- Forum

- categories

- Sanitation systems

- Toilets without urine diversion

- Innovations and research in toilet design

- Re: Breathable membrane enclosures for fecal sludge stabilization (University of Delaware, USA)

Re: Breathable membrane enclosures for fecal sludge stabilization (University of Delaware, USA)

83.3k views

- former member

-

Topic AuthorLess

- Posts: 101

- Likes received: 3

Re: Breathable membrane enclosures for fecal sludge stabilization (University of Delaware, USA)

The breathable membrane fabric could be used on the bottom as well, and no treatment should be needed, because none of the sludge constituents get through the fabric. Only water vapor and other gases.

The fabric facing upward would need to be UV-resistant; some fabrics are available of this type.

++++++++

Note by moderators: This post was made by a former user with the login name skdentel who is no longer a member of this discussion forum.

Please Log in to join the conversation.

You need to login to replyRe: Breathable membrane enclosures for fecal sludge stabilization (University of Delaware, USA)

skdentel wrote: Krischan,

Thanks for the question!

Your suggestion makes sense: the interior heat would increase the vapor pressure and drive off more vapor through the membrane. We also know that some air can penetrate from the exterior into the contents. However, this air entry will not be fast enough to maintain an aerobic interior, so the waste decomposition will be anaerobic and therefore generate organic sulfur and organic amine odorants. They're likely to penetrate the membrane, but we do not yet know the extent. There are also hydrophobic membranes that will not allow odor penetration, but this is at the expense of drying rate.

This is an interesting direction for further work. Because fecal wastes are predominantly water, the ability to release water content should be valuable in terms of volume reduction and waste stabilization.

Hmm, you are right, and potentially releasing quite a bit of methane into the atmosphere is probably not that wise either.

I am guessing that just increasing the surface to volume ration to keep in aerobic is probably not going to be cost efficient...

Unrelated to that:

I forgot to mention that the bottom should be probably water permeable to allow draining also, even though that would require some sort of treatment plant for the percolate.

If the drying/dewatering rate is too fast one might also run into trouble with the movement of the sludge through the "bag"... as always the devil lies in the details :-/

Please Log in to join the conversation.

You need to login to reply- former member

-

Topic AuthorLess

- Posts: 101

- Likes received: 3

Re: Breathable membrane enclosures for fecal sludge stabilization (University of Delaware, USA)

Thanks for the question!

Your suggestion makes sense: the interior heat would increase the vapor pressure and drive off more vapor through the membrane. We also know that some air can penetrate from the exterior into the contents. However, this air entry will not be fast enough to maintain an aerobic interior, so the waste decomposition will be anaerobic and therefore generate organic sulfur and organic amine odorants. They're likely to penetrate the membrane, but we do not yet know the extent. There are also hydrophobic membranes that will not allow odor penetration, but this is at the expense of drying rate.

This is an interesting direction for further work. Because fecal wastes are predominantly water, the ability to release water content should be valuable in terms of volume reduction and waste stabilization.

++++++++

Note by moderators: This post was made by a former user with the login name skdentel who is no longer a member of this discussion forum.

Please Log in to join the conversation.

You need to login to reply- former member

-

Topic AuthorLess

- Posts: 101

- Likes received: 3

Re: Breathable membrane enclosures for fecal sludge stabilization (University of Delaware, USA)

You are incorrect that landfilling is the most common option in the U.S. - and I assume you are talking about wastewater sludges. The most common option is in fact application to soils (55%) with landfilling at 21% (Source: Dentel, S.K. Wastewater Sludge Global Overview: United States. In Wastewater Sludge: A Global Overview of the Current Status and Future Prospects, IWA Publishing,2011). And, of course, the U.S. as a country does not exemplify urban areas.

You are also incorrect about the situation in Europe. Even in the five countries with the largest sludge production, agricultural use is less than half (45%), and in the other countries that allow land application, it is typically used for only 10-15% of all sludges. Nor is there a "rampant" trend to increase these numbers over time(source: G. Mininni and S. Dentel, State of sewage sludge management and legislation on agricultural use in EU member states and in the United States" 1st Intl. IWA Conf. on Holistic Sludge Management,May 2013, Västerås, Sweden).

Your reference to a "blanket unwillingness" is also incorrect. I *have* done an in-depth literature search and, as I have indicated in my previous posts, although the membrane is refractory, there is no evidence of toxicity or environmental harm from its use. To repeat research of this nature when it has already been performed would not be an appropriate use of Gates Foundation funding.

++++++++

Note by moderators: This post was made by a former user with the login name skdentel who is no longer a member of this discussion forum.

Please Log in to join the conversation.

You need to login to reply- Elisabeth

-

- User is blocked

- Freelance consultant since 2012

Less- Posts: 3372

- Karma: 54

- Likes received: 932

Re: Breathable membrane enclosures for fecal sludge stabilization (University of Delaware, USA)

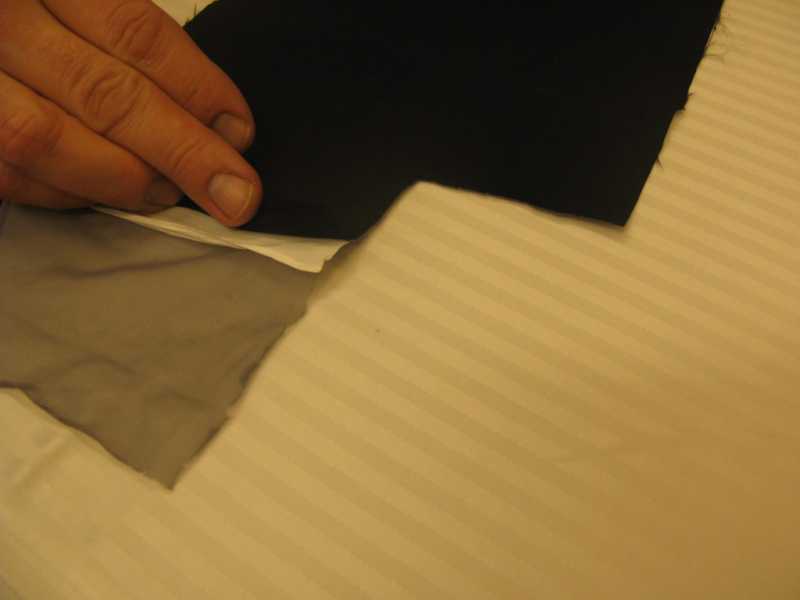

Here is the photo, one can see the three layers of fabric (the photo was taken on a white table cloth). The teflon / PTFE / breathable membrane part is the thin white film in the middle - protected by the two other layers:

And two more photos attached below.

(and please let's not start that whole debate again whether this teflon/PTFE material is a problem for the environment, I think it has been discussed sufficiently above. If anyone wants to discuss it further in a more broader sense, please start a new thread on it. Here, let's rather focus on the research ideas, e.g. the ones that Kris posted above).

I saw that Steve Dentel's team got Phase 2 or follow-up funding from the BMGF - congratulations!!

Could you tell us more about it please, Steve?

I saw it here on Sanitation Updates:

sanitationupdates.wordpress.com/2014/04/...gs-for-pit-latrines/

A team at the University of Delaware has received US$ 250,000 in additional funding to continue its research on “breathable membrane” linings for pit latrines.

The breathable fabric helps to prevent groundwater pollution, while also protecting sanitation workers from exposure to pathogens. Heat from biodegradation of the feces or from the sun gradually expels water vapour, but prevents the escape of particulate or dissolved constituents.

Dentel is piloting the membrane technology in the slums of Kanpur, India, in collaboration with WaterAid. He wants to get them in place before the beginning of the rainy season in June. Since the membrane is reusable, the cost of using susch a sophisticated technology can be reduced.

At the same time, Dentel is working with UD engineering colleagues Daniel Cha and Paul Imhoff to apply the technology in wastewater treatment facilities in the USA and South Korea.

What exactly are the research objectives of this Phase 2? How much time do you have for it? What are these planned applications in the USA and South Korea?

Kind regards,

Elisabeth

Freelance consultant on environmental and climate projects

Attachments:

-

IMG_4467smaller.jpg

(Filesize: 16KB)

IMG_4467smaller.jpg

(Filesize: 16KB)

-

IMG_4471.JPG (Filesize: 25KB)

-

IMG_4472.JPG (Filesize: 18KB)

Please Log in to join the conversation.

You need to login to replyRe: Breathable membrane enclosures for fecal sludge stabilization (University of Delaware, USA)

Here in Uganda we have been brainstorming for a while to find a sustainable way to deal with fecal sludge from emptied pit latrines (or potentially also UDDTs) in a simple, but relatively safe way that can be scaled up in a decentralized fashion.

One of the ideas was to use these kind of breathable membranes to come up with an more safe and less odor problematic alternative to sludge drying beds that could be used in (peri-)urban settings.

The concept I have in mind are long black sacks (not unlike the plastic bag bio-digesters) made out of these breathable membranes that are fed with freshly emptied sludge from one side, while the somewhat dried and thus storage, dehumidification and solar-heat treated sludge can be removed on the other side then.

Given a long enough storage period and sufficient heating from the sun (maybe supported by running a heat-exchanger coil underneath the bags that is feed by standard solar water heaters) the result should be quite safe to handle in (non-food?) agriculture I assume.

I also guess that the smelly ammonia that probably can escape through the membrane is less of a problem given that the pit-latrine contents are already a bit older mostly.

The question really is if it can be made to smell only a little and if the treatment is sufficient without needing a lot of space and expensive foil/membrane.

It would be also interesting to see if non-permeable foil might work sufficiently well too, although the drying properties are definitely a plus of the breathable membrane.

I also wonder how UV stable the material is and if it might be necessary to do the heating completely through external heat exchangers instead, which I would like to avoid as those add to the cost.

Any thoughts on this are appreciated.

Please Log in to join the conversation.

You need to login to replyRe: Breathable membrane enclosures for fecal sludge stabilization (University of Delaware, USA)

Founding Member of Water-Wise Vermont (formerly Vermonters Against Toxic Sludge)

Please Log in to join the conversation.

You need to login to reply- former member

-

Topic AuthorLess

- Posts: 101

- Likes received: 3

Re: Breathable membrane enclosures for fecal sludge stabilization (University of Delaware, USA)

Thanks for the very pertinent questions!

1) You are correct that we originally proposed a simple liner that would be placed directly in a latrine pit. This will prevent any contaminants or pathogens from escaping, and will allow water to be gradually released through the fabric enclosure (which contains the membrane).

The rate at which the water can be removed has to exceed the rate of water addition with feces and urine. When we examined the membrane performance in our research, we had to divide the drying process into two scenarios. Essentially, the membrane lets water out of the fecal sludge if either(a) the temperature of the sludge is higher than that of water outside the enclosure, or (b) there is air outside the membrane that is at less than 100% humidity.

In either case, the thermodynamic reason is the same, but the practical result for drying is that for (a), the sludge must be pretty warm. We've done a heat balance and found that the solar energy above an outhouse might provide enough heat, but only on sunny days, and it complicates what we want to be a very simple system.

Solution (b) is faster than (a) and it will work with simple pit liners IF the soil around the pit is fairly porous and also unsaturated. This might be the case in very dry climates. But in more common situations, we need a way for the water vapor to escape once it has gone through the membrane. I think a practical approach is to combine the membrane fabric with a porous material on its exterior; when this lines the pit, the vapor should go through the membrane fabric and then travel upward and out in the porous layer. The porous layer can be connected to the air vent above the outhouse to increase air flow. We have not tested this approach yet.

What we anticipate in India is a bit similar. The main difference is limited space for dug pits in the crowded urban spaces, so the enclosure is above ground and more open to the air - probably not directly, but within a perforated drum, for example. This means that the outside of the membrane fabric always contains air rather than water, so the drying will be faster. Of course we need to figure out how fast this happens in the rainy season when the humidity is high.

2) The rooftop latrines are unlikely to have running water directly available, so water needs to be carried up. This will mean the water used will not be excessive, so the amount of water sent to the enclosure can be handled. Our tests will determine whether this is the case; if it is not, we will need to increase the amount of membrane area by redesigning or enlarging the enclosure.

3) The result is simply dried sludge as you would have if you air dried it. There is a picture in my paper and presentation, linked previously in this thread. Although we have measured 99% decrease in fecal coliform levels in the dried sludge, this does not mean land application is safe; we need to look at parasite survival such as Ascaris, which will undoubtedly be more difficult. I think the answer is that this process will make the sludge a bit safer, but not completely safe. I would not recommend its use in agriculture unless we find drying conditions that really produce a sanitized dry product.

Thanks for your interest, and I hope my answers are helpful.

++++++++

Note by moderators: This post was made by a former user with the login name skdentel who is no longer a member of this discussion forum.

Please Log in to join the conversation.

You need to login to reply- former member

-

Topic AuthorLess

- Posts: 101

- Likes received: 3

Re: Breathable membrane enclosures for fecal sludge stabilization (University of Delaware, USA)

If sewage sludge is a "perfect sanitation corollary" then it also points out issues with the precautionary principle. If these sludges are not land applied, the only alternative for urban areas is incineration. This has not been proven perfectly safe, and it not likely to be, given the dioxin and Hg stack emissions and the continued presence of heavy metals in the ash, but it is practiced in the European countries where land application has been ruled out. Essentially, there is NO solution to this problem that is completely consistent with the precautionary principle. If Hakan wants us to throw away our Teflon frying pans, should we also shut down the big wastewater treatment plants that generate these sludges?

So the precautionary principle tells us many things we can't do, because they can't be proven completely safe. Unfortunately, the precautionary principle does not offer any solutions unless we stop everything we are doing. If you think there's another alternative to the sludge problem besides land application and incineration, I can identify environmental risks associated with it which, according to the precautionary principle, would rule it out.

I am not against the precautionary principle if it is used as guidance. But taken to absolutism, it may even be harmful. Back to the current topic, we have 600,000 child deaths per year from diarrheal causes, but you would have me do additional research on the environmental fate of PTFE instead of direct sanitation research. I have done my due diligence in searching the wide range of prior research on PTFE and, as I said previously, I find no convincing evidence that it will cause ANY environmental harm in the applications I propose. But you propose that I should spend all the funds entrusted to me by the Gates Foundation on further such research, which would again find no environmental harm.

You are free to choose your own priorities, but I can state from experience that there is not an infinite pool of research money. Given this fact, and the finite amount of funding that I have, I will continue to work on directly solving sanitation problems--problems that lead to clear environmental harms, including human deaths--and I am working on solving them using what I know to be a process with very minimal (or zero) environmental risk.

++++++++

Note by moderators: This post was made by a former user with the login name skdentel who is no longer a member of this discussion forum.

Please Log in to join the conversation.

You need to login to replyRe: Breathable membrane enclosures for fecal sludge stabilization (University of Delaware, USA)

I think the concept of your research is very interesting and would like to ask you a few more questions.

1.) You switched from using the "bags" as a pit liner to having them suspended above ground. Is this purely because that works better for your Indian research partner? In other words, in a rural setting, where digging pits is cheap and feasible could the technology still be used as your team originally envisioned?

2.) In your original post you mention this is a concept for waterless toilets. Yet now you work in India where people are washers. Can the technology cope with the washing water or are people encouraged to shift to wiping?

3.) Could you post some pictures and a description and analyses of the final dried product? As there is no additive (such as ash) I have no idea of what to expect from the dried material. Further, you state in your presentation that the dried material can be an input in agriculture. I am not sure I see how this technology would kill all pathogens in the fecal waste without secondary treatment. Do you have a vision for this?

Kind regards

Marijn Zandee

E: This email address is being protected from spambots. You need JavaScript enabled to view it.

Please Log in to join the conversation.

You need to login to replyRe: Breathable membrane enclosures for fecal sludge stabilization (University of Delaware, USA)

A perfect sanitation corollary exists in the production and land application of toxic sewage sludge in the Global North. We all know that sewage sludge contains a plethora of industrial toxics but because its yet to be proven beyond a doubt that dumping this material on land (including agricultural land and, increasingly, on our gardens, yards and school grounds) is dangerous, we persist in doing so. Many of us are just waiting for the other shoe to drop, an event that will likely occur too late to clean up the mess that we've created. Of course, strict adherence to the precautionary principle would preclude these actions. But, at the same time, Europe is quite guilty of land applying sludge too, proving that how the precautionary principle is applied has its limitations.

Anyway, I see this as a lesson in performing due diligence and always adhering to the precautionary principle. Our work is simply too important to be so easily undercut.

Founding Member of Water-Wise Vermont (formerly Vermonters Against Toxic Sludge)

Please Log in to join the conversation.

You need to login to reply- HakanJonsson

-

Less

- Posts: 12

- Karma: 3

- Likes received: 10

Re: Write-up from webinar 6 - Vapor-permeable membranes (Steve Dentel, University of Delaware, USA)

I just wanted to point out that this is an issue that ought to be watched out for, especially as Steve has not said that the PTFE is not on the surface of the bag meterial.

I do realize that this is an interesting technology with many benefits, and these might well outweigh the potential risks. None the less, one should be aware also of potential risks. This was my whole point.

Best wishes,

Håkan

Please Log in to join the conversation.

You need to login to reply- Forum

- categories

- Sanitation systems

- Toilets without urine diversion

- Innovations and research in toilet design

- Re: Breathable membrane enclosures for fecal sludge stabilization (University of Delaware, USA)