- Resource recovery

- Resource recovery from excreta, faecal sludge or wastewater

- Production of biochar, fuel or electricity

- Hybrid Microbial-Electrochemical System for Wastewater Treatment (Texas A&M University, USA)

Hybrid Microbial-Electrochemical System for Wastewater Treatment (Texas A&M University, USA)

10.1k views

Re: Questions for Arum - Hybrid Microbial-Electrochemical System for Waste Utilization

Dear Arum,

Thank you for sharing your results. It is very interesting to read about your fascinating and high-tech treatment approach.

As you mentioned in the presentation of your project, you have been testing the electrodes in a scaled-up system as well as testing the electrodes in a MEC setting for hydrogen production. What is the current state of this work? Has it been possible to achieve your goals from an energy generation point of view?

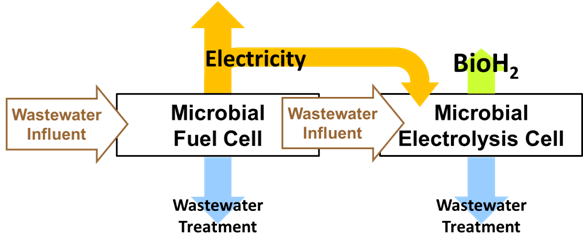

From the figure that you attached to your post, two different wastewater streams can be distinguished. Are these two streams (from MFC and MEC) installed in series? What is the result when it comes to the treatment of wastewater? Do you have to combine this technology with other methods to achieve desired treatment efficiencies?

Adapting advanced technologies to become applicable outside the lab, and even more so in a developing country context, is in most cases a big challenge. Are you developing or planning to carry out pilots in a real “setting” in the US and elsewhere? What are your strategies concerning this issue; considering costs (initial investments, O&M), capacity of locals, availability of process materials, etc?

Looking forward to get an update on your research.

Best regards,

Arno and team

Thank you for sharing your results. It is very interesting to read about your fascinating and high-tech treatment approach.

As you mentioned in the presentation of your project, you have been testing the electrodes in a scaled-up system as well as testing the electrodes in a MEC setting for hydrogen production. What is the current state of this work? Has it been possible to achieve your goals from an energy generation point of view?

From the figure that you attached to your post, two different wastewater streams can be distinguished. Are these two streams (from MFC and MEC) installed in series? What is the result when it comes to the treatment of wastewater? Do you have to combine this technology with other methods to achieve desired treatment efficiencies?

Adapting advanced technologies to become applicable outside the lab, and even more so in a developing country context, is in most cases a big challenge. Are you developing or planning to carry out pilots in a real “setting” in the US and elsewhere? What are your strategies concerning this issue; considering costs (initial investments, O&M), capacity of locals, availability of process materials, etc?

Looking forward to get an update on your research.

Best regards,

Arno and team

Arno Rosemarin PhD

Stockholm Environment Institute

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.sei.org

www.ecosanres.org

Stockholm Environment Institute

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.sei.org

www.ecosanres.org

Please Log in to join the conversation.

You need to login to replyRe: Hybrid Microbial-Electrochemical System for Wastewater Treatment (Texas A&M University, USA)

Dear Arum,

Thanks for introducing your highly innovative project on wastewater treatment.

With this mail I just want to give attention to the video from your presentation at the 2nd Fecal Sludge Management Conference in Durban (2012), in order to give all Forum users access to more information about this project.

Best regards,

Kim

Thanks for introducing your highly innovative project on wastewater treatment.

With this mail I just want to give attention to the video from your presentation at the 2nd Fecal Sludge Management Conference in Durban (2012), in order to give all Forum users access to more information about this project.

Best regards,

Kim

Kim Andersson

Stockholm Environment Institute

Postbox 24218,104 51 Stockholm, Sweden

This email address is being protected from spambots. You need JavaScript enabled to view it.

Stockholm Environment Institute

Postbox 24218,104 51 Stockholm, Sweden

This email address is being protected from spambots. You need JavaScript enabled to view it.

Please Log in to join the conversation.

You need to login to replyHybrid Microbial-Electrochemical System for Wastewater Treatment (Texas A&M University, USA)

Dear all,

I’m pleased to share our work on the Forum. We are interested in solving grand challenge problems in the broad area of health and energy through the use of micro/nano systems technology. This particular research shown below has been supported by the Bill & Melinda Gates Foundation.

Title of grant: Hybrid Microbial-Electrochemical System for Waste Utilization

Lead organization: Texas A&M University, College Station, TX, USA

Start and end date: November 01, 2011 – October 31, 2013

Short description of the project: This project aims to develop a self-sustainable system for simultaneous wastewater treatment and electricity/biogas generation. This hybrid system is composed of a microbial fuel cell (MFC) to generate electricity from wastewater to directly power a microbial electrolysis cell (MEC) system to produce biogas (biomethane and biohydrogen) for clean combustible fuel. Recent developments in bioelectrochemical systems (BESs) such MFCs and MECs enabled clean production of electricity and hydrogen from organic substrates in wastewater through the use of bacterial catalysis. However several challenges remain. MFCs have not been put to practical use because of its low power density compared with other fuel cell technologies. MEC technology needs external power to overcome the thermodynamic barriers to produce hydrogen gas.

Goal: The goal of this project is to develop a hybrid microbial fuel cell (MFC) – microbial electrolysis cell (MEC) system using low-cost highly-efficient 3D multi-length scale porous matrix electrodes decorated with carbon nanotubes and nanoparticle catalysts for simultaneous wastewater treatment and electricity/biogas production.

Objectives: The hybrid MFC-MEC coupled system being developed here directly generates electricity from wastewater using locally available electrochemically active bacteria, which is then utilized by the MFC/MEC system to generate high-purity biohydrogen. This biohydrgen can be then used as clean combustible fuel sources. The highly efficient and low-cost MFC-MEC system is enabled by 3D multi-length scale porous matrix electrodes decorated with carbon nanotubes and nanoparticle catalysts. This electrode can accelerate and significantly improve microbe-electrode interaction and thus improve the microbial electron transfer efficiency.

Current state of affairs: We have successfully developed highly efficient nanomaterial-based electrodes and have tested their performances in MECs. We are currently working on testing the electrodes in a scaled-up system as well as testing the electrodes in an MEC setting for hydrogen production.

Biggest successes so far:

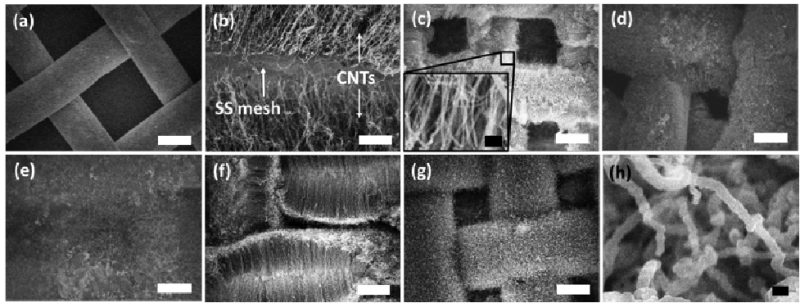

1. Multi-wall carbon nanotube (MWCNT) directly grown on stainless steel mesh (SSM) for dramatic improvement of MFC electricity generation efficiency

Our electrodes consist of multi-wall carbon nanotubes (MWCNTs) directly grown in the radial direction from the wires of stainless steel (SS) meshes, providing extremely large three-dimensional surfaces while ensuring minimal ohmic loss between CNTs and SS meshes. We succeeded to fabricate diverse characteristics of MWCNTs directly on SSM providing relatively larger sites for microbe and electrode interactions and higher conductivity and more conduits for electron transfer. The power densities obtained with these anodes were 540-fold higher compared to unmodified SS mesh, which far exceeded the highest reported improvements for MFCs with nanomaterial-decorated electrodes. See Figure 1 for details.

Figure 1. As-synthesized CNT-SS mesh electrodes: CNTs were directly grown in the radial direction from the cylindrical wires of SS meshes. (a) A bare SS mesh without CNTs for reference. (b) CNTs on a SS mesh partially scratched off to expose both the SS mesh and CNTs to show the physical contacts between them. The average lengths of CNTs for Sample A (c), Sample B (d), and Sample C (e) were respectively short (~8 μm), intermediate (~13 μm), and long (~19 μm). The length of the CNTs were measured based on the size of the open area between the SS mesh wires (see the decreasing rectangular open areas between the mesh wires in (c-e) compared to the bare SS mesh in (a). The holes of the SS mesh in Sample C were almost filled by CNTs, compared to ~38-μm square opening without CNTs in (a). (f) Sample D showing aligned and densely packed CNTs compared to the other CNTs. (g) Sample E showing amorphous carbon layers intentionally deposited to alter the electrical contacts between CNTs and microbes. (h) The diameter of CNTs with amorphous carbon layers in Sample E is larger than that of Sample A shown in the inset of (c). Scale bars of (a) and (c-g) indicate 20 μm; (b) 2 μm; and the inset of (c) and (h) 200 nm.

2. Design principles that enable the development of high-performance carbon nanotube (CNT)-based electrodes in bioelectrochemical systems (BESs)

Our investigation of length, packing density, and surface conditions of CNTs lead to understanding of the effective charge transfer between microbes and electrodes, and provides insight into methods broadly applicable to developing highly efficient microbial electrochemical cells.

It was found that the longer CNTs provided more sites for microbes to transfer charge, resulting in higher power output. It was also important to maintain large enough spaces between CNTs for microbes to be intercalated in between. We also found that the graphitic layer of CNTs with minimum amorphous carbon provided an excellent substrate for charge interaction. The results of this systematic study offer great potential for advancing the development of microbial electrochemical systems by providing a highly efficient nanomaterial-based electrode that delivers large surface area, high electrochemical activity, and minimum ohmic loss.

Main challenges: One of the main challenges was to successfully synthesize CNTs on various low-cost bare electrodes. Different CNT conditions resulted in different power performance, so process optimization was the biggest challenge. This challenge has now been solved. The second challenge is to have enough voltage from a single MFC. We are currently working on connecting multiple MFCs to produce enough voltage to directly drive MEC hydrogen production. However with the biggest challenge solved now, we believe we can move rapidly towards testing the electrodes in a scaled-up system as well as address the hybrid MFC-MEC connection challenge.

Links and further readings:

www.susana.org/images/documents/07-cap-d...m-university-usa.pdf

Hou, H., Li, L., Cho, Y., de Figueiredo, P., Han, A. 2009. Microfabricated Microbial Fuel Cell Arrays Reveal Electrochemically Active Microbes. PLoS ONE, 4(8 ), e6570.

Hou, H., Li, L., de Figueiredo, P., Han, A. 2011. Air-cathode microbial fuel cell array: A device for identifying and characterizing electrochemically active microbes. Biosensors and Bioelectronics, 26(5), 2680-2684.

Hou, H., Li, L., Ceylan, C.U., Haynes, A., Cope, J., Wilkinson, H.H., Erbay, C., Figueiredo, P.d., Han, A. 2012. A microfluidic microbial fuel cell array that supports long-term multiplexed analyses of electricigens. Lab on a Chip, 12(20), 4151-4159.

Han, A., Hou, H., Li, L., Kim, H. S., and de Figueiredo, P. 2013. Microfabricated Devices in Microbial Bioenergy Sciences. Trends in Biotechnology, Vol. 31 (4), pp. 225-232.

Arum Han, Ph.D.

Director, NanoBio Systems Lab.

Associate Professor

Dept. Electrical and Computer Engineering &

Dept. Biomedical Engineering

Texas A&M University

Faculty of Texas A&M Health Science Center

Faculty of Texas A&M Institute for Neuroscience

309C WERC, TAMU 3128 College Station, TX 77843-3128

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Phone: 979-845-9686

Fax: 979-845-6259

Homepage: biomems.tamu.edu

I’m pleased to share our work on the Forum. We are interested in solving grand challenge problems in the broad area of health and energy through the use of micro/nano systems technology. This particular research shown below has been supported by the Bill & Melinda Gates Foundation.

Title of grant: Hybrid Microbial-Electrochemical System for Waste Utilization

Lead organization: Texas A&M University, College Station, TX, USA

Start and end date: November 01, 2011 – October 31, 2013

Short description of the project: This project aims to develop a self-sustainable system for simultaneous wastewater treatment and electricity/biogas generation. This hybrid system is composed of a microbial fuel cell (MFC) to generate electricity from wastewater to directly power a microbial electrolysis cell (MEC) system to produce biogas (biomethane and biohydrogen) for clean combustible fuel. Recent developments in bioelectrochemical systems (BESs) such MFCs and MECs enabled clean production of electricity and hydrogen from organic substrates in wastewater through the use of bacterial catalysis. However several challenges remain. MFCs have not been put to practical use because of its low power density compared with other fuel cell technologies. MEC technology needs external power to overcome the thermodynamic barriers to produce hydrogen gas.

Goal: The goal of this project is to develop a hybrid microbial fuel cell (MFC) – microbial electrolysis cell (MEC) system using low-cost highly-efficient 3D multi-length scale porous matrix electrodes decorated with carbon nanotubes and nanoparticle catalysts for simultaneous wastewater treatment and electricity/biogas production.

Objectives: The hybrid MFC-MEC coupled system being developed here directly generates electricity from wastewater using locally available electrochemically active bacteria, which is then utilized by the MFC/MEC system to generate high-purity biohydrogen. This biohydrgen can be then used as clean combustible fuel sources. The highly efficient and low-cost MFC-MEC system is enabled by 3D multi-length scale porous matrix electrodes decorated with carbon nanotubes and nanoparticle catalysts. This electrode can accelerate and significantly improve microbe-electrode interaction and thus improve the microbial electron transfer efficiency.

Current state of affairs: We have successfully developed highly efficient nanomaterial-based electrodes and have tested their performances in MECs. We are currently working on testing the electrodes in a scaled-up system as well as testing the electrodes in an MEC setting for hydrogen production.

Biggest successes so far:

1. Multi-wall carbon nanotube (MWCNT) directly grown on stainless steel mesh (SSM) for dramatic improvement of MFC electricity generation efficiency

Our electrodes consist of multi-wall carbon nanotubes (MWCNTs) directly grown in the radial direction from the wires of stainless steel (SS) meshes, providing extremely large three-dimensional surfaces while ensuring minimal ohmic loss between CNTs and SS meshes. We succeeded to fabricate diverse characteristics of MWCNTs directly on SSM providing relatively larger sites for microbe and electrode interactions and higher conductivity and more conduits for electron transfer. The power densities obtained with these anodes were 540-fold higher compared to unmodified SS mesh, which far exceeded the highest reported improvements for MFCs with nanomaterial-decorated electrodes. See Figure 1 for details.

Figure 1. As-synthesized CNT-SS mesh electrodes: CNTs were directly grown in the radial direction from the cylindrical wires of SS meshes. (a) A bare SS mesh without CNTs for reference. (b) CNTs on a SS mesh partially scratched off to expose both the SS mesh and CNTs to show the physical contacts between them. The average lengths of CNTs for Sample A (c), Sample B (d), and Sample C (e) were respectively short (~8 μm), intermediate (~13 μm), and long (~19 μm). The length of the CNTs were measured based on the size of the open area between the SS mesh wires (see the decreasing rectangular open areas between the mesh wires in (c-e) compared to the bare SS mesh in (a). The holes of the SS mesh in Sample C were almost filled by CNTs, compared to ~38-μm square opening without CNTs in (a). (f) Sample D showing aligned and densely packed CNTs compared to the other CNTs. (g) Sample E showing amorphous carbon layers intentionally deposited to alter the electrical contacts between CNTs and microbes. (h) The diameter of CNTs with amorphous carbon layers in Sample E is larger than that of Sample A shown in the inset of (c). Scale bars of (a) and (c-g) indicate 20 μm; (b) 2 μm; and the inset of (c) and (h) 200 nm.

2. Design principles that enable the development of high-performance carbon nanotube (CNT)-based electrodes in bioelectrochemical systems (BESs)

Our investigation of length, packing density, and surface conditions of CNTs lead to understanding of the effective charge transfer between microbes and electrodes, and provides insight into methods broadly applicable to developing highly efficient microbial electrochemical cells.

It was found that the longer CNTs provided more sites for microbes to transfer charge, resulting in higher power output. It was also important to maintain large enough spaces between CNTs for microbes to be intercalated in between. We also found that the graphitic layer of CNTs with minimum amorphous carbon provided an excellent substrate for charge interaction. The results of this systematic study offer great potential for advancing the development of microbial electrochemical systems by providing a highly efficient nanomaterial-based electrode that delivers large surface area, high electrochemical activity, and minimum ohmic loss.

Main challenges: One of the main challenges was to successfully synthesize CNTs on various low-cost bare electrodes. Different CNT conditions resulted in different power performance, so process optimization was the biggest challenge. This challenge has now been solved. The second challenge is to have enough voltage from a single MFC. We are currently working on connecting multiple MFCs to produce enough voltage to directly drive MEC hydrogen production. However with the biggest challenge solved now, we believe we can move rapidly towards testing the electrodes in a scaled-up system as well as address the hybrid MFC-MEC connection challenge.

Links and further readings:

www.susana.org/images/documents/07-cap-d...m-university-usa.pdf

Hou, H., Li, L., Cho, Y., de Figueiredo, P., Han, A. 2009. Microfabricated Microbial Fuel Cell Arrays Reveal Electrochemically Active Microbes. PLoS ONE, 4(8 ), e6570.

Hou, H., Li, L., de Figueiredo, P., Han, A. 2011. Air-cathode microbial fuel cell array: A device for identifying and characterizing electrochemically active microbes. Biosensors and Bioelectronics, 26(5), 2680-2684.

Hou, H., Li, L., Ceylan, C.U., Haynes, A., Cope, J., Wilkinson, H.H., Erbay, C., Figueiredo, P.d., Han, A. 2012. A microfluidic microbial fuel cell array that supports long-term multiplexed analyses of electricigens. Lab on a Chip, 12(20), 4151-4159.

Han, A., Hou, H., Li, L., Kim, H. S., and de Figueiredo, P. 2013. Microfabricated Devices in Microbial Bioenergy Sciences. Trends in Biotechnology, Vol. 31 (4), pp. 225-232.

Arum Han, Ph.D.

Director, NanoBio Systems Lab.

Associate Professor

Dept. Electrical and Computer Engineering &

Dept. Biomedical Engineering

Texas A&M University

Faculty of Texas A&M Health Science Center

Faculty of Texas A&M Institute for Neuroscience

309C WERC, TAMU 3128 College Station, TX 77843-3128

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Phone: 979-845-9686

Fax: 979-845-6259

Homepage: biomems.tamu.edu

Attachments:

-

Picture1.png

(Filesize: 34KB)

Picture1.png

(Filesize: 34KB)

-

Picture2.png

(Filesize: 343KB)

Picture2.png

(Filesize: 343KB)

Please Log in to join the conversation.

You need to login to reply

Share this thread:

- Resource recovery

- Resource recovery from excreta, faecal sludge or wastewater

- Production of biochar, fuel or electricity

- Hybrid Microbial-Electrochemical System for Wastewater Treatment (Texas A&M University, USA)

Recently active users. Who else has been active?

Time to create page: 0.179 seconds