- Resource recovery

- Resource recovery from excreta, faecal sludge or wastewater

- Production of biochar, fuel or electricity

- Pivot Plant: Converting human waste to fuel to finance complete sanitation (Waste Enterprisers Holding and Pivot Ltd, Kenya)

Pivot Plant: Converting human waste to fuel to finance complete sanitation (Waste Enterprisers Holding and Pivot Ltd, Kenya)

12.6k views

Re: Pivot Plant: Converting human waste to fuel to finance complete sanitation (Waste Enterprisers Holding and Pivot Ltd, Kenya)

Dear All

Yield of degraded sludge from pit latrine vary widely. It depends on medium of cleaning- water or paper etc, soil condition, retention time in pit. Further per capita quantity of human excreta also varies widely in different regions/ countries, also depending on dietary habit- vegetarian or non-vegetarian. I got 220 kg of degraded sludge from a leach pit toilet used by 4 members of a family daily. It was filled in 3 years and sludge was taken out after 2 years of its filling. Soil condition was clay sandy with water table more than 25 meters. It shows 17-18 kg of sludge per capita per year. In case of clay soil or high water table, sludge will have higher moisture content and hence higher weight.

Pawan

Yield of degraded sludge from pit latrine vary widely. It depends on medium of cleaning- water or paper etc, soil condition, retention time in pit. Further per capita quantity of human excreta also varies widely in different regions/ countries, also depending on dietary habit- vegetarian or non-vegetarian. I got 220 kg of degraded sludge from a leach pit toilet used by 4 members of a family daily. It was filled in 3 years and sludge was taken out after 2 years of its filling. Soil condition was clay sandy with water table more than 25 meters. It shows 17-18 kg of sludge per capita per year. In case of clay soil or high water table, sludge will have higher moisture content and hence higher weight.

Pawan

Pawan Jha

Chairman

Foundation for Environment and Sanitation

Mahavir Enclave

New Delhi 110045, India

Web: www.foundation4es.org

Linked: linkedin.com/in/drpkjha

Chairman

Foundation for Environment and Sanitation

Mahavir Enclave

New Delhi 110045, India

Web: www.foundation4es.org

Linked: linkedin.com/in/drpkjha

Please Log in to join the conversation.

You need to login to reply- kevintayler

-

- I am a water and sanitation engineer, also interested in general urban housing issues. In recent years, I have worked on FSM for various organizations

Less- Posts: 79

- Karma: 11

- Likes received: 46

Re: Pivot Plant: Converting human waste to fuel to finance complete sanitation (Waste Enterprisers Holding and Pivot Ltd, Kenya)

Dear All

Thanks for the reply from AMurray - sorry that I can't figure out your first name from the post - I did not realize that until I started to reply.

I think that my basic point regarding sludge quantity remains. The 60 litres per person per year figure quoted by EAWAG is based on earlier work and is not necessarily accurate. There is quite a lot of subsequent work on sludge quantities, which generally shows that accumulation rates are lower than this - although higher in Africa than in Asia. The other factor is the solids content of the sludge. This can indeed be quite high, as work by the people in e-Thekwini has shown.

The other factor to take into account is that the solids content of sludge tends to decrease with time so that there will generally be more solids content in fresh sludge than in digested sludge.

Overall, my point is that this is a key figure for the business case and is something that really needs further investigation. My own review of the literature shows that there are major variations in the figures for solid content of sludge.

On the other point, delivery of sludge to the processing site, I think that more will be needed to develop an effective collection and transport system. The system described in the link seems to rely entirely on gulpers and 50 gallon drums, which will presumably be carried in pick-ups. I wonder if anyone has done any analysis of the financial aspects of this. I would have thought that there would be a need for transfer stations with larger trucks to move sludge from residential areas to the processing plant. It would probably be worthwhile to explore different scenarios, bearing in mind Eric Dudley's question - what might go wrong?

I hope that this is helpful

Kevin

Thanks for the reply from AMurray - sorry that I can't figure out your first name from the post - I did not realize that until I started to reply.

I think that my basic point regarding sludge quantity remains. The 60 litres per person per year figure quoted by EAWAG is based on earlier work and is not necessarily accurate. There is quite a lot of subsequent work on sludge quantities, which generally shows that accumulation rates are lower than this - although higher in Africa than in Asia. The other factor is the solids content of the sludge. This can indeed be quite high, as work by the people in e-Thekwini has shown.

The other factor to take into account is that the solids content of sludge tends to decrease with time so that there will generally be more solids content in fresh sludge than in digested sludge.

Overall, my point is that this is a key figure for the business case and is something that really needs further investigation. My own review of the literature shows that there are major variations in the figures for solid content of sludge.

On the other point, delivery of sludge to the processing site, I think that more will be needed to develop an effective collection and transport system. The system described in the link seems to rely entirely on gulpers and 50 gallon drums, which will presumably be carried in pick-ups. I wonder if anyone has done any analysis of the financial aspects of this. I would have thought that there would be a need for transfer stations with larger trucks to move sludge from residential areas to the processing plant. It would probably be worthwhile to explore different scenarios, bearing in mind Eric Dudley's question - what might go wrong?

I hope that this is helpful

Kevin

Kevin Tayler

Independent water and sanitation consultant

Horsham

UK

Independent water and sanitation consultant

Horsham

UK

Please Log in to join the conversation.

You need to login to replyRe: Pivot Plant: Converting human waste to fuel to finance complete sanitation (Waste Enterprisers Holding and Pivot Ltd, Kenya)

Hi Kevin,

Thanks for your continued interest and engagement!

In short, you're right. The total solids numbers that Tim quoted are based on our best available information and make assumptions about collection rates, total solids generation, and freshness of the FS upon collection.

However, total solids accumulation on the order of 15 kg/person•year is supported in the literature. Eawag (1998) quotes pit latrine accumulation of 0.06 m3/person•year @ 20% solids after one year. This amounts to 12 kg solids. Cofie (2010) quotes an average daily solids accumulation of 47 g/person, which amounts to 17 kg solids/person•year. I'd also point out that our company was part of the FaME team that worked in Accra, Kampala, and Dakar and the reason the per capita numbers appear low for the latter two cities is that the researchers working on that portion of the study only counted FS that is currently being properly collected and transported to a designated dumping site (whether for treatment or straight disposal). They were intentionally conservative in order to calculate the minimum financial return on the reuse of FS that could be readily accessed.

Like many (dare I say most?) cities in sub-Saharan Africa, the majority of FS generated in the slum/informal settlements of Kampala and Dakar is informally emptied and dumped within the community itself. Mombasa is no exception, however, we're already working with pit latrine emptiers in informal communities to determine effective means and incentives for getting the waste out of the communities and to our production plant. (You can learn more about that work here: forum.susana.org/forum/categories/53-fae...nings-and-incentives )

We'll continue to keep this post updated with our progress and production rates as we learn more.

Thanks for your continued interest and engagement!

In short, you're right. The total solids numbers that Tim quoted are based on our best available information and make assumptions about collection rates, total solids generation, and freshness of the FS upon collection.

However, total solids accumulation on the order of 15 kg/person•year is supported in the literature. Eawag (1998) quotes pit latrine accumulation of 0.06 m3/person•year @ 20% solids after one year. This amounts to 12 kg solids. Cofie (2010) quotes an average daily solids accumulation of 47 g/person, which amounts to 17 kg solids/person•year. I'd also point out that our company was part of the FaME team that worked in Accra, Kampala, and Dakar and the reason the per capita numbers appear low for the latter two cities is that the researchers working on that portion of the study only counted FS that is currently being properly collected and transported to a designated dumping site (whether for treatment or straight disposal). They were intentionally conservative in order to calculate the minimum financial return on the reuse of FS that could be readily accessed.

Like many (dare I say most?) cities in sub-Saharan Africa, the majority of FS generated in the slum/informal settlements of Kampala and Dakar is informally emptied and dumped within the community itself. Mombasa is no exception, however, we're already working with pit latrine emptiers in informal communities to determine effective means and incentives for getting the waste out of the communities and to our production plant. (You can learn more about that work here: forum.susana.org/forum/categories/53-fae...nings-and-incentives )

We'll continue to keep this post updated with our progress and production rates as we learn more.

The following user(s) like this post: Elisabeth

Please Log in to join the conversation.

You need to login to reply- kevintayler

-

- I am a water and sanitation engineer, also interested in general urban housing issues. In recent years, I have worked on FSM for various organizations

Less- Posts: 79

- Karma: 11

- Likes received: 46

Re: Pivot Plant: Converting human waste to fuel to finance complete sanitation (Waste Enterprisers Holding and Pivot Ltd, Kenya)

Dear Tim

Thanks for your earlier answer. This topic has stimulated my interest. I have been working on other aspects of FSM over the last 3 years but have not really looked at re-use options.

I would like to return to my initial question concerning the amount of dried sludge available. Based on a population of 1.2 million, the 50 tonnes of dried solids per day requires around 15kg of dried solids per person per year. I assume that the 50 tonnes per year applies to total solids (TS). I gave some rough calculations in my earlier email, based on figures from South Africa but I have done some further research, using information from both the FAME report on Accra, Dakar and Kampala and older studies of septic tanks from Europe and North America. (See www.tremolet.com/publications/report-fin...ar-kampala-and-accra for the FAME report).

All these studies give per-capita TS production figures of the order of 2 - 4kg/yr.The only exception is Accra where the figure for public latrine sludge comes out at 13.8kg/c.yr but this is assuming that sludge production is 730 litres per capita per year, which is very high and presumably reflects the fact that almost fresh faeces is regularly removed from public toilets.

Based on these figures, I think that the 50 tonnes per day figure is optimistic, if it refers to total solids. It may be that it refers to partially dried solids but this would have implications for the calorific value. A study conducted for the work in Accra, Kampala and Dakar arrived at a figure of 17.3 MJ/kg total solids (TS). (See www.iwaponline.com/washdev/004/0223/0040223.pdf) and clearly the TS figure is the relevant one.

The calculation in my earlier email, based on information from South Africa, gives a higher per-capita TS figure. Interestingly, the South African figures are taken from pit latrines with very low water contents - typically around 65 - 75% depending on depth. At these moisture contents, sludge will not be liquid and will have to be dug out.

One last point about the FAME calculations is that they assume high per-capita sludge volumes, 573 litres per person per year in the case of Dakar and around 290 litres per person per year in Kampala. These figures are much higher than those generally quoted in the literature (20 - 70 litres per person per year for pit latrines and leach-pits and 70 - 100 litres per person per year for septic tanks (mainly based on research in Europe and North America).

Overall, it seems to me that there are quite a lot of uncertainties here. Perhaps the next step after determining the technical viability of the approach should be to carry out more detailed assessment of the total amount of dried sludge that will actually be available. One point to note here is that there is a need to accurately assess both the TS content of septage and the amount of septage produced, neither of which is easy. The FAME reports do try to cross-check, using different approaches but I would still be worried about their assumptions on per-capita production.

I hope that this is helpful

Kevin

Thanks for your earlier answer. This topic has stimulated my interest. I have been working on other aspects of FSM over the last 3 years but have not really looked at re-use options.

I would like to return to my initial question concerning the amount of dried sludge available. Based on a population of 1.2 million, the 50 tonnes of dried solids per day requires around 15kg of dried solids per person per year. I assume that the 50 tonnes per year applies to total solids (TS). I gave some rough calculations in my earlier email, based on figures from South Africa but I have done some further research, using information from both the FAME report on Accra, Dakar and Kampala and older studies of septic tanks from Europe and North America. (See www.tremolet.com/publications/report-fin...ar-kampala-and-accra for the FAME report).

All these studies give per-capita TS production figures of the order of 2 - 4kg/yr.The only exception is Accra where the figure for public latrine sludge comes out at 13.8kg/c.yr but this is assuming that sludge production is 730 litres per capita per year, which is very high and presumably reflects the fact that almost fresh faeces is regularly removed from public toilets.

Based on these figures, I think that the 50 tonnes per day figure is optimistic, if it refers to total solids. It may be that it refers to partially dried solids but this would have implications for the calorific value. A study conducted for the work in Accra, Kampala and Dakar arrived at a figure of 17.3 MJ/kg total solids (TS). (See www.iwaponline.com/washdev/004/0223/0040223.pdf) and clearly the TS figure is the relevant one.

The calculation in my earlier email, based on information from South Africa, gives a higher per-capita TS figure. Interestingly, the South African figures are taken from pit latrines with very low water contents - typically around 65 - 75% depending on depth. At these moisture contents, sludge will not be liquid and will have to be dug out.

One last point about the FAME calculations is that they assume high per-capita sludge volumes, 573 litres per person per year in the case of Dakar and around 290 litres per person per year in Kampala. These figures are much higher than those generally quoted in the literature (20 - 70 litres per person per year for pit latrines and leach-pits and 70 - 100 litres per person per year for septic tanks (mainly based on research in Europe and North America).

Overall, it seems to me that there are quite a lot of uncertainties here. Perhaps the next step after determining the technical viability of the approach should be to carry out more detailed assessment of the total amount of dried sludge that will actually be available. One point to note here is that there is a need to accurately assess both the TS content of septage and the amount of septage produced, neither of which is easy. The FAME reports do try to cross-check, using different approaches but I would still be worried about their assumptions on per-capita production.

I hope that this is helpful

Kevin

Kevin Tayler

Independent water and sanitation consultant

Horsham

UK

Independent water and sanitation consultant

Horsham

UK

Please Log in to join the conversation.

You need to login to replyRe: Pivot Plant: Converting human waste to fuel to finance complete sanitation (Waste Enterprisers Holding and Pivot Ltd, Kenya)

Dear Chris and Kevin,

Great questions and thanks for your interest in our work! We are currently under construction in Mombasa as well as working on some parallel projects for the sourcing of FS from the poorer areas of the city. Therefore, I'll have to ask for patience from the audience on answers to some of these questions - we would like to have specifics from the plant in full operation before spouting off.

Kevin to address your specific questions on volumes available we did a similar calculation and based that on the total population living in and very near Mombasa of 1.2 million people. Our estimate came to 50 tons per day. I don't have our formula or source off the top of my head but can get it for you. I believe we used WHO for our per person per day estimates but I'll have to check.

In terms of collection rate, we are estimating 80% collection at full scale - we are anticipating a minimum of a 2-3 year ramp up time to get there.

The other important aspect of collection that I should note is that we don't plan to do much of it ourselves. The parallel work we have running is to figure out the best incentives for local entrepreneurs to bring us sludge. We would love to pair technology coming from other Gates grantees with local business people in Mombasa and enable a thriving local market for sludge. The other avenue to pursue, again with Gates grantees is partnering with firms that are experts in collection but not "productizing" the FS. Firms like Sanergy or WSUP come to mind. But before we are able to do any of that, we need to get our demonstration plant built so that we fully understand our internal economics and operations and can go to potential partners with a solid proposal.

Great questions and thanks for your interest in our work! We are currently under construction in Mombasa as well as working on some parallel projects for the sourcing of FS from the poorer areas of the city. Therefore, I'll have to ask for patience from the audience on answers to some of these questions - we would like to have specifics from the plant in full operation before spouting off.

Kevin to address your specific questions on volumes available we did a similar calculation and based that on the total population living in and very near Mombasa of 1.2 million people. Our estimate came to 50 tons per day. I don't have our formula or source off the top of my head but can get it for you. I believe we used WHO for our per person per day estimates but I'll have to check.

In terms of collection rate, we are estimating 80% collection at full scale - we are anticipating a minimum of a 2-3 year ramp up time to get there.

The other important aspect of collection that I should note is that we don't plan to do much of it ourselves. The parallel work we have running is to figure out the best incentives for local entrepreneurs to bring us sludge. We would love to pair technology coming from other Gates grantees with local business people in Mombasa and enable a thriving local market for sludge. The other avenue to pursue, again with Gates grantees is partnering with firms that are experts in collection but not "productizing" the FS. Firms like Sanergy or WSUP come to mind. But before we are able to do any of that, we need to get our demonstration plant built so that we fully understand our internal economics and operations and can go to potential partners with a solid proposal.

~~-~-~~-~-~~-~-~~-~-~~-~-~~-~-~~-~-~~-~-

Timothy Wade, MBA

Partner and Chief Business Development Officer

Waste Enterprisers Holding LLC

Pivot Ltd.

Mobile: +1 206 650 8025

Skype: timwikoff

Timothy Wade, MBA

Partner and Chief Business Development Officer

Waste Enterprisers Holding LLC

Pivot Ltd.

Mobile: +1 206 650 8025

Skype: timwikoff

Please Log in to join the conversation.

You need to login to reply- kevintayler

-

- I am a water and sanitation engineer, also interested in general urban housing issues. In recent years, I have worked on FSM for various organizations

Less- Posts: 79

- Karma: 11

- Likes received: 46

Re: Pivot Plant: Converting human waste to fuel to finance complete sanitation (Waste Enterprisers Holding and Pivot Ltd, Kenya)

Dear Tim

I would like to follow up on Chris Canaday's question about the economic costs of the system. It would also be useful if you could provide some further information on how you plan to go to scale.

You say that the present plant can produce about 5 tonnes of fuel per day. You don't say what the ratio of fuel produced to feedstock of dried sludge is but I assume that it is not more than one.

Long-term sludge accumulation rates are typically of the order of 25 - 50 litres per person per year. According to the work done by Nwaneri et al in South Africa, the average water content of the top metre in a pit latrine, the part from which sludge is most likely to be removed is about 75%. Assuming that sludge removal equates to 40 litres per person per year, that equates to about 10kg of dry solids per year. The population of Mombasa is around 1 million so the amount of dry solids generated if every person in the city used a pit latrine and the sludge from all these pit latrines was collected, the amount of dry solids available would be about 10,000 tonnes per year or about 27 tonnes per day. My question here is whether there will be enough sludge to keep your proposed 40 tonnes per day plant going, bearing in mind that it will be hard to get 100% coverage of sludge collection services. Many people in peripheral areas are likely to build a new pit rather than empty their old one.

The economic question concerns the relationship of the cost of bringing all sludge to a single treatment site (as opposed to more localized solutions that involve less transport)and the sales potential from the fuel produced by the process. My impression is that the transport costs are going to be rather high. A related point is the balance between the fuel produced and the fuel used in bringing sludge to the treatment point.

I guess that you have looked at these points so it would be good if you can expand on them.

Thanks

Kevin Tayler

I would like to follow up on Chris Canaday's question about the economic costs of the system. It would also be useful if you could provide some further information on how you plan to go to scale.

You say that the present plant can produce about 5 tonnes of fuel per day. You don't say what the ratio of fuel produced to feedstock of dried sludge is but I assume that it is not more than one.

Long-term sludge accumulation rates are typically of the order of 25 - 50 litres per person per year. According to the work done by Nwaneri et al in South Africa, the average water content of the top metre in a pit latrine, the part from which sludge is most likely to be removed is about 75%. Assuming that sludge removal equates to 40 litres per person per year, that equates to about 10kg of dry solids per year. The population of Mombasa is around 1 million so the amount of dry solids generated if every person in the city used a pit latrine and the sludge from all these pit latrines was collected, the amount of dry solids available would be about 10,000 tonnes per year or about 27 tonnes per day. My question here is whether there will be enough sludge to keep your proposed 40 tonnes per day plant going, bearing in mind that it will be hard to get 100% coverage of sludge collection services. Many people in peripheral areas are likely to build a new pit rather than empty their old one.

The economic question concerns the relationship of the cost of bringing all sludge to a single treatment site (as opposed to more localized solutions that involve less transport)and the sales potential from the fuel produced by the process. My impression is that the transport costs are going to be rather high. A related point is the balance between the fuel produced and the fuel used in bringing sludge to the treatment point.

I guess that you have looked at these points so it would be good if you can expand on them.

Thanks

Kevin Tayler

Kevin Tayler

Independent water and sanitation consultant

Horsham

UK

Independent water and sanitation consultant

Horsham

UK

Please Log in to join the conversation.

You need to login to replyRe: Pivot Plant: Converting human waste to fuel to finance complete sanitation (Waste Enterprisers Holding and Pivot Ltd, Kenya)

Hi Tim,

What is the dewatering process?

So the sludge is dried, but not pyrolized or anything?

What temperatures are achieved, for how long, in the Thermal Drying stage?

Do you have a break-down of the economic and environmental costs of the system?

What does the final solid fuel look like? Is it a briquette?

Thanks for sharing this info. Good luck with your project. Please keep us informed.

Best wishes,

Chris Canaday

What is the dewatering process?

So the sludge is dried, but not pyrolized or anything?

What temperatures are achieved, for how long, in the Thermal Drying stage?

Do you have a break-down of the economic and environmental costs of the system?

What does the final solid fuel look like? Is it a briquette?

Thanks for sharing this info. Good luck with your project. Please keep us informed.

Best wishes,

Chris Canaday

Conservation Biologist and EcoSan Promoter

Omaere Ethnobotanical Park

Puyo, Pastaza, Ecuador, South America

inodoroseco.blogspot.com

Omaere Ethnobotanical Park

Puyo, Pastaza, Ecuador, South America

inodoroseco.blogspot.com

Please Log in to join the conversation.

You need to login to replyRe: Pivot Plant: Converting human waste to fuel to finance complete sanitation (Waste Enterprisers Holding and Pivot Ltd, Kenya)

Dear Pawan,

Thank you for your comments. And I totally agree that learning the limitations of a proposed solution is also important. Not every idea can succeed, so it is important to explore and document when something won't work.

For the FS to Biodiesel research in Ghana, there were a few challenges but the most vital resulted from the actual observed yields of lipids from FS. On average, our samples from exhauster trucks were recording about 9% lipid yield from 100% dried FS. However, as you know the trucks carry sludge that has a range of 1-5% TSS. The second negative twist that we observed was that only 50% of the lipids recovered were saponifiable (able to convert to diesel). Therefore for an average size truck of 8m3 carrying 3% TSS FS, we were only able to produce 13.5 liters of biodiesel. Due to the cost implications on both capex and opex to move that volume of liquid around, the production of biodiesel was untenable as a financially viable business.

Dr. Chandran of Columbia University (co-PI on the FS to BD grant) and several students are furthering the fermentation research to explore the possibility of raising yields by producing more FFA. However that work is ongoing and I'm not certain that it has the ability to raise the lipid level high enough to make biodiesel a viable business model. You would need to discuss with Dr. Chandran about that.

For the solid fuel - we agree that the stigma may be too great for individual buyers. Therefore we are targeting industrial users of biomass fuels. Any company with a large boiler or kiln. We have done this to avoid some of the stigma issues around the feedstock for the fuel. We have found that industrial users are concerned about safety but if those concerns can be satisfied by 3rd party lab results, they are willing to purchase the fuel.

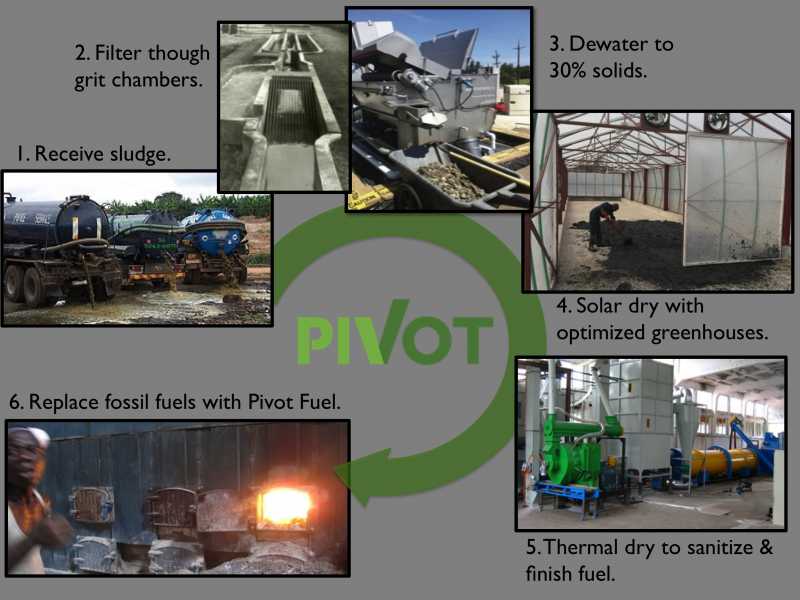

Regarding the process - you can see our process train in the attached picture from my last post. Happy to answer any direct questions you may have about that.

All the best,

Tim

Thank you for your comments. And I totally agree that learning the limitations of a proposed solution is also important. Not every idea can succeed, so it is important to explore and document when something won't work.

For the FS to Biodiesel research in Ghana, there were a few challenges but the most vital resulted from the actual observed yields of lipids from FS. On average, our samples from exhauster trucks were recording about 9% lipid yield from 100% dried FS. However, as you know the trucks carry sludge that has a range of 1-5% TSS. The second negative twist that we observed was that only 50% of the lipids recovered were saponifiable (able to convert to diesel). Therefore for an average size truck of 8m3 carrying 3% TSS FS, we were only able to produce 13.5 liters of biodiesel. Due to the cost implications on both capex and opex to move that volume of liquid around, the production of biodiesel was untenable as a financially viable business.

Dr. Chandran of Columbia University (co-PI on the FS to BD grant) and several students are furthering the fermentation research to explore the possibility of raising yields by producing more FFA. However that work is ongoing and I'm not certain that it has the ability to raise the lipid level high enough to make biodiesel a viable business model. You would need to discuss with Dr. Chandran about that.

For the solid fuel - we agree that the stigma may be too great for individual buyers. Therefore we are targeting industrial users of biomass fuels. Any company with a large boiler or kiln. We have done this to avoid some of the stigma issues around the feedstock for the fuel. We have found that industrial users are concerned about safety but if those concerns can be satisfied by 3rd party lab results, they are willing to purchase the fuel.

Regarding the process - you can see our process train in the attached picture from my last post. Happy to answer any direct questions you may have about that.

All the best,

Tim

~~-~-~~-~-~~-~-~~-~-~~-~-~~-~-~~-~-~~-~-

Timothy Wade, MBA

Partner and Chief Business Development Officer

Waste Enterprisers Holding LLC

Pivot Ltd.

Mobile: +1 206 650 8025

Skype: timwikoff

Timothy Wade, MBA

Partner and Chief Business Development Officer

Waste Enterprisers Holding LLC

Pivot Ltd.

Mobile: +1 206 650 8025

Skype: timwikoff

Please Log in to join the conversation.

You need to login to replyRe: Pivot Plant: Converting human waste to fuel to finance complete sanitation (Waste Enterprisers Holding and Pivot Ltd, Kenya)

Dear Tim

To know something is not possible, is also an achievement. It will help save time and money of other researchers. But the point is what went wrong? Your process of biodiesel production appeared to be lucrative. Is there any problem with the process or technically not feasible to achieve the assumptions. I remember you had mentioned the production of 10% VFA from FSM.

Solid fuel should not be the problem. However, its social acceptability may have some problem in some communities. You may like to mention your process to make such fuels.

Regards

Pawan

To know something is not possible, is also an achievement. It will help save time and money of other researchers. But the point is what went wrong? Your process of biodiesel production appeared to be lucrative. Is there any problem with the process or technically not feasible to achieve the assumptions. I remember you had mentioned the production of 10% VFA from FSM.

Solid fuel should not be the problem. However, its social acceptability may have some problem in some communities. You may like to mention your process to make such fuels.

Regards

Pawan

Pawan Jha

Chairman

Foundation for Environment and Sanitation

Mahavir Enclave

New Delhi 110045, India

Web: www.foundation4es.org

Linked: linkedin.com/in/drpkjha

Chairman

Foundation for Environment and Sanitation

Mahavir Enclave

New Delhi 110045, India

Web: www.foundation4es.org

Linked: linkedin.com/in/drpkjha

Please Log in to join the conversation.

You need to login to replyRe: Pivot Plant: Converting human waste to fuel to finance complete sanitation (Waste Enterprisers Holding and Pivot Ltd, Kenya)

Hi Marijn,

Thanks for your questions and interest in our work. The biodiesel route has been shelved. Our research led us to some concrete conclusions about the overall business case for biodiesel from FS not being a viable one. I believe you can read more about that in the discussion string about the project started by Melanie Valencia (forum.susana.org/forum/categories/98-res...usa-and-kumasi-ghana).

Regarding the new project, you are correct that we have switched to a solid fuel product. Our process train has 3 major components - dewatering, solar drying and thermal drying. I've attached an image to show you the process train.

It should be noted that we have produced approximately 25 tons of fuel at pilot scale and conducted burning trials but that we have yet to run a plant of substantial scale. We are currently building a plant that will produce 5 tons of fuel per day. With this demonstration scale, we will be able to prove the economics and performance of our dewatering solution and our optimized greenhouses.

Thanks for your questions and interest in our work. The biodiesel route has been shelved. Our research led us to some concrete conclusions about the overall business case for biodiesel from FS not being a viable one. I believe you can read more about that in the discussion string about the project started by Melanie Valencia (forum.susana.org/forum/categories/98-res...usa-and-kumasi-ghana).

Regarding the new project, you are correct that we have switched to a solid fuel product. Our process train has 3 major components - dewatering, solar drying and thermal drying. I've attached an image to show you the process train.

It should be noted that we have produced approximately 25 tons of fuel at pilot scale and conducted burning trials but that we have yet to run a plant of substantial scale. We are currently building a plant that will produce 5 tons of fuel per day. With this demonstration scale, we will be able to prove the economics and performance of our dewatering solution and our optimized greenhouses.

~~-~-~~-~-~~-~-~~-~-~~-~-~~-~-~~-~-~~-~-

Timothy Wade, MBA

Partner and Chief Business Development Officer

Waste Enterprisers Holding LLC

Pivot Ltd.

Mobile: +1 206 650 8025

Skype: timwikoff

Timothy Wade, MBA

Partner and Chief Business Development Officer

Waste Enterprisers Holding LLC

Pivot Ltd.

Mobile: +1 206 650 8025

Skype: timwikoff

Attachments:

-

Slide1.jpg

(Filesize: 51KB)

Slide1.jpg

(Filesize: 51KB)

The following user(s) like this post: Marijn Zandee

Please Log in to join the conversation.

You need to login to replyRe: Pivot Plant: Converting human waste to fuel to finance complete sanitation (Waste Enterprisers Holding and Pivot Ltd, Kenya)

Dear Tim,

Some brief questions,

Can you tell us some more about the technology you are planning to use for this new project in Kenya? The project in Ghana you referred to was focused on producing bio diesel and this one seems focused on producing a solid fuel. Therefore , I am curious if the biodiesel route has been shelved and what technology for creating a solid fuel you have in mind.

Success with your project,

Marijn

Some brief questions,

Can you tell us some more about the technology you are planning to use for this new project in Kenya? The project in Ghana you referred to was focused on producing bio diesel and this one seems focused on producing a solid fuel. Therefore , I am curious if the biodiesel route has been shelved and what technology for creating a solid fuel you have in mind.

Success with your project,

Marijn

Marijn Zandee

E: This email address is being protected from spambots. You need JavaScript enabled to view it.

E: This email address is being protected from spambots. You need JavaScript enabled to view it.

Please Log in to join the conversation.

You need to login to replyPivot Plant: Converting human waste to fuel to finance complete sanitation (Waste Enterprisers Holding and Pivot Ltd, Kenya)

I would like to introduce to you today a new grant that we recently received from the Bill & Melinda Gates Foundation.

Name of lead organization: Pivot Ltd

Title of project: Pivot Plant: Converting human waste to fuel to finance complete sanitation

Primary contact at lead organization:

Dr. Ashley Muspratt, Founder and CEO Waste Enterprisers Holding and Pivot Ltd

Grantee location: Mombasa, Kenya

Developing country where the research will be tested: Mombasa, Kenya

Start and end date: July 8, 2014 – May 31, 2015

Grant type: Other (belongs to Urban Sanitation Marketing portfolio of WSH team)

See here:

www.gatesfoundation.org/How-We-Work/Quic...s/2014/07/OPP1109150

Grant size: US$ 251,600

Short description of the project:

Pivot is building our first fecal sludge to solid fuel facility (called Pivot Works) that will act as a commercial-scale demonstration factory. When successful, this sanitation process and business model will dramatically lower the barrier to delivering complete sanitation in low-income urban areas of developing countries by generating a viable revenue stream from the sale of fecal sludge-derived by-products.

Goal(s):

Further information:

Website: www.pivotworks.co/

Related discussion on the forum:

forum.susana.org/forum/categories/99-fae...-and-incentives#9454

Current state of affairs:

Currently, we are under construction, specifically the initial stage of site preparation. We plan to continue construction into November and begin producing Pivot Fuel by the end of the year.

Biggest successes so far:

Local buy-in and operating approvals for the pilot facility

Main challenges / frustration:

Working with local officials to explain the benefits of improved FS management in their city

Negotiating purchase agreements with customers prior to having the approvals from local authorities.

We will test the assumption that building this demo plant will both increase the willingness of local authorities to approve similar projects in the future as well as give new customers the confidence they need to enter into long-term purchase agreements.

I am happy to answer any questions you may have.

Regards,

Tim

P.S. The organisation that I work for was previously also involved in this grant which was also funded by the Bill & Melinda Gates Foundation:

Faecal sludge to biodiesel

forum.susana.org/forum/categories/98-res...usa-and-kumasi-ghana

The reason for the move from Ghana to Kenya was based on market research for the solid fuel. We need cement companies to buy the product but currently there aren't any kilns operating in Ghana.

Name of lead organization: Pivot Ltd

Title of project: Pivot Plant: Converting human waste to fuel to finance complete sanitation

Primary contact at lead organization:

Dr. Ashley Muspratt, Founder and CEO Waste Enterprisers Holding and Pivot Ltd

Grantee location: Mombasa, Kenya

Developing country where the research will be tested: Mombasa, Kenya

Start and end date: July 8, 2014 – May 31, 2015

Grant type: Other (belongs to Urban Sanitation Marketing portfolio of WSH team)

See here:

www.gatesfoundation.org/How-We-Work/Quic...s/2014/07/OPP1109150

Grant size: US$ 251,600

Short description of the project:

Pivot is building our first fecal sludge to solid fuel facility (called Pivot Works) that will act as a commercial-scale demonstration factory. When successful, this sanitation process and business model will dramatically lower the barrier to delivering complete sanitation in low-income urban areas of developing countries by generating a viable revenue stream from the sale of fecal sludge-derived by-products.

Goal(s):

- Build a facility in Mombasa, Kenya with an initial capacity of 5 tonnes Pivot Fuel per day

- Significantly de-risk the project and unleash commercial capital to take the plant to its full-scale of 40 tonnes Pivot Fuel per day

- Leverage this demonstration plant to generate a pipeline of expansion opportunities, furthering the vision of radically improving public and environmental health in cities across sub-Saharan Africa and beyond.

- Refine the technical process at scale

- Validate the financial assumptions and business model

- Demonstrate ability to deliver and close sales

- Secure a large-volume long-term purchase agreement from a customer operating in Mombasa

- Develop a pattern of reliable revenue generation

- Work with potential technology and community partners to test effective collection pilots for sourcing FS from the poorest communities

Further information:

Website: www.pivotworks.co/

Related discussion on the forum:

forum.susana.org/forum/categories/99-fae...-and-incentives#9454

Current state of affairs:

Currently, we are under construction, specifically the initial stage of site preparation. We plan to continue construction into November and begin producing Pivot Fuel by the end of the year.

Biggest successes so far:

Local buy-in and operating approvals for the pilot facility

Main challenges / frustration:

Working with local officials to explain the benefits of improved FS management in their city

Negotiating purchase agreements with customers prior to having the approvals from local authorities.

We will test the assumption that building this demo plant will both increase the willingness of local authorities to approve similar projects in the future as well as give new customers the confidence they need to enter into long-term purchase agreements.

I am happy to answer any questions you may have.

Regards,

Tim

P.S. The organisation that I work for was previously also involved in this grant which was also funded by the Bill & Melinda Gates Foundation:

Faecal sludge to biodiesel

forum.susana.org/forum/categories/98-res...usa-and-kumasi-ghana

The reason for the move from Ghana to Kenya was based on market research for the solid fuel. We need cement companies to buy the product but currently there aren't any kilns operating in Ghana.

~~-~-~~-~-~~-~-~~-~-~~-~-~~-~-~~-~-~~-~-

Timothy Wade, MBA

Partner and Chief Business Development Officer

Waste Enterprisers Holding LLC

Pivot Ltd.

Mobile: +1 206 650 8025

Skype: timwikoff

Timothy Wade, MBA

Partner and Chief Business Development Officer

Waste Enterprisers Holding LLC

Pivot Ltd.

Mobile: +1 206 650 8025

Skype: timwikoff

Please Log in to join the conversation.

You need to login to reply

Share this thread:

- Resource recovery

- Resource recovery from excreta, faecal sludge or wastewater

- Production of biochar, fuel or electricity

- Pivot Plant: Converting human waste to fuel to finance complete sanitation (Waste Enterprisers Holding and Pivot Ltd, Kenya)

Recently active users. Who else has been active?

Time to create page: 0.223 seconds