- Forum

- categories

- Sanitation systems

- Shared toilets, community toilets, public toilets

- Public toilets in India

- NEWgenerator for recovery of nutrients, energy and water from excreta (Uni of South Florida, USA) - anaerobic membrane bioreactor (field tests now in Kerala, India)

NEWgenerator for recovery of nutrients, energy and water from excreta (Uni of South Florida, USA) - anaerobic membrane bioreactor (field tests now in Kerala, India)

18.5k views

Re: Video from webinar 7 available NEWgenerator (University of South Florida, USA)

Hi Elisabeth,

Thank you for putting all the details together so meticulously .

Daniel, It is interesting to note that your webinar did evoke a number of interesting queries. We look forward to work with your team. As we did some initial site survey together, the community is enquiring on the next time we shall be coming back with eToilet and the treatment plant. As the monsoons are also nearing, they feel that the facility is pretty much urgent.

We sincerely believe that technologies be brought to the real field and test their efficacy among users. eToilet has gone through a number of product improvisation stages, purely based on user feedback .So thanks to the user community who helped us to shape a much robust eToilet when compared what we had three years. With partners like Daniel, we hope to bring in a new paradigm in human waste collection, processing and regeneration.

Thank you for putting all the details together so meticulously .

Daniel, It is interesting to note that your webinar did evoke a number of interesting queries. We look forward to work with your team. As we did some initial site survey together, the community is enquiring on the next time we shall be coming back with eToilet and the treatment plant. As the monsoons are also nearing, they feel that the facility is pretty much urgent.

We sincerely believe that technologies be brought to the real field and test their efficacy among users. eToilet has gone through a number of product improvisation stages, purely based on user feedback .So thanks to the user community who helped us to shape a much robust eToilet when compared what we had three years. With partners like Daniel, we hope to bring in a new paradigm in human waste collection, processing and regeneration.

Please Log in to join the conversation.

You need to login to replyRe: Video from webinar 7 available NEWgenerator (University of South Florida, USA)

Hi Daniel

Maybe something that could be useful? :

A Combination of an Anaerobic Baffled Reactor with Membrane Filtration for Decentralised Wastewater Treatment

S. Pillay, S. Pollet, K.M. Foxon and Buckley C.A

Pollution Research Group, School of Chemical Engineering, Howard College, University of KwaZulu-Natal, DURBAN, South Africa, 4041

www.iwaponline.com/wpt/005/wpt0050097.htm

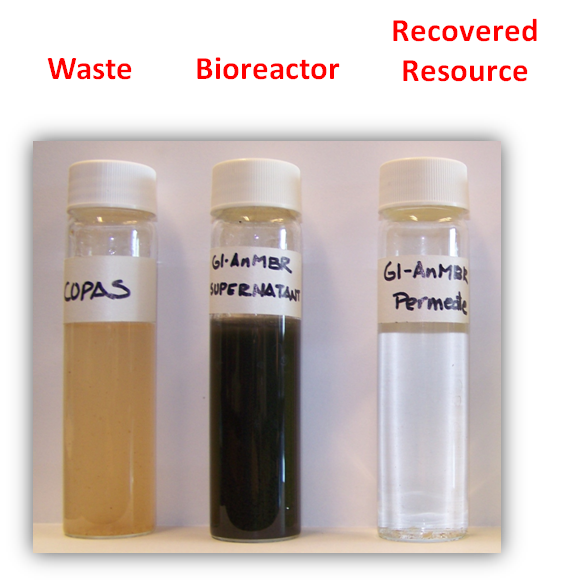

The application was polishing from advanced septic tanks (baffled reactor). In the first picture, an external membrane (A4 plate-and-sheet MF module) was used externally to the last compartment of 8 chamber pilot ABR. The ABR treated screened domestic wastewater (middle-income households). The last bottle in second picture was the effluent quality. It was a while ago for my MSC so I don't have the COD quality etc.

The third picture was from lab-system (hollow-fibre UF and MF, external modules). The Pollution Research Group, UKZN also tested a locally made woven-fibre module and a MF A4 plate-and-sheet type. The woven-fibre was developed through another WRC project - the module could be dried unlike other modules and the dried fouling layer scraped off (see pdf attachment *). The wastewater was different in the lab system - we used VIP sludge with no pit additives hence the colour.

In both applications, we used a hydraulic head from 300 mm to 600 mm ie gravity driven (not more than a metre). Fluxes were low around 1-2 L/m^2.h. The VIP treatment system displayed different fouling layers on plate and frame and hollow-fibre modules.

It would interesting to see what type of fluxes you guys are getting, mode of operation (submerged or sidestream; energy or gravity-driven).

All the best

Sudhir

* Development of a Membrane Pack for Immersed Membrane Bioreactors

Report to the Water Research Commission by V L Pillay and E P Jacobs on behalf of

Durban Institute of Technology & Institute of Polymer Science, University of Stellenbosch

Maybe something that could be useful? :

A Combination of an Anaerobic Baffled Reactor with Membrane Filtration for Decentralised Wastewater Treatment

S. Pillay, S. Pollet, K.M. Foxon and Buckley C.A

Pollution Research Group, School of Chemical Engineering, Howard College, University of KwaZulu-Natal, DURBAN, South Africa, 4041

www.iwaponline.com/wpt/005/wpt0050097.htm

The application was polishing from advanced septic tanks (baffled reactor). In the first picture, an external membrane (A4 plate-and-sheet MF module) was used externally to the last compartment of 8 chamber pilot ABR. The ABR treated screened domestic wastewater (middle-income households). The last bottle in second picture was the effluent quality. It was a while ago for my MSC so I don't have the COD quality etc.

The third picture was from lab-system (hollow-fibre UF and MF, external modules). The Pollution Research Group, UKZN also tested a locally made woven-fibre module and a MF A4 plate-and-sheet type. The woven-fibre was developed through another WRC project - the module could be dried unlike other modules and the dried fouling layer scraped off (see pdf attachment *). The wastewater was different in the lab system - we used VIP sludge with no pit additives hence the colour.

In both applications, we used a hydraulic head from 300 mm to 600 mm ie gravity driven (not more than a metre). Fluxes were low around 1-2 L/m^2.h. The VIP treatment system displayed different fouling layers on plate and frame and hollow-fibre modules.

It would interesting to see what type of fluxes you guys are getting, mode of operation (submerged or sidestream; energy or gravity-driven).

All the best

Sudhir

* Development of a Membrane Pack for Immersed Membrane Bioreactors

Report to the Water Research Commission by V L Pillay and E P Jacobs on behalf of

Durban Institute of Technology & Institute of Polymer Science, University of Stellenbosch

Physical Address:

Water Research Commission, 4 Daventry Road, Lynnwood Bridge Office Park, Bloukrans Building, Pretoria.

Postal Address:

Private Bag X03

GEZINA, 0031, South Africa

email: This email address is being protected from spambots. You need JavaScript enabled to view it.

mobile: +27 (0)60 502 1841

Water Research Commission, 4 Daventry Road, Lynnwood Bridge Office Park, Bloukrans Building, Pretoria.

Postal Address:

Private Bag X03

GEZINA, 0031, South Africa

email: This email address is being protected from spambots. You need JavaScript enabled to view it.

mobile: +27 (0)60 502 1841

Attachments:

-

ABR-MF.jpg

(Filesize: 14KB)

ABR-MF.jpg

(Filesize: 14KB)

-

ABR-MFeffluent.jpg

(Filesize: 9KB)

ABR-MFeffluent.jpg

(Filesize: 9KB)

-

LabUFMFsystem.jpg

(Filesize: 15KB)

LabUFMFsystem.jpg

(Filesize: 15KB)

Please Log in to join the conversation.

You need to login to reply- Elisabeth

-

- User is blocked

- Freelance consultant since 2012

Less- Posts: 3372

- Karma: 54

- Likes received: 932

Re: Video from webinar 7 available NEWgenerator (University of South Florida, USA)

Here are the three questions that Daniel was asked in the webinar after his presentation (you can listen to it here:

)

(1)

Brian: "Do the membranes have to be cleaned or replaced on some timescale?"

Answer by Daniel: "All membranes foul, and the question is how to you manage and control that. A lot of literature deals with membrane fouling control. We have to anticipate the amount of fouling that will take place and design for it. We expect that we don't have to clean the system for several months (in our lab set-up it was 4-6 months). The cleaning process should be simple enough so that the same person doing the maintenance on the toilets of Eram Scientific can also do it.

For replacement we anticipate membrane replacement every 5 years. The costs for membranes have come down significantly in recent years, they are almost a commodity now and are manufactured in many countries, including India."

(2)

Marc Deshusses: "What is the typical COD you get in the permeate?"

Answer by Daniel: "Depends on the wastewater strength; we observe 98% rejection of COD. Therefore usually less than 20 mg/L or even less than 10 mg/L of COD in the permeate. Always within the WHO Reuse guidelines." (follow-up question by myself: which one do you mean exactly? COD is not stipulated in the 2006 WHO Guidelines?)

(3)

Nelson Ekane: "Please explain the kind of cooperation you will have with Eram Scientific?"

Answer by Daniel: "As explained in my presentation: Eram operates these public toilets (forum.susana.org/forum/categories/105-pr...mit=12&start=24#8018) and need partners to recycle the water from their toilets. We will demonstrate our process at one location of their public toilets in India (Kerala). Our intention is to take the toilet completely off the grid (in terms of water, wastewater, energy), to recycle all water so that no additional fresh water is needed to operate the toilet (need to ensure that the recycled water is safe *). Also the energy, we predict that the NEWGenerator will produce enough energy (from the biogas of the anaerobic process) to provide the energy needed to run the toilet (lighting, pumps).

* Not for drinking but for everything else, I asume.

)

(1)

Brian: "Do the membranes have to be cleaned or replaced on some timescale?"

Answer by Daniel: "All membranes foul, and the question is how to you manage and control that. A lot of literature deals with membrane fouling control. We have to anticipate the amount of fouling that will take place and design for it. We expect that we don't have to clean the system for several months (in our lab set-up it was 4-6 months). The cleaning process should be simple enough so that the same person doing the maintenance on the toilets of Eram Scientific can also do it.

For replacement we anticipate membrane replacement every 5 years. The costs for membranes have come down significantly in recent years, they are almost a commodity now and are manufactured in many countries, including India."

(2)

Marc Deshusses: "What is the typical COD you get in the permeate?"

Answer by Daniel: "Depends on the wastewater strength; we observe 98% rejection of COD. Therefore usually less than 20 mg/L or even less than 10 mg/L of COD in the permeate. Always within the WHO Reuse guidelines." (follow-up question by myself: which one do you mean exactly? COD is not stipulated in the 2006 WHO Guidelines?)

(3)

Nelson Ekane: "Please explain the kind of cooperation you will have with Eram Scientific?"

Answer by Daniel: "As explained in my presentation: Eram operates these public toilets (forum.susana.org/forum/categories/105-pr...mit=12&start=24#8018) and need partners to recycle the water from their toilets. We will demonstrate our process at one location of their public toilets in India (Kerala). Our intention is to take the toilet completely off the grid (in terms of water, wastewater, energy), to recycle all water so that no additional fresh water is needed to operate the toilet (need to ensure that the recycled water is safe *). Also the energy, we predict that the NEWGenerator will produce enough energy (from the biogas of the anaerobic process) to provide the energy needed to run the toilet (lighting, pumps).

* Not for drinking but for everything else, I asume.

Dr. Elisabeth von Muench

Freelance consultant on environmental and climate projects

Freelance consultant on environmental and climate projects

Please Log in to join the conversation.

You need to login to reply- Elisabeth

-

- User is blocked

- Freelance consultant since 2012

Less- Posts: 3372

- Karma: 54

- Likes received: 932

Re: Video from webinar 7 available NEWgenerator (University of South Florida, USA)

This is the presentation that Daniel gave last week, with the title

"A compact water recycling and energy harvesting system for off-grid public toilets in low-income urban areas: The NEWgeneratorTM anaerobic membrane bioreactor ready for field testing in India ":

Here is the video to go with the presentation (13 minutes, includes questions and answers):

And here is the log from the chat:

(the questions were answered by Daniel Yeh and some of his team members: Onur Ozcan, Robert Bair and Jorge Calabria (I have indicated them in bold); You see it here in chronological order although I have moved things around a little to get answers closer to the questions in some cases)

++++++++++

Brian von Herzen: Do the membranes have to be cleaned or replaced on some timescale? --> This was answered verbally by Daniel, see next post.

Marc Deshusses: What is the typical COD you get in the permeate? --> This was answered verbally by Daniel, see next post.

Brian von Herzen: Is the long time between cleanings based on the biological activity on or near the surface of the filter?

ARNO ROSEMARIN: What happens to the nitrogen in the anaerobic treatment. Denitrification means loss as N2.

Jorge Calabria: The system lacks aeration so organic nitrogen converts to ammonia and is not nitrified. We are investigating the use of zeolite to remove ammonia via ion exchange.

Tugrul Yegenaga: Are we talking system suıtability for villages and not systems for cıtıes wıth a mıllıon of population

Robert Bair: Tugrul, at this moment we are focusing on urban settings where the MBR's capabilities and advantages are more relevant.

Lesego Toteng: How does the o&M cost of the new tech compare with its investment cost for a low income country?

Clare Backman: You mention to take toilets off the grid, how many toilets can this cope with?

Robert Bair: Clare, at this moment we are looking at coupling with two e-toilets capable of handling the waste of 200 people per day. However, this technology is highly scalable allowing for greater uses depending on design.

Jeremy Kohlitz: What are the energy requirements to run the membrane technology and how does that compare with other common wastewater treatment technologies?

Onur Ozcan: Membrane driven systems can have varying degrees of energy requirements depending on modes of operation, membrane type, and fouling control strategies employed. According to our estimations membrane operation energy requirements can be supplied by the energy recovered from the waste.

Daniel Yeh: Jeremy, even with the membrane, the energy profile of the NEWgen AnMBR is much more favorable than traditional activated sludge systems (which cannot recover energy). Our system is anticipated to be energy positive and we hope we can demonstrate such through the RTTC India field trial.

Elisabeth von Muench: Daniel or Robert: what can you tell us about the capital cost for the MBR at this stage? What is your target capacity at the moment (in terms of m3/d or people using the public toilet)?

Elisabeth von Muench: Are the people using the e-toilets using them as their main and only toilet or just as an occasional toilet when they are out and about in town? I.e. are they more like community toilets or normal public toilets?

Daniel Yeh: Elisabeth, currently, the eToilets are used in public areas or schools, so they are used occasionally. For the RTTC India, we are looking at a community toilet so they will be used as the primary mode of daily sanitation. In either case, we are sizing the NEWgen to handle 100 users per day

Tugrul Yegenaga: Shools whıch we are experıenced to rennovate, usually are ın between 500 to 1000 students wıthın cıty urban area.

Daniel Yeh: Tugrul, for the project, we are planning on a 100 user/d system. If it is a school with larger population, we can have larger capacity toilets and size the NEWgen to accommodate.

Sebastien: What happens with the anaerobic sludge that is left behind the membrane?

Sebastien: I may have missed this, but how is the anaerobic sludge, i.e. the retentate, handled?

Robert Bair: Sebastien, due to the anaerobic conditions, biomass accumulation is much less than in traditional aerobic reactors. We also run our system with a much longer solids retention time to enhance biological activity. When a fraction of the biomass is wasted, it is heat sterilized prior to land application.

Tugrul Yegenaga: we as granted by Rotary Int. beıng a rotary club ın turkey we have project thetıs for doıng thıs and also next year too I mean to say pılot school can be concentrated to cover out 5 schools whıch we do

Daniel Yeh: Tugrul, we would love to learn more about your work with schools in turkey and see if there is potential for collaboration. Lets talk more off line thanks.

Tugrul Yegenaga: can I have you e mail addresss to convey you a presentatıon

Sebastien: Thanks for the answer on sludge sterilization. In the US, Anaerobic MBRs usually rely on biogas sparging to control fouling, Do I understand that your team has a membrane that is not as susceptible to fouling?

Daniel Yeh: Hi Sebastien, I'm guessing you are referring to the Michigan AnMBR system? All MBRs or membrane processes are susceptable to fouling. The key is control. and design. part of our patent pending process is the fouling control so that it can be easily managed and not present a problem.

Sebastien: Indeed. I also have on my mind the recent work by McCarty's team on Anaerobic Fluidized Bed Membrane Bioreactors where they got around the issue of sparging

Onur Ozcan: Using a lot of GAC...

Sebastien: My understanding is they have a quantity of GAC, yes, but that it is a one-time cost. The GAC is not wasted i.e. it remains in the reactor indefinitely. But I am just asking because fouling control is the most critical element of MBRs and I was curious what the mechanism is.

Onur Ozcan: Yes, very true. We are following the development of Dr. McCarty's fluidized bed reactor technology.

Sebastien: I look forward to learning more about it as the patents and papers come out.

Onur Ozcan: I believe it may have potential. Pilot testing may present more information.

Elisabeth von Muench: Sebastien: you don't have to wait for the patents and papers, but I am sure Daniel will also keep us updated with progress on the forum : -)

Daniel Yeh: Hi Sebastian, as Elisabeth said we will definitely update our progress on the forum. I'm also glad to chat with you more directly and learn more about your work and interests. Thanks.

Sebastien: Thank you for your answers! I am not doing direct research on MBRs, but one of my advisors is Craig Criddle and I pay close attention to anaerobic systems. It looks like you and Craig have written at least one paper together.

Daniel Yeh: I postdoced with Craig at Stanford and he taught me everything I know about WW and AnMBR.

Sebastien: Thanks for the information! I look forward to following your work

++++++++++++++

I will put the questions and answers from the video in a separate post.

Do we have other people on this forum who are working with anaerobic MBRs or have worked with them in the past? Your experiences? These anaerobic MBRs have been around for a while.

Regards,

Elisabeth

"A compact water recycling and energy harvesting system for off-grid public toilets in low-income urban areas: The NEWgeneratorTM anaerobic membrane bioreactor ready for field testing in India ":

This attachment is hidden for guests.

Please log in or register to see it.

Please log in or register to see it.

Here is the video to go with the presentation (13 minutes, includes questions and answers):

And here is the log from the chat:

(the questions were answered by Daniel Yeh and some of his team members: Onur Ozcan, Robert Bair and Jorge Calabria (I have indicated them in bold); You see it here in chronological order although I have moved things around a little to get answers closer to the questions in some cases)

++++++++++

Brian von Herzen: Do the membranes have to be cleaned or replaced on some timescale? --> This was answered verbally by Daniel, see next post.

Marc Deshusses: What is the typical COD you get in the permeate? --> This was answered verbally by Daniel, see next post.

Brian von Herzen: Is the long time between cleanings based on the biological activity on or near the surface of the filter?

ARNO ROSEMARIN: What happens to the nitrogen in the anaerobic treatment. Denitrification means loss as N2.

Jorge Calabria: The system lacks aeration so organic nitrogen converts to ammonia and is not nitrified. We are investigating the use of zeolite to remove ammonia via ion exchange.

Tugrul Yegenaga: Are we talking system suıtability for villages and not systems for cıtıes wıth a mıllıon of population

Robert Bair: Tugrul, at this moment we are focusing on urban settings where the MBR's capabilities and advantages are more relevant.

Lesego Toteng: How does the o&M cost of the new tech compare with its investment cost for a low income country?

Clare Backman: You mention to take toilets off the grid, how many toilets can this cope with?

Robert Bair: Clare, at this moment we are looking at coupling with two e-toilets capable of handling the waste of 200 people per day. However, this technology is highly scalable allowing for greater uses depending on design.

Jeremy Kohlitz: What are the energy requirements to run the membrane technology and how does that compare with other common wastewater treatment technologies?

Onur Ozcan: Membrane driven systems can have varying degrees of energy requirements depending on modes of operation, membrane type, and fouling control strategies employed. According to our estimations membrane operation energy requirements can be supplied by the energy recovered from the waste.

Daniel Yeh: Jeremy, even with the membrane, the energy profile of the NEWgen AnMBR is much more favorable than traditional activated sludge systems (which cannot recover energy). Our system is anticipated to be energy positive and we hope we can demonstrate such through the RTTC India field trial.

Elisabeth von Muench: Daniel or Robert: what can you tell us about the capital cost for the MBR at this stage? What is your target capacity at the moment (in terms of m3/d or people using the public toilet)?

Elisabeth von Muench: Are the people using the e-toilets using them as their main and only toilet or just as an occasional toilet when they are out and about in town? I.e. are they more like community toilets or normal public toilets?

Daniel Yeh: Elisabeth, currently, the eToilets are used in public areas or schools, so they are used occasionally. For the RTTC India, we are looking at a community toilet so they will be used as the primary mode of daily sanitation. In either case, we are sizing the NEWgen to handle 100 users per day

Tugrul Yegenaga: Shools whıch we are experıenced to rennovate, usually are ın between 500 to 1000 students wıthın cıty urban area.

Daniel Yeh: Tugrul, for the project, we are planning on a 100 user/d system. If it is a school with larger population, we can have larger capacity toilets and size the NEWgen to accommodate.

Sebastien: What happens with the anaerobic sludge that is left behind the membrane?

Sebastien: I may have missed this, but how is the anaerobic sludge, i.e. the retentate, handled?

Robert Bair: Sebastien, due to the anaerobic conditions, biomass accumulation is much less than in traditional aerobic reactors. We also run our system with a much longer solids retention time to enhance biological activity. When a fraction of the biomass is wasted, it is heat sterilized prior to land application.

Tugrul Yegenaga: we as granted by Rotary Int. beıng a rotary club ın turkey we have project thetıs for doıng thıs and also next year too I mean to say pılot school can be concentrated to cover out 5 schools whıch we do

Daniel Yeh: Tugrul, we would love to learn more about your work with schools in turkey and see if there is potential for collaboration. Lets talk more off line thanks.

Tugrul Yegenaga: can I have you e mail addresss to convey you a presentatıon

Sebastien: Thanks for the answer on sludge sterilization. In the US, Anaerobic MBRs usually rely on biogas sparging to control fouling, Do I understand that your team has a membrane that is not as susceptible to fouling?

Daniel Yeh: Hi Sebastien, I'm guessing you are referring to the Michigan AnMBR system? All MBRs or membrane processes are susceptable to fouling. The key is control. and design. part of our patent pending process is the fouling control so that it can be easily managed and not present a problem.

Sebastien: Indeed. I also have on my mind the recent work by McCarty's team on Anaerobic Fluidized Bed Membrane Bioreactors where they got around the issue of sparging

Onur Ozcan: Using a lot of GAC...

Sebastien: My understanding is they have a quantity of GAC, yes, but that it is a one-time cost. The GAC is not wasted i.e. it remains in the reactor indefinitely. But I am just asking because fouling control is the most critical element of MBRs and I was curious what the mechanism is.

Onur Ozcan: Yes, very true. We are following the development of Dr. McCarty's fluidized bed reactor technology.

Sebastien: I look forward to learning more about it as the patents and papers come out.

Onur Ozcan: I believe it may have potential. Pilot testing may present more information.

Elisabeth von Muench: Sebastien: you don't have to wait for the patents and papers, but I am sure Daniel will also keep us updated with progress on the forum : -)

Daniel Yeh: Hi Sebastian, as Elisabeth said we will definitely update our progress on the forum. I'm also glad to chat with you more directly and learn more about your work and interests. Thanks.

Sebastien: Thank you for your answers! I am not doing direct research on MBRs, but one of my advisors is Craig Criddle and I pay close attention to anaerobic systems. It looks like you and Craig have written at least one paper together.

Daniel Yeh: I postdoced with Craig at Stanford and he taught me everything I know about WW and AnMBR.

Sebastien: Thanks for the information! I look forward to following your work

++++++++++++++

I will put the questions and answers from the video in a separate post.

Do we have other people on this forum who are working with anaerobic MBRs or have worked with them in the past? Your experiences? These anaerobic MBRs have been around for a while.

Regards,

Elisabeth

Dr. Elisabeth von Muench

Freelance consultant on environmental and climate projects

Freelance consultant on environmental and climate projects

This message has an attachment file.

Please log in or register to see it.

Please Log in to join the conversation.

You need to login to reply- Elisabeth

-

- User is blocked

- Freelance consultant since 2012

Less- Posts: 3372

- Karma: 54

- Likes received: 932

Re: NEWgenerator for recovery of nutrients, energy and water from human wastes (University of South Florida, USA)

Dear all,

In case you have been following this thread and are interested in this research project, then the upcoming webinar number 7 on “Adding missing links in sanitation value chains” could be interesting for you:

Daniel's presentation in this webinar is entitled:

A compact water recycling and energy harvesting system for off-grid public toilets in low-income urban areas: The NEWgeneratorTM anaerobic membrane bioreactor ready for field testing in India

The webinar will take place on:

Tuesday 29 April 2014, 16:30 - 17:15

(CET - Central European Time; time converter to find your local time: www.timeanddate.com/worldclock/converter.html )

More details of the webinar, which has 3 presenters, are available here on the forum:

forum.susana.org/forum/categories/139-in...mit=12&start=12#8145

There is no need to download any software to attend (simply go to this website: seint.adobeconnect.com/seiwebinar/). However, you must obtain the password to enter the room. To obtain the password, please e-mail me or use the "contact" button on the left side of this post.

I look forward to meeting you all at the webinar! If you have questions about the content of Daniel's research before the webinar, please put them here on the forum.

Regards,

Elisabeth

P.S. Pawan: Daniel told me by e-mail that he has seen your questions and will answer them soon.

In case you have been following this thread and are interested in this research project, then the upcoming webinar number 7 on “Adding missing links in sanitation value chains” could be interesting for you:

Daniel's presentation in this webinar is entitled:

A compact water recycling and energy harvesting system for off-grid public toilets in low-income urban areas: The NEWgeneratorTM anaerobic membrane bioreactor ready for field testing in India

The webinar will take place on:

Tuesday 29 April 2014, 16:30 - 17:15

(CET - Central European Time; time converter to find your local time: www.timeanddate.com/worldclock/converter.html )

More details of the webinar, which has 3 presenters, are available here on the forum:

forum.susana.org/forum/categories/139-in...mit=12&start=12#8145

There is no need to download any software to attend (simply go to this website: seint.adobeconnect.com/seiwebinar/). However, you must obtain the password to enter the room. To obtain the password, please e-mail me or use the "contact" button on the left side of this post.

I look forward to meeting you all at the webinar! If you have questions about the content of Daniel's research before the webinar, please put them here on the forum.

Regards,

Elisabeth

P.S. Pawan: Daniel told me by e-mail that he has seen your questions and will answer them soon.

Dr. Elisabeth von Muench

Freelance consultant on environmental and climate projects

Freelance consultant on environmental and climate projects

Please Log in to join the conversation.

You need to login to replyRe: NEWgenerator for recovery of nutrients, energy and water from human wastes (University of South Florida, USA)

Hello Deniel

Congratulations for getting the proposal with Eram Scietific awarded last month by DBT/BMGF in Delhi. Your detail information on the system developed is highly appreciated. However, I have some queries.

What is biogas production rate i.e., volume of biogas(cft or cum) per day per user of toilet? What is minimum number of users of toilet per day required to make utilization of biogas for cooking and electricity purposes, economically feasible? What is the pore size of AnMBR? Is it sufficient only for Helminths or bacteria as well. What is frequency of clogging and maintenance/ repair of the AnMBR? How settled sludge from biodigester plant is taken out and treated to make it pathogen free before using for agriculture / land use? I hope your experience with the above points will help a lot to Eram scientific to achieve the objectives of the present proposal. Regards Pawan

Congratulations for getting the proposal with Eram Scietific awarded last month by DBT/BMGF in Delhi. Your detail information on the system developed is highly appreciated. However, I have some queries.

What is biogas production rate i.e., volume of biogas(cft or cum) per day per user of toilet? What is minimum number of users of toilet per day required to make utilization of biogas for cooking and electricity purposes, economically feasible? What is the pore size of AnMBR? Is it sufficient only for Helminths or bacteria as well. What is frequency of clogging and maintenance/ repair of the AnMBR? How settled sludge from biodigester plant is taken out and treated to make it pathogen free before using for agriculture / land use? I hope your experience with the above points will help a lot to Eram scientific to achieve the objectives of the present proposal. Regards Pawan

Pawan Jha

Chairman

Foundation for Environment and Sanitation

Mahavir Enclave

New Delhi 110045, India

Web: www.foundation4es.org

Linked: linkedin.com/in/drpkjha

Chairman

Foundation for Environment and Sanitation

Mahavir Enclave

New Delhi 110045, India

Web: www.foundation4es.org

Linked: linkedin.com/in/drpkjha

Please Log in to join the conversation.

You need to login to replyRe: NEWgenerator for recovery of nutrients, energy and water from human wastes (University of South Florida, USA)

Just announced this week….NEWGenerator has advanced to the Final 4 round of the Cade Museum Prize. The final showdown will be on May 8, when the finalists will convene in Gainesville, FL to present their technology and business case to a panel of esteemed judges. We are up against three really cool and important technologies (one medical diagnostic, one app, one software), but we are SO ready for this. The team is really fired up.

Stay tuned !

www.cademuseum.org/prize

newgenerator.tumblr.com/

[The Cade Museum for Creativity and Invention was founded in honor of Dr. James Robert Cade, professor of Renal Medicine and lead inventor of Gatorade, the World's most popular sports drink]

Stay tuned !

www.cademuseum.org/prize

newgenerator.tumblr.com/

[The Cade Museum for Creativity and Invention was founded in honor of Dr. James Robert Cade, professor of Renal Medicine and lead inventor of Gatorade, the World's most popular sports drink]

Daniel H. Yeh, Ph.D., P.E., LEED AP BD+C

Associate Professor, Dept. of Civil & Environmental Engineering

College of Engineering, University of South Florida

4202 E. Fowler Avenue, ENB118, Tampa, FL 33620-5350 USA

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it. TEL: +1(813)974-4746

Skype: ecol-mem Twitter<@dhyeh>

www.linkedin.com/in/danielyeh (LinkedIn page)

newgenerator.tumblr.com/ (NEWgenerator project)

mbr.eng.usf.edu (research group)

Please Log in to join the conversation.

You need to login to reply- Elisabeth

-

- User is blocked

- Freelance consultant since 2012

Less- Posts: 3372

- Karma: 54

- Likes received: 932

Re: NEWgenerator for recovery of nutrients, energy and water from human wastes (University of South Florida, USA)

And here you see the happy researchers who received this new grant. Daniel Yeh is the second from the right and Bincy Baby from Eram Scientific (who has also written on the forum regularly, see link in the post above) is the first from the left:

Congratulations!

Daniel also came to the small SuSanA meeting we had in Delhi yesterday together with his PhD student who will do the work on the field trials. (myself or the SuSanA secretariat will provide more feedback about this SuSanA meeting this week; it was a meeting with the aim to bring together BMGF grantees with Indian practitioners on the ground)

The demonstration will be in Kerala, India. Daniel said he will describe more once they have things more finalized with the grant arrangements.

Eram Scientific, the company that is implementing and operating these public "e-toilets" is by the way the not-for profit arm of the larger Eram Group. The anaerobic membrane bioreactor that Daniel's team has been working on will treat the effluent from the "e-toilets" to a high standard for reuse (the toilets are conventional flush toilets). The intended application would be for water-scarce urban areas in India.

Eram has about 400 of these public toilets installed mainly in Kerala (one of the wealthier states of India in the South); normally their public toilets are connected to conventional systems, i.e. sewer (and hopefully treatment plant at the end of the sewer) or septic tanks and maybe DEWATS in some cases (I am not sure on that one will check with Bincy).

They also have about 100 of them in schools in Kerala. What is mainly novel about them is the stainless steel fabrication in a container as well as the very high emphasis on "automated cleanliness" (e.g. automated floor cleaning - with the downside of having a higher water consumption).

Daniel, Bincy: please correct me if I got any of the facts wrong.

Greetings,

Elisabeth

Congratulations!

Daniel also came to the small SuSanA meeting we had in Delhi yesterday together with his PhD student who will do the work on the field trials. (myself or the SuSanA secretariat will provide more feedback about this SuSanA meeting this week; it was a meeting with the aim to bring together BMGF grantees with Indian practitioners on the ground)

The demonstration will be in Kerala, India. Daniel said he will describe more once they have things more finalized with the grant arrangements.

Eram Scientific, the company that is implementing and operating these public "e-toilets" is by the way the not-for profit arm of the larger Eram Group. The anaerobic membrane bioreactor that Daniel's team has been working on will treat the effluent from the "e-toilets" to a high standard for reuse (the toilets are conventional flush toilets). The intended application would be for water-scarce urban areas in India.

Eram has about 400 of these public toilets installed mainly in Kerala (one of the wealthier states of India in the South); normally their public toilets are connected to conventional systems, i.e. sewer (and hopefully treatment plant at the end of the sewer) or septic tanks and maybe DEWATS in some cases (I am not sure on that one will check with Bincy).

They also have about 100 of them in schools in Kerala. What is mainly novel about them is the stainless steel fabrication in a container as well as the very high emphasis on "automated cleanliness" (e.g. automated floor cleaning - with the downside of having a higher water consumption).

Daniel, Bincy: please correct me if I got any of the facts wrong.

Greetings,

Elisabeth

Dr. Elisabeth von Muench

Freelance consultant on environmental and climate projects

Freelance consultant on environmental and climate projects

Attachments:

-

DSCN3603smaller.jpg

(Filesize: 226KB)

DSCN3603smaller.jpg

(Filesize: 226KB)

Please Log in to join the conversation.

You need to login to replyRe: NEWgenerator for recovery of nutrients, energy and water from human wastes (University of South Florida, USA)

Just announced on World Water Day at the Reinvent the Toilet Fair in New Delhi, The team of Eram Scientific's eToilet (forum.susana.org/forum/categories/105-pr...ram-scientific-india) and USF's NEWgenerator (this thread) was selected one of six winning entries for the Reinvent the Toilet: India Challenge. We will be working to demonstrate closed-loop, off-grid, sanitation in a slum in India this coming year.

www.birac.nic.in/news_desc.php?id=112

businesswireindia.com/news/news-details/...ration-toilets/38706

gatesfoundation.isebox.net/water-sanitat...he-toilet-fair-india

www.birac.nic.in/news_desc.php?id=112

businesswireindia.com/news/news-details/...ration-toilets/38706

gatesfoundation.isebox.net/water-sanitat...he-toilet-fair-india

Daniel H. Yeh, Ph.D., P.E., LEED AP BD+C

Associate Professor, Dept. of Civil & Environmental Engineering

College of Engineering, University of South Florida

4202 E. Fowler Avenue, ENB118, Tampa, FL 33620-5350 USA

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it. TEL: +1(813)974-4746

Skype: ecol-mem Twitter<@dhyeh>

www.linkedin.com/in/danielyeh (LinkedIn page)

newgenerator.tumblr.com/ (NEWgenerator project)

mbr.eng.usf.edu (research group)

Please Log in to join the conversation.

You need to login to replyRe: NEWgenerator for recovery of nutrients, energy and water from human wastes (University of South Florida, USA)

We are thrilled to be informed last week that the NEWgenerator has been selected as a Sweet 16 Round Finalist for the Cade Museum Prize of Creativity and Invention (www.cademuseum.org/prize/). Members of our team will be attending a reception this week at the Florida Innovation Hub (www.floridainnovationhub.ufl.edu/) to participate in "speed dating" with entrepreneurs and potential investors, and pitch the project/product "shark tank" style.

The Cade Museum Prize is designed to encourage creativity and invention by providing an incentive for early-stage companies to move new ideas and products closer to the marketplace. Judges use the following criteria to advance entries to each round of competition:

Creativity: How creative is the idea compared to others in its field? Is it a Big Leap Forward or a Small Tweak to an existing technology?

Breadth of Impact: What could change as a result of this invention? A market segment or the world?

Liklihood of Success: How far away is the invention from market? Will it be able to capture and defend market space?

If we advance to the Final Four, I will share the good news here and on our tumblr site (NEWgenerator.tumblr.com). Thanks.

The Cade Museum Prize is designed to encourage creativity and invention by providing an incentive for early-stage companies to move new ideas and products closer to the marketplace. Judges use the following criteria to advance entries to each round of competition:

Creativity: How creative is the idea compared to others in its field? Is it a Big Leap Forward or a Small Tweak to an existing technology?

Breadth of Impact: What could change as a result of this invention? A market segment or the world?

Liklihood of Success: How far away is the invention from market? Will it be able to capture and defend market space?

If we advance to the Final Four, I will share the good news here and on our tumblr site (NEWgenerator.tumblr.com). Thanks.

Daniel H. Yeh, Ph.D., P.E., LEED AP BD+C

Associate Professor, Dept. of Civil & Environmental Engineering

College of Engineering, University of South Florida

4202 E. Fowler Avenue, ENB118, Tampa, FL 33620-5350 USA

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it. TEL: +1(813)974-4746

Skype: ecol-mem Twitter<@dhyeh>

www.linkedin.com/in/danielyeh (LinkedIn page)

newgenerator.tumblr.com/ (NEWgenerator project)

mbr.eng.usf.edu (research group)

Please Log in to join the conversation.

You need to login to replyNEWgenerator for recovery of nutrients, energy and water from excreta (Uni of South Florida, USA) - anaerobic membrane bioreactor (field tests now in Kerala, India)

I am happy to forward to you the profile for the NEWgenerator project, a research project funded by the Bill & Melinda Gates Foundation:

Title of grant:

NEWgeneratorTM for recovery of nutrients, energy and water from human wastes

Subtitle: Advanced anaerobic membrane bioreactor (AnMBR) technology for decentralized sanitation through resource recovery

Name of lead organization: University of South Florida

Primary contact at lead organization: Daniel H. Yeh (myself)

Grantee location: Tampa, Florida, USA

Developing country where the research is being or will be tested: Currently targeting India, but we welcome partnership in other countries.

Short description of the project:

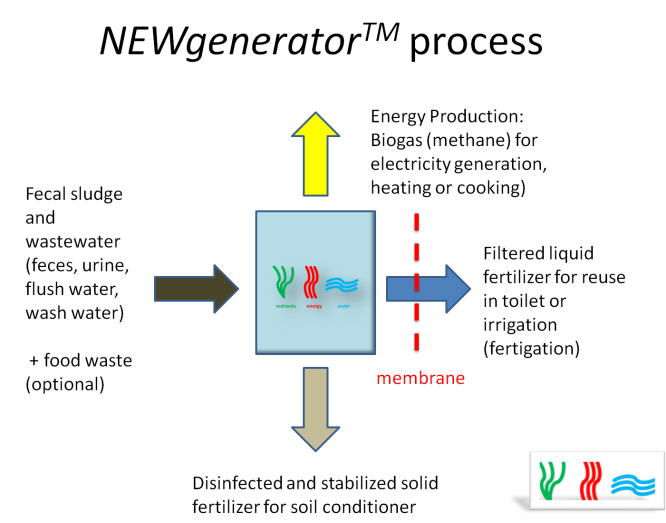

The NEWgenerator is a compact and robust resource recovery machine that is paired with pit latrines, septic tanks, fecal sludge pits and self-standing toilets to treat, recycle and harvest embedded nutrients, energy and water in human wastes. It is intended for “wet pits” from communities that utilize water for washing or flushing, which renders the fecal sludge too wet for combustion processes such as pyrolysis for biochar. The NEWgenerator is a hybrid anaerobic membrane bioreactor (AnMBR) machine which is packaged in a small-footprint modular housing for off-grid deployment. Unlike its more common aerobic (activated sludge) MBR counterpart, the AnMBR does not require aeration (less energy to operate), produces 90% less microbial biomass (less handling) and recovers (rather than remove) nutrients such as NPK. Key processes of the NEWgenerator include: high-rate anaerobic digestion for rapid waste solids disintegration and high-level pathogen destruction (e.g., against Giardia and Ascaris), membrane ultrafiltration (sub-micron) of reactor solids and colloids to liberate pathogen-safe clean water and nutrients, permeate (clean water) collection and storage, biogas collection and electricity generation, and associated ruggedized sensors, data loggers and micro-controllers.

The AnMBR technology is highly scale-able; It can be sized for single family to neighborhoods. Several versions of the NEWgenerator can be made available. One application of the NEWgenerator is to provide resource harvesting and recovery at regional faecal sludge collection facilities. Another current direction of the NEWgenerator product development is to directly couple with an upstream sanitation provision (e.g., public toilet) in a dense urban setting (e.g., slum) to create a net-zero-water and net-surplus-energy urban sanitation system which harvests the economic potential of human wastes (feces and urine) and other urban biomass (e.g., food waste).

Goal(s):

The overall goal of the project is to develop an affordable, highly efficient, robust, reliable, off-grid, closed-loop sanitation system for harvesting energy, water and nutrients from waste urban biomass, both post-consumer (feces and urine) and pre-consumer (food waste).

You will see the abbreviation TRL a few times below.

For a definition of the different levels, see susana.org/lang-en/library?view=ccbktypeitem&type=2&id=1834

Objectives:

Grant type: GCE Round 7 Phase I

Funding for this research currently ongoing (yes/no): No, currently under consideration for additional funding.

Research or implementation partners:

Working with Eram Scientific Solutions (Kerala, India - see: forum.susana.org/forum/categories/105-pr...ram-scientific-india), we are targeting opportunities for field testing of a combined eToilet + NEWgenerator as an integrated system for human waste harvesting and conversion to nutrients, energy and water. The NEWgen can also be used for water cycling from public toilets, as well as dewatering of faecal sludge wet pits, to extend the operation run cycle.

Links, further readings – results to date:

Edit on 9 May 2017: Further discussions about the pilots in India are available here: forum.susana.org/forum/categories/india

Please visit the project’s main website for updates and ongoing media coverage of our project.

NEWgenerator.tumblr.com

The laboratory TRL5 version of the NEWgenerator is described in the following paper published in Journal of Membrane Science (www.sciencedirect.com/science/article/pii/S037673881300135X):

Prieto, A.L., H. Futselaar, P.N.L. Lens, R. Bair and D.H. Yeh. (2013). Development and start up of a gas-lift anaerobic membrane bioreactor (Gl-AnMBR) for conversion of sewage to energy, water and nutrients. Journal of Membrane Science. 441:158-167. dx.doi.org/10.1016/j.memsci.2013.02.016

The field TRL6 version has been piloted in a relevant environment and two manuscripts are under preparation. We demonstrated:

- Feasibility of NEWgen operating under field condition (over considerable ambient temperature swings) treating actual wastewater from the influent to a septic tank. The system was resilient against surges in organic loading, when additional organics was added to push the limits of performance. Despite spikes in loading, COD removal was consistently high, as was biogas production and pathogen removal.

- Water and nutrients recycled from the NEWgen was tested for fertigation in a greenhouse hydroponic system. Tomatoes and cucumbers were grown successfully using biofertilizer recovered from the NEWgen, comparable to a commercial synthetic fertilizer.

Additional background material:

1) "NEWgenerator membrane biotechnology for the recovery of nutrients, Energy and Water from Human Wastes" - Dr. Daniel Yeh presentation at Int’l Faecal Sludge Management Conference 2 (FSM2), Durban, South Africa, Oct. 30, 2012

www.susana.org/en/resources/library/details/2007

Presentation video:

2) TRL5 NEWgenerator system (video)

3) “Can MBRs solve the World’s Water Crisis?” (Water Environment & Technology, 2004, article on the Bellagio Principle)

dl.dropboxusercontent.com/u/3819653/BMGF...%20MBR%20article.pdf

4) “Clean Vision” on application of MBRs for developing communities (USF Engineer, 2006)

dl.dropboxusercontent.com/u/3819653/BMGF...neer%20DHY%20MBR.pdf

5) “Could a new energy source start right here?”

www.myfoxtampabay.com/story/18612577/cou...rce-start-right-here

(Fox 13 News, May 24, 2012, story by Lloyd Sowers) This is a video report on our lab’s efforts to recovery resources from wastewater using membrane biotechnology. Highlighted are our research on cultivating biofuel microalgae at the City of Tampa’s wastewater treatment plant (featuring PhD Candidate Ivy Cormier), and also our NEWGenerator project with the Gates Foundation.

6) Members of the USF Membrane Biotechnology Lab

dl.dropboxusercontent.com/u/3819653/BMGF...20lab%20members.docx

Current state of affairs:

We have developed the TRL5 version of the NEWgenerator in the laboratory, using synthetic sewage with complex organic particulates. We have successfully field piloted a TRL6 version of the NEWgenerator using the septic tank at a local school as influent. The TRL7 version has undergone preliminary design. Detailed design and fabrication are pending confirmation of continued funding for the TRL7 phase of the project.

Biggest successes so far:

We have created a TRL6 total recycling and reuse system, coupling the NEWgenerator with resource recovery via a hydroponic greenhouse called the BioFertilizer Farm (BFF). We are eager to build and demonstrate the TRL7 version so that we can advance the technology to scale via the commercial marketplace. Our own bias aside, we do feel that the anaerobic MBR is one of the most promising technologies for addressing the global sanitation, water, energy and food crisis.

[March 2013] We had the pleasure and honor of hosting officials from the USEPA (Nancy Stoner of Office of Water and staff) and Water Environment Federation in our Membrane Biotechnology Lab. It was part of the USEPA Office of Water’s media announcement on a new initiative called “USEPA’s Blueprint for Integrating Technology Innovation into the National Water Program (Version 1.0)” (water.epa.gov/blueprint.cfm). During the visit, we were able to highlight BMGF’s support though WaSH GCE and describe the RTT initiative. We also demonstrated to the officials our NEWgenerator process, which is well aligned with the new EPA blueprint.

Below are some links to media coverage of the event:

USF scientists see opportunity gushing from water treatment (The Tampa Tribune, TBO.com)

tbo.com/news/education/usf-water-science...ws-crowd-b82470227z1

Cleaning up dirty water can create energy (WMNF Story, text, audio and videos)

www.wmnf.org/news_stories/cleaning-up-di...er-can-create-energy

WEF and U.S. EPA Tour Innovations at University of South Florida (WEF Highlights)

news.wef.org/wef-and-u-s-epa-tour-innova...ty-of-south-florida/

Main challenges / frustration:

One of the main challenges encountered in our project has been on advocating and communicating membrane technology to clear up misunderstanding and misperceptions. The membrane is an amazing modern marvel of engineering and material science, capable of high levels of separation with an absolute, reliable, physical barrier. However, membranes are still frequently viewed as too expensive, too experimental, too delicate, too “high tech,” or requiring frequent cleaning or replacement. The truth is that membranes have come a long, long way since first invented decades ago. Membrane performance and durability have increased significantly, while costs (both capex and opex) have decreased drastically. These were all made possible with rapid growths in demand, volume and market size. Due to global demands for water treatment, recycling and purification, membranes are manufactured worldwide and available in just about every country, becoming better and cheaper by the day. In fact, the global demand for membranes is projected to reach $25.7 billion by 2017.

At a recent water/wastewater technology tradeshow that we attended in India (Aquatech, New Delhi, April 2013), membrane manufacturers and distributors abound, all jockeying for a slice of the growing membrane marketplace in developing or transitioning countries like India. In my opinion, the real problem with membranes is in NOT using them. Despite their advantages, membranes are to this date mostly used for industrial and municipal water/wastewater markets. With the exception of a few scattered instances, they are not used to provide water purification or sanitation intervention in poor communities (e.g., urban slums) in developing countries, where the needs for water and sanitation improvements are dire. That, to me, is a great injustice; we have a high performance, small-footprint, commercially-available product that is underutilized. To date, membrane manufacturers and equipment providers have not targeted pro-poor markets, such as slum communities. These markets are seen as too risky, too diffuse, too transient and lack a clear customer demand. In fact, they are barely on the radar screen of membrane technology providers and receive occasional consideration only for humanitarian reasons (such as post disaster relief). Through the NEWgenerator, we aim to demonstrate, to both the sanitation sector and membrane industry, that membrane application for poor communities is not only possible, but is necessary and is an untapped market with tremendous potential.

Another misunderstanding is related to the different types of membranes used for the NEWgen. We are not using RO membrane, which is often used for desalination. Hence, there is no concentrate (brine) for disposal. We are using ultrafiltration membranes (UF), which offer sub-micron size pores that are a good compromise between contaminant rejection and water throughput. Just as all clothes get dirty, all membranes do foul to some extent. That is not necessarily a bad thing, since fouling has been shown to actually enhance membrane rejection if managed properly (numerous studies in literature). The key is to manage the fouling so that the system generates permeate at a rate/quality/manner that is satisfactory over a design period of performance. With over 10 years of experience working with membranes and strong ties with the membrane industry and other membrane labs, we have developed protocols and techniques for sustainable flux that allows the NEWgen to be operated reliably over long periods.

One of our biggest challenges has been related to dealing with high temperature under the Florida sun, where the temperature in the reactor shed can rise to 50C and render working conditions quite difficult. Another was dealing with occasional plumbing and component failures from heat stress. However, the heat stress trial has prepared us well (physiologically and mentally) for working in tropical environments such as India and Africa. We have also gained valuable experience in designing and fabricating the system with heat durability in mind.

I am happy to take any questions or receive your comments on our research project.

Regards,

Daniel

Title of grant:

NEWgeneratorTM for recovery of nutrients, energy and water from human wastes

Subtitle: Advanced anaerobic membrane bioreactor (AnMBR) technology for decentralized sanitation through resource recovery

Name of lead organization: University of South Florida

Primary contact at lead organization: Daniel H. Yeh (myself)

Grantee location: Tampa, Florida, USA

Developing country where the research is being or will be tested: Currently targeting India, but we welcome partnership in other countries.

Short description of the project:

The NEWgenerator is a compact and robust resource recovery machine that is paired with pit latrines, septic tanks, fecal sludge pits and self-standing toilets to treat, recycle and harvest embedded nutrients, energy and water in human wastes. It is intended for “wet pits” from communities that utilize water for washing or flushing, which renders the fecal sludge too wet for combustion processes such as pyrolysis for biochar. The NEWgenerator is a hybrid anaerobic membrane bioreactor (AnMBR) machine which is packaged in a small-footprint modular housing for off-grid deployment. Unlike its more common aerobic (activated sludge) MBR counterpart, the AnMBR does not require aeration (less energy to operate), produces 90% less microbial biomass (less handling) and recovers (rather than remove) nutrients such as NPK. Key processes of the NEWgenerator include: high-rate anaerobic digestion for rapid waste solids disintegration and high-level pathogen destruction (e.g., against Giardia and Ascaris), membrane ultrafiltration (sub-micron) of reactor solids and colloids to liberate pathogen-safe clean water and nutrients, permeate (clean water) collection and storage, biogas collection and electricity generation, and associated ruggedized sensors, data loggers and micro-controllers.

The AnMBR technology is highly scale-able; It can be sized for single family to neighborhoods. Several versions of the NEWgenerator can be made available. One application of the NEWgenerator is to provide resource harvesting and recovery at regional faecal sludge collection facilities. Another current direction of the NEWgenerator product development is to directly couple with an upstream sanitation provision (e.g., public toilet) in a dense urban setting (e.g., slum) to create a net-zero-water and net-surplus-energy urban sanitation system which harvests the economic potential of human wastes (feces and urine) and other urban biomass (e.g., food waste).

Goal(s):

The overall goal of the project is to develop an affordable, highly efficient, robust, reliable, off-grid, closed-loop sanitation system for harvesting energy, water and nutrients from waste urban biomass, both post-consumer (feces and urine) and pre-consumer (food waste).

You will see the abbreviation TRL a few times below.

For a definition of the different levels, see susana.org/lang-en/library?view=ccbktypeitem&type=2&id=1834

Objectives:

- Using our knowledge of the laboratory TRL5 system (simulated environment), to design, fabricate, field test and demonstrate the TRL6 version (relevant environment) of the NEWgenerator using real sewage.

- To demonstrate reuse potential of nutrients, energy and water recovered from waste biomass, in particularly for agriculture.

- Using knowledge gained from field tests of the TRL6 system, to design a TRL7 system for field demonstration in an actual environment (with country partner).

- To take the NEWgenerator technology to scale via the commercial marketplace.

Grant type: GCE Round 7 Phase I

Funding for this research currently ongoing (yes/no): No, currently under consideration for additional funding.

Research or implementation partners:

Working with Eram Scientific Solutions (Kerala, India - see: forum.susana.org/forum/categories/105-pr...ram-scientific-india), we are targeting opportunities for field testing of a combined eToilet + NEWgenerator as an integrated system for human waste harvesting and conversion to nutrients, energy and water. The NEWgen can also be used for water cycling from public toilets, as well as dewatering of faecal sludge wet pits, to extend the operation run cycle.

Links, further readings – results to date:

Edit on 9 May 2017: Further discussions about the pilots in India are available here: forum.susana.org/forum/categories/india

Please visit the project’s main website for updates and ongoing media coverage of our project.

NEWgenerator.tumblr.com

The laboratory TRL5 version of the NEWgenerator is described in the following paper published in Journal of Membrane Science (www.sciencedirect.com/science/article/pii/S037673881300135X):

Prieto, A.L., H. Futselaar, P.N.L. Lens, R. Bair and D.H. Yeh. (2013). Development and start up of a gas-lift anaerobic membrane bioreactor (Gl-AnMBR) for conversion of sewage to energy, water and nutrients. Journal of Membrane Science. 441:158-167. dx.doi.org/10.1016/j.memsci.2013.02.016

The field TRL6 version has been piloted in a relevant environment and two manuscripts are under preparation. We demonstrated:

- Feasibility of NEWgen operating under field condition (over considerable ambient temperature swings) treating actual wastewater from the influent to a septic tank. The system was resilient against surges in organic loading, when additional organics was added to push the limits of performance. Despite spikes in loading, COD removal was consistently high, as was biogas production and pathogen removal.

- Water and nutrients recycled from the NEWgen was tested for fertigation in a greenhouse hydroponic system. Tomatoes and cucumbers were grown successfully using biofertilizer recovered from the NEWgen, comparable to a commercial synthetic fertilizer.

Additional background material:

1) "NEWgenerator membrane biotechnology for the recovery of nutrients, Energy and Water from Human Wastes" - Dr. Daniel Yeh presentation at Int’l Faecal Sludge Management Conference 2 (FSM2), Durban, South Africa, Oct. 30, 2012

www.susana.org/en/resources/library/details/2007

Presentation video:

2) TRL5 NEWgenerator system (video)

3) “Can MBRs solve the World’s Water Crisis?” (Water Environment & Technology, 2004, article on the Bellagio Principle)

dl.dropboxusercontent.com/u/3819653/BMGF...%20MBR%20article.pdf

4) “Clean Vision” on application of MBRs for developing communities (USF Engineer, 2006)

dl.dropboxusercontent.com/u/3819653/BMGF...neer%20DHY%20MBR.pdf

5) “Could a new energy source start right here?”

www.myfoxtampabay.com/story/18612577/cou...rce-start-right-here

(Fox 13 News, May 24, 2012, story by Lloyd Sowers) This is a video report on our lab’s efforts to recovery resources from wastewater using membrane biotechnology. Highlighted are our research on cultivating biofuel microalgae at the City of Tampa’s wastewater treatment plant (featuring PhD Candidate Ivy Cormier), and also our NEWGenerator project with the Gates Foundation.

6) Members of the USF Membrane Biotechnology Lab

dl.dropboxusercontent.com/u/3819653/BMGF...20lab%20members.docx

Current state of affairs:

We have developed the TRL5 version of the NEWgenerator in the laboratory, using synthetic sewage with complex organic particulates. We have successfully field piloted a TRL6 version of the NEWgenerator using the septic tank at a local school as influent. The TRL7 version has undergone preliminary design. Detailed design and fabrication are pending confirmation of continued funding for the TRL7 phase of the project.

Biggest successes so far:

We have created a TRL6 total recycling and reuse system, coupling the NEWgenerator with resource recovery via a hydroponic greenhouse called the BioFertilizer Farm (BFF). We are eager to build and demonstrate the TRL7 version so that we can advance the technology to scale via the commercial marketplace. Our own bias aside, we do feel that the anaerobic MBR is one of the most promising technologies for addressing the global sanitation, water, energy and food crisis.

[March 2013] We had the pleasure and honor of hosting officials from the USEPA (Nancy Stoner of Office of Water and staff) and Water Environment Federation in our Membrane Biotechnology Lab. It was part of the USEPA Office of Water’s media announcement on a new initiative called “USEPA’s Blueprint for Integrating Technology Innovation into the National Water Program (Version 1.0)” (water.epa.gov/blueprint.cfm). During the visit, we were able to highlight BMGF’s support though WaSH GCE and describe the RTT initiative. We also demonstrated to the officials our NEWgenerator process, which is well aligned with the new EPA blueprint.

Below are some links to media coverage of the event:

USF scientists see opportunity gushing from water treatment (The Tampa Tribune, TBO.com)

tbo.com/news/education/usf-water-science...ws-crowd-b82470227z1

Cleaning up dirty water can create energy (WMNF Story, text, audio and videos)

www.wmnf.org/news_stories/cleaning-up-di...er-can-create-energy

WEF and U.S. EPA Tour Innovations at University of South Florida (WEF Highlights)

news.wef.org/wef-and-u-s-epa-tour-innova...ty-of-south-florida/

Main challenges / frustration:

One of the main challenges encountered in our project has been on advocating and communicating membrane technology to clear up misunderstanding and misperceptions. The membrane is an amazing modern marvel of engineering and material science, capable of high levels of separation with an absolute, reliable, physical barrier. However, membranes are still frequently viewed as too expensive, too experimental, too delicate, too “high tech,” or requiring frequent cleaning or replacement. The truth is that membranes have come a long, long way since first invented decades ago. Membrane performance and durability have increased significantly, while costs (both capex and opex) have decreased drastically. These were all made possible with rapid growths in demand, volume and market size. Due to global demands for water treatment, recycling and purification, membranes are manufactured worldwide and available in just about every country, becoming better and cheaper by the day. In fact, the global demand for membranes is projected to reach $25.7 billion by 2017.

At a recent water/wastewater technology tradeshow that we attended in India (Aquatech, New Delhi, April 2013), membrane manufacturers and distributors abound, all jockeying for a slice of the growing membrane marketplace in developing or transitioning countries like India. In my opinion, the real problem with membranes is in NOT using them. Despite their advantages, membranes are to this date mostly used for industrial and municipal water/wastewater markets. With the exception of a few scattered instances, they are not used to provide water purification or sanitation intervention in poor communities (e.g., urban slums) in developing countries, where the needs for water and sanitation improvements are dire. That, to me, is a great injustice; we have a high performance, small-footprint, commercially-available product that is underutilized. To date, membrane manufacturers and equipment providers have not targeted pro-poor markets, such as slum communities. These markets are seen as too risky, too diffuse, too transient and lack a clear customer demand. In fact, they are barely on the radar screen of membrane technology providers and receive occasional consideration only for humanitarian reasons (such as post disaster relief). Through the NEWgenerator, we aim to demonstrate, to both the sanitation sector and membrane industry, that membrane application for poor communities is not only possible, but is necessary and is an untapped market with tremendous potential.

Another misunderstanding is related to the different types of membranes used for the NEWgen. We are not using RO membrane, which is often used for desalination. Hence, there is no concentrate (brine) for disposal. We are using ultrafiltration membranes (UF), which offer sub-micron size pores that are a good compromise between contaminant rejection and water throughput. Just as all clothes get dirty, all membranes do foul to some extent. That is not necessarily a bad thing, since fouling has been shown to actually enhance membrane rejection if managed properly (numerous studies in literature). The key is to manage the fouling so that the system generates permeate at a rate/quality/manner that is satisfactory over a design period of performance. With over 10 years of experience working with membranes and strong ties with the membrane industry and other membrane labs, we have developed protocols and techniques for sustainable flux that allows the NEWgen to be operated reliably over long periods.

One of our biggest challenges has been related to dealing with high temperature under the Florida sun, where the temperature in the reactor shed can rise to 50C and render working conditions quite difficult. Another was dealing with occasional plumbing and component failures from heat stress. However, the heat stress trial has prepared us well (physiologically and mentally) for working in tropical environments such as India and Africa. We have also gained valuable experience in designing and fabricating the system with heat durability in mind.

I am happy to take any questions or receive your comments on our research project.

Regards,

Daniel

Daniel H. Yeh, Ph.D., P.E., LEED AP BD+C

Associate Professor, Dept. of Civil & Environmental Engineering

College of Engineering, University of South Florida

4202 E. Fowler Avenue, ENB118, Tampa, FL 33620-5350 USA

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it. TEL: +1(813)974-4746

Skype: ecol-mem Twitter<@dhyeh>

www.linkedin.com/in/danielyeh (LinkedIn page)

newgenerator.tumblr.com/ (NEWgenerator project)

mbr.eng.usf.edu (research group)

Attachments:

-

overview.png

(Filesize: 70KB)

overview.png

(Filesize: 70KB)

-

overview2.png

(Filesize: 467KB)

overview2.png

(Filesize: 467KB)

Please Log in to join the conversation.

You need to login to reply

Share this thread:

- Forum

- categories

- Sanitation systems

- Shared toilets, community toilets, public toilets

- Public toilets in India

- NEWgenerator for recovery of nutrients, energy and water from excreta (Uni of South Florida, USA) - anaerobic membrane bioreactor (field tests now in Kerala, India)

Recently active users. Who else has been active?

Time to create page: 0.271 seconds