerial shot DTF Chuka © WSTF/GIZ

DTF Machakos © WSTF/GIZ

Faecal sludge discharge in Nakuru DTF © WSTF/GIZ

Anaerobic Baffled Reactor in DTF Chuka © WSTF/GIZ

Sludge drying bed in Machakos DTF © WSTF/GIZ

Vertical flow constructed wetland in Homa Bay DTF © WSTF/GIZ

Operator office in Chuka DTF © WSTF/GIZ

Samples in Chuka DTF: incoming vs treated effluent © WSTF/GIZ

Alexandra Dubois

Technical Advisor

Sector Programme Water Policy – Innovations for Resilience

Division Climate Change, Environment & Infrastructure

GIZ │Deutsche Gesellschaft für

Internationale Zusammenarbeit (GIZ) GmbH

Friedrich-Ebert-Allee 32

53113 Bonn, Germany

Technical Advisor

Sector Programme Water Policy – Innovations for Resilience

Division Climate Change, Environment & Infrastructure

GIZ │Deutsche Gesellschaft für

Internationale Zusammenarbeit (GIZ) GmbH

Friedrich-Ebert-Allee 32

53113 Bonn, Germany

Attachments:

-

aerialshot...huka.jpg

(Filesize: 129KB)

aerialshot...huka.jpg

(Filesize: 129KB)

-

DTFMachakos.jpg

(Filesize: 93KB)

DTFMachakos.jpg

(Filesize: 93KB)

-

Nakuru-21.jpg

(Filesize: 238KB)

Nakuru-21.jpg

(Filesize: 238KB)

-

Chuka-332.jpg

(Filesize: 249KB)

Chuka-332.jpg

(Filesize: 249KB)

-

Sludgedryi...5-03.JPG (Filesize: 525KB)

-

VerticalFl...5-03.JPG (Filesize: 440KB)

-

Chuka-322.jpg

(Filesize: 291KB)

Chuka-322.jpg

(Filesize: 291KB)

-

SamplesinC...5-03.JPG (Filesize: 392KB)

The following user(s) like this post: Elisabeth, depinder, Fahim1988

Please Log in to join the conversation.

You need to login to reply- AlexandraDubois

-

- Administrator

- Technical advisor specialized in water, sanitation and hygiene. I work for GIZ since 2012 and have gathered experience in the sub-Saharan region mainly. Since January 2022, I work as an advisor for the “Water Policy Sector Programme - Innovations for Resilience” in Bonn and I am part of the SuSanA secretariat.

Less- Posts: 66

- Karma: 6

- Likes received: 47

Re: Key documents for Category 1 "Design and Technologies" (Decentralised Treatment Facilities)

Dear all

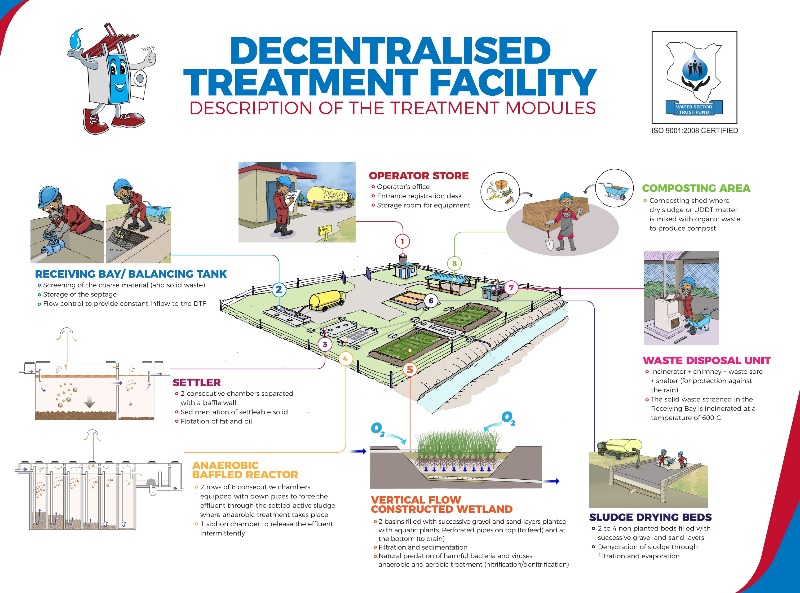

After a long period of silence, let me give you a short update on the DTF implementation. First of all, a quick reminder on the general layout, the DTF can treat up to 22m3 and comprises the following modules:

1. The Receiving Bay / Balancing Tank: for screening and flow rate control

2. The Settler tank: for separation liquid and solid (sedimentation of heavy particles and flotation of lighter particle)

3. The Anaerobic Baffled Reactor: for the anaerobic treatment

4. The Vertical Flow Constructed Wetland: as polishing step (filtration, sedimentation, chemical adsorption, aerobic/anaerobic treatment)

5. In addition to the main treatment line, the DTF has 2 sludge drying beds (for the desludging of the settler and the ABR), 1 composting shed, 1 incinerator (to get rid of the screened solid waste) and 1 operator office

You can find the description of each module in the DTF poster:

The UBSUP programme (the description can be found here and the explanative video here is implementing 11 of this DTF. As of today 7 DTF are completed and in operation and the 4 remaining are following closely. The overall implementation was not without challenge, however I believe that thanks to our standardized approach and our strategy to build the capacity of the Water Services Providers (WSP: the main implementer), we managed to achieve a lot (consequently reaching a significant number of beneficiaries) in a limited period of time. All implementing tools (trainings material, technical drawings, BoQ, monitoring tools, etc.) can be found either in the SuSanA library or the WSTF toolkit . With regards to the challenges and lessons learned, here is a non-exhaustive list of what comes to mind off the top of my head:

1. It crucial to convince the institutional stakeholders to accept and adopt on-site and decentralised sanitation options, as they tend to hold a strong belief that conventional sewerage is the only option for sanitation. National up-scaling works best with sector structure as they provide an ideal ground to replicate a concept in different areas.

2. In a context where decentralised treatment facilities are not common, it is important to provide the necessary support to the main actors involved in the DTF construction (technical team of the WSP) to ensure sustainability and quality of the implementation. This support can be quite demanding, but the standardized approach enables to reduce the amount of effort: grouped trainings, same design therefore no need for customisation, same implementing tools available online, etc.

3. Proper appraisal of the amount of faecal sludge to be treated is needed before constructing a DTF. The demand should be enough to justify the investment and operation costs of a DTF. The demand should be calculated by the amount of faecal sludge that can be emptied and transported: collection services activities rather than number of inhabitant or even number toilets. We are currently facing the situation where the DTF is operating way below capacity because there are no vacuum trucks available and because of their design, most of the latrines can’t be emptied.

4. In order to achieve maximum efficiency, it is recommended to focus on the main purpose of a treatment plant, which is to guarantee safe treatment and disposal of the waste water and faecal sludge. The topic of reuse and recycling is very trendy nowadays (biogas, fertiliser, briquettes, etc.) and might look very attractive from an external point of view, however it can easily divert the attention from the real aim and consume time and effort where it is most needed. The reuse aspect should be taken on case-by-case basis, it should be considered when socially and economically relevant.

5. A proper business model is required to set a fair tariff while ensuring the sustainability of the activity. The model should be developed with the actors involved in the operation of the DTF for it to suit with the local context.

I have attached the effluent quality test results of one of the DTF (Machakos). As you will see, the final effluent is not reaching the quality standards, therefore the UBSUP team is doing some adjustments in the operation procedures and is also working on a new DTF design to increase the capacity to 50m3/day and improve the general performance of the plant. I will keep you posted on the new design very soon.

After a long period of silence, let me give you a short update on the DTF implementation. First of all, a quick reminder on the general layout, the DTF can treat up to 22m3 and comprises the following modules:

1. The Receiving Bay / Balancing Tank: for screening and flow rate control

2. The Settler tank: for separation liquid and solid (sedimentation of heavy particles and flotation of lighter particle)

3. The Anaerobic Baffled Reactor: for the anaerobic treatment

4. The Vertical Flow Constructed Wetland: as polishing step (filtration, sedimentation, chemical adsorption, aerobic/anaerobic treatment)

5. In addition to the main treatment line, the DTF has 2 sludge drying beds (for the desludging of the settler and the ABR), 1 composting shed, 1 incinerator (to get rid of the screened solid waste) and 1 operator office

You can find the description of each module in the DTF poster:

The UBSUP programme (the description can be found here and the explanative video here is implementing 11 of this DTF. As of today 7 DTF are completed and in operation and the 4 remaining are following closely. The overall implementation was not without challenge, however I believe that thanks to our standardized approach and our strategy to build the capacity of the Water Services Providers (WSP: the main implementer), we managed to achieve a lot (consequently reaching a significant number of beneficiaries) in a limited period of time. All implementing tools (trainings material, technical drawings, BoQ, monitoring tools, etc.) can be found either in the SuSanA library or the WSTF toolkit . With regards to the challenges and lessons learned, here is a non-exhaustive list of what comes to mind off the top of my head:

1. It crucial to convince the institutional stakeholders to accept and adopt on-site and decentralised sanitation options, as they tend to hold a strong belief that conventional sewerage is the only option for sanitation. National up-scaling works best with sector structure as they provide an ideal ground to replicate a concept in different areas.

2. In a context where decentralised treatment facilities are not common, it is important to provide the necessary support to the main actors involved in the DTF construction (technical team of the WSP) to ensure sustainability and quality of the implementation. This support can be quite demanding, but the standardized approach enables to reduce the amount of effort: grouped trainings, same design therefore no need for customisation, same implementing tools available online, etc.

3. Proper appraisal of the amount of faecal sludge to be treated is needed before constructing a DTF. The demand should be enough to justify the investment and operation costs of a DTF. The demand should be calculated by the amount of faecal sludge that can be emptied and transported: collection services activities rather than number of inhabitant or even number toilets. We are currently facing the situation where the DTF is operating way below capacity because there are no vacuum trucks available and because of their design, most of the latrines can’t be emptied.

4. In order to achieve maximum efficiency, it is recommended to focus on the main purpose of a treatment plant, which is to guarantee safe treatment and disposal of the waste water and faecal sludge. The topic of reuse and recycling is very trendy nowadays (biogas, fertiliser, briquettes, etc.) and might look very attractive from an external point of view, however it can easily divert the attention from the real aim and consume time and effort where it is most needed. The reuse aspect should be taken on case-by-case basis, it should be considered when socially and economically relevant.

5. A proper business model is required to set a fair tariff while ensuring the sustainability of the activity. The model should be developed with the actors involved in the operation of the DTF for it to suit with the local context.

I have attached the effluent quality test results of one of the DTF (Machakos). As you will see, the final effluent is not reaching the quality standards, therefore the UBSUP team is doing some adjustments in the operation procedures and is also working on a new DTF design to increase the capacity to 50m3/day and improve the general performance of the plant. I will keep you posted on the new design very soon.

This attachment is hidden for guests.

Please log in or register to see it.

Please log in or register to see it.

Alexandra Dubois

Technical Advisor

Sector Programme Water Policy – Innovations for Resilience

Division Climate Change, Environment & Infrastructure

GIZ │Deutsche Gesellschaft für

Internationale Zusammenarbeit (GIZ) GmbH

Friedrich-Ebert-Allee 32

53113 Bonn, Germany

Technical Advisor

Sector Programme Water Policy – Innovations for Resilience

Division Climate Change, Environment & Infrastructure

GIZ │Deutsche Gesellschaft für

Internationale Zusammenarbeit (GIZ) GmbH

Friedrich-Ebert-Allee 32

53113 Bonn, Germany

Attachments:

-

DTFmodules.jpg

(Filesize: 146KB)

DTFmodules.jpg

(Filesize: 146KB)

The following user(s) like this post: fppirco, Fahim1988

Please Log in to join the conversation.

You need to login to reply- annetempel

-

Topic Author

Topic Author- I work for GIZ's sustainable sanitation programme

Less- Posts: 59

- Karma: 5

- Likes received: 33

Key documents for Category 1 "Design and Technologies" (Decentralised Treatment Facilities)

Dear all,

key documents about the design and technologies of decentralised treatment facilities produced in the context of GIZ's water sector reform programme are available in the SuSanA library:

www.susana.org/en/resources/library/details/2448

The library entry contains the following documents:

Kind regards,

Annkathrin

* Edit on 18 Sept 18: No longer available, now obsolete

key documents about the design and technologies of decentralised treatment facilities produced in the context of GIZ's water sector reform programme are available in the SuSanA library:

www.susana.org/en/resources/library/details/2448

The library entry contains the following documents:

DTF Design Adaption Manual (pdf) • Size: 3.06 MB*DTF Construction Manual (pdf) • Size: 11.26 MB- DTF BoQ (xlsx) • Size: 0.22 MB

DTF 3D simulation (pdf) • Size: 0.21 MB- DTF Structural Drawings of Modules (pdf) • Size: 10.12 MB

Kind regards,

Annkathrin

* Edit on 18 Sept 18: No longer available, now obsolete

GIZ Sustainable Sanitation Programme

Division for Climate Change, Environment & Infrastructure

Division for Climate Change, Environment & Infrastructure

The following user(s) like this post: JotaCarlos, Faith, kashif123, jincysan

Please Log in to join the conversation.

You need to login to reply

Share this thread:

- Forum

- categories

- Sanitation systems

- Faecal sludge management (FSM)

- Faecal sludge treatment technologies

- Key documents for Category 1 "Design and Technologies" (Decentralised Treatment Facilities)

Recently active users. Who else has been active?

Time to create page: 0.625 seconds