- Forum

- categories

- Sanitation systems

- Faecal sludge management (FSM)

- Faecal sludge treatment technologies

- Any successful experience with siphon system?

Any successful experience with siphon system?

25.5k views

siphon-update:

on "flexible self-acting siphon`s for raw sewage", based on idea of fixed self-acting siphon by Dr. Werner HEYN from Hamburg, Germany

Animation

~1929: now open Patent US1727828 - Self-acting siphon by Dr.-Ing. Werner HEYN from Hamburg, Germany, www.google.com/patents/US1727828

4 French suppliers for self-acting siphon`s for raw sewage by now:

aquasaf.fr/en/

jean-voisin.fr/produits/equipements/chasse-poste/

www.alistep.com/?lang=en

www.ineautec.com

Any other "inventors" for "flexible self-acting siphon`s for raw sewage" around the globe?

Regards,

Detlef SCHWAGER

on "flexible self-acting siphon`s for raw sewage", based on idea of fixed self-acting siphon by Dr. Werner HEYN from Hamburg, Germany

Animation

~1929: now open Patent US1727828 - Self-acting siphon by Dr.-Ing. Werner HEYN from Hamburg, Germany, www.google.com/patents/US1727828

4 French suppliers for self-acting siphon`s for raw sewage by now:

aquasaf.fr/en/

jean-voisin.fr/produits/equipements/chasse-poste/

www.alistep.com/?lang=en

www.ineautec.com

Any other "inventors" for "flexible self-acting siphon`s for raw sewage" around the globe?

Regards,

Detlef SCHWAGER

www.aqua-verde.de, AquaVerde Ltd. Zanzibar

"simple" Sanitation-Solutions by gravity

Low-Tech Solutions with High-Tech Effects

"Inspired by Circular Economy and Cooperation"

www.flickr.com/photos/aqua-verde/

"simple" Sanitation-Solutions by gravity

Low-Tech Solutions with High-Tech Effects

"Inspired by Circular Economy and Cooperation"

www.flickr.com/photos/aqua-verde/

Please Log in to join the conversation.

You need to login to reply

Operating principle of the self priming siphon (Float-operated flush):

videos:

Regards,

Detlef

videos:

Regards,

Detlef

www.aqua-verde.de, AquaVerde Ltd. Zanzibar

"simple" Sanitation-Solutions by gravity

Low-Tech Solutions with High-Tech Effects

"Inspired by Circular Economy and Cooperation"

www.flickr.com/photos/aqua-verde/

"simple" Sanitation-Solutions by gravity

Low-Tech Solutions with High-Tech Effects

"Inspired by Circular Economy and Cooperation"

www.flickr.com/photos/aqua-verde/

Please Log in to join the conversation.

You need to login to reply

see

my first unsuccessful trail of floating-valve for "automated" distribution to a larger vertical CW

Regards,

Detlef

Regards,

Detlef

www.aqua-verde.de, AquaVerde Ltd. Zanzibar

"simple" Sanitation-Solutions by gravity

Low-Tech Solutions with High-Tech Effects

"Inspired by Circular Economy and Cooperation"

www.flickr.com/photos/aqua-verde/

"simple" Sanitation-Solutions by gravity

Low-Tech Solutions with High-Tech Effects

"Inspired by Circular Economy and Cooperation"

www.flickr.com/photos/aqua-verde/

Please Log in to join the conversation.

You need to login to reply

Dear Kevin,

it's true that the flexible part is the main problem to solve. We do it now from EPDM liner which we use for CW lining. It's quite durable, but it's not the best solution because it must be glued to the form of a hose. Flout from rissy plastic has also EPDM hose but it looks similar to the hoses on the siphon. But I can't find any such product yet (maybe in car industry one can find hoses like this).

For small wetlands we use 50 mm pipes which is enough. But Rissy plastic produce Flouts with as much as 100 mm and it can be set in parallel so it should be enough for quite big wetlands.

After the pretreatment there is no problem with clogging. The device is somewhat similar to the flouting siphon, so I presume it should be working on french system also (we do have pumps for the first stage and flout only for the second stage - but it's because insufficient slope). Anyway you should have pretreatment with (fine) screens on the french system.

it's true that the flexible part is the main problem to solve. We do it now from EPDM liner which we use for CW lining. It's quite durable, but it's not the best solution because it must be glued to the form of a hose. Flout from rissy plastic has also EPDM hose but it looks similar to the hoses on the siphon. But I can't find any such product yet (maybe in car industry one can find hoses like this).

For small wetlands we use 50 mm pipes which is enough. But Rissy plastic produce Flouts with as much as 100 mm and it can be set in parallel so it should be enough for quite big wetlands.

After the pretreatment there is no problem with clogging. The device is somewhat similar to the flouting siphon, so I presume it should be working on french system also (we do have pumps for the first stage and flout only for the second stage - but it's because insufficient slope). Anyway you should have pretreatment with (fine) screens on the french system.

Please Log in to join the conversation.

You need to login to reply

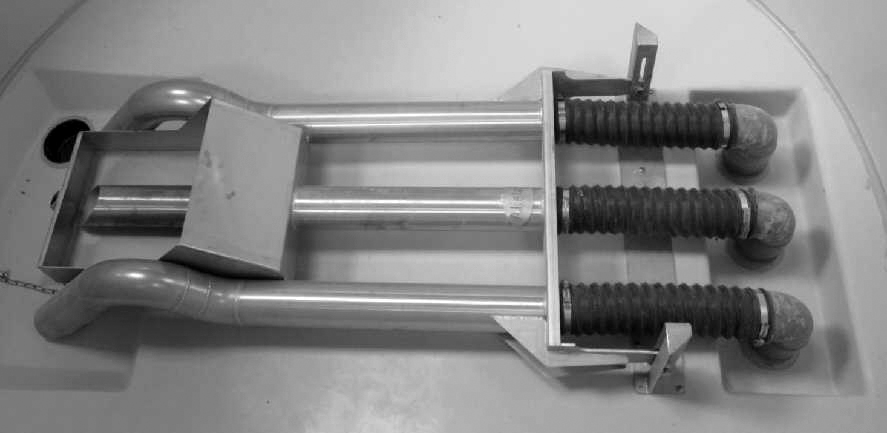

see dual siphon made from stainless steel with a open float for raw sewage by ALISTEP, France. This device is taking sludge too for distributing to larger CW's:

forum.susana.org/forum/categories?func=v...034&limit=1000#17383

after years of use: even without minimum maintenance is is functioning. The flexible hose last 5-10 years. Without cleaning they last longer...

forum.susana.org/forum/categories?func=v...034&limit=1000#17383

after years of use: even without minimum maintenance is is functioning. The flexible hose last 5-10 years. Without cleaning they last longer...

www.aqua-verde.de, AquaVerde Ltd. Zanzibar

"simple" Sanitation-Solutions by gravity

Low-Tech Solutions with High-Tech Effects

"Inspired by Circular Economy and Cooperation"

www.flickr.com/photos/aqua-verde/

"simple" Sanitation-Solutions by gravity

Low-Tech Solutions with High-Tech Effects

"Inspired by Circular Economy and Cooperation"

www.flickr.com/photos/aqua-verde/

Attachments:

-

P5251955.JPG (Filesize: 74KB)

-

P5251966.JPG (Filesize: 67KB)

Please Log in to join the conversation.

You need to login to reply- kevintayler

-

- I am a water and sanitation engineer, also interested in general urban housing issues. In recent years, I have worked on FSM for various organizations

Less- Posts: 79

- Karma: 11

- Likes received: 46

Dear Vitec

Thanks for the information - it is now clear how it works. As you say it is simple and it seems that the first one has been working since 1992 with no problems. The challenge for a 'do it yourself' approach will presumably be to ensure that the flexible hose part works OK and is durable. That should not be a problem for small installations but may be an issue at larger sizes - it looks to me from the flout literature that they are mainly used in smaller sizes, the largest size in the Rissy literature is 4". I realize when I look back over the thread AquaVerde is describing the same system. The example referred to in that post has a 50mm dia pipe. I could not understand that system before but your references make the operation clear. I think that the system would work OK for septage after primary treatment in an ABR or something similar - perhaps with a minimum pipe diameter of 75mm. I will certainly bear it in mind for future projects.

Thanks again

Kevin

Thanks for the information - it is now clear how it works. As you say it is simple and it seems that the first one has been working since 1992 with no problems. The challenge for a 'do it yourself' approach will presumably be to ensure that the flexible hose part works OK and is durable. That should not be a problem for small installations but may be an issue at larger sizes - it looks to me from the flout literature that they are mainly used in smaller sizes, the largest size in the Rissy literature is 4". I realize when I look back over the thread AquaVerde is describing the same system. The example referred to in that post has a 50mm dia pipe. I could not understand that system before but your references make the operation clear. I think that the system would work OK for septage after primary treatment in an ABR or something similar - perhaps with a minimum pipe diameter of 75mm. I will certainly bear it in mind for future projects.

Thanks again

Kevin

Kevin Tayler

Independent water and sanitation consultant

Horsham

UK

Independent water and sanitation consultant

Horsham

UK

Please Log in to join the conversation.

You need to login to reply

Dear Kevin,

the principle of the flowing outlet is really simple. It's based on buoyancy. The plastic box opened on top side is attached to outlet from tank somewhere near its bottom with flexible part. The box is moving up with water to a certain level when it can't go more up and the box is filled with water and goes quickly to the bottom and drains the whole tank.

I've found several designs on the internet, but the best design is from Rissy Plastics www.rissyplastics.com/ - they call it The Flout and their design is patented for the USA. But it's quite cheap if you live in US. For us from other countries is best to do it DIY for small wetlands and buy it for the bigger ones (duty process is the problem here). There are better videos and drawings on the webpage too.

the principle of the flowing outlet is really simple. It's based on buoyancy. The plastic box opened on top side is attached to outlet from tank somewhere near its bottom with flexible part. The box is moving up with water to a certain level when it can't go more up and the box is filled with water and goes quickly to the bottom and drains the whole tank.

I've found several designs on the internet, but the best design is from Rissy Plastics www.rissyplastics.com/ - they call it The Flout and their design is patented for the USA. But it's quite cheap if you live in US. For us from other countries is best to do it DIY for small wetlands and buy it for the bigger ones (duty process is the problem here). There are better videos and drawings on the webpage too.

The following user(s) like this post: kevintayler

Please Log in to join the conversation.

You need to login to reply- kevintayler

-

- I am a water and sanitation engineer, also interested in general urban housing issues. In recent years, I have worked on FSM for various organizations

Less- Posts: 79

- Karma: 11

- Likes received: 46

Hi Alexandra

I guess that I did not look closely enough at your previous post. As you say, the question is how well it will work with the higher solids concentration in septage. However, from what I remember of your initial posts, the siphon will follow an ABR. I have also been promoting the use of simple hopper-bottomed sedimentation tanks for initial solids - liquid separation at septage treatment facilities. That is mainly in the context of Asia and African conditions are rather different - my impression is that the material removed from pit latrines often has a high solids content and I guess that it will not always be well digested. In Indonesia, where I have been mainly working, the septage tends to be well digested and have a high water content. It would be interesting to compare notes on experience. I think with new (and rediscovered)technologies, the important thing is to assess their performance in real situations.

On Vitec's suggested alternative, I confess that I cannot understand exactly how it works fom the sketch and the video. Does it need power? Vitec if you can clarify, that would be useful. The big advantage of the dosing siphon approach is its simplicity and the fact that it does not need power so I would say that any alternative would have to meet these criteria and also be more operationally robust.

I guess that I did not look closely enough at your previous post. As you say, the question is how well it will work with the higher solids concentration in septage. However, from what I remember of your initial posts, the siphon will follow an ABR. I have also been promoting the use of simple hopper-bottomed sedimentation tanks for initial solids - liquid separation at septage treatment facilities. That is mainly in the context of Asia and African conditions are rather different - my impression is that the material removed from pit latrines often has a high solids content and I guess that it will not always be well digested. In Indonesia, where I have been mainly working, the septage tends to be well digested and have a high water content. It would be interesting to compare notes on experience. I think with new (and rediscovered)technologies, the important thing is to assess their performance in real situations.

On Vitec's suggested alternative, I confess that I cannot understand exactly how it works fom the sketch and the video. Does it need power? Vitec if you can clarify, that would be useful. The big advantage of the dosing siphon approach is its simplicity and the fact that it does not need power so I would say that any alternative would have to meet these criteria and also be more operationally robust.

Kevin Tayler

Independent water and sanitation consultant

Horsham

UK

Independent water and sanitation consultant

Horsham

UK

Please Log in to join the conversation.

You need to login to reply

Dear Alexandra,

I would recommend to use completly different design, which is more reliable and also more simple to build. It is so called flowing outlet . It can be build easily DIY from plastic pipes, EPDM liner (for flexible part) and some plastic box (we use plastic boxes for electrical installations). Only thing that has to be set is the needed height of the water in the tank (it can be as low as 30 cm) for the desired volume of water. I attached a simple drawing, but I can supply more detailed one if You wish.

Best regards from Czech Republic

I would recommend to use completly different design, which is more reliable and also more simple to build. It is so called flowing outlet . It can be build easily DIY from plastic pipes, EPDM liner (for flexible part) and some plastic box (we use plastic boxes for electrical installations). Only thing that has to be set is the needed height of the water in the tank (it can be as low as 30 cm) for the desired volume of water. I attached a simple drawing, but I can supply more detailed one if You wish.

Best regards from Czech Republic

This attachment is hidden for guests.

Please log in or register to see it.

Please log in or register to see it.

This message has an attachment file.

Please log in or register to see it.

Please Log in to join the conversation.

You need to login to reply- AlexandraDubois

-

Topic Author

Topic Author- Administrator

- Technical advisor specialized in water, sanitation and hygiene. I work for GIZ since 2012 and have gathered experience in the sub-Saharan region mainly. Since January 2022, I work as an advisor for the “Water Policy Sector Programme - Innovations for Resilience” in Bonn and I am part of the SuSanA secretariat.

Less- Posts: 66

- Karma: 6

- Likes received: 47

Dear Kevin

Thank you for your answer. We have actually used the design provided by Fluid Dynamic Siphons Inc (1st link) to develop our own design. You will find in attachment the drawings of our siphon (pdf) with the specific dimension that we used in order to get a flush of 1.5m3 every 1.30h. We have installed and tested successfully our prototype in one of our DTF (see video in the last post), the next step will be to use it in real condition (with treated sludge). I will keep you posted.

Again, thank you very much for your help and contribution. Unfortunately the second link that you sent is not working...

Best regards from Nairobi

Alexandra

Thank you for your answer. We have actually used the design provided by Fluid Dynamic Siphons Inc (1st link) to develop our own design. You will find in attachment the drawings of our siphon (pdf) with the specific dimension that we used in order to get a flush of 1.5m3 every 1.30h. We have installed and tested successfully our prototype in one of our DTF (see video in the last post), the next step will be to use it in real condition (with treated sludge). I will keep you posted.

Again, thank you very much for your help and contribution. Unfortunately the second link that you sent is not working...

Best regards from Nairobi

Alexandra

Alexandra Dubois

Technical Advisor

Sector Programme Water Policy – Innovations for Resilience

Division Climate Change, Environment & Infrastructure

GIZ │Deutsche Gesellschaft für

Internationale Zusammenarbeit (GIZ) GmbH

Friedrich-Ebert-Allee 32

53113 Bonn, Germany

Technical Advisor

Sector Programme Water Policy – Innovations for Resilience

Division Climate Change, Environment & Infrastructure

GIZ │Deutsche Gesellschaft für

Internationale Zusammenarbeit (GIZ) GmbH

Friedrich-Ebert-Allee 32

53113 Bonn, Germany

This message has an attachment file.

Please log in or register to see it.

Please Log in to join the conversation.

You need to login to reply- kevintayler

-

- I am a water and sanitation engineer, also interested in general urban housing issues. In recent years, I have worked on FSM for various organizations

Less- Posts: 79

- Karma: 11

- Likes received: 46

I have only come across this thread now so am rather late in contributing. Siphons are widely used in sewage treatment plants prior to trickling filters. For information on a typical design - see www.siphons.com/bell-siphon-417.html and for an explanation of the mechanism see www.siphons.com/how-siphons-work.html. These websites are produced by a manufacturer.

The link that I have given is for a 4 inch - 100mm diameter discharge pipe but the website gives a range of sizes. The siphons that I saw years ago in the UK water industry were metal but the manufacturer on the links provided above uses polyethylene - which I would imagine is now the industry standard. I have never actually designed a siphon so I am not sure how critical the dimensions are. However, it should be possible to produce something based on these dimensions. Perhaps the first thing will be check the revised design against this

I hope that this is helpful

Kevin

The link that I have given is for a 4 inch - 100mm diameter discharge pipe but the website gives a range of sizes. The siphons that I saw years ago in the UK water industry were metal but the manufacturer on the links provided above uses polyethylene - which I would imagine is now the industry standard. I have never actually designed a siphon so I am not sure how critical the dimensions are. However, it should be possible to produce something based on these dimensions. Perhaps the first thing will be check the revised design against this

I hope that this is helpful

Kevin

Kevin Tayler

Independent water and sanitation consultant

Horsham

UK

Independent water and sanitation consultant

Horsham

UK

Please Log in to join the conversation.

You need to login to reply

see

Schwimmerventil (float valve) for larger pre-treated sewage volumes

from 20 May 2016

www.aqua-verde.de, AquaVerde Ltd. Zanzibar

"simple" Sanitation-Solutions by gravity

Low-Tech Solutions with High-Tech Effects

"Inspired by Circular Economy and Cooperation"

www.flickr.com/photos/aqua-verde/

"simple" Sanitation-Solutions by gravity

Low-Tech Solutions with High-Tech Effects

"Inspired by Circular Economy and Cooperation"

www.flickr.com/photos/aqua-verde/

Please Log in to join the conversation.

You need to login to reply

Share this thread:

- Forum

- categories

- Sanitation systems

- Faecal sludge management (FSM)

- Faecal sludge treatment technologies

- Any successful experience with siphon system?

Recently active users. Who else has been active?

Time to create page: 0.173 seconds