- Resource recovery

- Vermitechnology

- Vermifilters (or vermi-digesters)

- Scaleable secondary treatment vermifilter design

Scaleable secondary treatment vermifilter design

6032 views

- HarryTams

-

Less

- Posts: 31

- Likes received: 14

I have taken note of the 10 meter height that that little pump can go and I do have at least 8 meters rise on this property above the pump under the primary digester. I can use a gravity system from the secondary digester to irrigate the fruit trees. Details for a dosing valve and sump would be appreciated.

Would there be any odour from the primary digester from a 1 toilet, 1 kitchen, one person system?

I'll be in Canada until early January so will not construct the system until mid January.

Harry

Please Log in to join the conversation.

You need to login to replyI describe this as second generation technology because it overcomes some of the key limitations to the currently commercialised technology. These include:

- retaining aerobic conditions throughout the media as scale (volume of media) increases

- Cost-effective scaleable construction that offers high treatment levels at low capital cost while using simple methods suitable for community ownership.

What attracted me to drainage cells is their strength. They are designed for large weight loads and by placing them vertically on edge all the cable ties do is hold them in place - there is almost no load on the cable ties. Cable ties also come in lots of sizes and are made from nylon - they are designed to be strong. Sure, there might be a height limit for such a structure, but because the structure is a lattice I would not expect there to be any problem up to 10m... which is way higher than I was imagining the optimum treatment height to be anyway.1. did you test that the structure is strong enough to contain the weight of the filter media once the filter becomes 3m or higher? I am specifically concerned about the cable binders, but also the drainage cells may not be made to hold weight.

2. filling the 'socks' in the column may not be easy once we get above 3m.

I'm not sure why, could you explain?

3. if you ever have to maintain the system, i.e. replacing the media because it has become blocked or polluted by misuse, you have no choice than dismantling all the relevant columns.

What maintenance are you envisaging? Certainly if you used inorganic media (gravels etc), porosity would decrease over time as the inter-particle spaces become occupied with humus. Because I only use organic media, the only issue would be initially topping up the media as it degrades. Once the media is a stable humus, topping up would become much less frequent and this would be easy anyway. Another issue could be compaction of the media. As reactor depth increases, the weight of the media could compress the media more in the lower section of the column. Thereore, I just don't know what depth of media is optimal and the only way to find out is to build prototypes. I would take a conservative approach to depth and start with 2m... perhaps be bold and try 3m. I would also suggest that 30mm core thickness drainage cells would never block during the normal life of a second generation vermifilter, but because worms are distributing their castings indiscriminately, some humus will end up in the cavity. Maybe 50 mm core thickness would be best. Or perhaps every 20-30 years the vermifilter would need to be dismantled, then reassembled. Not a deal breaker though... and if the structure requires dismantling and reassembling this would be very easy - a pair of cutters for the cable ties, one column at a time. The drainage cells wouldn't be damaged and could simply be assembled again. The socks would be emptied of contents in stages as the drainage cells are removed. Everything, including socks and media could be reused.

What examples of misuse would pollute the media such that it would need replacing? I can't think of circumstances where organic media would need to be replaced, and in fact vermi-humus should become a tradeable product for application as 'elite' media in vermifilters because of its longevity and performance.

I am not convinced that crates would look more professional, because in both cases I would expect the reactor to be clad in a sheet material (plywood, fibrolite, sheet metal), or perhaps even textile cloth. I believe there is a significant cost saving by using drainage cells, along with improved performance, over stacked crates.

cheers

Dean

Vermifilter.com

www.vermifilter.com

Please Log in to join the conversation.

You need to login to reply- hajo

-

- retired in Germany... but still interested in water and sanitation... especially in OSS... and especially in Africa...

Less- Posts: 288

- Karma: 15

- Likes received: 156

with the plastic drainage cells, I have the following concerns and questions:

- did you test that the structure is strong enough to contain the weight of the filter media once the filter becomes 3m or higher? I am specifically concerned about the cable binders, but also the drainage cells may not be made to hold weight.

- filling the 'socks' in the column may not be easy once we get above 3m.

- ... and if you ever have to maintain the system, i.e. replacing the media because it has become blocked or polluted by misuse, you have no choice than dismantling all the relevant columns.

And one aspect which I have to repeat again: the crates will look more professional than the drainage cells to prospective administrators and financiers who still need to be convinced of VC technology.

ciao

Hajo

Albert Einstein

Any intelligent fool can make things bigger and more complex... It takes a touch of a genius - and a lot of courage to move in the opposite direction.

E.F. Schumacher

Everything should be made as simple as possible, but not simpler.

Albert Einstein

Please Log in to join the conversation.

You need to login to replyCheers

Dean

Vermifilter.com

www.vermifilter.com

Please Log in to join the conversation.

You need to login to reply- HarryTams

-

Less

- Posts: 31

- Likes received: 14

I notice that the fruit bin pictured is vented. The ones i have seen here and used in vineyards are like tanks to hold grapes. Are we after bins that are vented?

I have a small fruit grove of a dozen trees bordered will tall native grass (Lomandra Elongata). In total about 75 square meters that will be irrigated from this set-up. Directly into the ground with flexible slotted 75mm drainage pipe.

Will this proposed set-up be sufficient?

Harry

Please Log in to join the conversation.

You need to login to replyyour toilet and kitchen sink can feed straight into a primary vermidigester, which filters out and decomposes the solids. Make it wide... the easiest materials for making one of these is a 1m3 fruit bin (the forklift type):

Textile cloth inside, with a 10cm layer of pine bark. Add the worms in a month or two.

The water filters through the media into a sump below the digester, where you can set up a 12v macerator pump and float switch at the bottom. This would pick up any sediment that settles and yes, you'd pump the liquid into the top of the secondary vermifilter.

I've had no problems with the seaflo 12v macerator, this lifts over 10 m head.

You'd really only need one secondary column, but you could make it say 2m high and the cavity in the drainage cell would provide ventilation between the substrate and the cladding.

I recommend composted bark as the medium, plenty of that in Tazzie! Good luck and let us know how you go...

cheers

Dean

Vermifilter.com

www.vermifilter.com

Attachments:

-

image.png

(Filesize: 275KB)

image.png

(Filesize: 275KB)

-

seaflo-macerator.jpg

(Filesize: 20KB)

seaflo-macerator.jpg

(Filesize: 20KB)

Please Log in to join the conversation.

You need to login to reply- HarryTams

-

Less

- Posts: 31

- Likes received: 14

Harry

Please Log in to join the conversation.

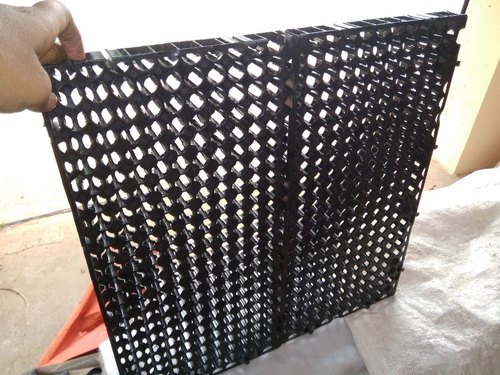

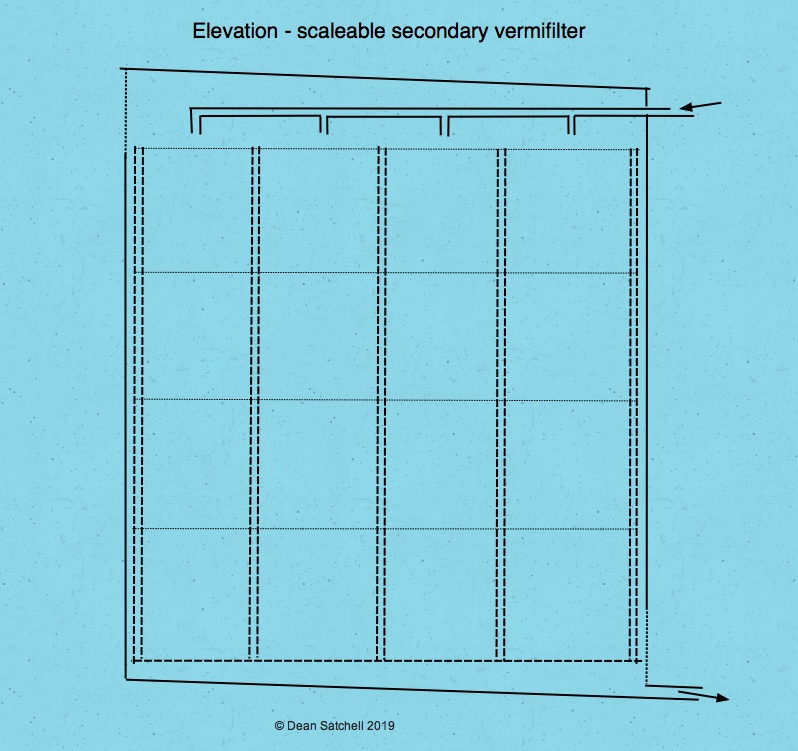

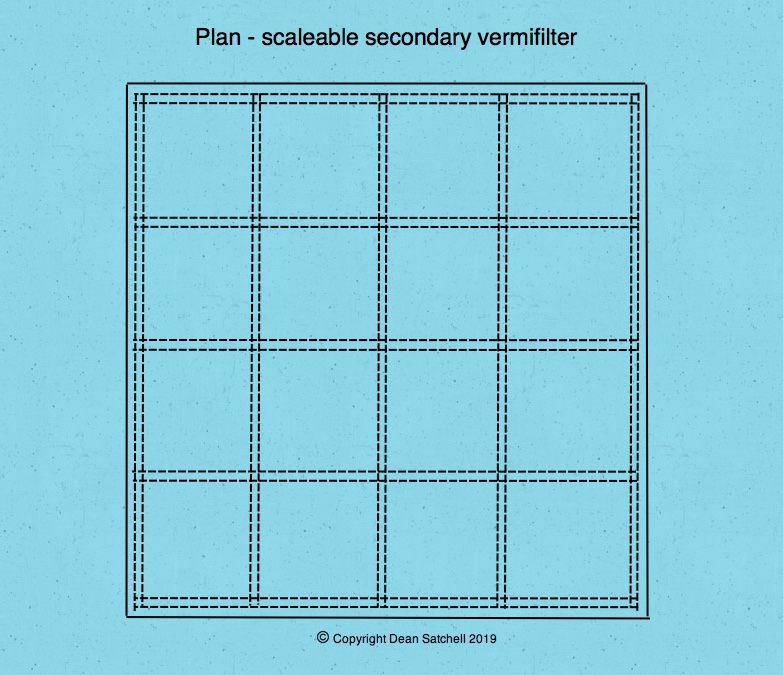

You need to login to replyThe design attaches vertical drainage cells together with cable ties into a self-supporting structure with cavities or "columns" that have a ventilated air space between them. 500 - 600 mm width drainage cells are the optimum size, each column has a single influent entry point at the top:

Each column is a vertical cavity the height of the structure. A textile cloth "sock" is inserted into each column and filled with media. The sock holds the media in place but also is free draining and allows worms to migrate from one column to the next:

The cavity in each drainage cell allows air to flow right around each column and throughout the full height of the column, ensuring adequate ventilation into the media regardless of how deep the reactor is. The deeper the reactor, the greater the level of treatment.

Note that walls and roof enclose the reactor and these have ventilation grills at both the bottom and top to allow for good passive air flow, but also restrict vermin and insect entry.

The structure would be installed on top of a false floor that allows ventilation underneath the reactor but also acts as a sump to direct flow of treated wastewater out of the reactor. The false floor could be made from plastic pallets that sit on a concrete surface:

This design is suitable for both recirculating and single pass commercial-scale secondary vermifilters and is fully scaleable for both depth and width by simply adding more drainage cells.

Vermifilter.com

www.vermifilter.com

Attachments:

-

plastic-dr...x500.jpg

(Filesize: 63KB)

plastic-dr...x500.jpg

(Filesize: 63KB)

-

secondaryc...ion2.jpg

(Filesize: 183KB)

secondaryc...ion2.jpg

(Filesize: 183KB)

-

secondaryc...lan2.jpg

(Filesize: 179KB)

secondaryc...lan2.jpg

(Filesize: 179KB)

-

textile.jpg

(Filesize: 189KB)

textile.jpg

(Filesize: 189KB)

-

plastic-pallet.jpg

(Filesize: 39KB)

plastic-pallet.jpg

(Filesize: 39KB)

Please Log in to join the conversation.

You need to login to reply- Resource recovery

- Vermitechnology

- Vermifilters (or vermi-digesters)

- Scaleable secondary treatment vermifilter design