- Resource recovery

- Resource recovery from excreta, faecal sludge or wastewater

- Literally “Making gold out of shit”... Open Source: Sewage Sludge Carbonisation by small public utility for wastewater in East-Germany, ZV Frohnbach, by Dr. Steffen Heinrich, for larger wwpt!?

Literally “Making gold out of shit”... Open Source: Sewage Sludge Carbonisation by small public utility for wastewater in East-Germany, ZV Frohnbach, by Dr. Steffen Heinrich, for larger wwpt!?

1411 views

Re: Literally “Making gold out of shit”... Open Source: Sewage Sludge Carbonisation by small public utility for wastewater in East-Germany, ZV Frohnbach, by Dr. Steffen Heinrich, for larger wwpt!?

On the "affecting the tariffs for users", in this particular case it is a positive storry, no increase of tariffs at all. On the other side of this "storry" the total much higher costs for transport and insineration would increase the tariffs significant if no on-side carbonisation would be put in place. In other words the German insineration mafia got lost on this public utility  )))

)))

www.aqua-verde.de, AquaVerde Ltd. Zanzibar

"simple" Sanitation-Solutions by gravity

Low-Tech Solutions with High-Tech Effects

"Inspired by Circular Economy and Cooperation"

www.flickr.com/photos/aqua-verde/

"simple" Sanitation-Solutions by gravity

Low-Tech Solutions with High-Tech Effects

"Inspired by Circular Economy and Cooperation"

www.flickr.com/photos/aqua-verde/

Please Log in to join the conversation.

You need to login to replyRe: Literally “Making gold out of shit”... Open Source: Sewage Sludge Carbonisation by small public utility for wastewater in East-Germany, ZV Frohnbach, by Dr. Steffen Heinrich, for larger wwpt!?

Dear Alehandro,

Yes an English version of the book + digital annex is in progress. Did you see the videos with English voice over? They give you a good explanation of FS treatment progress.

You may contact Dr. Heinrich very direct by e-mail too, you will find it on the internet.

All the Best

Detlef

Yes an English version of the book + digital annex is in progress. Did you see the videos with English voice over? They give you a good explanation of FS treatment progress.

You may contact Dr. Heinrich very direct by e-mail too, you will find it on the internet.

All the Best

Detlef

www.aqua-verde.de, AquaVerde Ltd. Zanzibar

"simple" Sanitation-Solutions by gravity

Low-Tech Solutions with High-Tech Effects

"Inspired by Circular Economy and Cooperation"

www.flickr.com/photos/aqua-verde/

"simple" Sanitation-Solutions by gravity

Low-Tech Solutions with High-Tech Effects

"Inspired by Circular Economy and Cooperation"

www.flickr.com/photos/aqua-verde/

Please Log in to join the conversation.

You need to login to reply- alevy

-

- Moderator

- Engineer working sanitation since 2018. Interests in decentralized wastewater systems, FSM, sustainable sanitation planning and water and fecal sludge reuse. Ingeniero trabajando en saneamiento desde el 2018. Interesado en sistemas de saneamiento descentralizados, planificación de saneamiento sostenible y reúso de agua y lodos. Aguatuya

Less- Posts: 13

- Likes received: 4

Re: Literally “Making gold out of shit”... Open Source: Sewage Sludge Carbonisation by small public utility for wastewater in East-Germany, ZV Frohnbach, by Dr. Steffen Heinrich, for larger wwpt!?

Hi Detlef,

Thank you for sharing this amazing experience.

Being convinced of the value of high-quality byproducts such as biochar within the circularity of the sanitation chain, I do think its value shines brighter in contexts and in this particular case, for instance, where transportation costs for large volumes of sludge are high.

For instance, here in Bolivia, most small-scale wastewater utilities only task themselves to drying the sludge since once dried, farmers come and pick it up at no cost for them (besides transportation), meaning also that the utility incurs in no further costs.

Those conditions are obviously improvable, given that the sludge characteristics are not the best and therefore pose a risk for farmers and consumers if not handled correctly. In the scenario described, implementing this system (besides the initial investment cost) implies operational costs that would end up affecting the tariffs for users. Sadly, tariffs are the biggest obstacle for water and wastewater utilities alike in our country, handicapping them in many aspects.

Back to the experience in Neiderfrohna, I have a couple questions. What is the process of the wastewater and how is the sludge produced? Also, could you better describe the process the sludge does through all the way to the pre-drying process?

Regarding the product: When starting to produce the biochar, what was the perception of the farmers? And a couple years later, has the market for it grown?

Lastly, would you happen to know if there's an English version planned for the book?

Best regards.

Thank you for sharing this amazing experience.

Being convinced of the value of high-quality byproducts such as biochar within the circularity of the sanitation chain, I do think its value shines brighter in contexts and in this particular case, for instance, where transportation costs for large volumes of sludge are high.

For instance, here in Bolivia, most small-scale wastewater utilities only task themselves to drying the sludge since once dried, farmers come and pick it up at no cost for them (besides transportation), meaning also that the utility incurs in no further costs.

Those conditions are obviously improvable, given that the sludge characteristics are not the best and therefore pose a risk for farmers and consumers if not handled correctly. In the scenario described, implementing this system (besides the initial investment cost) implies operational costs that would end up affecting the tariffs for users. Sadly, tariffs are the biggest obstacle for water and wastewater utilities alike in our country, handicapping them in many aspects.

Back to the experience in Neiderfrohna, I have a couple questions. What is the process of the wastewater and how is the sludge produced? Also, could you better describe the process the sludge does through all the way to the pre-drying process?

Regarding the product: When starting to produce the biochar, what was the perception of the farmers? And a couple years later, has the market for it grown?

Lastly, would you happen to know if there's an English version planned for the book?

Best regards.

Alejandro Levy

AGUATUYA

Calle Nicolás Ortiz N° 33 (TESAI of. 1B)

Tel (591) 4 424 2164

Casilla 6264

Cochabamba – Bolivia

AGUATUYA

Calle Nicolás Ortiz N° 33 (TESAI of. 1B)

Tel (591) 4 424 2164

Casilla 6264

Cochabamba – Bolivia

Please Log in to join the conversation.

You need to login to replyRe: Literally “Making gold out of shit”... Open Source: Sewage Sludge Carbonisation by small public utility for wastewater in East-Germany, ZV Frohnbach, by Dr. Steffen Heinrich, for larger wwpt!?

www.aqua-verde.de, AquaVerde Ltd. Zanzibar

"simple" Sanitation-Solutions by gravity

Low-Tech Solutions with High-Tech Effects

"Inspired by Circular Economy and Cooperation"

www.flickr.com/photos/aqua-verde/

"simple" Sanitation-Solutions by gravity

Low-Tech Solutions with High-Tech Effects

"Inspired by Circular Economy and Cooperation"

www.flickr.com/photos/aqua-verde/

Attachments:

-

Pyrolysisu...1-30.jpg

(Filesize: 67KB)

Pyrolysisu...1-30.jpg

(Filesize: 67KB)

-

housingofd...isis.jpg

(Filesize: 88KB)

housingofd...isis.jpg

(Filesize: 88KB)

-

DrSteffenH...1-30.jpg

(Filesize: 105KB)

DrSteffenH...1-30.jpg

(Filesize: 105KB)

-

SewageSlud...1-30.jpg

(Filesize: 150KB)

SewageSlud...1-30.jpg

(Filesize: 150KB)

The following user(s) like this post: alevy

Please Log in to join the conversation.

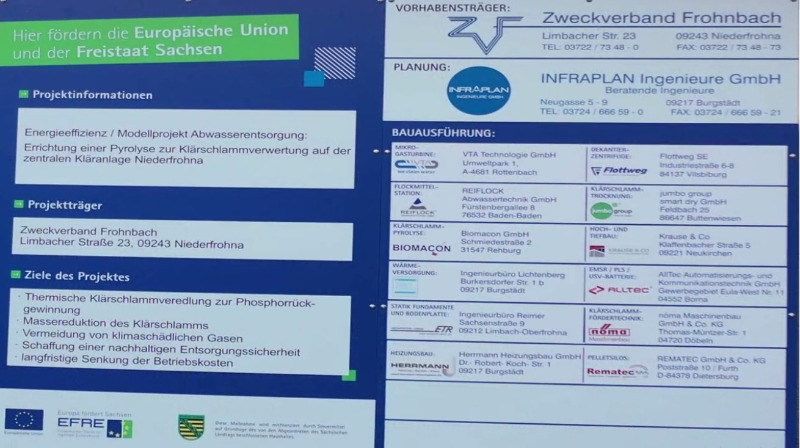

You need to login to replyLiterally “Making gold out of shit”... Open Source: Sewage Sludge Carbonisation by small public utility for wastewater in East-Germany, ZV Frohnbach, by Dr. Steffen Heinrich, for larger wwpt!?

Literally “Making gold out of shit”...

Open Source: Sewage Sludge Carbonisation by small public utility for wastewater in East-Germany, ZV Frohnbach, by Dr. Steffen Heinrich, for larger wwpt!?

Dear Susana's,

First of all, I or public utility ZV Frohnbach from East-Germany, do not want to sale anything to you.

I just want to let you and on other levels, to know about an Open Source (“copy-paste” of a "detailed documentation of the process tested in Niederfrohna, East-Germany with explanations of the system technology, technical data, material and energy balances, operational experience and economic considerations was compiled in a specialist book, with digitized additional information (calculation aids, documents and videos)") of a simple "Sewage Sludge Carbonisation" by a small public utility for wastewater treatment from East-Germany, by Dr. Steffen Heinrich, an East-German friend of mine (location: 50°52'39.33"N, 12°44'55.16"E).

This public utility is using since ~2-3 years a purposly simple Pyrolysis-Carbonisation system by making use of the inert sludge energy to do drying and pyrolysis, without extra energy inputs! Only for the startup of main processes an external energy input is needed. All machine components are "just from the shelf", German made. This pilot plant on just ~340 m2 ground for ~40,000 PE wwtp is now running since ~2-3 years without any problems.

See pdf's, pictures and 4 videos in English language at link:

www.mediafire.com/folder/0fwztczs2r7tg/Sewage_Sludge_Pyrolyse

This pilot plant costed ~3.2 MEURO, a possible “copy-past”-plant would cost "only" ~1.5 MEURO, as it is now ready for “copy-paste”. Under German law-condition this small public utility is now saving every year ~250,000 EURO by not transporting and burning the surplus sludge any more. In opposition to that former endeavour, they give it now to farmers/gardeners for free as soil enhancer, as by German law any public utility is not allowed to sale anything for extra-profit.

Maybe decision makers have a look in this simple "Sewage Sludge Carbonisation" details and pick up this Open Source (no licence fees!) idea for public utilities financial advantages and for industries too. Avoiding future sludge waste costs by generating profits and healthy soils through this “farm-gold”.

Literally “Making gold out of shit”...

Best Regards,

Detlef SCHWAGER

PS:

What to do with the sewage sludge?

Rising disposal costs, no disposal capacities, new laws and regulations breathing down your neck - what to do?

Sewage sludge pyrolysis as an economical and environmentally friendly alternative

The public utility ZV Fronbach, Dr. Steffen Heinrich and infraplan-ingenieure.de have developed together a new concept for its municipal sewage treatment plant with a treatment capacity of ~40,000 PE and carried out several large-scale tests for both drying and pyrolysis. The focus was on the integration of all available energy sources (sewage gas, electrical energy and waste heat from CHP) in order to achieve an acceptable energy and CO2 balance. The concept is scalable and therefore also suitable for wastewater treatment plants of any size from 10,000 PE.

Model project for the Free State of Saxony

It is important to the Free State of Saxony to demonstrate options for future sewage sludge disposal. This is why the Free State supported the model project "Construction of a pyrolysis plant for sewage sludge utilisation" of the Frohnbach special purpose association. Realisation at the Niederfrohna sewage treatment plant started back in 2018. The centrepiece is the drying and pyrolysis unit, which is integrated into the existing sewage treatment plant site. The amount of sewage sludge is reduced by around 90% from ~1,450 tonnes per year to less than ~170 tonnes of biochar per year. This contains over ~20 tonnes of valuable phosphorus per year.

Advantages for the sewage treatment plant operator:

- Independence from price increases and disposal routes

- Decentralised solution, can therefore be used at any wastewater treatment plant

- No need to change the existing treatment process

- Significant reduction in the volume of sewage sludge

- Elimination of costly sewage sludge transport (~75% water!)

- Heat recovery with pyrolysis gas or utilisation of process heat for sewage treatment plant operation (local heating network, digestion, drying)

- Biochar is used to improve soils (> 9 Ma.-% of biochar contains N, Mg, S, Si, K, P, Ca)

- Biochar can be stored well as a sterile and dry product

- Basis for other phosphorus recovery processes

Sewage sludge pyrolysis becomes more energy efficient the better the sewage sludge is pre-dried (at least ~80 to 90% dry matter). It is particularly promising to use undigested sewage sludge. Because this has almost twice the energy content compared to residual sludge from digestion towers. However, depending on the drying process, increased odour pollution must be expected.

Open Source: Sewage Sludge Carbonisation by small public utility for wastewater in East-Germany, ZV Frohnbach, by Dr. Steffen Heinrich, for larger wwpt!?

Dear Susana's,

First of all, I or public utility ZV Frohnbach from East-Germany, do not want to sale anything to you.

I just want to let you and on other levels, to know about an Open Source (“copy-paste” of a "detailed documentation of the process tested in Niederfrohna, East-Germany with explanations of the system technology, technical data, material and energy balances, operational experience and economic considerations was compiled in a specialist book, with digitized additional information (calculation aids, documents and videos)") of a simple "Sewage Sludge Carbonisation" by a small public utility for wastewater treatment from East-Germany, by Dr. Steffen Heinrich, an East-German friend of mine (location: 50°52'39.33"N, 12°44'55.16"E).

This public utility is using since ~2-3 years a purposly simple Pyrolysis-Carbonisation system by making use of the inert sludge energy to do drying and pyrolysis, without extra energy inputs! Only for the startup of main processes an external energy input is needed. All machine components are "just from the shelf", German made. This pilot plant on just ~340 m2 ground for ~40,000 PE wwtp is now running since ~2-3 years without any problems.

See pdf's, pictures and 4 videos in English language at link:

www.mediafire.com/folder/0fwztczs2r7tg/Sewage_Sludge_Pyrolyse

This pilot plant costed ~3.2 MEURO, a possible “copy-past”-plant would cost "only" ~1.5 MEURO, as it is now ready for “copy-paste”. Under German law-condition this small public utility is now saving every year ~250,000 EURO by not transporting and burning the surplus sludge any more. In opposition to that former endeavour, they give it now to farmers/gardeners for free as soil enhancer, as by German law any public utility is not allowed to sale anything for extra-profit.

Maybe decision makers have a look in this simple "Sewage Sludge Carbonisation" details and pick up this Open Source (no licence fees!) idea for public utilities financial advantages and for industries too. Avoiding future sludge waste costs by generating profits and healthy soils through this “farm-gold”.

Literally “Making gold out of shit”...

Best Regards,

Detlef SCHWAGER

PS:

What to do with the sewage sludge?

Rising disposal costs, no disposal capacities, new laws and regulations breathing down your neck - what to do?

Sewage sludge pyrolysis as an economical and environmentally friendly alternative

The public utility ZV Fronbach, Dr. Steffen Heinrich and infraplan-ingenieure.de have developed together a new concept for its municipal sewage treatment plant with a treatment capacity of ~40,000 PE and carried out several large-scale tests for both drying and pyrolysis. The focus was on the integration of all available energy sources (sewage gas, electrical energy and waste heat from CHP) in order to achieve an acceptable energy and CO2 balance. The concept is scalable and therefore also suitable for wastewater treatment plants of any size from 10,000 PE.

Model project for the Free State of Saxony

It is important to the Free State of Saxony to demonstrate options for future sewage sludge disposal. This is why the Free State supported the model project "Construction of a pyrolysis plant for sewage sludge utilisation" of the Frohnbach special purpose association. Realisation at the Niederfrohna sewage treatment plant started back in 2018. The centrepiece is the drying and pyrolysis unit, which is integrated into the existing sewage treatment plant site. The amount of sewage sludge is reduced by around 90% from ~1,450 tonnes per year to less than ~170 tonnes of biochar per year. This contains over ~20 tonnes of valuable phosphorus per year.

Advantages for the sewage treatment plant operator:

- Independence from price increases and disposal routes

- Decentralised solution, can therefore be used at any wastewater treatment plant

- No need to change the existing treatment process

- Significant reduction in the volume of sewage sludge

- Elimination of costly sewage sludge transport (~75% water!)

- Heat recovery with pyrolysis gas or utilisation of process heat for sewage treatment plant operation (local heating network, digestion, drying)

- Biochar is used to improve soils (> 9 Ma.-% of biochar contains N, Mg, S, Si, K, P, Ca)

- Biochar can be stored well as a sterile and dry product

- Basis for other phosphorus recovery processes

Sewage sludge pyrolysis becomes more energy efficient the better the sewage sludge is pre-dried (at least ~80 to 90% dry matter). It is particularly promising to use undigested sewage sludge. Because this has almost twice the energy content compared to residual sludge from digestion towers. However, depending on the drying process, increased odour pollution must be expected.

www.aqua-verde.de, AquaVerde Ltd. Zanzibar

"simple" Sanitation-Solutions by gravity

Low-Tech Solutions with High-Tech Effects

"Inspired by Circular Economy and Cooperation"

www.flickr.com/photos/aqua-verde/

"simple" Sanitation-Solutions by gravity

Low-Tech Solutions with High-Tech Effects

"Inspired by Circular Economy and Cooperation"

www.flickr.com/photos/aqua-verde/

Attachments:

-

signboardp...tion.jpg

(Filesize: 96KB)

signboardp...tion.jpg

(Filesize: 96KB)

The following user(s) like this post: alevy

Please Log in to join the conversation.

You need to login to reply

Share this thread:

- Resource recovery

- Resource recovery from excreta, faecal sludge or wastewater

- Literally “Making gold out of shit”... Open Source: Sewage Sludge Carbonisation by small public utility for wastewater in East-Germany, ZV Frohnbach, by Dr. Steffen Heinrich, for larger wwpt!?

Time to create page: 0.495 seconds