- Forum

- categories

- Sanitation systems

- Toilets without urine diversion

- Innovations and research in toilet design

- Re: Blue Diversion AUTARKY - A self-sustaining toilet off the grid (EAWAG, Switzerland)

Re: Blue Diversion AUTARKY - A self-sustaining toilet off the grid (EAWAG, Switzerland)

31.9k views

Re: Blue Diversion AUTARKY - A self-sustaining toilet off the grid (EAWAG, Switzerland)

Dear readers

We would like to update you with further insights on the different modules of the AUTARKY-project, namely the urine, water and feces treatment in our toilet. As mentioned in the project description, we separate the three streams and treat them on-site, even the feces!

Urine treatment

Two processes are necessary to treat the source-separated urine in the AUTARKY toilet: urine stabilization and water removal. Stabilization is necessary to avoid malodour which occurs during storage, to inactivate pathogens and to conserve the valuable nutrient urea. Once the urine is stabilized the volume of the urine will be reduced by evaporation, the remaining end-product is a mix of salts. After further external treatment steps these salts can be used as fertilizer in agriculture.

Urine stabilization in detail

The main goal of this treatment step is to prevent urea hydrolysis, which is a process that converts urea to ammonia and carbon dioxide. Through the addition of calcium hydroxide to fresh urine the pH increases to values above 12 and prevents microbial urea hydrolysis. An additional benefit of the high pH value is the killing of pathogens and the prevention of biological processes that produce malodour.

When Ca(OH)2 is added to the urine only about the amount dissolves, which is needed to reach the necessary high pH value. This allows providing a depot of Ca(OH)2 in the stabilization tank; therefore no expensive and complicated dosage mechanisms are required. Moreover, calcium hydroxide is a cheap reagent and readily available worldwide. An additional benefit of Ca(OH)2 dosage is the precipitation of calcium phosphate. This mineral could be recovered apart from the other urine compounds and used for fertilizer production.

Urine water removal in detail

The direct application of human urine as fertilizer is a common practice in many rural areas worldwide. However, the high water content of urine – no matter if stabilized or not – requires significant storage capacity and can make the transport to the agricultural fields very costly. Volume reduction does not only reduce costs for storage and transport but could also facilitate field application of the concentrated fertilizer. Standard volume reduction techniques are most often energy intensive processes, because they require high temperatures (distillation) or pressures (reverse osmosis). We are currently focusing on several evaporation techniques, which do not require any heating and pressurizing processes. One example is the evaporation pipe where urine is trickled down a pipe, which is aerated with ambient air that takes up water. Our goal is to recover a hygienically safe end-product that concentrates valuable nutrients that will be applied to cropland.

Water treatment

The preceding project Blue Diversion, achieved tremendous progress towards developing gravity driven membrane technology (GDM) into a practical toilet water recycling system for urban developing world applications (www.bluediversiontoilet.com/water-quality-and-energy.html). The goal of AUTARKY is to better understand and verify the safety of our system with respect to the user and to explore alternative technologies which may reduce capital and energy costs. We are also examining how the same membrane technology functions in systems representing higher and lower organic and nutrient loading. The gravity driven membrane achieves approximately 95% removal of organic carbon entering the system. Additional treatment is required to maintain microbial stability within the clean water tank. Microbial stability refers here to water with limited potential for contamination and growth of pathogens. The electrolysis unit in the previous version of the toilet has demonstrated an ability to reduce organic carbon concentrations and produce a chlorine residual, both of which help to limit pathogen growth.

Treatment technologies such as activated carbon, ozone and UV light are being considered as alternatives to the electrolysis. These alternatives may be less expensive to install and maintain, and they may produce superior water quality given considerations such as their impact on biology of the membrane. The advantages and disadvantages of each technology will be first evaluated in batch; promising technologies will then be integrated into full-scale toilet systems. A quantitative microbial risk assessment will be performed on the entire module. In this regard, pathogen surrogates are used to investigate passage through the membrane and in competitive experiments with the natural bacteria community which forms in the clean water reservoir.

Feces treatment

In the Autarky toilet, feces are separated from urine and collected in a container at the bottom of the toilet. They may contain harmful compounds such as pathogens and must be inactivated quickly to avoid anaerobic decomposition and the emission of malodorous gases. In our approach the organic matter of the feces sludge is completely mineralized to carbon dioxide, water and minerals such as phosphate salts. The remaining streams are off-gas and a mixture of water and minerals. The off-gas contains mainly nitrogen, carbon dioxide and oxygen and can be safely vented to the atmosphere. The aqueous stream may be utilized as a fertilizer.

Feces mineralization in detail

When mixed with air and heated above ca. 400°C under high pressure, the feces sludge decomposes and is oxidized completely to carbon dioxide and water. This process is called “hydrothermal oxidation” or HTO. The water in the sludge does not evaporate but mixes with the air and provides a reaction environment for an efficient conversion of the organic matter within a few minutes. We are developing a comprehensive computer model of the HTO reactor to be built for the Autarky toilet. This computer model is fed with data from experiments carried out in small autoclaves with real fecal sludge. We determined that the oxidation reaction is rapid above ca. 300°C and runs to completion within a few minutes at 400°C. The next step is to build a small laboratory-scale prototype to perform experiments under more realistic conditions and to test the model predictions. With the validated model a full-scale prototype will be designed and built in 2016.

We are happy to answer your questions or give you more detailed information,

best,

Steffi

We would like to update you with further insights on the different modules of the AUTARKY-project, namely the urine, water and feces treatment in our toilet. As mentioned in the project description, we separate the three streams and treat them on-site, even the feces!

Urine treatment

Two processes are necessary to treat the source-separated urine in the AUTARKY toilet: urine stabilization and water removal. Stabilization is necessary to avoid malodour which occurs during storage, to inactivate pathogens and to conserve the valuable nutrient urea. Once the urine is stabilized the volume of the urine will be reduced by evaporation, the remaining end-product is a mix of salts. After further external treatment steps these salts can be used as fertilizer in agriculture.

Urine stabilization in detail

The main goal of this treatment step is to prevent urea hydrolysis, which is a process that converts urea to ammonia and carbon dioxide. Through the addition of calcium hydroxide to fresh urine the pH increases to values above 12 and prevents microbial urea hydrolysis. An additional benefit of the high pH value is the killing of pathogens and the prevention of biological processes that produce malodour.

When Ca(OH)2 is added to the urine only about the amount dissolves, which is needed to reach the necessary high pH value. This allows providing a depot of Ca(OH)2 in the stabilization tank; therefore no expensive and complicated dosage mechanisms are required. Moreover, calcium hydroxide is a cheap reagent and readily available worldwide. An additional benefit of Ca(OH)2 dosage is the precipitation of calcium phosphate. This mineral could be recovered apart from the other urine compounds and used for fertilizer production.

Urine water removal in detail

The direct application of human urine as fertilizer is a common practice in many rural areas worldwide. However, the high water content of urine – no matter if stabilized or not – requires significant storage capacity and can make the transport to the agricultural fields very costly. Volume reduction does not only reduce costs for storage and transport but could also facilitate field application of the concentrated fertilizer. Standard volume reduction techniques are most often energy intensive processes, because they require high temperatures (distillation) or pressures (reverse osmosis). We are currently focusing on several evaporation techniques, which do not require any heating and pressurizing processes. One example is the evaporation pipe where urine is trickled down a pipe, which is aerated with ambient air that takes up water. Our goal is to recover a hygienically safe end-product that concentrates valuable nutrients that will be applied to cropland.

Water treatment

The preceding project Blue Diversion, achieved tremendous progress towards developing gravity driven membrane technology (GDM) into a practical toilet water recycling system for urban developing world applications (www.bluediversiontoilet.com/water-quality-and-energy.html). The goal of AUTARKY is to better understand and verify the safety of our system with respect to the user and to explore alternative technologies which may reduce capital and energy costs. We are also examining how the same membrane technology functions in systems representing higher and lower organic and nutrient loading. The gravity driven membrane achieves approximately 95% removal of organic carbon entering the system. Additional treatment is required to maintain microbial stability within the clean water tank. Microbial stability refers here to water with limited potential for contamination and growth of pathogens. The electrolysis unit in the previous version of the toilet has demonstrated an ability to reduce organic carbon concentrations and produce a chlorine residual, both of which help to limit pathogen growth.

Treatment technologies such as activated carbon, ozone and UV light are being considered as alternatives to the electrolysis. These alternatives may be less expensive to install and maintain, and they may produce superior water quality given considerations such as their impact on biology of the membrane. The advantages and disadvantages of each technology will be first evaluated in batch; promising technologies will then be integrated into full-scale toilet systems. A quantitative microbial risk assessment will be performed on the entire module. In this regard, pathogen surrogates are used to investigate passage through the membrane and in competitive experiments with the natural bacteria community which forms in the clean water reservoir.

Feces treatment

In the Autarky toilet, feces are separated from urine and collected in a container at the bottom of the toilet. They may contain harmful compounds such as pathogens and must be inactivated quickly to avoid anaerobic decomposition and the emission of malodorous gases. In our approach the organic matter of the feces sludge is completely mineralized to carbon dioxide, water and minerals such as phosphate salts. The remaining streams are off-gas and a mixture of water and minerals. The off-gas contains mainly nitrogen, carbon dioxide and oxygen and can be safely vented to the atmosphere. The aqueous stream may be utilized as a fertilizer.

Feces mineralization in detail

When mixed with air and heated above ca. 400°C under high pressure, the feces sludge decomposes and is oxidized completely to carbon dioxide and water. This process is called “hydrothermal oxidation” or HTO. The water in the sludge does not evaporate but mixes with the air and provides a reaction environment for an efficient conversion of the organic matter within a few minutes. We are developing a comprehensive computer model of the HTO reactor to be built for the Autarky toilet. This computer model is fed with data from experiments carried out in small autoclaves with real fecal sludge. We determined that the oxidation reaction is rapid above ca. 300°C and runs to completion within a few minutes at 400°C. The next step is to build a small laboratory-scale prototype to perform experiments under more realistic conditions and to test the model predictions. With the validated model a full-scale prototype will be designed and built in 2016.

We are happy to answer your questions or give you more detailed information,

best,

Steffi

Steffi Enssle

Eawag (The Swiss Federal Institute of Aquatic Science and Technology)

Process Engineering

www.autarky.ch

www.bluediversiontoilet.com

Eawag (The Swiss Federal Institute of Aquatic Science and Technology)

Process Engineering

www.autarky.ch

www.bluediversiontoilet.com

Please Log in to join the conversation.

You need to login to replyBlue Diversion AUTARKY - A self-sustaining toilet off the grid (EAWAG, Switzerland)

Here is the description of a new grant we received from the Bill & Melinda Gates Foundation in the area of sanitation technology development:

Title of grant: Blue Diversion AUTARKY - A self-sustaining toilet off the grid

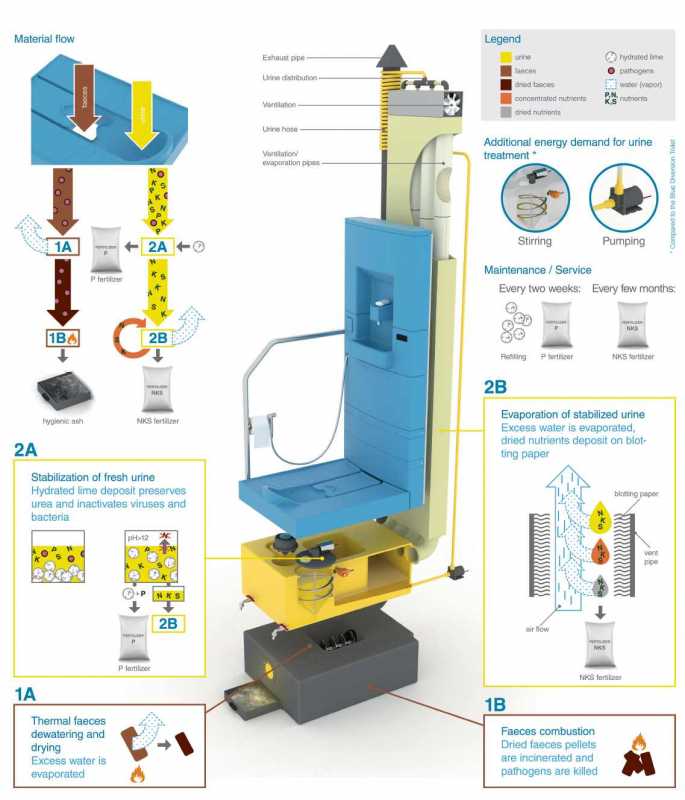

Image to give you a visual impression (the pdf file in higher resolution is available here: www.susana.org/en/resources/library/details/2237):

“Blue Diversion AUTARKY” is the continuation of Eawag's RTTC project "Blue Diversion" (see here on the forum: forum.susana.org/forum/categories/106-us...and-and-austria#3692). In this new phase we will develop technologies and prototype reactors for the on-site treatment of source-separated urine, feces and polluted water from anal cleansing and handwashing.

The urine treatment reactor will consist of a first process step, in which calcium hydroxide is dosed to the fresh urine to increase the pH to above 12 to stabilize the nitrogen content, to precipitate phosphorus and to inactivate pathogens. In the second step the water is removed by passive evaporation techniques driven by atmospheric energy to avoid further energy requirements. The final products of the urine treatment are two solids; one containing all phosphorus, another containing all other nutrients and salts.

The feces treatment will be based on hydrothermal oxidation (HTO, also known as supercritical water oxidation SCWO). Its final products are water and precipitated solids. The latter contains all the phosphorus from feces. To heat up the process energy is needed once, it can be provided by a generator or a simple 220V power plug. Further energy demand is covered by a solar panel.

The water treatment reactor is based on gravity driven membrane technology (GDM) developed during the previous phases of the "Blue Diversion" project (see also in the SuSanA project database: www.susana.org/en/resources/projects?search=blue+diversion). The goal is to better understand and verify the safety of the system with respect to the user, and to explore alternative technologies such as activated carbon, ozone and UV light which may reduce capital and energy costs.

We are also examining how the same membrane technology functions in systems representing higher and lower organic loading as used in the toilets from other RTTC-partners e.g. RTI International (see also in the SuSanA project database the projects by RTI: www.susana.org/en/resources/projects?sea...h+Triangle+Institute).

Goal:

To develop a self-sustaining toilet off the grid.

Objectives:

Development of prototype reactors for the on-site treatment of source-separated urine, feces and polluted water.

Research or implementation partners:

- Eawag (Swiss Federal Institute of Aquatic Science and Technology)

- PSI (Paul Scherrer Institute)

- FHNW (University of Applied Sciences and Arts Northwestern Switzerland)

- EPFL (Swiss Federal Institute of Technology in Lausanne)

- SLU (Swedish University of Agriculture)

- EOOS (Austrian Design Office)

Links, further readings:

Project website: www.autarky.ch

Related projects:

- www.bluediversiontoilet.com, the Autarky project is building on the results from the Blue Diversion project, especially regarding the water treatment.

- www.vuna.ch, the VUNA experience gives great insights about urine treatment and inspiration for the Autarky urine module.

Poster/flyer in English and French, as well as further documents in future are in the SuSanA library: www.susana.org/en/resources/library/details/2237

Current state of affairs:

Selection of one reactor set-up for urine, feces and water treatment.

Biggest successes so far:

Not applicable, project just started.

Main challenges / frustration:

Not applicable, project just started.

If you have any questions, please don't hesitate to ask me here on the forum.

Regards,

Steffi

Title of grant: Blue Diversion AUTARKY - A self-sustaining toilet off the grid

Image to give you a visual impression (the pdf file in higher resolution is available here: www.susana.org/en/resources/library/details/2237):

- Name of lead organization: Eawag (The Swiss Federal Institute of Aquatic Science and Technology)

- Primary contact at lead organization: Kai Udert, Project lead and myself (Stefanie Enssle), Project coordination

- Grantee location: Dübendorf, Switzerland

- Developing country where the research will be tested: The current focus lies on process engineering and reactor construction. It is too early to think of field-testing, although South Africa might be an option.

- Start and end date: 01/ 2015 – 12/ 2016 (extended to April 2017)

- Grant type: Reinvent the Toilet Challenge (RTTC)

- Grant size in USD: $2,826,507 (as per BMGF grant database )

“Blue Diversion AUTARKY” is the continuation of Eawag's RTTC project "Blue Diversion" (see here on the forum: forum.susana.org/forum/categories/106-us...and-and-austria#3692). In this new phase we will develop technologies and prototype reactors for the on-site treatment of source-separated urine, feces and polluted water from anal cleansing and handwashing.

The urine treatment reactor will consist of a first process step, in which calcium hydroxide is dosed to the fresh urine to increase the pH to above 12 to stabilize the nitrogen content, to precipitate phosphorus and to inactivate pathogens. In the second step the water is removed by passive evaporation techniques driven by atmospheric energy to avoid further energy requirements. The final products of the urine treatment are two solids; one containing all phosphorus, another containing all other nutrients and salts.

The feces treatment will be based on hydrothermal oxidation (HTO, also known as supercritical water oxidation SCWO). Its final products are water and precipitated solids. The latter contains all the phosphorus from feces. To heat up the process energy is needed once, it can be provided by a generator or a simple 220V power plug. Further energy demand is covered by a solar panel.

The water treatment reactor is based on gravity driven membrane technology (GDM) developed during the previous phases of the "Blue Diversion" project (see also in the SuSanA project database: www.susana.org/en/resources/projects?search=blue+diversion). The goal is to better understand and verify the safety of the system with respect to the user, and to explore alternative technologies such as activated carbon, ozone and UV light which may reduce capital and energy costs.

We are also examining how the same membrane technology functions in systems representing higher and lower organic loading as used in the toilets from other RTTC-partners e.g. RTI International (see also in the SuSanA project database the projects by RTI: www.susana.org/en/resources/projects?sea...h+Triangle+Institute).

Goal:

To develop a self-sustaining toilet off the grid.

Objectives:

Development of prototype reactors for the on-site treatment of source-separated urine, feces and polluted water.

Research or implementation partners:

- Eawag (Swiss Federal Institute of Aquatic Science and Technology)

- PSI (Paul Scherrer Institute)

- FHNW (University of Applied Sciences and Arts Northwestern Switzerland)

- EPFL (Swiss Federal Institute of Technology in Lausanne)

- SLU (Swedish University of Agriculture)

- EOOS (Austrian Design Office)

Links, further readings:

Project website: www.autarky.ch

Related projects:

- www.bluediversiontoilet.com, the Autarky project is building on the results from the Blue Diversion project, especially regarding the water treatment.

- www.vuna.ch, the VUNA experience gives great insights about urine treatment and inspiration for the Autarky urine module.

Poster/flyer in English and French, as well as further documents in future are in the SuSanA library: www.susana.org/en/resources/library/details/2237

Current state of affairs:

Selection of one reactor set-up for urine, feces and water treatment.

Biggest successes so far:

Not applicable, project just started.

Main challenges / frustration:

Not applicable, project just started.

If you have any questions, please don't hesitate to ask me here on the forum.

Regards,

Steffi

Steffi Enssle

Eawag (The Swiss Federal Institute of Aquatic Science and Technology)

Process Engineering

www.autarky.ch

www.bluediversiontoilet.com

Eawag (The Swiss Federal Institute of Aquatic Science and Technology)

Process Engineering

www.autarky.ch

www.bluediversiontoilet.com

Attachments:

-

autarkyposter.jpg

(Filesize: 50KB)

autarkyposter.jpg

(Filesize: 50KB)

The following user(s) like this post: christian.rieck, Marijn Zandee, cecile

Please Log in to join the conversation.

You need to login to reply

Share this thread:

- Forum

- categories

- Sanitation systems

- Toilets without urine diversion

- Innovations and research in toilet design

- Re: Blue Diversion AUTARKY - A self-sustaining toilet off the grid (EAWAG, Switzerland)

Recently active users. Who else has been active?

Time to create page: 0.233 seconds