- Forum

- categories

- Sanitation systems

- Treatment of wastewater, sludges, organic waste, excreta

- Anaerobic treatment systems (biogas sanitation)

- Biogas sanitation (systems focusing on biogas production)

- ADPL (Anaerobic Digestion Pasteurization Latrine) Duke Biogas toilet (Duke University, USA) - testing in Kenya, India and the Philippines

ADPL (Anaerobic Digestion Pasteurization Latrine) Duke Biogas toilet (Duke University, USA) - testing in Kenya, India and the Philippines

32.3k views

Re: Effective Sewage Sanitation with Low CO2 Footprint (Duke University in Durham, North Carolina, USA)

McCarty's Anaerobic Baffled Reactor (ABR) and CHP's (CON2 or prefab ABR's) for "Effective Sewage Sanitation with Low CO2 Footprint"?

Dear Joan,

It seams to me your US-group and the EU funded biogas-group "speetkits" for security related research (2012-2016), working more or less on the same issues involved, but very separated!

In my opinion the existing German containerised ABR + CHP "CON2" (insulated and heated) for mesophilic temperature range in Germany is doing already the "job" your separated groups are looking for. You can use the excess heat of the CHP for the needed thermal treatment to sanitise/kill pathogens in effluent/sludge and might dry the sludge or use the gas straight in a heater. Furthermore heat pumps could be used too.

As Prof. McCarty's (USA, 1981) original ABR-Design is an "Open-Source" and do not has a user restricting Patent attached, you might do your own ABR + biogas heater + heat pump or CHP.

2007 Colloquium on Water - Prof. Perry L. McCarty: (1 h 12 min)

Instate of simple purchasing a German CON2 (45-75kWel. (costs 5,000EUR/kWel.)) you might better do your "own" simple ABR, by stacking two fibreglass body's of ready made prefab ABRs from BORDA e.V., Bremen (Made in Asia or Africa), in an used and insulated container. An additional heating and insulation between the two fibreglass body's could keep the fermenter easier in the mesophilic temperature range in cold climates. Maybe add on top of your self-made ABR an insulated airtight fabrics for simple gas storage above the ABR it self, or store gas in a separate used sea-container (with airtight fabrics) nearby.

To simplify your design you might not use insulation and heating of fermenter, only in cold climates you will need insulated and additional heating of fermenter, in the tropics they "run" easier within the mesophilic temperature range, see many examples of BORDA's very simple ABR's in Asia and Africa.

I hope my hands-on view as an biogas-outsider is heplfull to you and your project/research outcome.

Good Luck & Best Regards,

Detlef SCHWAGER

See:

forum.susana.org/forum/categories/61-wg-...isposal-faecal-sludg

Dear Joan,

It seams to me your US-group and the EU funded biogas-group "speetkits" for security related research (2012-2016), working more or less on the same issues involved, but very separated!

In my opinion the existing German containerised ABR + CHP "CON2" (insulated and heated) for mesophilic temperature range in Germany is doing already the "job" your separated groups are looking for. You can use the excess heat of the CHP for the needed thermal treatment to sanitise/kill pathogens in effluent/sludge and might dry the sludge or use the gas straight in a heater. Furthermore heat pumps could be used too.

As Prof. McCarty's (USA, 1981) original ABR-Design is an "Open-Source" and do not has a user restricting Patent attached, you might do your own ABR + biogas heater + heat pump or CHP.

2007 Colloquium on Water - Prof. Perry L. McCarty: (1 h 12 min)

Instate of simple purchasing a German CON2 (45-75kWel. (costs 5,000EUR/kWel.)) you might better do your "own" simple ABR, by stacking two fibreglass body's of ready made prefab ABRs from BORDA e.V., Bremen (Made in Asia or Africa), in an used and insulated container. An additional heating and insulation between the two fibreglass body's could keep the fermenter easier in the mesophilic temperature range in cold climates. Maybe add on top of your self-made ABR an insulated airtight fabrics for simple gas storage above the ABR it self, or store gas in a separate used sea-container (with airtight fabrics) nearby.

To simplify your design you might not use insulation and heating of fermenter, only in cold climates you will need insulated and additional heating of fermenter, in the tropics they "run" easier within the mesophilic temperature range, see many examples of BORDA's very simple ABR's in Asia and Africa.

I hope my hands-on view as an biogas-outsider is heplfull to you and your project/research outcome.

Good Luck & Best Regards,

Detlef SCHWAGER

See:

forum.susana.org/forum/categories/61-wg-...isposal-faecal-sludg

www.aqua-verde.de, AquaVerde Ltd. Zanzibar

"simple" Sanitation-Solutions by gravity

Low-Tech Solutions with High-Tech Effects

"Inspired by Circular Economy and Cooperation"

www.flickr.com/photos/aqua-verde/

"simple" Sanitation-Solutions by gravity

Low-Tech Solutions with High-Tech Effects

"Inspired by Circular Economy and Cooperation"

www.flickr.com/photos/aqua-verde/

Please Log in to join the conversation.

You need to login to replyRe: Effective Sewage Sanitation with Low CO2 Footprint (Duke University in Durham, North Carolina, USA)

Thank you for the response Dorothee. As for your questions:

1. I have not seen a similar project. For one, household biogas digesters have been used for a while, especially in rural areas of China and India, but were mainly used for livestock wastes and sometimes with human wastes added. Using only undiluted human waste was mainly thought to not be a sufficient feedstock for effective biogas digestion due to the high nitrogen content within urine. Biogas digesters have been used often for providing biogas as a energy source for many things, but I have not seen it for sterilizing the human waste itself. Additionally the heat-exchanger is a novel addition that helps make the sterilization possible.

2. In our prototype, we are using typical amounts of urine and feces per person per day to daily feed the reactor to simulate field conditions. Issues could arise if the urine input greatly increases over feces input in the field. This is why our system is being geared towards households instead of public facilities where the feces input would be more regular and large influx of urine only less likely.

3. We have not modeled for the critical level of feces input (though would be good to do), but our feeding of typical urine and feces per day is based on a 10-person household. With this feeding, our system would produce about 400 L biogas per day, and maintaining our heater (with the first version heat exchanger) at 75C would use about 230-280 L per biogas per day. We have a second version heat exchanger that is tube-in-shell instead of counter-current that from initial tests will reduce biogas requirements due to increased efficiency.

4. I am not sure if I understand this question. We are looking into other ways that could be used in conjunction with our heater to sterilize digester effluent such as passive solar so that biogas production could be diverted into other uses.

5.a. We have run our lab-scale prototype for one year now. Full-scale systems will be installed this June in Eldoret, Kenya, and sometime within the year in Iquitos, Peru.

5.b. The final effluent is pathogen-free but high levels of nutrients (nitrogen) remain. The sterilized effluent can be used as a fertilizer or can be allowed to percolate through the ground.

5.c. I see the niche location as peri-urban and urban areas where municipal sewage is not available, and land space for pit latrines or other systems is limited. Additionally, areas that have need for fertilizer could also find this system attractive.

Thank you,

Aaron Forbis-Stokes

1. I have not seen a similar project. For one, household biogas digesters have been used for a while, especially in rural areas of China and India, but were mainly used for livestock wastes and sometimes with human wastes added. Using only undiluted human waste was mainly thought to not be a sufficient feedstock for effective biogas digestion due to the high nitrogen content within urine. Biogas digesters have been used often for providing biogas as a energy source for many things, but I have not seen it for sterilizing the human waste itself. Additionally the heat-exchanger is a novel addition that helps make the sterilization possible.

2. In our prototype, we are using typical amounts of urine and feces per person per day to daily feed the reactor to simulate field conditions. Issues could arise if the urine input greatly increases over feces input in the field. This is why our system is being geared towards households instead of public facilities where the feces input would be more regular and large influx of urine only less likely.

3. We have not modeled for the critical level of feces input (though would be good to do), but our feeding of typical urine and feces per day is based on a 10-person household. With this feeding, our system would produce about 400 L biogas per day, and maintaining our heater (with the first version heat exchanger) at 75C would use about 230-280 L per biogas per day. We have a second version heat exchanger that is tube-in-shell instead of counter-current that from initial tests will reduce biogas requirements due to increased efficiency.

4. I am not sure if I understand this question. We are looking into other ways that could be used in conjunction with our heater to sterilize digester effluent such as passive solar so that biogas production could be diverted into other uses.

5.a. We have run our lab-scale prototype for one year now. Full-scale systems will be installed this June in Eldoret, Kenya, and sometime within the year in Iquitos, Peru.

5.b. The final effluent is pathogen-free but high levels of nutrients (nitrogen) remain. The sterilized effluent can be used as a fertilizer or can be allowed to percolate through the ground.

5.c. I see the niche location as peri-urban and urban areas where municipal sewage is not available, and land space for pit latrines or other systems is limited. Additionally, areas that have need for fertilizer could also find this system attractive.

Thank you,

Aaron Forbis-Stokes

Aaron Forbis-Stokes, Ph.D.

Sanitation Technology Consultant

Triangle Environmental Health Initiative

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.triangle-environmental.com

Sanitation Technology Consultant

Triangle Environmental Health Initiative

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.triangle-environmental.com

Please Log in to join the conversation.

You need to login to replyRe: Effective Sewage Sanitation with Low CO2 Footprint (Duke University in Durham, North Carolina, USA)

Dear Aaron

Many thanks for the update on your project and the additional picture.

I have one burning question: You’re idea seems obvious – use the biogas from the sludge to sanitize it. Did nobody so far test it in the past?

And if yes? Isn't it difficult to control the optimal urine/feces composition you need to have enough biogas in the field? What is the critical level of needed biogas to feed the heater (faeces/persons per day)?

Aren't there any other ways to proceed the slurry from the digester?

I understand that your prototype is in the very early stage, but when and where is field testing planned? And what happens at the end to the effluent? What would be the niche for such a toilet?

Best regards

Dorothee

Many thanks for the update on your project and the additional picture.

I have one burning question: You’re idea seems obvious – use the biogas from the sludge to sanitize it. Did nobody so far test it in the past?

And if yes? Isn't it difficult to control the optimal urine/feces composition you need to have enough biogas in the field? What is the critical level of needed biogas to feed the heater (faeces/persons per day)?

Aren't there any other ways to proceed the slurry from the digester?

I understand that your prototype is in the very early stage, but when and where is field testing planned? And what happens at the end to the effluent? What would be the niche for such a toilet?

Best regards

Dorothee

WG1 Co-lead

Developing methods and tools to support strategic planning for sustainable sanitation. Particular interested in novel technologies contributing to more inclusive and circular sanitation. This email address is being protected from spambots. You need JavaScript enabled to view it.

Developing methods and tools to support strategic planning for sustainable sanitation. Particular interested in novel technologies contributing to more inclusive and circular sanitation. This email address is being protected from spambots. You need JavaScript enabled to view it.

Please Log in to join the conversation.

You need to login to reply- basangreen

-

Less

- Posts: 3

- Likes received: 0

Re: Reply: Effective Sewage Sanitation with Low CO2 Footprint (Duke University in Durham, North Carolina, USA)

Dear Sir First thanks for good news.I'm professor of Mongolian University of Science and technology, working and focusing development low cost sanitation in rural Mongolia, I would like share your experience and knowledge in Mongolian case.

rgs,

Prof.Basandorj

rgs,

Prof.Basandorj

Please Log in to join the conversation.

You need to login to replyRe: Effective Sewage Sanitation with Low CO2 Footprint (Duke University in Durham, North Carolina, USA)

Dear all

My name is Aaron Forbis-Stokes, and I am working with the team of the "Effective Sewage Sanitation with Low CO2 Footprint" grant at the Duke University.

It is now almost one year since our last update on our project (find a presentation of the project above)

Before this project moves to a field demonstration phase, I would like to give you a short overview on the current status.

Results of part I (anaerobic digester):

Research is underway to optimize biogas production, and improve the design and thermal efficiency of the heat sterilization system. Further, pathogen disinfection experiments with virus and helminth ova are being considered. Demonstration of the efficacy of the system as a replacement for pit latrines in the field is warranted.

Main challenges / frustration:

Field test under actual conditions needs to be done yet.

My name is Aaron Forbis-Stokes, and I am working with the team of the "Effective Sewage Sanitation with Low CO2 Footprint" grant at the Duke University.

It is now almost one year since our last update on our project (find a presentation of the project above)

Before this project moves to a field demonstration phase, I would like to give you a short overview on the current status.

Results of part I (anaerobic digester):

- Overall, the data demonstrate that efficient anaerobic digestion can be obtained using undiluted human excreta as a feedstock. A well-adapted bacterial inoculum can effectively convert wastes to biogas (about 350-400 liters of biogas per day in a full-scale digester for an extended family of 10 persons) even in the presence of high ammonia and volatile fatty acids concentrations.

- A COD balance can be used to estimate the amount of biomass formed. The results indicate an average total COD (chemical oxygen demand) removal in the range of 80 to 85%. More research, in particular with actual faeces and urine, is needed to refine this number and understand the true rate of biomass accumulation under actual field conditions.

- A low-cost system that uses the biogas produced during the anaerobic process to heat-sterilize the treated sewage effluent with an efficient heat recovery was designed and tested. The heat-sterilization system comprises a heater and a countercurrent heat exchanger for a heat recovery. Both are constructed using common and cheap materials (paint/food can, steel sheet, simple tubing).

- The countercurrent heat exchanger is capable to recover energy from the stream leaving the heater and heat the digester effluent reaching energy savings close to 800 kJ/d, reducing the biogas consumption by 15-20 %.

- A biogas flow rate of 230 – 280 L/d is enough to maintain the heat-sterilization system between 65 and 75 °C with a normal loading. This is an estimated 60-70 % of the total biogas produced in the anaerobic reactor, thus leaving surplus gas (~150 L/d) for other uses.

- To demonstrate the efficiency of the heat-sterilization system to inactivate pathogens, two tests were conducted using Escherichia coli as an indicator organism. The results show a complete elimination of E. coli at both temperatures (65 and 75 °C) in the effluent of the heater.

Research is underway to optimize biogas production, and improve the design and thermal efficiency of the heat sterilization system. Further, pathogen disinfection experiments with virus and helminth ova are being considered. Demonstration of the efficacy of the system as a replacement for pit latrines in the field is warranted.

Main challenges / frustration:

Field test under actual conditions needs to be done yet.

Aaron Forbis-Stokes, Ph.D.

Sanitation Technology Consultant

Triangle Environmental Health Initiative

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.triangle-environmental.com

Sanitation Technology Consultant

Triangle Environmental Health Initiative

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.triangle-environmental.com

Please Log in to join the conversation.

You need to login to reply- JoanColon

-

Topic AuthorLess

Topic AuthorLess- Posts: 3

- Likes received: 1

ADPL (Anaerobic Digestion Pasteurization Latrine) Duke Biogas toilet (Duke University, USA) - testing in Kenya, India and the Philippines

Title of grant: Effective Sewage Sanitation with Low CO2 Footprint

Researchers: Marc Deshusses, Joan Colon and Aaron Forbis-Stokes

Name of lead organisation: Duke University

Grantee location: Durham, North Carolina, USA

Primary contact at lead organisation: Aaron Forbis-Stokes

Developing country where the research is being tested: Kenya (Eldoret)

Goal: Provide proof of concept of anaerobic digestion coupled with heat sterilization for a self-sanitizing system for developing communities

Short description:

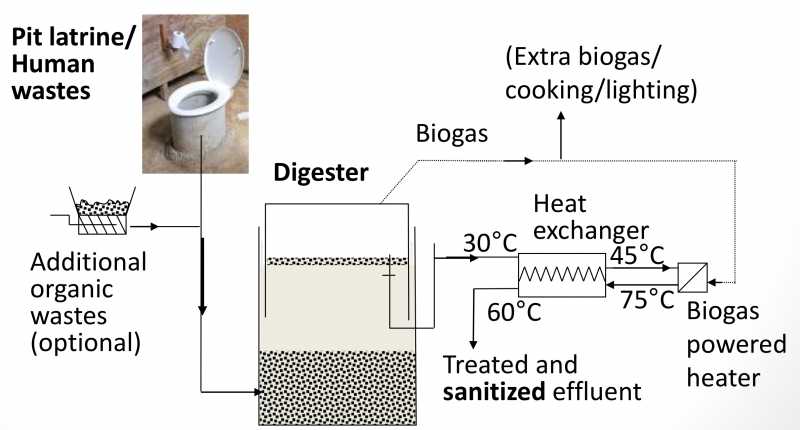

The overall objective of our project is to develop and demonstrate the proof of concept a novel self-contained and energy neutral sanitation technology that relies on anaerobic digestion of the wastes to generate biogas and utilization of the biogas thus produced to heat-sterilize the treated effluent. The system utilizes simple and reliable equipment so that it does not require a skilled operator or any special maintenance regime.

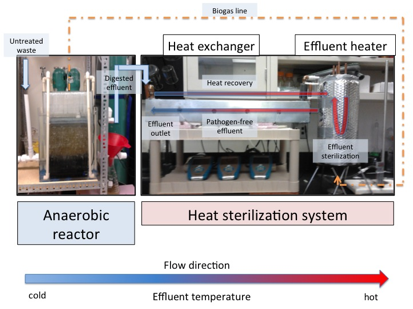

Flowsheet and concept of the novel sanitation technology (not to scale):

The advantages of the proposed technology are:

The project has been divided in two main parts:

a) The anaerobic reactor (lab scale): design and performance

b) The heat sterilization system (full-scale or near full-scale): design, construction and proof of concept to heat-sterilize the treated sewage effluent

The main goal of the lab anaerobic reactor is to prove the suitability of a mixture of feces and urine to serve as a substrate for the anaerobic process focused mainly in the yield and rate of biogas production. The concern is mainly to achieve usual biogas yields and obtain suitable rates of biogas production.

Regarding the heat sterilization system, the challenge is to design a simple and low-cost system with virtually no moving parts, that can effectively deployed, e.g., as a replacement of pit latrines.

Start and end date: 1 Nov 2011 to 30 April 2013

Grant type: Grand Challenges Explorations Round 7

Funding for this research currently ongoing: yes

Research or implementation partners: Chepkoilel University, Eldoret, Kenya

Video of presentation by Marc Deshusses at the Fecal Sludge Management Conference in Durban 2012:

Further readings from the Fecal Sludge Management Conference in Durban 2012:

Presentation and paper: www.susana.org/en/resources/library/details/1757

The picture below shows our prototype anaerobic digester and heat sterilization and recovery systems:

A semi-continuous floating dome digester with a working volume of 17 liters is used for the anaerobic digestion of simulant feces and urine (see our earlier report on the recipe and suitability of feces and urine simulants). The bioreactor is currently working with an organic loading rate of 1.8 gCOD/(lreactor day) with a maximum biogas production of 14 l/d and a total removal efficiency close to 85 % of the inlet COD. The biogas produced contains a methane concentration of about 65 %. For indication, the system is roughly 1:30 scale, and thus a full-scale digester for an extended family of 10 would have roughly a volume of 0,55 m3, and would produce about 400-450 l of biogas per day. Our experiments are currently determining how much of that biogas is required for the sterilization of the effluent.

Biogas (or a mimic of methane and CO2 in some experiments) is then used to maintain the effluent heater above 70 °C. In order to increase the total efficiency of the heat sterilization system a simple countercurrent heat exchanger is incorporated for heat recovery. It is well known that a short exposure to temperatures ranging from 55-75 °C provides several log reductions of bacteria, virus, and helminth ova. The next step of the project is to carry out different pathogen inactivation analysis to demonstrate and quantify the efficiency of the heat sterilization system.

Researchers: Marc Deshusses, Joan Colon and Aaron Forbis-Stokes

Name of lead organisation: Duke University

Grantee location: Durham, North Carolina, USA

Primary contact at lead organisation: Aaron Forbis-Stokes

Developing country where the research is being tested: Kenya (Eldoret)

Goal: Provide proof of concept of anaerobic digestion coupled with heat sterilization for a self-sanitizing system for developing communities

Short description:

The overall objective of our project is to develop and demonstrate the proof of concept a novel self-contained and energy neutral sanitation technology that relies on anaerobic digestion of the wastes to generate biogas and utilization of the biogas thus produced to heat-sterilize the treated effluent. The system utilizes simple and reliable equipment so that it does not require a skilled operator or any special maintenance regime.

Flowsheet and concept of the novel sanitation technology (not to scale):

The advantages of the proposed technology are:

- Simple low-cost process/equipment, suited for deployment in developing countries

- Effective sanitation of wastes in one single stage without sludge formation

- Self-contained, energy neutral system

- Eliminates methane emissions, a potent greenhouse gas while providing sanitation

- No electricity or additional energy is required

- No water is required during daily operation

The project has been divided in two main parts:

a) The anaerobic reactor (lab scale): design and performance

b) The heat sterilization system (full-scale or near full-scale): design, construction and proof of concept to heat-sterilize the treated sewage effluent

The main goal of the lab anaerobic reactor is to prove the suitability of a mixture of feces and urine to serve as a substrate for the anaerobic process focused mainly in the yield and rate of biogas production. The concern is mainly to achieve usual biogas yields and obtain suitable rates of biogas production.

Regarding the heat sterilization system, the challenge is to design a simple and low-cost system with virtually no moving parts, that can effectively deployed, e.g., as a replacement of pit latrines.

Start and end date: 1 Nov 2011 to 30 April 2013

Grant type: Grand Challenges Explorations Round 7

Funding for this research currently ongoing: yes

Research or implementation partners: Chepkoilel University, Eldoret, Kenya

Video of presentation by Marc Deshusses at the Fecal Sludge Management Conference in Durban 2012:

Further readings from the Fecal Sludge Management Conference in Durban 2012:

Presentation and paper: www.susana.org/en/resources/library/details/1757

***

Information from July 2012

The purpose of this report is to show the concept and the design of the prototypes of the anaerobic reactor and the heat sterilization system together with some preliminary results.The picture below shows our prototype anaerobic digester and heat sterilization and recovery systems:

A semi-continuous floating dome digester with a working volume of 17 liters is used for the anaerobic digestion of simulant feces and urine (see our earlier report on the recipe and suitability of feces and urine simulants). The bioreactor is currently working with an organic loading rate of 1.8 gCOD/(lreactor day) with a maximum biogas production of 14 l/d and a total removal efficiency close to 85 % of the inlet COD. The biogas produced contains a methane concentration of about 65 %. For indication, the system is roughly 1:30 scale, and thus a full-scale digester for an extended family of 10 would have roughly a volume of 0,55 m3, and would produce about 400-450 l of biogas per day. Our experiments are currently determining how much of that biogas is required for the sterilization of the effluent.

Biogas (or a mimic of methane and CO2 in some experiments) is then used to maintain the effluent heater above 70 °C. In order to increase the total efficiency of the heat sterilization system a simple countercurrent heat exchanger is incorporated for heat recovery. It is well known that a short exposure to temperatures ranging from 55-75 °C provides several log reductions of bacteria, virus, and helminth ova. The next step of the project is to carry out different pathogen inactivation analysis to demonstrate and quantify the efficiency of the heat sterilization system.

Attachments:

-

Untitled1.png

(Filesize: 160KB)

Untitled1.png

(Filesize: 160KB)

-

graph_system.jpg

(Filesize: 36KB)

graph_system.jpg

(Filesize: 36KB)

The following user(s) like this post: kbehin

Please Log in to join the conversation.

You need to login to reply

Share this thread:

- Forum

- categories

- Sanitation systems

- Treatment of wastewater, sludges, organic waste, excreta

- Anaerobic treatment systems (biogas sanitation)

- Biogas sanitation (systems focusing on biogas production)

- ADPL (Anaerobic Digestion Pasteurization Latrine) Duke Biogas toilet (Duke University, USA) - testing in Kenya, India and the Philippines

Recently active users. Who else has been active?

Time to create page: 0.242 seconds