- Resource recovery

- Resource recovery from excreta, faecal sludge or wastewater

- Production of biochar, fuel or electricity

- Conversion of human waste into biochar using pyrolysis at a community-scale facility in Kenya (Stanford University and Climate Foundation, USA and Kenya)

Conversion of human waste into biochar using pyrolysis at a community-scale facility in Kenya (Stanford University and Climate Foundation, USA and Kenya)

34.1k views

Conversion of human waste into biochar using pyrolysis at a community-scale facility in Kenya (Stanford University and Climate Foundation, USA and Kenya)

Dear all,

I'm Laura Talsma, working for the Climate Foundation on bridging the technology development in the US with its end users and biochar markets in East Africa. I've started working for this team in the phase 2 of the Reinvent the Toilet Challenge, which I'll tell you more about soon, but for now some of the results of the completed Phase 1.

Let me start with a photo of the project team for Phase 1 (I'm not on the photo because I joined for Phase 2):

We’d like to introduce this project, related to the conversion of human solid waste to biochar, in the first phase of the Reinvent the Toilet Challenge funded by the Bill & Melinda Gates Foundation. The project is aimed at eliminating the risk of human waste, and creating a resource from it at the same time - biochar as a soil amendment in agriculture is a very valuable substrate for nutrients, and can retain water in the soils.

The Human Solid Waste (HSW) Biochar Reactor Project will demonstrate an economic value chain that converts human solid waste from thousands of people into agricultural fertilizer substrate in a single day.

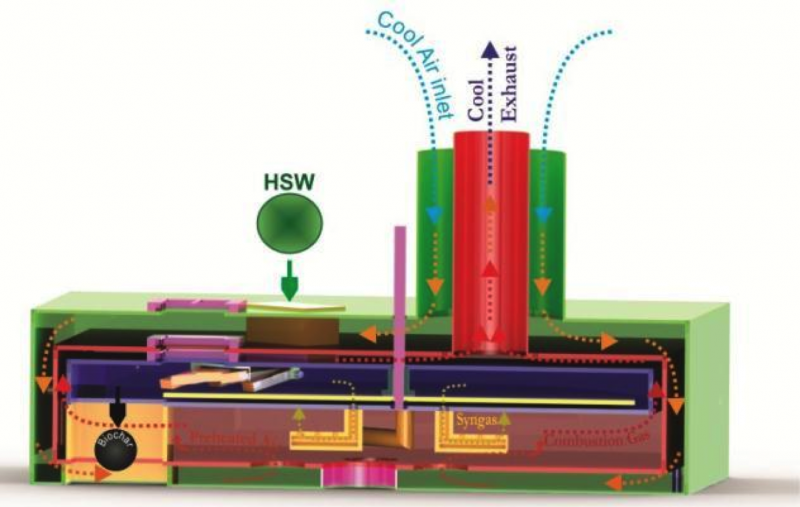

Figure below: Overview of the biochar reactor for treating human solid waste (HSW); the HSW is gasified, thus producing syngas. The syngas is burnt to pyrolyse the HSW on a rotating plate, and thereby sanitize it. The biochar produced is completely pathogen-free.

Name of lead organization: Stanford University & The Climate Foundation (www.climatefoundation.org/)

Primary contact at lead organization: Brian Von Herzen

Grantee location: Stanford, California, USA

Developing country where the research is being or will be tested: Kenya

Goals:

The goal of this project is to design, build, and test a self-contained system that can pyrolyze (decompose organic material at high temperatures without oxygen) human solid waste into a type of biological charcoal (biochar) that captures and stores carbon. The design target of phase 1 was to deliver a proof of concept of the technology, towards the ultimate goal of processing two tons of human waste daily at a facility located in the slums of Nairobi.

Short description of the project:

In the Reinvent the Toilet Challenge (RTTC), researchers from all over the world are challenged to come up with a radical new technology for treating human waste, and eventually making it accessible for the whole world. Just treatment is not enough though; the solution has to be affordable, and has to produce valuable elements from the waste - either energy, clean water, nutrients, or all. Phase 1 of the RTTC was aimed at proving the feasibility of the technology; in August 2012, a working prototype of the biochar reactor was demonstrated at the Reinvent the Toilet Fair at the headquarters of the Bill & Melinda Gates Foundation. Together with Sanergy in Nairobi, the technology will be developed further to make it ready to process human waste on a large scale in Kenya.

Start and end date: June 2011 - October 2012

Grant type: RTTC phase 1 (Reinvent The Toilet Challenge), started June 2011, grant size: USD 397,100 (grantee Stanford University: www.gatesfoundation.org/How-We-Work/Quic...s/2011/06/OPP1038375)

Grant size for Phase 2: USD 2,952,439 (grantee: Climate Foundation; started May 2013, www.gatesfoundation.org/How-We-Work/Quic...s/2013/05/OPP1069565)

Funding for this research currently ongoing (yes/no): yes (Phase 2)

Research or implementation partners: Stanford University

Figure below: The syngas burning, causing the pyrolysis of the HSW.

Figure below: the biochar produced by HSW; sanitized, and ready to use as a soil amendment.

Current state of affairs: The first phase of the biochar reactor development has been completed, showing the feasibility of using a biochar reactor for processing human waste. At the moment, a second phase of the project has been granted and started.

Biggest successes so far: The demonstration of a functional prototype human solid waste biochar reactor at the Reinvent the Toilet Fair in Seattle, August 2012.

The Phase I design has only one primary moving component, reducing complexity and possible failure modes. The reactor is relatively simple to operate, maintain and repair. The semi-continuous combustion of syngas from a HSW simulant input material stream, allowing for self-sustained, net-energy-positive operation.

Main challenges and opportunities:

Agile prototyping relies upon accessible modification of reactor designs and implementations. The biochar reactor can be built with more elegant resealable sealing. We are further investigating alternatives to our current gas-tight high-temperature sealing strategy.

There was syngas flammability variability across the fully anticipated range of operation of the reactor, due to incomplete mixing while using high moisture content HSW simulant. There will be a strong focus on pre-drying the material in the Phase II system.

Further links:

Documents in SuSanA library: www.susana.org/en/resources/library/details/1832

Presentation at the RTTC 1 fair in Seattle, Aug. 2012:

Video of the presentation by Brian von Herzen at the FSM2 Conference in Oct. 2012:

Paper and presentation slides to go with the same presentation:

www.susana.org/en/resources/library/details/1832

If you have any questions, please feel free to ask me here. Also, I will soon provide you with more information on the RTTC Phase 2 grant which we secured to continue with this work.

I'm Laura Talsma, working for the Climate Foundation on bridging the technology development in the US with its end users and biochar markets in East Africa. I've started working for this team in the phase 2 of the Reinvent the Toilet Challenge, which I'll tell you more about soon, but for now some of the results of the completed Phase 1.

Let me start with a photo of the project team for Phase 1 (I'm not on the photo because I joined for Phase 2):

We’d like to introduce this project, related to the conversion of human solid waste to biochar, in the first phase of the Reinvent the Toilet Challenge funded by the Bill & Melinda Gates Foundation. The project is aimed at eliminating the risk of human waste, and creating a resource from it at the same time - biochar as a soil amendment in agriculture is a very valuable substrate for nutrients, and can retain water in the soils.

The Human Solid Waste (HSW) Biochar Reactor Project will demonstrate an economic value chain that converts human solid waste from thousands of people into agricultural fertilizer substrate in a single day.

Figure below: Overview of the biochar reactor for treating human solid waste (HSW); the HSW is gasified, thus producing syngas. The syngas is burnt to pyrolyse the HSW on a rotating plate, and thereby sanitize it. The biochar produced is completely pathogen-free.

Name of lead organization: Stanford University & The Climate Foundation (www.climatefoundation.org/)

Primary contact at lead organization: Brian Von Herzen

Grantee location: Stanford, California, USA

Developing country where the research is being or will be tested: Kenya

Goals:

The goal of this project is to design, build, and test a self-contained system that can pyrolyze (decompose organic material at high temperatures without oxygen) human solid waste into a type of biological charcoal (biochar) that captures and stores carbon. The design target of phase 1 was to deliver a proof of concept of the technology, towards the ultimate goal of processing two tons of human waste daily at a facility located in the slums of Nairobi.

Short description of the project:

In the Reinvent the Toilet Challenge (RTTC), researchers from all over the world are challenged to come up with a radical new technology for treating human waste, and eventually making it accessible for the whole world. Just treatment is not enough though; the solution has to be affordable, and has to produce valuable elements from the waste - either energy, clean water, nutrients, or all. Phase 1 of the RTTC was aimed at proving the feasibility of the technology; in August 2012, a working prototype of the biochar reactor was demonstrated at the Reinvent the Toilet Fair at the headquarters of the Bill & Melinda Gates Foundation. Together with Sanergy in Nairobi, the technology will be developed further to make it ready to process human waste on a large scale in Kenya.

Start and end date: June 2011 - October 2012

Grant type: RTTC phase 1 (Reinvent The Toilet Challenge), started June 2011, grant size: USD 397,100 (grantee Stanford University: www.gatesfoundation.org/How-We-Work/Quic...s/2011/06/OPP1038375)

Grant size for Phase 2: USD 2,952,439 (grantee: Climate Foundation; started May 2013, www.gatesfoundation.org/How-We-Work/Quic...s/2013/05/OPP1069565)

Funding for this research currently ongoing (yes/no): yes (Phase 2)

Research or implementation partners: Stanford University

Figure below: The syngas burning, causing the pyrolysis of the HSW.

Figure below: the biochar produced by HSW; sanitized, and ready to use as a soil amendment.

Current state of affairs: The first phase of the biochar reactor development has been completed, showing the feasibility of using a biochar reactor for processing human waste. At the moment, a second phase of the project has been granted and started.

Biggest successes so far: The demonstration of a functional prototype human solid waste biochar reactor at the Reinvent the Toilet Fair in Seattle, August 2012.

The Phase I design has only one primary moving component, reducing complexity and possible failure modes. The reactor is relatively simple to operate, maintain and repair. The semi-continuous combustion of syngas from a HSW simulant input material stream, allowing for self-sustained, net-energy-positive operation.

Main challenges and opportunities:

Agile prototyping relies upon accessible modification of reactor designs and implementations. The biochar reactor can be built with more elegant resealable sealing. We are further investigating alternatives to our current gas-tight high-temperature sealing strategy.

There was syngas flammability variability across the fully anticipated range of operation of the reactor, due to incomplete mixing while using high moisture content HSW simulant. There will be a strong focus on pre-drying the material in the Phase II system.

Further links:

Documents in SuSanA library: www.susana.org/en/resources/library/details/1832

Presentation at the RTTC 1 fair in Seattle, Aug. 2012:

Video of the presentation by Brian von Herzen at the FSM2 Conference in Oct. 2012:

Paper and presentation slides to go with the same presentation:

www.susana.org/en/resources/library/details/1832

If you have any questions, please feel free to ask me here. Also, I will soon provide you with more information on the RTTC Phase 2 grant which we secured to continue with this work.

Attachments:

-

phase1reactor.png

(Filesize: 430KB)

phase1reactor.png

(Filesize: 430KB)

-

phase1flame.png

(Filesize: 512KB)

phase1flame.png

(Filesize: 512KB)

-

phase1char.png

(Filesize: 514KB)

phase1char.png

(Filesize: 514KB)

-

team1.jpg

(Filesize: 52KB)

team1.jpg

(Filesize: 52KB)

Please Log in to join the conversation.

You need to login to reply

Share this thread:

- Resource recovery

- Resource recovery from excreta, faecal sludge or wastewater

- Production of biochar, fuel or electricity

- Conversion of human waste into biochar using pyrolysis at a community-scale facility in Kenya (Stanford University and Climate Foundation, USA and Kenya)

Recently active users. Who else has been active?

Time to create page: 0.238 seconds