- Announcements and miscellaneous

- General announcements

- Introductions, persons or companies offering their services or products

- Affordable, sustainable, safe habitats and toilet and pipe manufacturing

Affordable, sustainable, safe habitats and toilet and pipe manufacturing

4487 views

Re: Affordable, sustainable, safe habitats and toilet and pipe manufacturing

Hi,

No for the production we need virgin Polyester and glass fiber resin plus sand. No emissions as the plant is working with electricity.

No homepage for the house but you find me at my FB page Oil for Shelter. About my partners company see www.conswiss.ch.

Estimated costs as per your question € 180 if produced in large series.

A wonderful Sunday and all best.

No for the production we need virgin Polyester and glass fiber resin plus sand. No emissions as the plant is working with electricity.

No homepage for the house but you find me at my FB page Oil for Shelter. About my partners company see www.conswiss.ch.

Estimated costs as per your question € 180 if produced in large series.

A wonderful Sunday and all best.

Attachments:

-

GRPTubewin...unit.png

(Filesize: 750KB)

GRPTubewin...unit.png

(Filesize: 750KB)

Please Log in to join the conversation.

You need to login to replyRe: Affordable, sustainable, safe habitats and toilet and pipe manufacturing

Hi,

This is very interesting. Please send us your webpage. In what countries do you work? Also please introduce yourself more generally.

Is the polyester virgin, or could it be taken from disposable Coke bottles?

The fiberglass I presume would have to be virgin.

What kind of exhausts does the factory make?

What would be the cost and weight of a tube 120 cm diameter and 250 cm long?

Could it support a floor part-way up?

Best wishes,

Chris Canaday

This is very interesting. Please send us your webpage. In what countries do you work? Also please introduce yourself more generally.

Is the polyester virgin, or could it be taken from disposable Coke bottles?

The fiberglass I presume would have to be virgin.

What kind of exhausts does the factory make?

What would be the cost and weight of a tube 120 cm diameter and 250 cm long?

Could it support a floor part-way up?

Best wishes,

Chris Canaday

Conservation Biologist and EcoSan Promoter

Omaere Ethnobotanical Park

Puyo, Pastaza, Ecuador, South America

inodoroseco.blogspot.com

Omaere Ethnobotanical Park

Puyo, Pastaza, Ecuador, South America

inodoroseco.blogspot.com

The following user(s) like this post: Shelterbuilding

Please Log in to join the conversation.

You need to login to replyAffordable, sustainable, safe habitats and toilet and pipe manufacturing

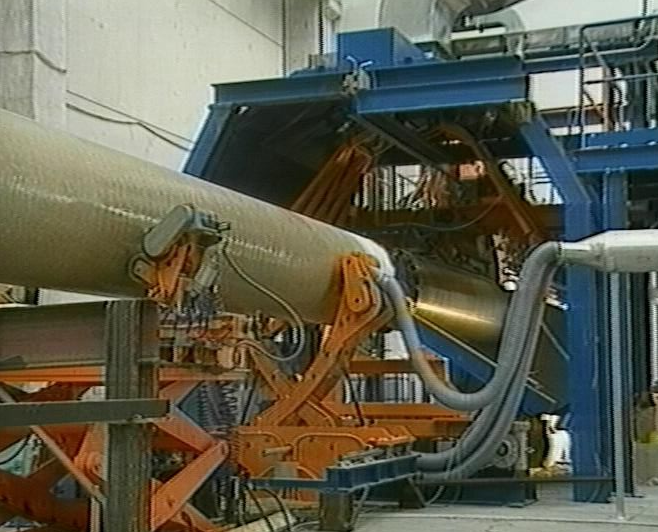

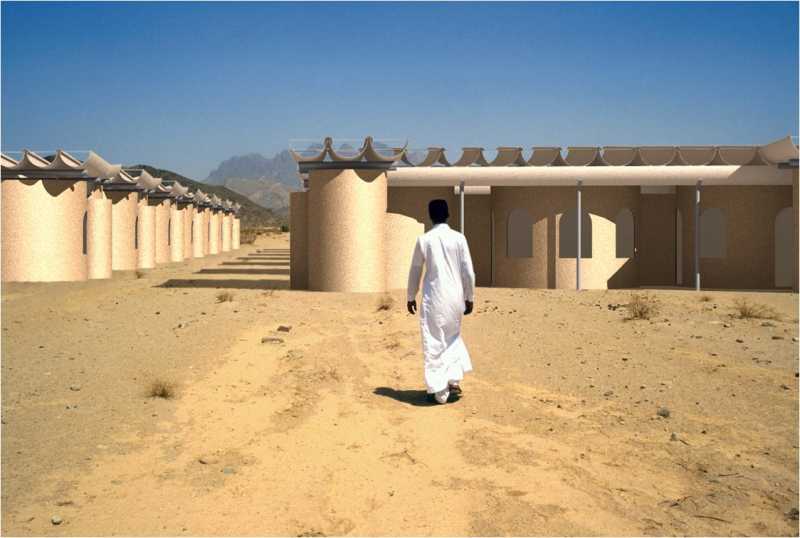

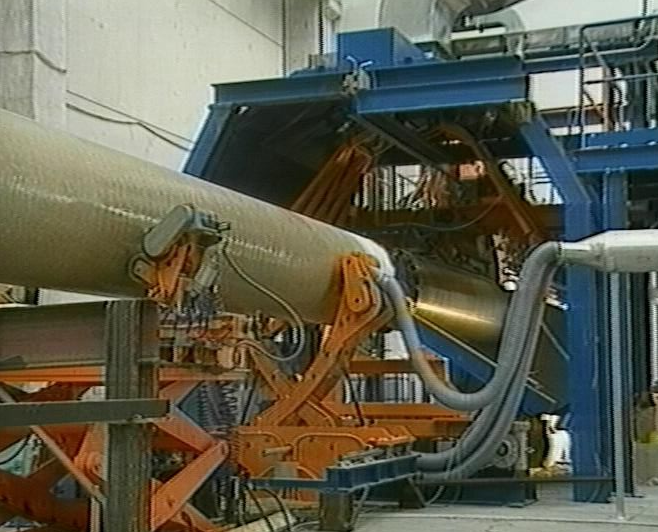

Cheap prefab houses and toilet compartment as well as water conducts made of glass fiber reinforced polyester.

By applying the proven GRP technology (glass fiber reinforced polyester tubes) from the pipeline and water industry storm, fire and earthquake safe, proper shelter homes can be produced on a large scale for people living at the base of the pyramid. They are deployable and even after a flood the elements can be reused.

The compound produced in a continuous process contains glassfiber, polyester and 50% sand.

The houses can be easily self-erected by its future owner by simple digging the large tubes about 0.5 m deep into the soil. The openings for windows and the door are cut out with a jig saw and reused. The roof collects the precious rainwater and stores it in a tank for personal use or irrigation. The lightweight roof is fixed with bamboo rods or similar and ropes. No heavy machinery needed.

They last for min. 50 years (guarantee granted in the pipeline industry).

The houses are resistant to all climatic influence whether in desert or tropical areas.

A single GRP plant can produce 2.500 family houses per year and even more with kitchen, toilet and roof starting at $ 4’000 ex works or less depending on numbers of rooms, or when more than one production line is in operation.

The same plant can produce water conducts and tanks for people, animals and irrigation. The water can be stored, purified, bottled and sold to create income.

By applying the proven GRP technology (glass fiber reinforced polyester tubes) from the pipeline and water industry storm, fire and earthquake safe, proper shelter homes can be produced on a large scale for people living at the base of the pyramid. They are deployable and even after a flood the elements can be reused.

The compound produced in a continuous process contains glassfiber, polyester and 50% sand.

The houses can be easily self-erected by its future owner by simple digging the large tubes about 0.5 m deep into the soil. The openings for windows and the door are cut out with a jig saw and reused. The roof collects the precious rainwater and stores it in a tank for personal use or irrigation. The lightweight roof is fixed with bamboo rods or similar and ropes. No heavy machinery needed.

They last for min. 50 years (guarantee granted in the pipeline industry).

The houses are resistant to all climatic influence whether in desert or tropical areas.

A single GRP plant can produce 2.500 family houses per year and even more with kitchen, toilet and roof starting at $ 4’000 ex works or less depending on numbers of rooms, or when more than one production line is in operation.

The same plant can produce water conducts and tanks for people, animals and irrigation. The water can be stored, purified, bottled and sold to create income.

Attachments:

-

HouseDet.1.jpg

(Filesize: 144KB)

HouseDet.1.jpg

(Filesize: 144KB)

-

414580_350...41_o.jpg

(Filesize: 38KB)

414580_350...41_o.jpg

(Filesize: 38KB)

-

Siedlungko...iert.gif

(Filesize: 93KB)

Siedlungko...iert.gif

(Filesize: 93KB)

-

GRPTubewin...unit.png

(Filesize: 750KB)

GRPTubewin...unit.png

(Filesize: 750KB)

The following user(s) like this post: mtfioravanti

Please Log in to join the conversation.

You need to login to reply

Share this thread:

- Announcements and miscellaneous

- General announcements

- Introductions, persons or companies offering their services or products

- Affordable, sustainable, safe habitats and toilet and pipe manufacturing

Recently active users. Who else has been active?

Time to create page: 0.159 seconds