- Forum

- categories

- Sanitation systems

- Treatment of wastewater, sludges, organic waste, excreta

- Anaerobic treatment systems (biogas sanitation)

- Biogas sanitation (systems focusing on biogas production)

- ADPL (Anaerobic Digestion Pasteurization Latrine) Duke Biogas toilet (Duke University, USA) - testing in Kenya, India and the Philippines

ADPL (Anaerobic Digestion Pasteurization Latrine) Duke Biogas toilet (Duke University, USA) - testing in Kenya, India and the Philippines

32.3k views

- Elisabeth

-

- User is blocked

- Freelance consultant since 2012

Less- Posts: 3372

- Karma: 54

- Likes received: 932

Re: ADPL (Anaerobic Digestion Pasteurization Latrine) Duke Biogas toilet

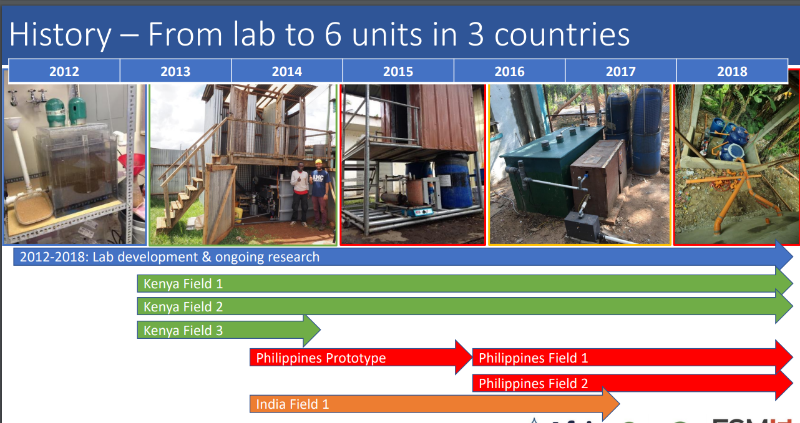

For anyone following this project, another update is available in this presentation at the FSM5 Conference in Cape Town in February 2019:

The Anaerobic Digestion Pasteurization Latrine: Operation in 3 Countries and Looking Ahead

fsm5.susana.org/images/FSM_Conference_Ma...rization-Latrine.pdf

Authors: Aaron Forbis-Stokes 1,2, Graham Miller 1 , Brandon Hunter 1 , Patrick O’Meara 3 , Felix Kiptoo 3 , Marc Deshusses 1

1 Duke University, Dept. of Civil & Environmental Engineering, Durham, NC, USA

2 Triangle Environmental, Durham, NC, USA

3 Wataalamu Repair & Maintenance, Eldoret, Kenya

Conference website: fsm5.susana.org/en/downloads/conference-materials

Screenshot of one slide:

Regards,

Elisabeth

The Anaerobic Digestion Pasteurization Latrine: Operation in 3 Countries and Looking Ahead

fsm5.susana.org/images/FSM_Conference_Ma...rization-Latrine.pdf

Authors: Aaron Forbis-Stokes 1,2, Graham Miller 1 , Brandon Hunter 1 , Patrick O’Meara 3 , Felix Kiptoo 3 , Marc Deshusses 1

1 Duke University, Dept. of Civil & Environmental Engineering, Durham, NC, USA

2 Triangle Environmental, Durham, NC, USA

3 Wataalamu Repair & Maintenance, Eldoret, Kenya

Conference website: fsm5.susana.org/en/downloads/conference-materials

Screenshot of one slide:

Regards,

Elisabeth

Dr. Elisabeth von Muench

Freelance consultant on environmental and climate projects

Freelance consultant on environmental and climate projects

Attachments:

-

TheAnaerob...head.png

(Filesize: 356KB)

TheAnaerob...head.png

(Filesize: 356KB)

Please Log in to join the conversation.

You need to login to replyRe: ADPL (Anaerobic Digestion Pasteurization Latrine) Duke Biogas toilet

We have received further funding for this project which used to be called "Effective Sewage Sanitation with Low CO2 Footprint" and started in 2011. It has now evolved somewhat:

Title of grant: ADPL (Anaerobic Digestion Pasteurization Latrine) Duke Biogas toilet

Subtitle: Further development of the Anaerobic Digestion Pasteurization Latrine, a simple, energy neutral self-contained sanitation technology relying on anaerobic digestion and heat pasteurization of the treated effluent.

This is a continuation of the research begun in 2011 which was funded by a previous GCE grant. In this phase, it is our objective to fully assess the potential of the ADPL to meet the Foundation’s criteria for Reinvented Toilets. We are intensifying monitoring efforts of our current five ADPL units in Kenya, India and the Philippines, improving implementation and operation, and redesigning the heat pasteurization system for improved efficacy and reliability.

Goal(s):

Provide a sanitation system for an extended household of 5-30 users based on an anaerobic digester that produces sufficient biogas to heat pasteurize the daily effluent flowing out of the digester. Sufficient biogas production and an efficient pasteurization system design will result in an energy self-sufficient solution. Effluent should be safe for on-site land application. Means of further improving the water quality of the effluent will be investigated.

Objectives:

Eldoret, Kenya: Wataalamu Repair & Maintenance

Chennai, India: IIT Madras

Cebu Island, the Philippines: Tesari Foundation

Links, further readings – results to date:

Our website: sanitation.pratt.duke.edu/onsite-treatme...te-treatment-project

Documents in SuSanA library: www.susana.org/en/resources/library/details/1757

Current state of affairs:

Our website: sanitation.pratt.duke.edu/onsite-treatment/current-progress

New Baffled Anaerobic Digesters For Eldoret ~ April, 2016

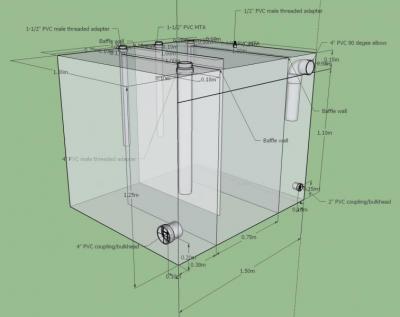

Two fixed dome anaerobic digesters designed by Aaron Forbis-Stokes using computational fluid dynamics were manufactured by Specialised Fibreglass in Nairobi and installed at the Eldoret North and Central sites. The new baffled design will improve average residence times and reduce solids in the effluent stream going into the heater and heat exchanger. The new digesters have four chambers and sampling ports for taking core samples and assessing solid deposition levels.

Biggest successes so far:

Installed new baffled digesters for improved solids retention, tipping buckets for flow rate measurement and Particle controller boards for more reliable control of heater temperatures and temperature monitoring in Eldoret, Kenya in April. Plans in place to roll these upgrades out in the Philippines and India this summer and early fall. Improved pasteurization system design underway.

Main challenges / frustration:

Managing suspended solids in the effluent, guaranteeing pasteurization holding times and temperatures during peak usage periods and consistently generating sufficient biogas to run the system on an ongoing basis.

Title of grant: ADPL (Anaerobic Digestion Pasteurization Latrine) Duke Biogas toilet

Subtitle: Further development of the Anaerobic Digestion Pasteurization Latrine, a simple, energy neutral self-contained sanitation technology relying on anaerobic digestion and heat pasteurization of the treated effluent.

- Name of lead organization: Duke University

- Primary contact at lead organization: Aaron Forbis-Stokes

- Grantee location: Durham, NC, USA

- Developing country where the research is being tested: Units are currently being tested in Kenya, India and the Philippines.

- Start and end date: November, 2015 – March, 2017

- Grant size: $ 341,337 (see BMGF grant database here )

This is a continuation of the research begun in 2011 which was funded by a previous GCE grant. In this phase, it is our objective to fully assess the potential of the ADPL to meet the Foundation’s criteria for Reinvented Toilets. We are intensifying monitoring efforts of our current five ADPL units in Kenya, India and the Philippines, improving implementation and operation, and redesigning the heat pasteurization system for improved efficacy and reliability.

Goal(s):

Provide a sanitation system for an extended household of 5-30 users based on an anaerobic digester that produces sufficient biogas to heat pasteurize the daily effluent flowing out of the digester. Sufficient biogas production and an efficient pasteurization system design will result in an energy self-sufficient solution. Effluent should be safe for on-site land application. Means of further improving the water quality of the effluent will be investigated.

Objectives:

- Actively maintain our five existing ADPL systems, expand scope and quality of monitoring

- Redesign heater-heat exchanger system for improved efficiency

- Improve biogas production through better digester design

- Develop means to achieve superior effluent quality for reuse (other than direct land application)

- Work with partners towards integration of the ADPL concept, aim for STeP evaluation or extended demonstration of resulting product(s)

Eldoret, Kenya: Wataalamu Repair & Maintenance

Chennai, India: IIT Madras

Cebu Island, the Philippines: Tesari Foundation

Links, further readings – results to date:

Our website: sanitation.pratt.duke.edu/onsite-treatme...te-treatment-project

Documents in SuSanA library: www.susana.org/en/resources/library/details/1757

Current state of affairs:

Our website: sanitation.pratt.duke.edu/onsite-treatment/current-progress

New Baffled Anaerobic Digesters For Eldoret ~ April, 2016

Two fixed dome anaerobic digesters designed by Aaron Forbis-Stokes using computational fluid dynamics were manufactured by Specialised Fibreglass in Nairobi and installed at the Eldoret North and Central sites. The new baffled design will improve average residence times and reduce solids in the effluent stream going into the heater and heat exchanger. The new digesters have four chambers and sampling ports for taking core samples and assessing solid deposition levels.

Biggest successes so far:

Installed new baffled digesters for improved solids retention, tipping buckets for flow rate measurement and Particle controller boards for more reliable control of heater temperatures and temperature monitoring in Eldoret, Kenya in April. Plans in place to roll these upgrades out in the Philippines and India this summer and early fall. Improved pasteurization system design underway.

Main challenges / frustration:

Managing suspended solids in the effluent, guaranteeing pasteurization holding times and temperatures during peak usage periods and consistently generating sufficient biogas to run the system on an ongoing basis.

Kathy Jooss

Project Manager,Pratt School of Engineering

Duke University, Durham, North Carolina, USA

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.sanitation.pratt.duke.edu

Project Manager,Pratt School of Engineering

Duke University, Durham, North Carolina, USA

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.sanitation.pratt.duke.edu

Please Log in to join the conversation.

You need to login to replyRe: Effective sewage sanitation with low CO2 footprint (Duke University in Durham, North Carolina, USA)

Hello all,

I wanted to provide a short update on the ongoing work with this project using the "Anaerobic Digestion Pasteurization Latrine." We have now been operating in Eldoret, Kenya, for over two years and have added two more systems in Chennai, India, and Toledo City, Philippines.

The following two links are the presentation slides and video from our presentation on this project at FSM3 in Hanoi, Vietnam.

Presentation

Video

We have already recently published a paper on the initial lab work on the proof-of-concept for this project by Joan Colon.

Publication

Thank you,

Aaron Forbis-Stokes

I wanted to provide a short update on the ongoing work with this project using the "Anaerobic Digestion Pasteurization Latrine." We have now been operating in Eldoret, Kenya, for over two years and have added two more systems in Chennai, India, and Toledo City, Philippines.

The following two links are the presentation slides and video from our presentation on this project at FSM3 in Hanoi, Vietnam.

Presentation

Video

We have already recently published a paper on the initial lab work on the proof-of-concept for this project by Joan Colon.

Publication

Thank you,

Aaron Forbis-Stokes

Aaron Forbis-Stokes, Ph.D.

Sanitation Technology Consultant

Triangle Environmental Health Initiative

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.triangle-environmental.com

Sanitation Technology Consultant

Triangle Environmental Health Initiative

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.triangle-environmental.com

The following user(s) like this post: Elisabeth

Please Log in to join the conversation.

You need to login to replyRe: Effective Sewage Sanitation with Low CO2 Footprint (Duke University in Durham, North Carolina, USA)

Dear Aaron,

sorry for being very late: en.wikipedia.org/wiki/Cogeneration:

Cogeneration or combined heat and power (CHP) is the use of a heat engine[1] or power station to simultaneously generate electricity and useful heat.

All the Best

Detlef

I am unfamiliar with the abbreviation "CHP." What does that stand for?

sorry for being very late: en.wikipedia.org/wiki/Cogeneration:

Cogeneration or combined heat and power (CHP) is the use of a heat engine[1] or power station to simultaneously generate electricity and useful heat.

All the Best

Detlef

www.aqua-verde.de, AquaVerde Ltd. Zanzibar

"simple" Sanitation-Solutions by gravity

Low-Tech Solutions with High-Tech Effects

"Inspired by Circular Economy and Cooperation"

www.flickr.com/photos/aqua-verde/

"simple" Sanitation-Solutions by gravity

Low-Tech Solutions with High-Tech Effects

"Inspired by Circular Economy and Cooperation"

www.flickr.com/photos/aqua-verde/

Please Log in to join the conversation.

You need to login to replyRe: Effective Sewage Sanitation with Low CO2 Footprint (Duke University in Durham, North Carolina, USA)

Thank you for the questions Dorothee.

The biogas production has been encouraging, and we have found sufficient biogas production for operating the pasteurization. Quantifying production has proved difficult in the field, however, so I cannot comment at the moment on comparison to lab production.

The reactor operates more like a completely mixed/completely stirred tank reactor in that flow in equals flow out (with the exception that we do not have mixing) - influent volume displaces the same volume of digester slurry into the heating system. Effluent is currently collected for lab testing.

Operation for the system is still being developed. Currently our local collaborators regularly check on operation. For the sites we are working with in Kenya, plots are owned and supervised by a landlord. We imagine that person would ultimately be the owner and the one responsible for the system. The systems in Kenya were built by a local company has the knowledge and abilities to construct future systems. The most likely business model set up would involve using the effluent as a fertilizer. One of the plot owners has already expressed interest in doing so. The excess biogas (what is not needed to power the pasteurization) would be more difficult to sell as a product, but represents a better option for cost savings by reducing the need to purchase other fuels.

Thanks!

Aaron

The biogas production has been encouraging, and we have found sufficient biogas production for operating the pasteurization. Quantifying production has proved difficult in the field, however, so I cannot comment at the moment on comparison to lab production.

The reactor operates more like a completely mixed/completely stirred tank reactor in that flow in equals flow out (with the exception that we do not have mixing) - influent volume displaces the same volume of digester slurry into the heating system. Effluent is currently collected for lab testing.

Operation for the system is still being developed. Currently our local collaborators regularly check on operation. For the sites we are working with in Kenya, plots are owned and supervised by a landlord. We imagine that person would ultimately be the owner and the one responsible for the system. The systems in Kenya were built by a local company has the knowledge and abilities to construct future systems. The most likely business model set up would involve using the effluent as a fertilizer. One of the plot owners has already expressed interest in doing so. The excess biogas (what is not needed to power the pasteurization) would be more difficult to sell as a product, but represents a better option for cost savings by reducing the need to purchase other fuels.

Thanks!

Aaron

Aaron Forbis-Stokes, Ph.D.

Sanitation Technology Consultant

Triangle Environmental Health Initiative

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.triangle-environmental.com

Sanitation Technology Consultant

Triangle Environmental Health Initiative

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.triangle-environmental.com

Please Log in to join the conversation.

You need to login to replyRe: Effective Sewage Sanitation with Low CO2 Footprint (Duke University in Durham, North Carolina, USA)

Thank you Naomi for this write up.

I would like to add one interesting point from the discussion. Bincy (see here for information on her project a self-sustained e-toilet ), having the perspective of the product designer, wondered why this toilet has to be elevated and if the group has thought of coming up with a underground structure.

In fact the reason why it is elevated is that they use gravity flow for the whole system and the heat digester and burner has to be flood-protected and accessible. Yu-ling from the University of the Toronto ( smoldering toilet ) confirmed the same aspect for her toilet.

Indeed, making these toilet flood-proof is yet another challenge!

But Aaron, I have another question for you:

Since you started the field testing, can you say already something on first experiences regarding water content of the sludge and biogas production? How does the lab simulation fit to the real conditions with the 25 people? Is the usage stable? If not, can the system absorb that?

Moreover I was also wondering how you are implementing the us of the sludge from the digester. Do you get temperature sufficiently high to be sure about the inactivation of pathogens? Who is using the sludge for what and what frequency do you empty the reactor (it is batch isn't it)?

And then something completely different: have you already though of an operation system? Who is going to own/construct the toilet and who takes care of the maintenance? Have you also thought about something like a business model as it was presented by Tove? What would be investment costs, life-spam and costs for the users?

Looking forward to hearing back from you!

Best regards

Dorothee

I would like to add one interesting point from the discussion. Bincy (see here for information on her project a self-sustained e-toilet ), having the perspective of the product designer, wondered why this toilet has to be elevated and if the group has thought of coming up with a underground structure.

In fact the reason why it is elevated is that they use gravity flow for the whole system and the heat digester and burner has to be flood-protected and accessible. Yu-ling from the University of the Toronto ( smoldering toilet ) confirmed the same aspect for her toilet.

Indeed, making these toilet flood-proof is yet another challenge!

But Aaron, I have another question for you:

Since you started the field testing, can you say already something on first experiences regarding water content of the sludge and biogas production? How does the lab simulation fit to the real conditions with the 25 people? Is the usage stable? If not, can the system absorb that?

Moreover I was also wondering how you are implementing the us of the sludge from the digester. Do you get temperature sufficiently high to be sure about the inactivation of pathogens? Who is using the sludge for what and what frequency do you empty the reactor (it is batch isn't it)?

And then something completely different: have you already though of an operation system? Who is going to own/construct the toilet and who takes care of the maintenance? Have you also thought about something like a business model as it was presented by Tove? What would be investment costs, life-spam and costs for the users?

Looking forward to hearing back from you!

Best regards

Dorothee

WG1 Co-lead

Developing methods and tools to support strategic planning for sustainable sanitation. Particular interested in novel technologies contributing to more inclusive and circular sanitation. This email address is being protected from spambots. You need JavaScript enabled to view it.

Developing methods and tools to support strategic planning for sustainable sanitation. Particular interested in novel technologies contributing to more inclusive and circular sanitation. This email address is being protected from spambots. You need JavaScript enabled to view it.

Please Log in to join the conversation.

You need to login to reply- NaomiRadke

-

- I am interested in sustainable sanitation and water management, working at seecon international

Less- Posts: 21

- Karma: 2

- Likes received: 8

Re: Effective Sewage Sanitation with Low CO2 Footprint (Duke University in Durham, North Carolina, USA)

This is to make you aware of Aaron’s contribution to the second expert chat with a group of BMGF grantees on September 12.

Aaron was representing the research team of the Duke University that is lead by Marc Deshusses. He was presenting the current state of the project – currently the anaeorobic digestion-pasteurisation latrine is field tested in Kenya – and subsequently answered to questions posed during the expert chat.

Please find a link to the youtube video of the expert chat below, starting at the beginning of Aaron’s presentation. I have also attached a pdf of his presentation below.

I have compiled below some points that struck me. You might find them interesting and as food for thought. Please do not hesitate to contact Aaron and his team members for questions/ideas/advice.

The set-up is quite simple: The toilet directly charges excreta into a the digestion tank of a aerobic digester with a floating dome so that both the slurry volume and gas pressure stay constant. The contents that enter the digester are urine, faeces and less than a litre of flush water per toilet visit. The heating tank is powered by the biogas produced in the digester and the system is thus self-containing. Extra biogas can be used at home for example for cooking or lighting.

Since March 2013 they had very steady conditions in their laboratory setting. Pleased with this process they started setting up their pilot study this May in Eldorte, Kenya, in collaboration with the University there.

3 systems had been built in the field, serving around 25 people each. The digester and heating system will continuously be monitored as has previously been done in their laboratory.

In the future they would like to learn about the strengths and weakness of the systems in the field setting they can improve on. Field of interests will also be 1) the feasibility for scale-up, 2) cost-benefit analysis for the extra biogas as burning fuels are very expensive and the treated waste is high in nitrogen and makes a great fertiliser, 3) health impacts of implementing the system.

Main take-aways from the results of their laboratory setting are:

- Digester: is expected to produce about 400 l of biogas per day for a system that was designed for the use by 10 persons

- Heater: for temperatures greater than 65 °C, 100% of the E. Coli was inactivated. To operate the heating tank at this level, 230-280 l of biogas per day are needed. Thus, access biogas is expected

The latrines need to be elevated so the system could work by gravity fall. Below the latrines are the digester and the heating tank. The treated waste that comes out of the heating system goes into the collection barrel where residents can come and collect the treated waste and use it as a fertiliser

Question 1: Regarding pathogen inactivation: have you tried micro-organisms apart from E. Coli?

Answer 1: No other pathogens have been tested in the laboratory yet. Yet, with the tested temperature and time in the tank they would expect to have an inactivation for other pathogens, too. This is something they would like to test in the future.

Question 2: Water content is important for biogas production. How do you manage to regulate that?

Answer 2: In the laboratory the setting was 1 litre of urine and 400 grams of faeces per person per day. That was the portions that were tested. In one phase a higher ratio of water as compared to urine and faeces was taken but they went back to the initial ratio after about 75 days.

Question 3 : How long is the digestion time?

Answer 3: In the laboratory a retention time of 40 days was chosen. The systems in the field are a little different: 45-50 days for a plot that is used by about 25 people. The digesters hold 2 cubic litres.

Aaron was representing the research team of the Duke University that is lead by Marc Deshusses. He was presenting the current state of the project – currently the anaeorobic digestion-pasteurisation latrine is field tested in Kenya – and subsequently answered to questions posed during the expert chat.

Please find a link to the youtube video of the expert chat below, starting at the beginning of Aaron’s presentation. I have also attached a pdf of his presentation below.

This attachment is hidden for guests.

Please log in or register to see it.

Please log in or register to see it.

I have compiled below some points that struck me. You might find them interesting and as food for thought. Please do not hesitate to contact Aaron and his team members for questions/ideas/advice.

The set-up is quite simple: The toilet directly charges excreta into a the digestion tank of a aerobic digester with a floating dome so that both the slurry volume and gas pressure stay constant. The contents that enter the digester are urine, faeces and less than a litre of flush water per toilet visit. The heating tank is powered by the biogas produced in the digester and the system is thus self-containing. Extra biogas can be used at home for example for cooking or lighting.

Since March 2013 they had very steady conditions in their laboratory setting. Pleased with this process they started setting up their pilot study this May in Eldorte, Kenya, in collaboration with the University there.

3 systems had been built in the field, serving around 25 people each. The digester and heating system will continuously be monitored as has previously been done in their laboratory.

In the future they would like to learn about the strengths and weakness of the systems in the field setting they can improve on. Field of interests will also be 1) the feasibility for scale-up, 2) cost-benefit analysis for the extra biogas as burning fuels are very expensive and the treated waste is high in nitrogen and makes a great fertiliser, 3) health impacts of implementing the system.

Main take-aways from the results of their laboratory setting are:

- Digester: is expected to produce about 400 l of biogas per day for a system that was designed for the use by 10 persons

- Heater: for temperatures greater than 65 °C, 100% of the E. Coli was inactivated. To operate the heating tank at this level, 230-280 l of biogas per day are needed. Thus, access biogas is expected

The latrines need to be elevated so the system could work by gravity fall. Below the latrines are the digester and the heating tank. The treated waste that comes out of the heating system goes into the collection barrel where residents can come and collect the treated waste and use it as a fertiliser

Question 1: Regarding pathogen inactivation: have you tried micro-organisms apart from E. Coli?

Answer 1: No other pathogens have been tested in the laboratory yet. Yet, with the tested temperature and time in the tank they would expect to have an inactivation for other pathogens, too. This is something they would like to test in the future.

Question 2: Water content is important for biogas production. How do you manage to regulate that?

Answer 2: In the laboratory the setting was 1 litre of urine and 400 grams of faeces per person per day. That was the portions that were tested. In one phase a higher ratio of water as compared to urine and faeces was taken but they went back to the initial ratio after about 75 days.

Question 3 : How long is the digestion time?

Answer 3: In the laboratory a retention time of 40 days was chosen. The systems in the field are a little different: 45-50 days for a plot that is used by about 25 people. The digesters hold 2 cubic litres.

// Naomi Radke

MSc Sustainable Development

This email address is being protected from spambots. You need JavaScript enabled to view it.

seecon international gmbh

society - economy - ecology - consulting

Basel, Switzerland

www.seecon.ch/

check out the SSWM toolbox for info on sustainable sanitation and water management:

www.sswm.info/

MSc Sustainable Development

This email address is being protected from spambots. You need JavaScript enabled to view it.

seecon international gmbh

society - economy - ecology - consulting

Basel, Switzerland

www.seecon.ch/

check out the SSWM toolbox for info on sustainable sanitation and water management:

www.sswm.info/

This message has an attachment file.

Please log in or register to see it.

Please Log in to join the conversation.

You need to login to replyRe: Effective Sewage Sanitation with Low CO2 Footprint (Duke University in Durham, North Carolina, USA)

Marijn,

Thank you for the questions.

1) The family size was an estimation for lab studies and organic loading. We are currently beginning implementation in Kenya for a multi-family system that will serve about 20 people. The system design will be altered for the amount of people regularly using the system. Considerations for residents not always being there will be made.

2) We like the floating dome because of the constant gas pressure and slurry level that it offers. Yes, it is more complicated and expensive, but we think this design would be more reliable for us.

3) The initial design was no flush. Field systems will be designed to be as little flush as possible. American Standard has developed a pan that can operate on only 1 L. Designs such as this will be explored to minimize flushing.

4) The additions of toilet paper, flush water, and other organics are still be evaluated in terms of biogas production as well as required biogas use to treat the effluent. Where we are currently implementing, users are wipers. The retention time raises a good question as I have not looked specifically for the retention time required for TP. The extra water is some ways is beneficial as it would reduce the nitrogen concentrations of the waste which can be inhibitory, but it does require considerations in system size designs.

Thank you again for the thoughtful questions,

Aaron

Thank you for the questions.

1) The family size was an estimation for lab studies and organic loading. We are currently beginning implementation in Kenya for a multi-family system that will serve about 20 people. The system design will be altered for the amount of people regularly using the system. Considerations for residents not always being there will be made.

2) We like the floating dome because of the constant gas pressure and slurry level that it offers. Yes, it is more complicated and expensive, but we think this design would be more reliable for us.

3) The initial design was no flush. Field systems will be designed to be as little flush as possible. American Standard has developed a pan that can operate on only 1 L. Designs such as this will be explored to minimize flushing.

4) The additions of toilet paper, flush water, and other organics are still be evaluated in terms of biogas production as well as required biogas use to treat the effluent. Where we are currently implementing, users are wipers. The retention time raises a good question as I have not looked specifically for the retention time required for TP. The extra water is some ways is beneficial as it would reduce the nitrogen concentrations of the waste which can be inhibitory, but it does require considerations in system size designs.

Thank you again for the thoughtful questions,

Aaron

Aaron Forbis-Stokes, Ph.D.

Sanitation Technology Consultant

Triangle Environmental Health Initiative

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.triangle-environmental.com

Sanitation Technology Consultant

Triangle Environmental Health Initiative

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.triangle-environmental.com

Please Log in to join the conversation.

You need to login to replyRe: Effective Sewage Sanitation with Low CO2 Footprint (Duke University in Durham, North Carolina, USA)

Mr. Mughal,

Thank you for the comment.

We prefer the floating dome design because of the constant gas pressure as well as slurry level because we operate the heating system continuously.

Mixing is still under consideration. We have not done any mixing in the lab system and have not found any issues so far. Some mixing is provided by waste loading as well as rising biogas bubbles. We will be implementing field systems soon, and these also do not have mixing devices. Fibrous materials will not be added, so scum formation related to that is not a concern at the moment, but future considerations and monitoring will be needed to address the mixing question.

Thank you,

Aaron

Thank you for the comment.

We prefer the floating dome design because of the constant gas pressure as well as slurry level because we operate the heating system continuously.

Mixing is still under consideration. We have not done any mixing in the lab system and have not found any issues so far. Some mixing is provided by waste loading as well as rising biogas bubbles. We will be implementing field systems soon, and these also do not have mixing devices. Fibrous materials will not be added, so scum formation related to that is not a concern at the moment, but future considerations and monitoring will be needed to address the mixing question.

Thank you,

Aaron

Aaron Forbis-Stokes, Ph.D.

Sanitation Technology Consultant

Triangle Environmental Health Initiative

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.triangle-environmental.com

Sanitation Technology Consultant

Triangle Environmental Health Initiative

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.triangle-environmental.com

Please Log in to join the conversation.

You need to login to replyRe: Effective Sewage Sanitation with Low CO2 Footprint (Duke University in Durham, North Carolina, USA)

Detlef,

Thank you very much for the comments. Our current target locations are in Kenya and Peru, so we are not looking into the the need for heating at the moment, but the information is helpful for future considerations. The ABR design is something that we are considering based on available materials. I will look more into the resources you've provided.

I am unfamiliar with the abbreviation "CHP." What does that stand for?

Thank you again for your comments,

Aaron

Thank you very much for the comments. Our current target locations are in Kenya and Peru, so we are not looking into the the need for heating at the moment, but the information is helpful for future considerations. The ABR design is something that we are considering based on available materials. I will look more into the resources you've provided.

I am unfamiliar with the abbreviation "CHP." What does that stand for?

Thank you again for your comments,

Aaron

Aaron Forbis-Stokes, Ph.D.

Sanitation Technology Consultant

Triangle Environmental Health Initiative

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.triangle-environmental.com

Sanitation Technology Consultant

Triangle Environmental Health Initiative

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.triangle-environmental.com

Please Log in to join the conversation.

You need to login to replyRe: Effective Sewage Sanitation with Low CO2 Footprint (Duke University in Durham, North Carolina, USA)

Dear Aaron,

Thank you for the posts and the updates.

I also have a few questions.

1.) a family size of 10 seems large to me (based on my Asian experience, maybe for SSA this is more realistic). This brings me to the question of how well the process would cope with under-feeding. For instance if some of the children of the household get send to boarding school, leave to work abroad or get married. What would be the minimum amount of people daily using this toilet for there to be sufficient gas to sterilize the effluent?

2.) Why did you select a floating dome approach. My intuition is that it could be cheaper and more reliable to work with a fixed dome concept, but then again I have never thought about such small units, so I may be overlooking something.

3.) For how much flushing water are you designing this? It seems it would have to be fairly low flush in order to not dilute the waste too much.

4.) Similar, if designed for wipers, is the retention time high enough to break down toilet paper. And if designed for washers, is the extra water ok for the mass balance?

regards

Marijn

Thank you for the posts and the updates.

I also have a few questions.

1.) a family size of 10 seems large to me (based on my Asian experience, maybe for SSA this is more realistic). This brings me to the question of how well the process would cope with under-feeding. For instance if some of the children of the household get send to boarding school, leave to work abroad or get married. What would be the minimum amount of people daily using this toilet for there to be sufficient gas to sterilize the effluent?

2.) Why did you select a floating dome approach. My intuition is that it could be cheaper and more reliable to work with a fixed dome concept, but then again I have never thought about such small units, so I may be overlooking something.

3.) For how much flushing water are you designing this? It seems it would have to be fairly low flush in order to not dilute the waste too much.

4.) Similar, if designed for wipers, is the retention time high enough to break down toilet paper. And if designed for washers, is the extra water ok for the mass balance?

regards

Marijn

Marijn Zandee

E: This email address is being protected from spambots. You need JavaScript enabled to view it.

E: This email address is being protected from spambots. You need JavaScript enabled to view it.

Please Log in to join the conversation.

You need to login to replyRe: Effective Sewage Sanitation with Low CO2 Footprint (Duke University in Durham, North Carolina, USA)

Dear Mr. Joan,

Quite often, the anaerobic digesters are fixed with mixing device to hasten and enhance gas production; mixing the contents; and prevent the formation of scum.

Regards,

F H Mughal

Quite often, the anaerobic digesters are fixed with mixing device to hasten and enhance gas production; mixing the contents; and prevent the formation of scum.

Regards,

F H Mughal

F H Mughal (Mr.)

Karachi, Pakistan

Karachi, Pakistan

Please Log in to join the conversation.

You need to login to reply

Share this thread:

- Forum

- categories

- Sanitation systems

- Treatment of wastewater, sludges, organic waste, excreta

- Anaerobic treatment systems (biogas sanitation)

- Biogas sanitation (systems focusing on biogas production)

- ADPL (Anaerobic Digestion Pasteurization Latrine) Duke Biogas toilet (Duke University, USA) - testing in Kenya, India and the Philippines

Recently active users. Who else has been active?

Time to create page: 0.142 seconds